Patents

Literature

64 results about "Subduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Subduction is a geological process that takes place at convergent boundaries of tectonic plates where one plate moves under another and is forced to sink due to gravity into the mantle. Regions where this process occurs are known as subduction zones. Rates of subduction are typically in centimeters per year, with the average rate of convergence being approximately two to eight centimeters per year along most plate boundaries.

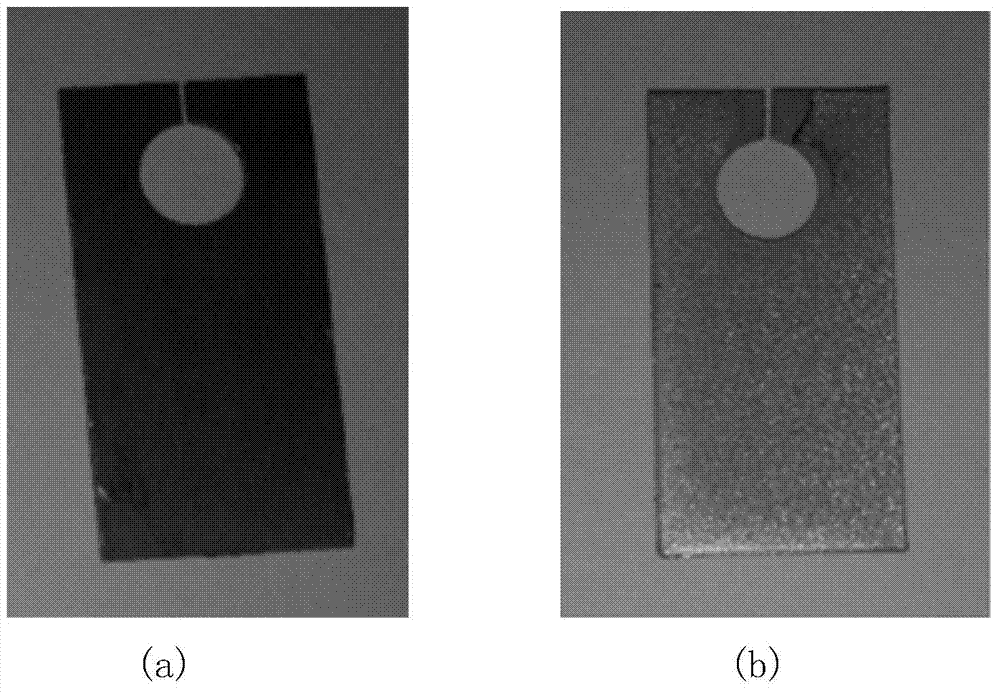

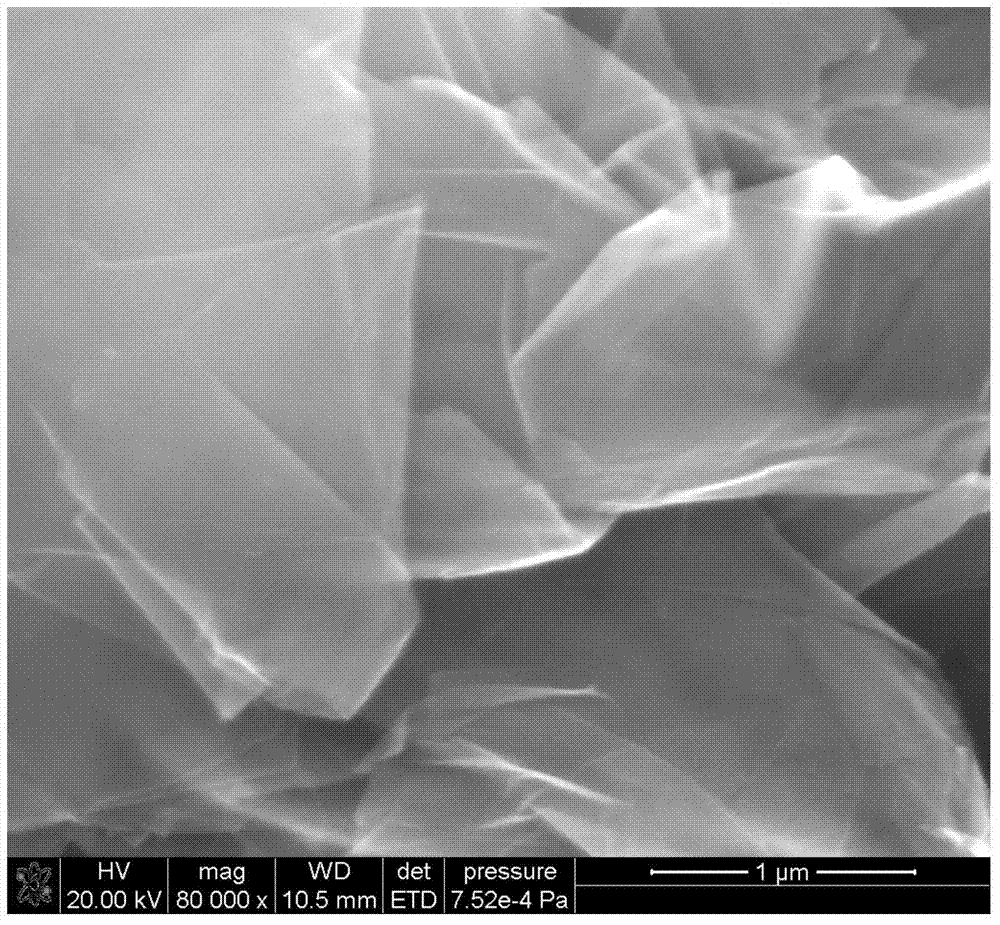

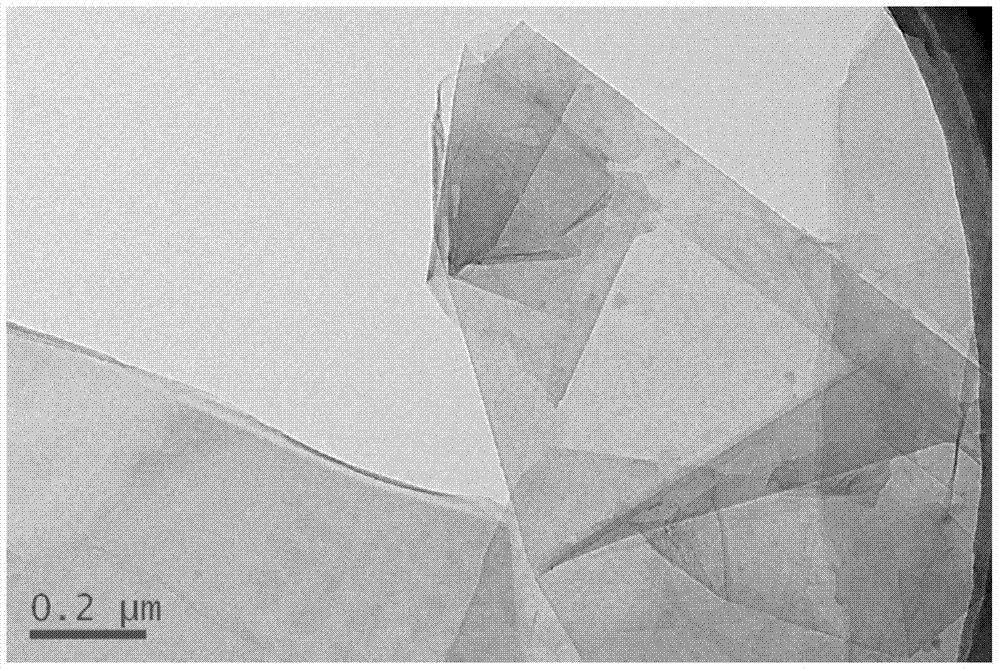

Plating solution for electroplating Ni/graphene compound heat conduction film on surface of substrate

The invention discloses a plating solution for electroplating a Ni / graphene compound heat conduction film on the surface of a substrate. Each liter of the plating solution comprises the following components by weight: 230g-380g of nickel salt, 30g-40g of boric acid, 0.1g-10g of a stress subduction agent, 0.1g-2g of graphene, 0.01g-0.1g of a dispersing agent and 0.05g-0.4g of a surfactant. According to the plating solution, by adding the surfactant, the wettability between the surface of the substrate and the plating solution is effectively improved; by adding the stress subduction agent, the stress among plating layers is effectively reduced; by virtue of a proper amount of graphene and dispersing agent, the Ni / graphene compound heat conduction film with the thickness of 10-50mu m can be formed on the surface of the substrate after plating, the film has high binding force with the substrate, and graphene is uniformly dispersed in the film, so that the heat conductivity coefficient of a material obtained after plating is greatly increased relative to that of the substrate.

Owner:GUANGXI NORMAL UNIV

Method for disposing sludge

InactiveCN102992567AHigh degradation rate of organic matterImprove adsorption capacitySludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSorbentOxidation-Reduction Agent

The invention provides a method for disposing sludge. The method comprises the following steps of: mixing sludge to be disposed with oxidants and an oxidation guide catalyst to carry out redox reaction; and mixing the redox reaction product with a flocculant to carry out coagulation to obtain a solid substance and filtrate, wherein the mass ratio of the oxidation guide catalyst to the dry basis of the sludge to be disposed is (3-8%):1; and the oxidation guide catalyst comprises 5-45wt% of metallic compounds and 55-95wt% of adsorbents. The method has the beneficial effects that when the sludge is disposed with the oxidation guide catalyst capsule adopted in the method provided by the invention, the initiation effect of the oxidation guide catalyst capsule can be exerted, without adding pH value regulators to the oxidation guide catalyst capsule, so that the oxidants can better decompose organic substances in the sludge in an oxidative manner; and therefore the sludge disposed by the method is neutral and the subduction amount of the sludge reaches the maximum, thus being beneficial to conduction of the subsequent process.

