A hydraulic blasting crack-co 2 Reservoir permeability enhancement method for fracturing with proppant

A technology of hydraulic blasting and proppant, which is applied in earthwork drilling, wellbore/well parts, mining fluids, etc. It can solve problems such as inability to achieve anti-reflection effects, achieve rapid cleaning, solve permanent storage, and save water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

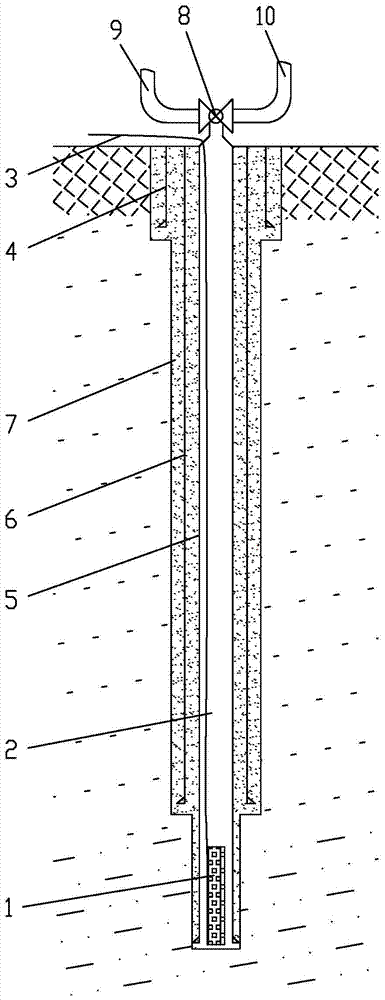

[0030] Example 1, see figure 1 , a hydraulic blasting crack-CO 2 The reservoir permeability enhancement method of fracturing with proppant is applied to the following coalbed methane reservoir, the dip angle is 14°, the average thickness is 5m, and the permeability distribution is 0.001~2.398×10 -3 μm 2 Between, the average value is 0.43×10 -3 μm 2 . Ground drilling is used to extract coalbed methane, and the designed well type is a vertical well type. The two-open well body structure scheme is adopted, and the specific implementation is carried out according to the following steps.

[0031] The first opening uses a φ311.1mm drill bit, and after drilling through the bedrock weathered zone for 20 meters, the φ244.5mm surface casing 4 is lowered, and the cement mortar 7 is injected between the surface casing 4 and the φ311.1mm drill hole. 7. Lift back to the ground surface to seal the surface loose layer and gravel layer and establish the wellhead.

[0032] The second ope...

Embodiment 2

[0036] Example 2, see figure 1 , a hydraulic blasting crack-CO 2 The reservoir permeability enhancement method of fracturing with proppant is applied to the target layer of the following shale gas reservoirs, and the shale gas is extracted by ground drilling. Select the "roller cone bit + screw" composite drilling technology, design the "three times" wellbore structure plan, and implement it according to the following steps.

[0037] In the first opening, the φ444.5mm drill bit was used to drill 200m, and the φ339.7mm surface casing 4 was lowered, and the interpolation cementing process of the cement mortar filling method as described in Example 1 was adopted to return the cement mortar 7 to the ground to establish Wellhead.

[0038] The second opening uses a φ311.1mm drill bit to drill to the shale gas layer, lower the φ244.5mm technical casing 6, and return the cement mortar 7 to the ground.

[0039] In the third opening, a φ215.9mm drill bit is used to drill shale gas re...

Embodiment 3

[0043] Example 3, see figure 1 , a hydraulic blasting crack-CO 2 The reservoir permeability enhancement method of fracturing with proppant is applied to the following crude oil reservoir, which is a low porosity and low permeability reservoir. The porosity of conventional core analysis is 7.5% to 12.9%, with an average of 9.54%. is 0.0667×10 -3 μm 2 ~1.47×10 -3 μm 2 , with an average of 0.486×10 -3 μm 2 ; The porosity measured by mercury intrusion analysis is 8.3% to 13.9%, with an average of 11.24%, and the permeability is 0.112×10 -3 μm 2 ~7.96×10 -3 μm 2 , with an average of 0.954×10 -3 μm 2 . The design well depth is 2060m, and the shaft structure is designed in two schemes, which are implemented according to the following steps.

[0044] In the first opening, a φ311.2mm drill bit is used to drill 81m, and the φ244.5mm surface casing 4 is lowered, and the cement mortar 7 is returned to the ground to establish a wellhead.

[0045] In the second opening, a φ215...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com