Smooth blasting method for tunneling

A technology of smooth blasting and tunneling, which is applied in blasting, tunneling, earthwork drilling and mining, etc. It can solve the problems that the health of construction workers on site is greatly affected, the ventilation time affects the efficiency of cycle footage, and the stability of surrounding rock is unfavorable. Achieve the effects of reducing the amount of explosives and drilling time, improving the utilization rate of blastholes, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

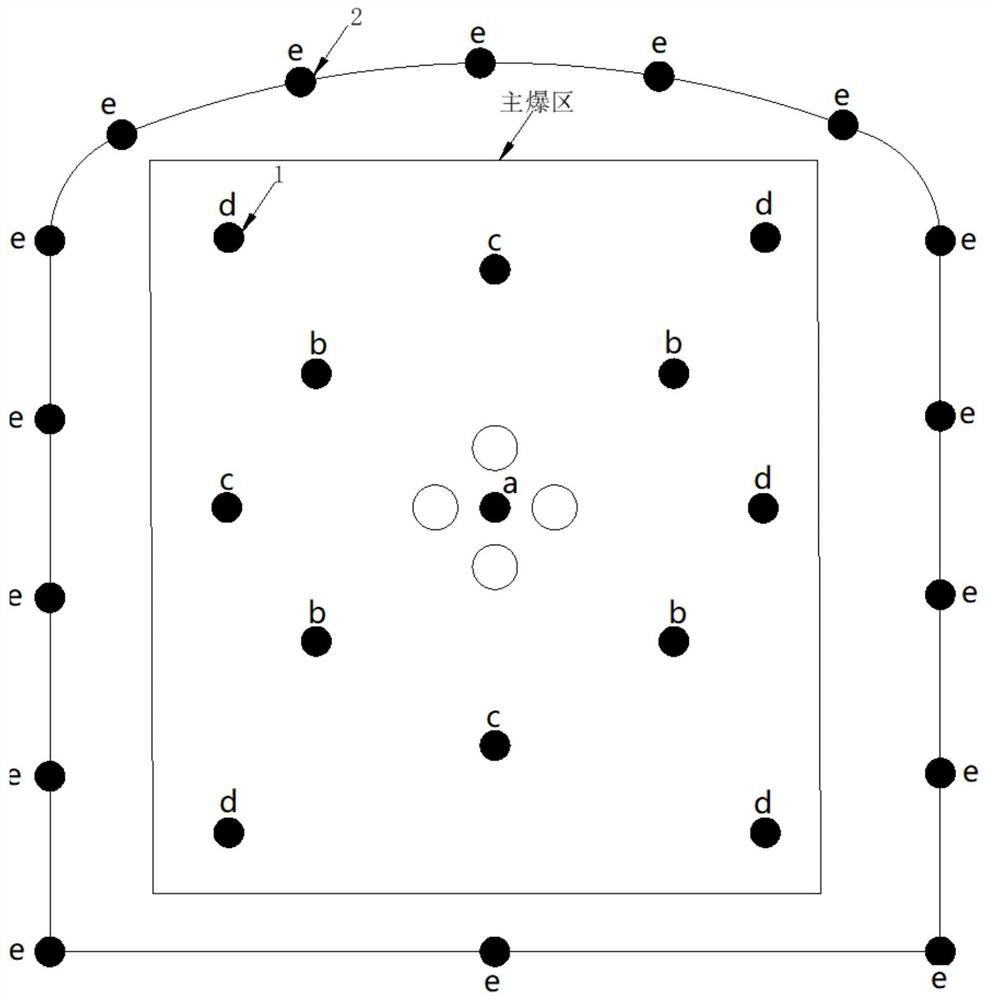

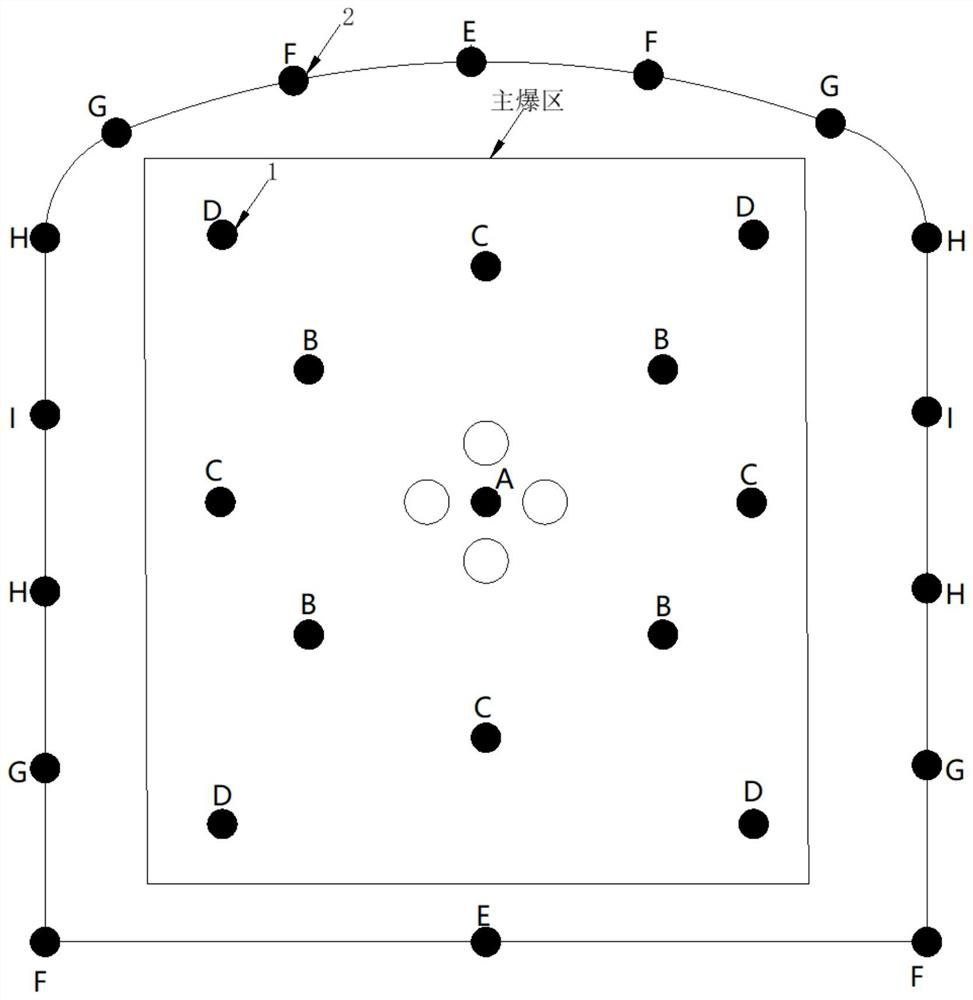

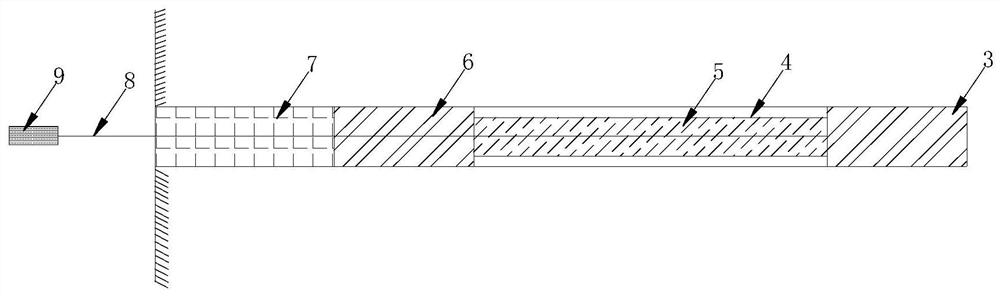

[0039] Embodiment 1: as Figure 1~2 As shown, a smooth blasting method for tunnel excavation adopts a peripheral light blasting hole charging structure with axially uncoupled water-interval energy-concentrating blasting, including the following specific steps:

[0040] 1) Determine the main blast zone and edge blast zone on the face of tunnel excavation, and open the main blast center hole in the center of the main blast zone (see figure 1 In a), a number of large-diameter hollow holes are symmetrically opened with the main blast central hole as the center, and several layers of main blast holes are symmetrically opened outside the large-diameter hollow holes and with the main blast central hole as the center (see figure 1 b, c and d) in b, several peripheral light blasting holes are opened in the edge detonation area (see figure 1 middle e);

[0041] The hole distance of the peripheral light blast hole is

[0042]

[0043]In the formula: K-explosion stress wave coeffici...

Embodiment 2

[0060] Embodiment 2: The rock properties of this embodiment are medium-hard rocks, the rock and soil properties are stable, and the joints and fissures are not developed;

[0061] Such as Figure 1~2 As shown, a smooth blasting method for tunnel excavation adopts a peripheral light blasting hole charging structure with axially uncoupled water-interval energy-concentrating blasting, including the following specific steps:

[0062] 1) According to the construction design requirements, determine the position of the main blast area and the reserved rock mass, determine the excavation contour line according to the position of the reserved rock mass, and determine the main blast area and edge detonation area of the tunnel excavation face. The center of the main blast area is provided with a main blast center hole (see figure 1 In a), a number of large-diameter hollow holes are symmetrically opened with the main blast central hole as the center, and several layers of main blast ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com