Owner:湖南清和环保技术有限公司

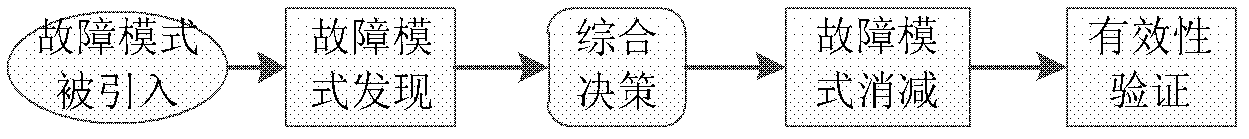

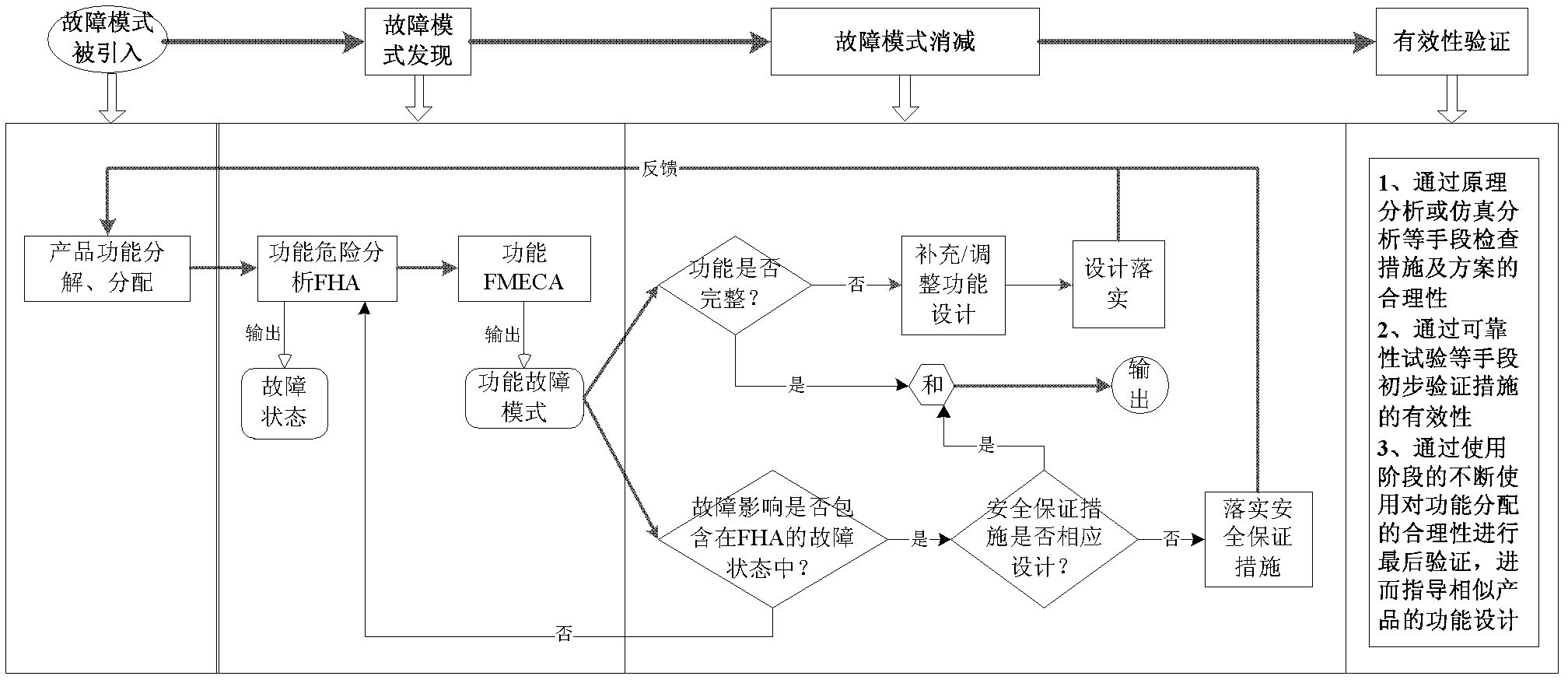

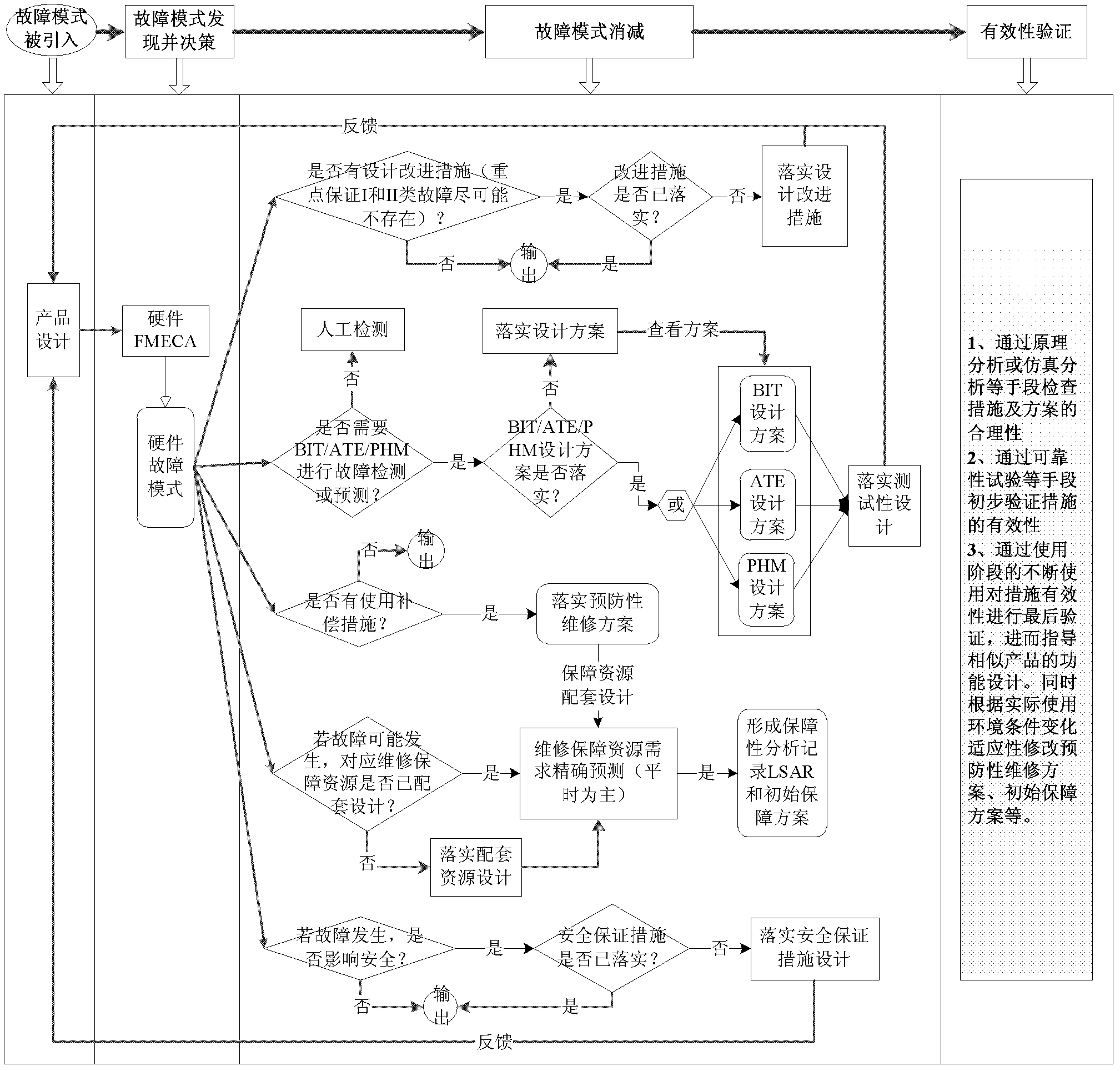

Fault mode subduction closure method based on logic decision

A failure mode subduction closure method based on a logic decision comprises four steps: step 1. Developing a FMECA analysis and classifying a result according to a certain standard; step 2. Taking a classified fault mode set as an object, calculating an influence of the fault mode subduction on an RMS index, calculating and determining an optimal fault mode subduction scheme based on a rough set theory; step 3. Implementing the fault mode subduction; step 4. Implementing validity verification. By using the method of the invention, design personnel takes the fault mode as a center, systematically considers a relation between a qualitative design and quantification index realization, simultaneously monitors each related reliability, maintainability, guarantee, testability and a security design condition and solves defects and insufficiencies one by one in the design so as to rapidly and effectively realize an RMS index requirement, shorten a development period and reduce development cost.

Owner:北京可维创业科技有限公司

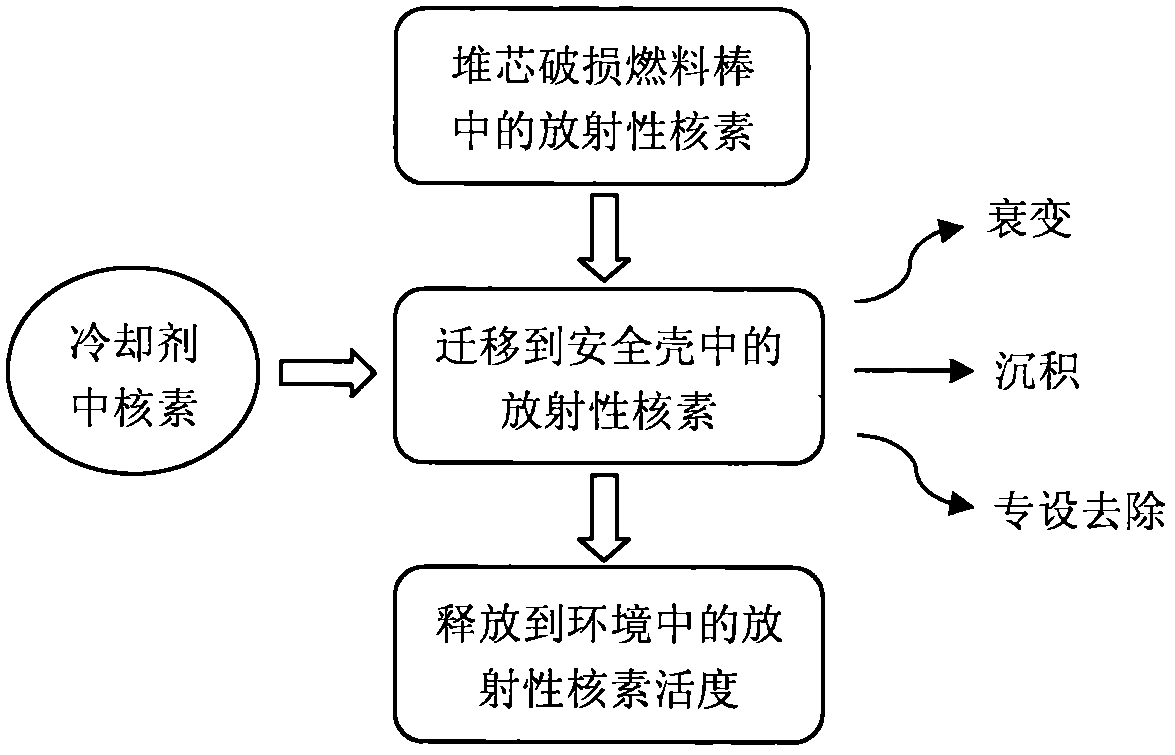

Pressurized water reactor nuclear power plant loss of coolant accident radioactive source term evaluation method

InactiveCN108537424AActivity classification calculationCalculations are reasonableResourcesNuclear engineeringPressurized water reactor

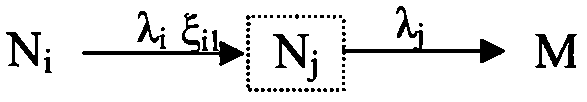

The invention relates to the field of nuclear radiation safety and particularly relates to a pressurized water reactor nuclear power plant loss of coolant accident radioactive source term evaluation method. The method comprises the following steps: (1) based on reactor equilibrium cycle life end core burden and the release share of radionuclides from the core to a containment atmosphere, the initial radioactivity of radionuclides released to the containment atmosphere by the reactor core is calculated; (2) the radionuclides are divided to three types according to decay types, and according tothe initial value of radionuclides in the containment atmosphere and a generation term and a subduction term during migration and release processes of the radionuclides in the containment, the radioactivity of each radionuclide in the containment atmosphere at different time is classified and calculated; and (3) according to the leakage rate of the containment and the radioactivity of the radionuclides in the containment atmosphere obtain in the second step, the radioactivity of the radionuclides released to the environment is subjected to integral calculation. The calculation method providedin the invention considers a complete nuclide decay chain, and the method is scientific and reasonable and strong in generality.

Owner:NUCLEAR & RADIATION SAFETY CENT

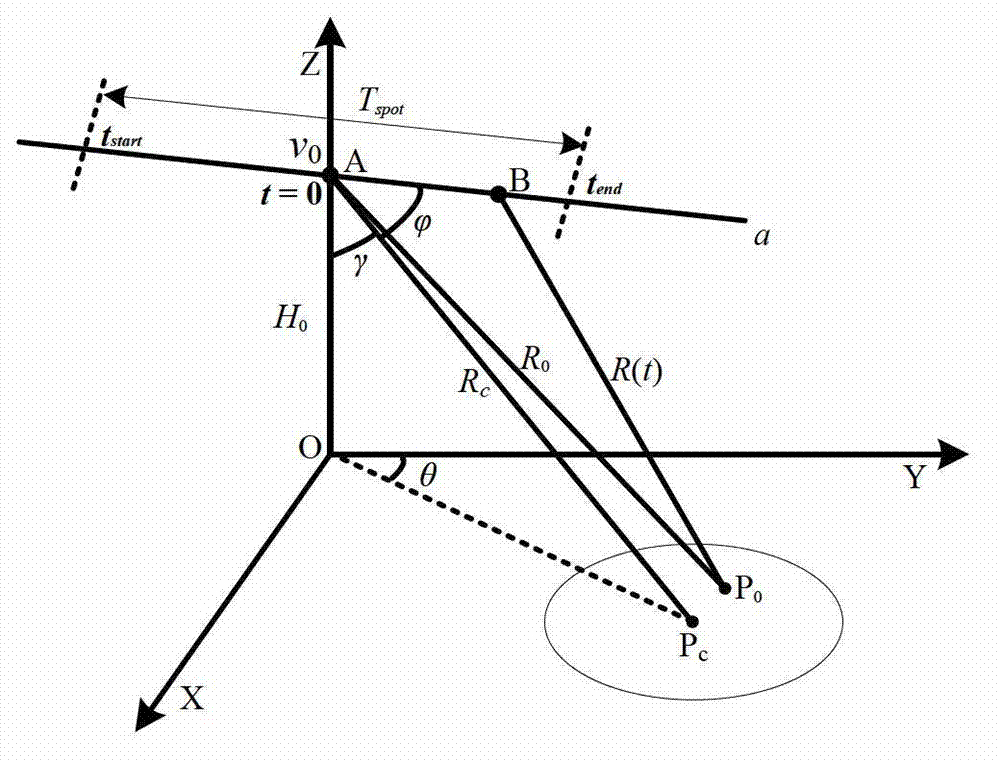

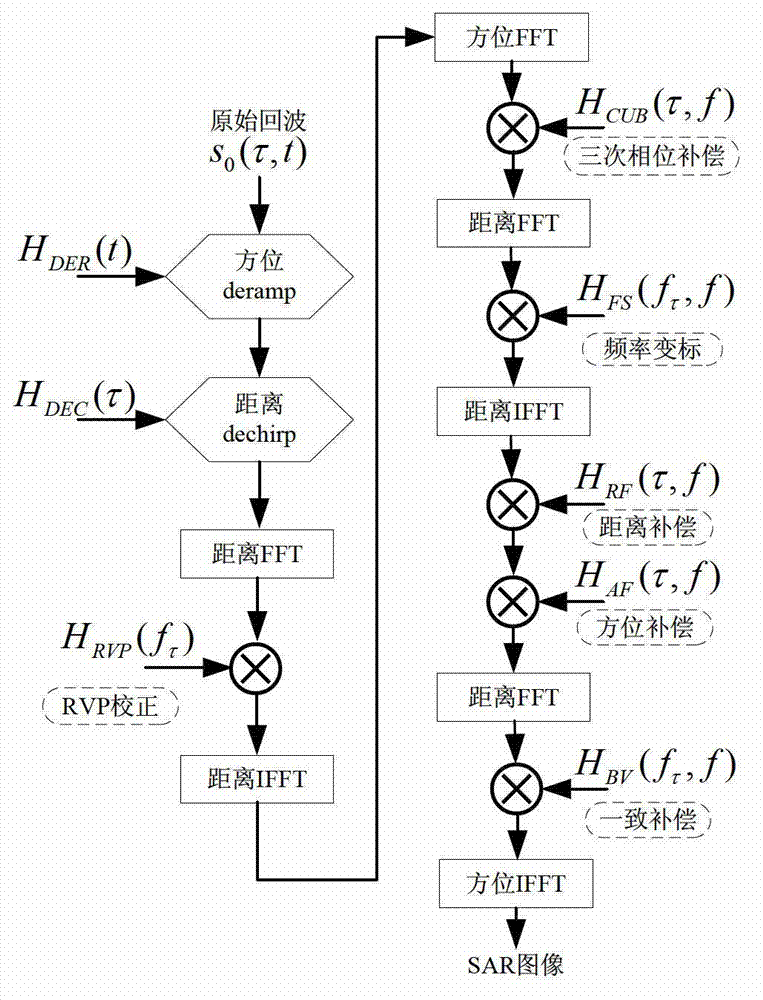

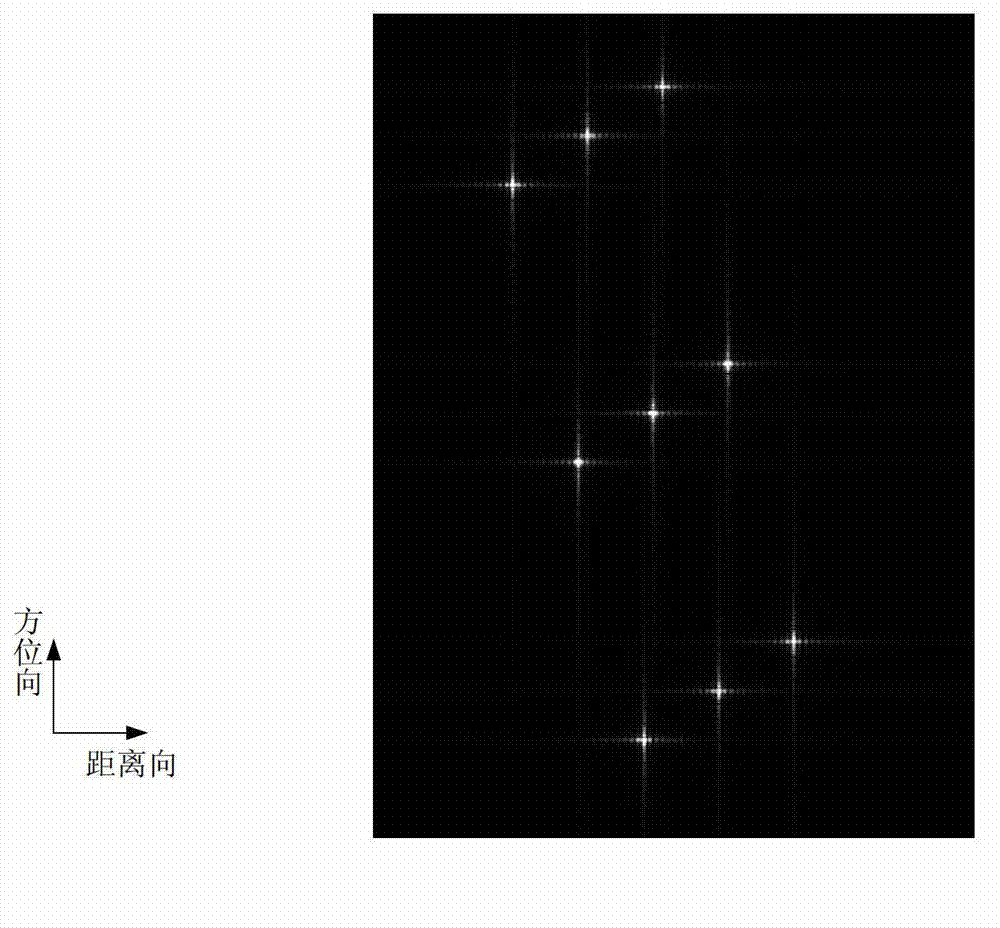

Spotlight SAR (synthetic aperture radar) imaging method based on NFS (nonlinear frequency scaling) of subduction mode

ActiveCN103048660ASolve the azimuth spectrum aliasing problemIncrease depth of focusRadio wave reradiation/reflectionFrequency spectrumSynthetic aperture radar

The invention provides a spotlight SAR (synthetic aperture radar) imaging method based on NFS (nonlinear frequency scaling) of a subduction mode. Collected spotlight full-aperture echo data of radar is sequentially subjected to the following processes: direction deramp process, distance dechirp process, residual video phase correction, three-time phase compensation, frequency scaling, distance compensation, direction compensation, and consistent compensation; and finally, azimuth IFFT (inverse fast fourier transform) is carried out on the data after the consistent compensation so that a final SAR image is obtained. According to the spotlight SAR imaging method based on NFS of the subduction mode, disclosed by the invention, a direction spectrum aliasing problem of a spotlight SAR is solved through an azimuth deramp process, the focus depth of range direction is increased by utilizing an NFS process, and high-precision spotlight SAR imaging under larger-distance focus depth is realized based on the subduction mode.

Owner:BEIHANG UNIV

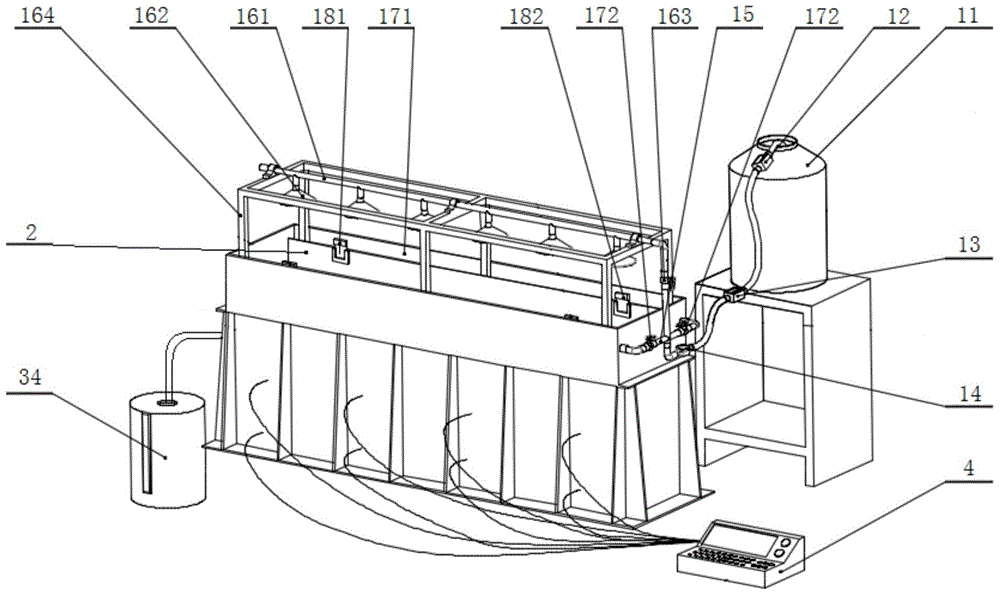

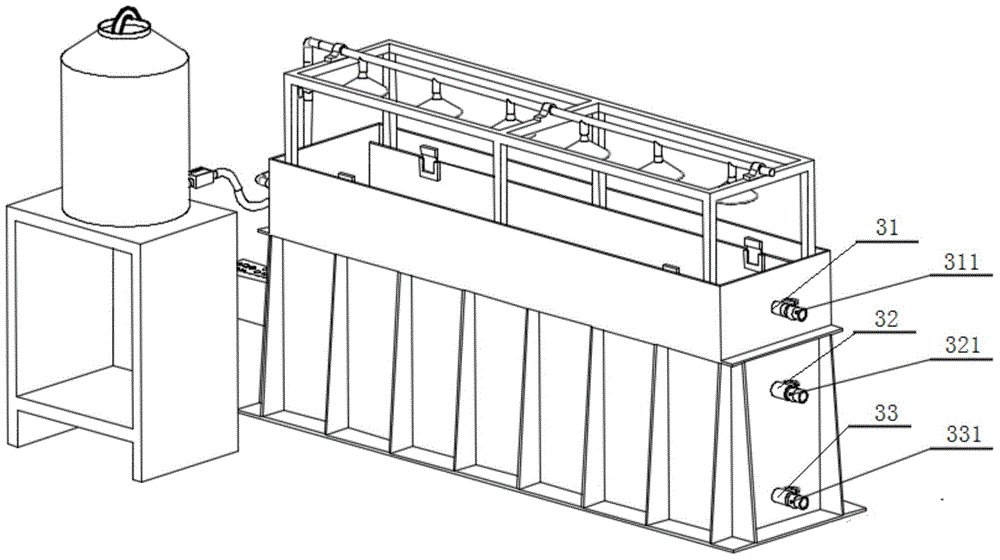

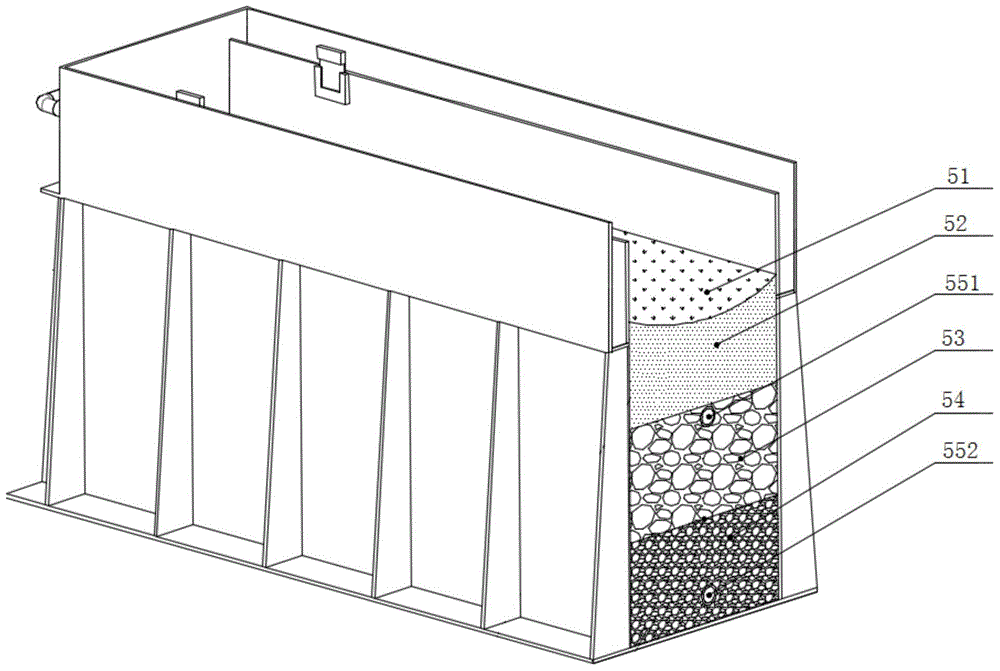

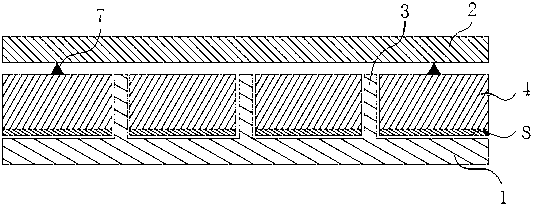

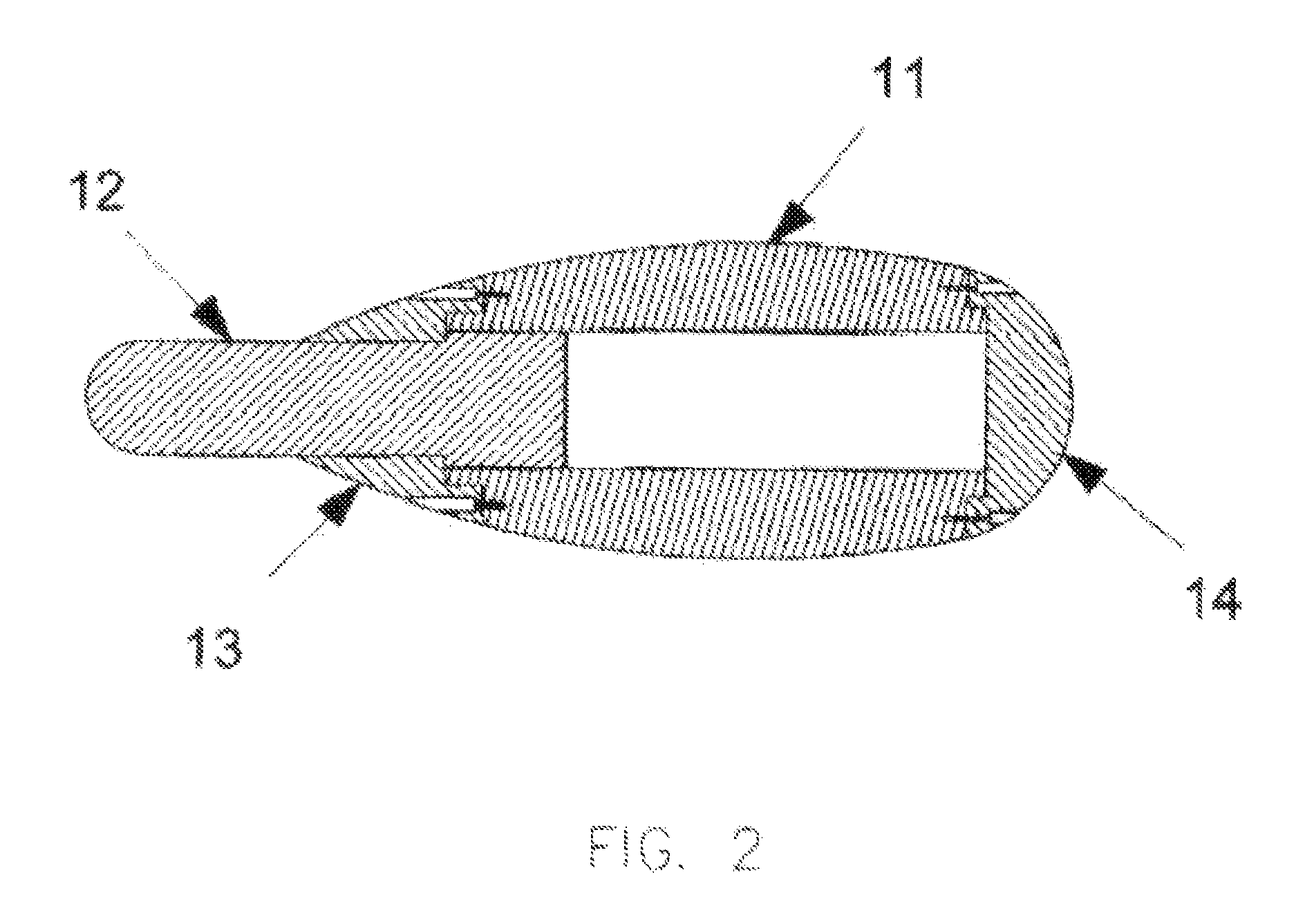

Ecological grassed swale simulation experiment device and experiment operating method thereof

The invention provides an ecological grassed swale simulation experiment device. The ecological grassed swale simulation experiment device comprises a runoff generation device, a flow-through device, a collecting device and a monitoring device, wherein an ecological grassed swale to be analyzed is arranged in the flow-through device; according to the ecological grassed swale simulation experiment device, experiment used water with different pollutant concentrations is prepared to generate surface runoffs with different pollutant concentrations; a water pump is adjusted to generate the surface runoffs with different hydraulic loadings and flow rate conditions; a corresponding valve is used for controlling to generate one or more of rainfall runoff, road runoff and green space runoff; different ecological grassed swales to be analyzed are quantitatively analyzed; the impact degree of the ecological grassed swales with different surface measures and different soil structures on rainwater interception and pollutant subduction is quantitatively analyzed, the structure of the ecological grassed swale suitable for different surface environments can be found, therefore, the simulation experiment device has very important significances on urban rainwater utilization, control of regulation and storage of urban rainfall surface runoff and pollution control. The invention also provides an experiment operating method.

Owner:SHANGHAI JIAO TONG UNIV

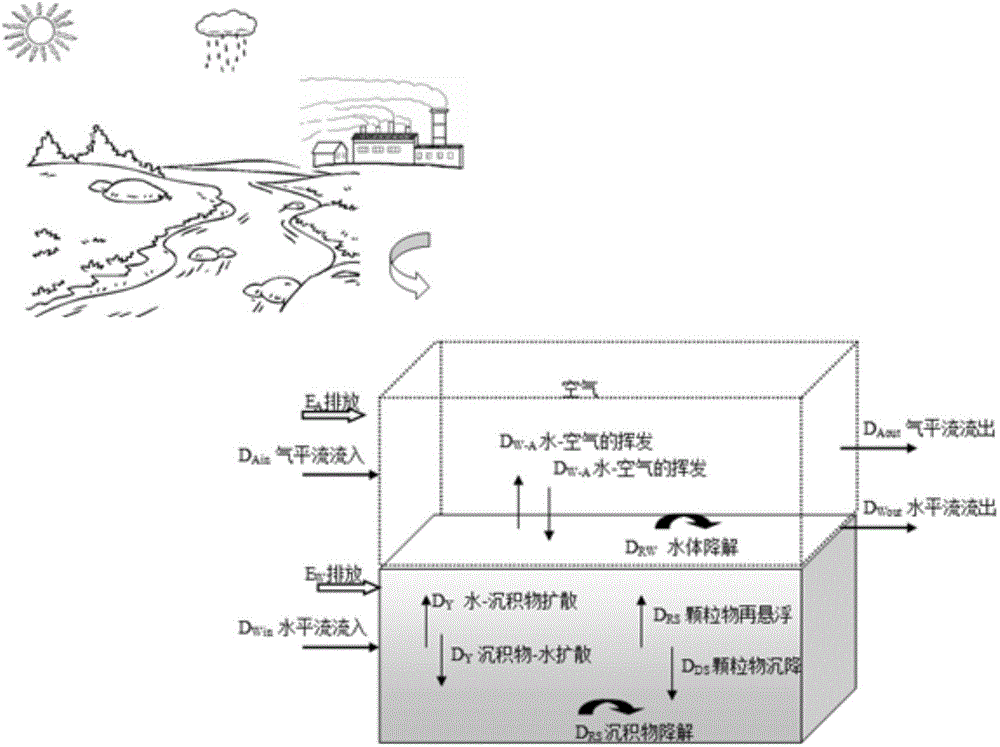

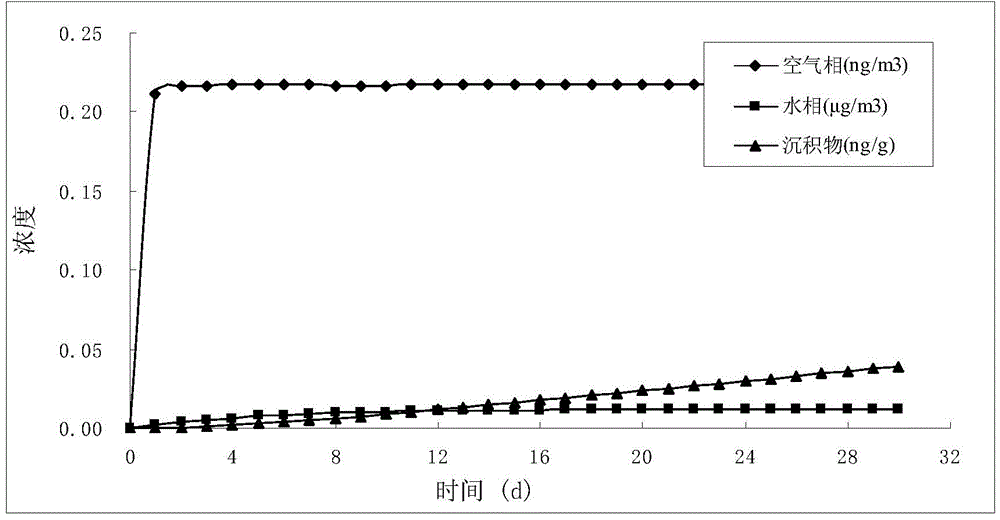

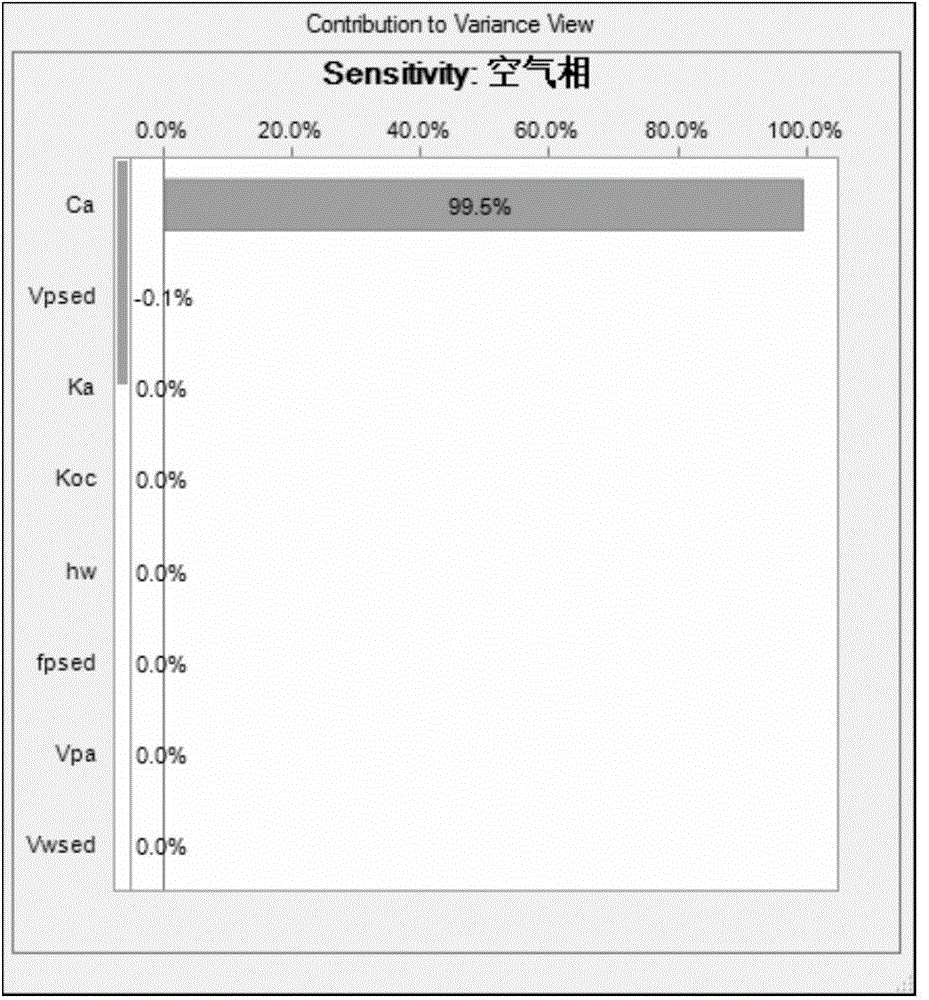

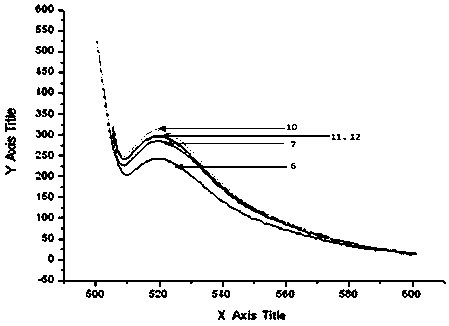

Organic chemical exposure level forecasting method for surface water environment medium

InactiveCN104820745ASimple structureTransparent prediction rulesSpecial data processing applicationsPredictive methodsModel system

The invention relates to the environment ecological risk assessment field, and in particular relates to an organic chemical exposure level forecasting model and data analysis system for a surface water environment medium based on mass balance and dynamic subduction under the surface water environment. The organic chemicals are finally discharged into the surrounding water environment along with the modern industrial production wastewater after being treated, and volatized into atmosphere along with the water, and then enter water bottom sediment through adsorption effect or settlement effect. An exposure forecasting model system which is simple in model structure, clear in forecasting rule, easy to understand and effective is established, the model in an appropriate level can be selected according to the research aim and requirements, and the model has significance to the environment exposure and security management of the organic chemicals and the environment ecologic risk assessment.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

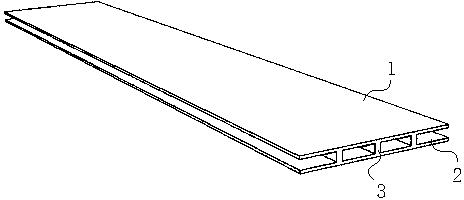

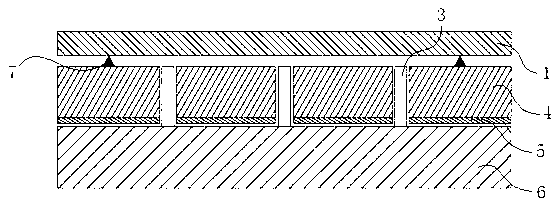

Explosive welding method of arranging multiple reinforcing ribs between large-area double-layer steel plates

InactiveCN103071908AReduce the amount of explosivesImprove economyNon-electric welding apparatusDetonationSheet steel

The invention discloses an explosive welding method of arranging multiple reinforcing ribs between large-area double-layer steel plates. The explosive welding method comprises the following steps of first-stage explosive welding: respectively fixing a die plate I, a die plate II and the reinforcing ribs on a base plate in a spot welding way, putting gap posts on the die plate I, putting an upper panel on the gap posts, arranging explosive on the upper surface of the upper panel, and carrying out the explosive welding; and second-stage explosive welding: overturning welded object obtained in the first stage, taking away the die plate I and the die plate II, filling a die plate III, covering the die plate I on the die plate III, putting the gap posts on the die plate I, putting a lower panel on the gap posts, arranging explosive on the upper surface of the lower panel, and carrying out the explosive welding. According to the explosive welding method disclosed by the invention, compared with the explosive loading amount adopted in an engineering practice in the past, the explosive loading amount is saved by about 18%; a boundary effect subduction method, which refers to a method of additionally arranging lengthened plates at two ends of a cover plate along a detonation spread direction, is adopted; and the explosive using amount is reduced, the welding rate is up to 100%, the strength of a combination interface exceeds that of base material, and the explosive method has the advantage of manufacturing large-area reinforcing rib double-layer steel structural components in good quality and low price.

Owner:中国人民解放军理工大学野战工程学院 +2

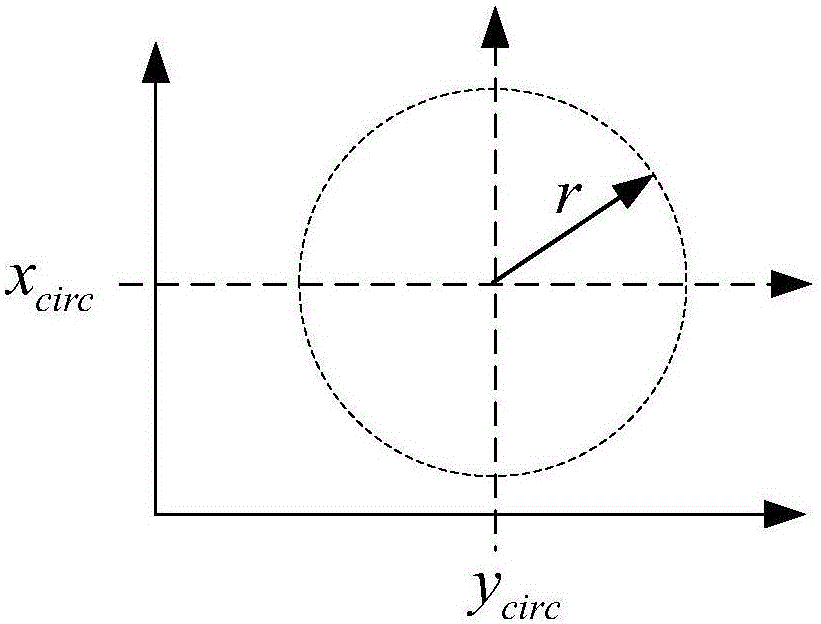

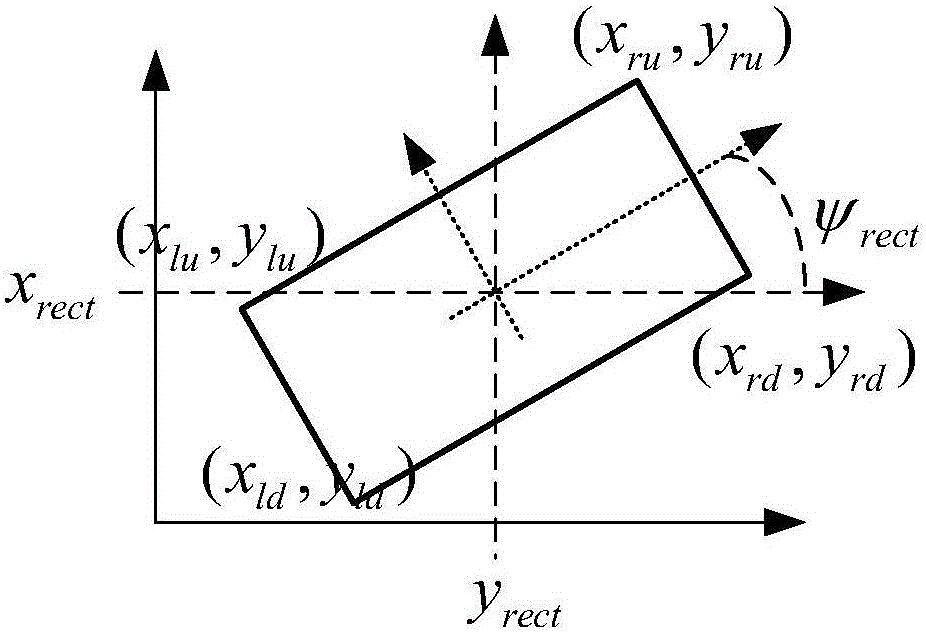

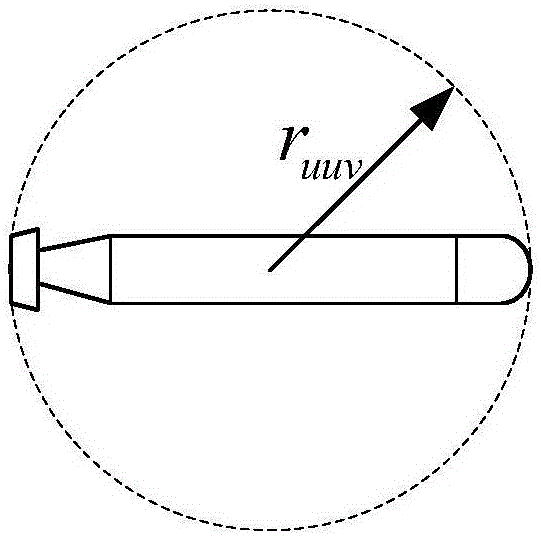

UUV 2D sea route planning method based on geographical circumvention theory

ActiveCN105929824ALess planning informationImprove planning efficiencyPosition/course control in two dimensionsCurrent pointRoute planning

The invention provides a UUV 2D sea route planning method based on the geography circumvention theory. The method comprises the following steps: 1. reading parameters of a sea route origin point Ob, a sea route terminal point Oe and each barrier from a mission text; 2. conducting expansion processing on barriers, calculating parameters of each expanded barrier; 3. establishing a set of circumvention points S; 4. if the current point Oc is planned to be the sea route terminal point Oe, or the current point Oc and the sea route terminal point Oe are planned to be visible, turning to step 6, and if not, executing the step 5; 5. searching for the barrier which is nearest to the current point Oc, based on the shape of the barrier, circumventing the barrier, obtaining circumvention points and putting the circumvention points to the set of the circumvention points S, updating the planning of the current point Oc, turning to the step 4; 6. putting the sea route terminal point Oe to the set of the circumvention pints S; 7. conducting subduction on the set of circumvention points S, which completes the planning. According to the invention, the method implements circumvention of the barriers through a simple geography theory, and enables the UUV to obtain a safe and untouched 2D sea route in a rapid and efficient manner in an environment with complex barriers.

Owner:HARBIN ENG UNIV

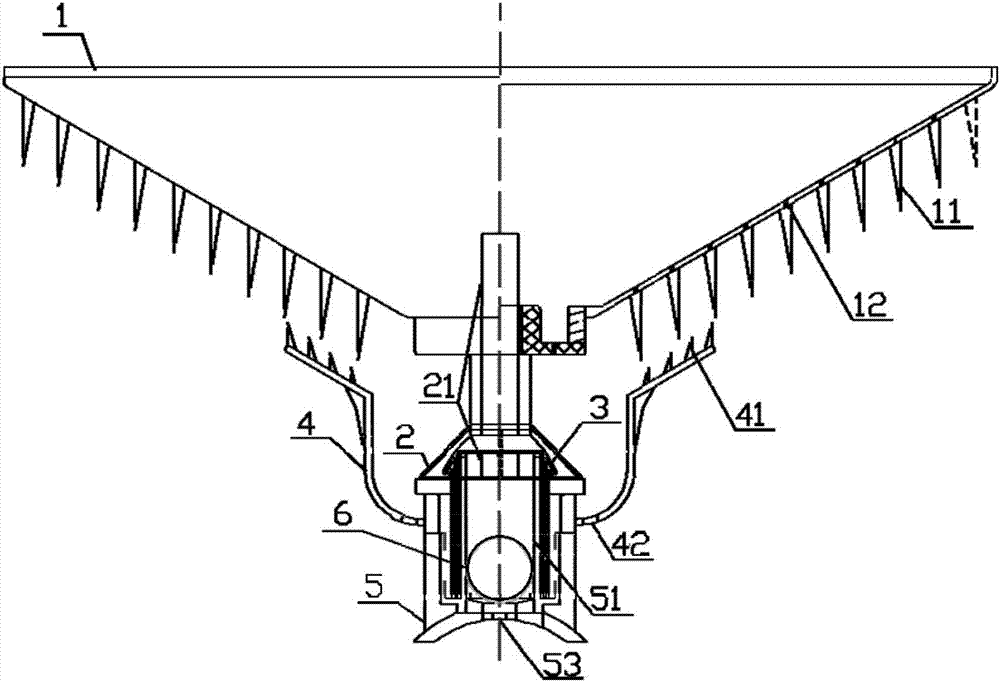

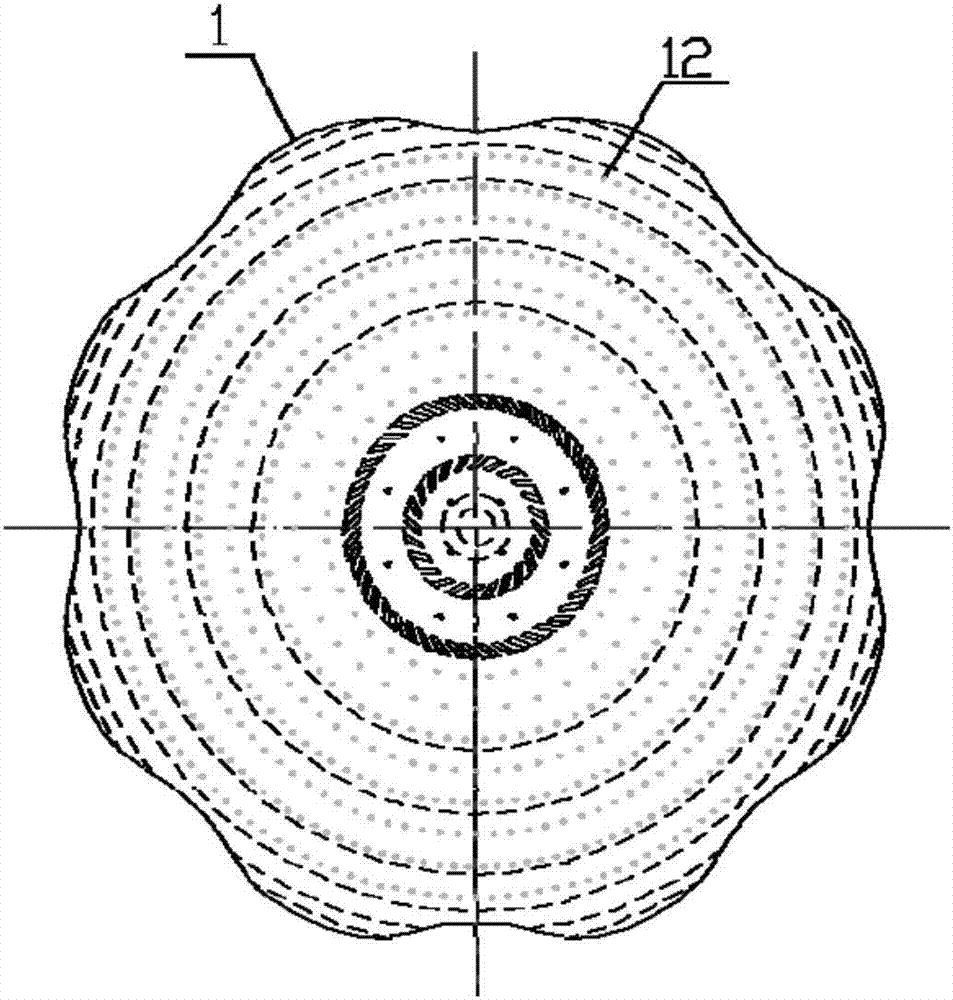

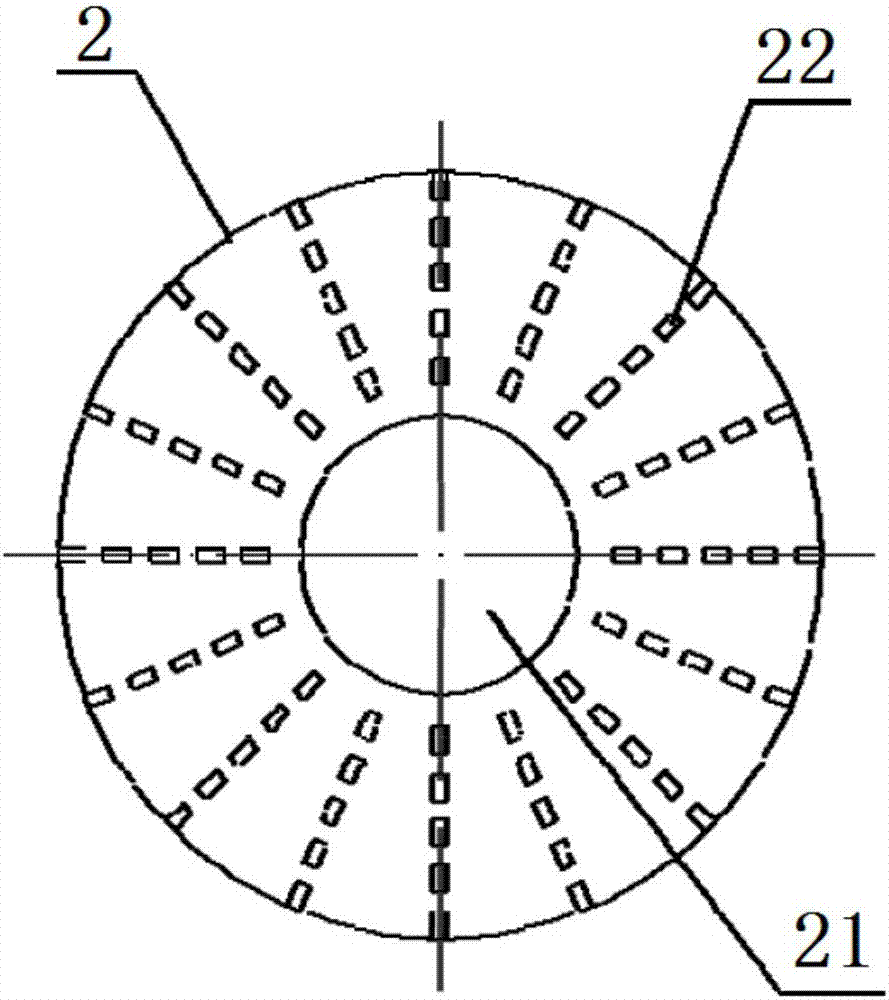

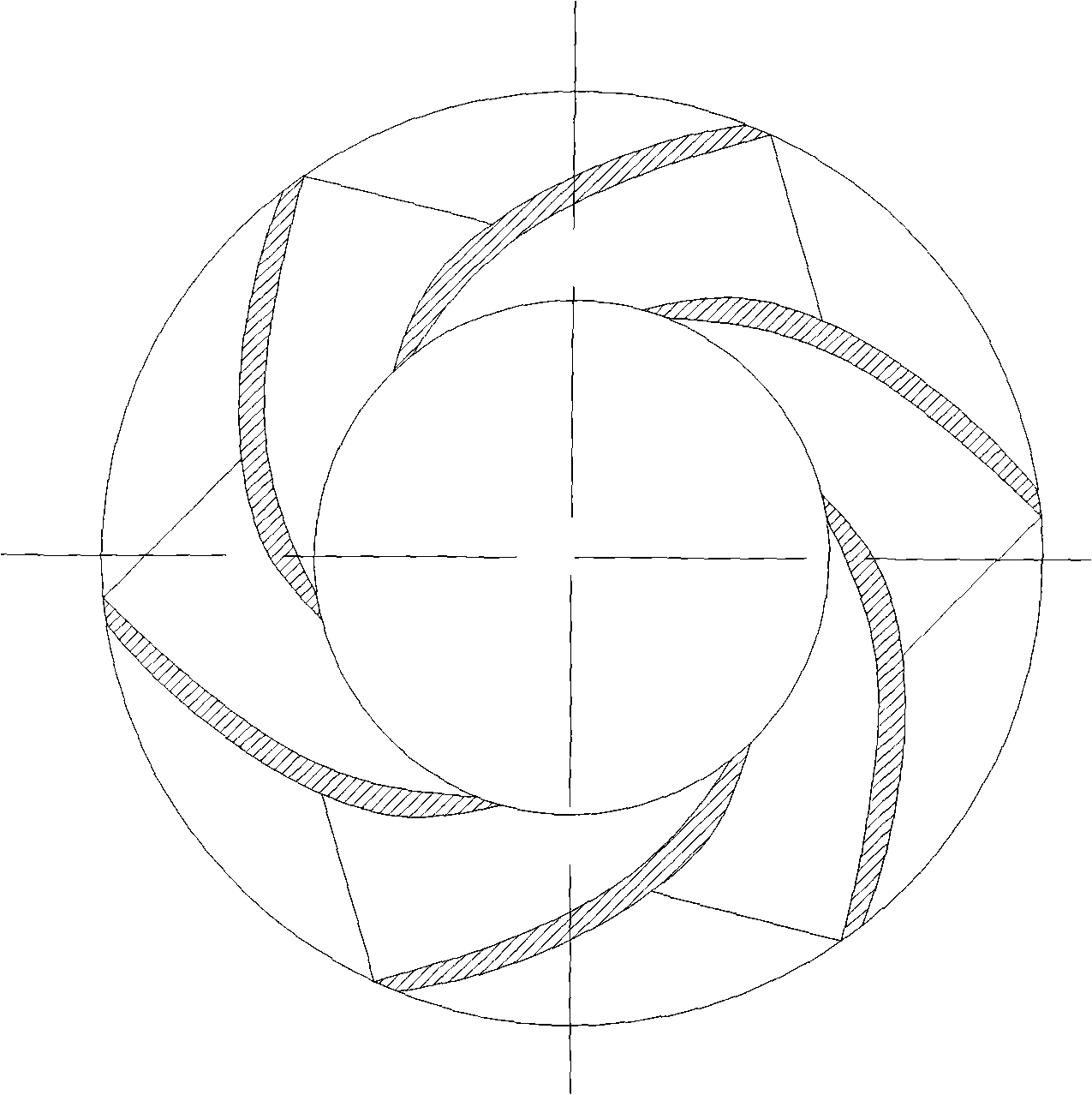

Curved surface aerator and aeration method

ActiveCN106966516AEvenly distributedReduce sizeTreatment using aerobic processesWater aerationInlet channelEngineering

The invention discloses a curved surface aerator and an aeration method. The curved surface aerator comprises a curved surface disc, a rotary cutter and an air flow subduction structure, wherein the rotary cutter is arranged below the curved surface disc; the air flow subduction structure is arranged below the rotary cutter; the rotary cutter and the air flow subduction structure are fixedly mounted on a base body; an air inlet channel is formed in the base body; the air inlet channel of the base body is communicated with the air flow subduction structure and an air channel in the rotary cutter in sequence; an air-water contact cylinder is arranged on the base body in a sleeving manner; the air-water contact cylinder is bent and extends upwards in an annular manner; the curved surface disc and the air-water contact cylinder are arranged opposite to each other; a bubble cutting structure is arranged between the curved surface disc and the air-water contact cylinder; the bubble cutting structure is used for cutting bubbles from the rotary cutter. The curved surface aerator disclosed by the invention is uniform and stable in bubble distribution, appropriate in size and reliable in property.

Owner:POWERCHINA ZHONGNAN ENG +1

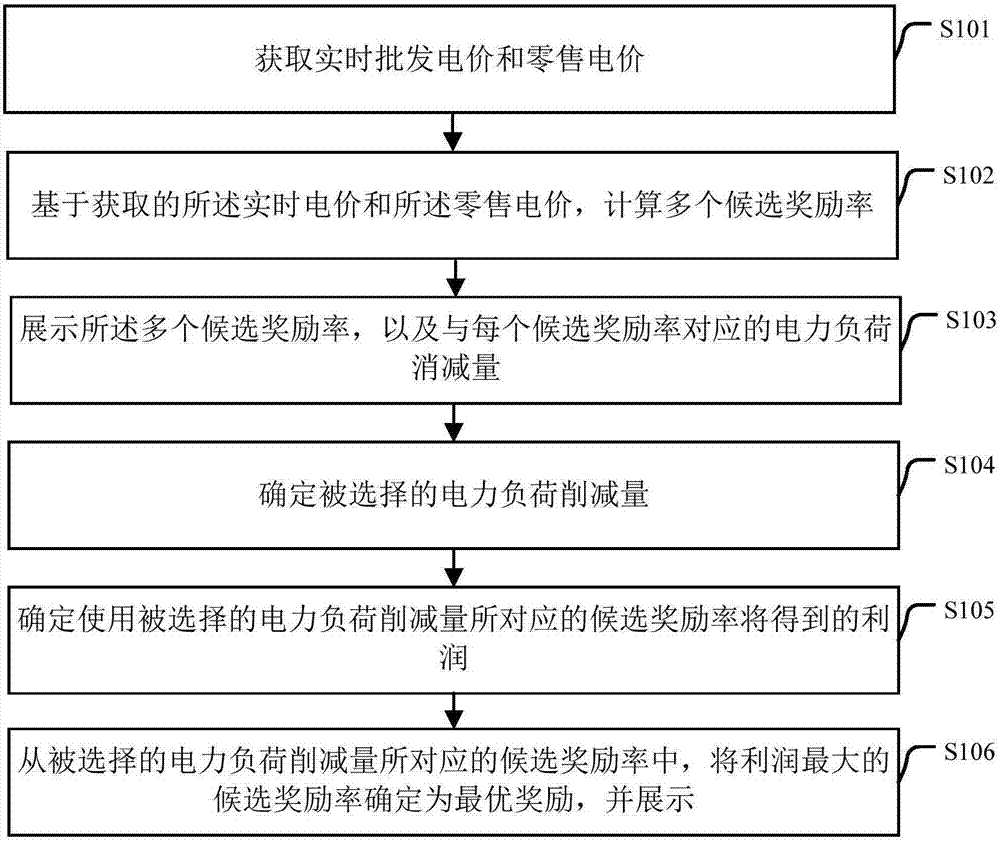

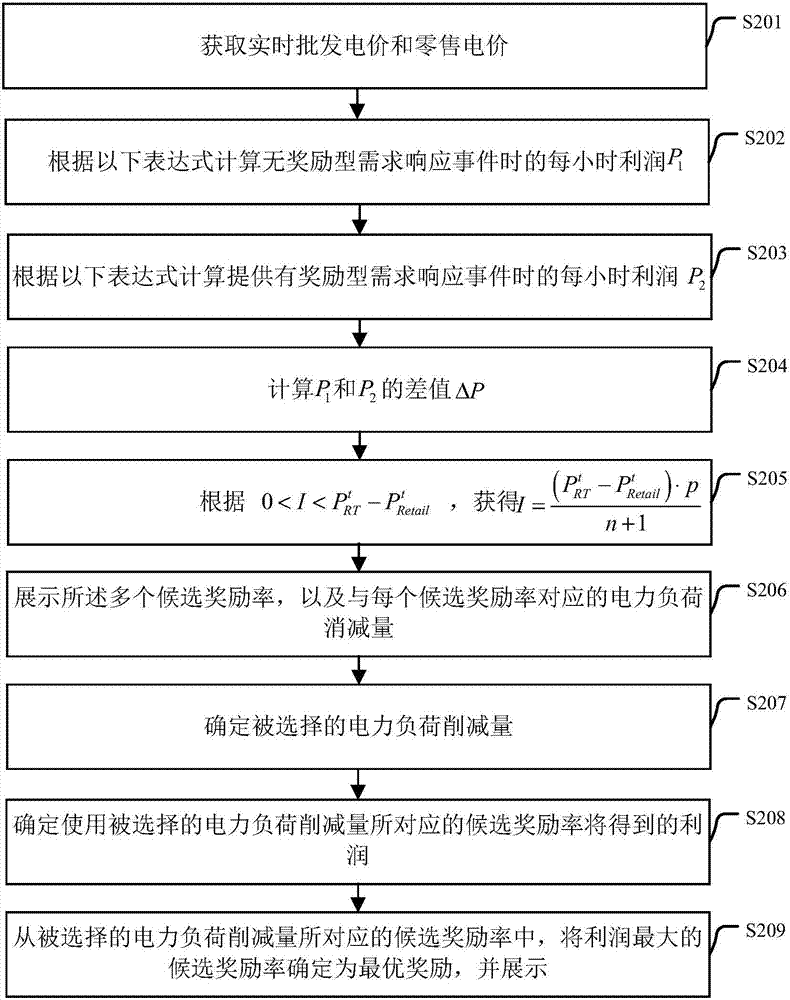

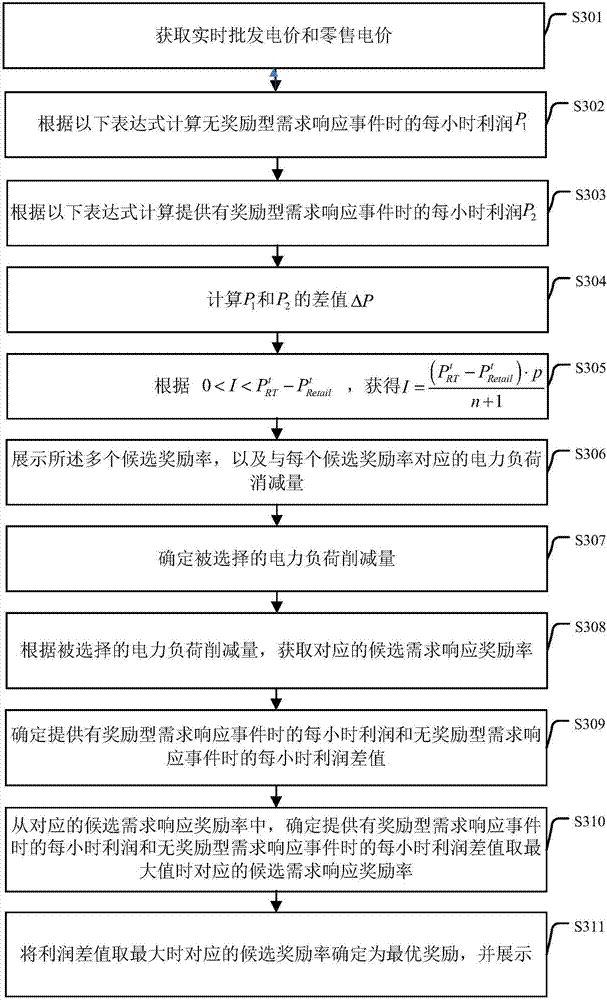

Method and device for real-time demand response reward determination in smart power network

The embodiment of the invention provides a method and device for real-time demand response reward determination in a smart power network. The method comprises: obtaining a real-time wholesale electricity price and a retail electricity price; based on the obtained wholesale electricity price and retail electricity price, calculating a plurality of candidate reward rates; displaying the candidate reward rates and electric power load subduction capacities corresponding to each candidate reward rate; determining a selected electric power load subduction capacity; determining the profit obtained by employing the candidate reward rate corresponding to the selected electric power load subduction capacity; and determining the candidate reward rate having the maximum profit as the optimal reward and performing display in the candidate reward rate corresponding to the selected electric power load subduction capacity. The method and device for the real-time demand response reward determination in the smart power network are employed to realize reward rate regulation to call the electric power load subduction capacities of electricity consumption users.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

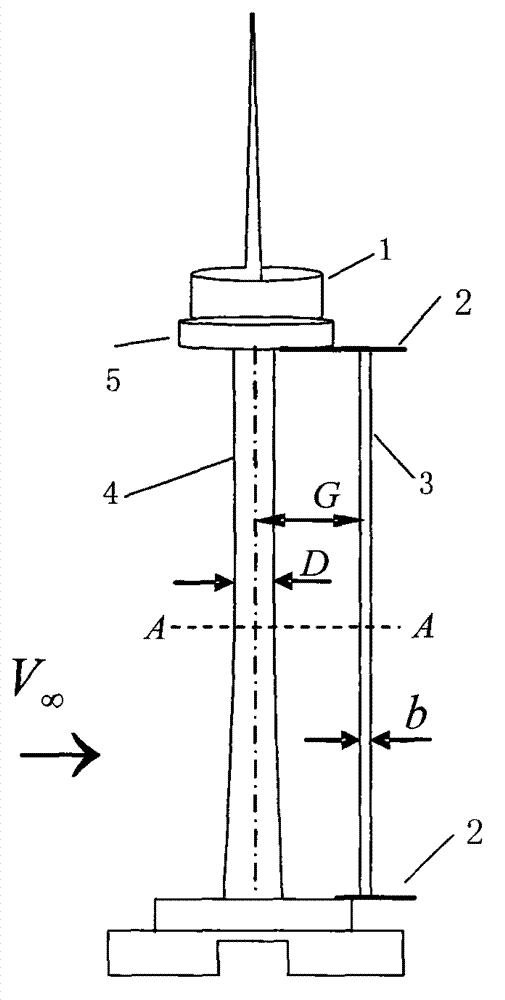

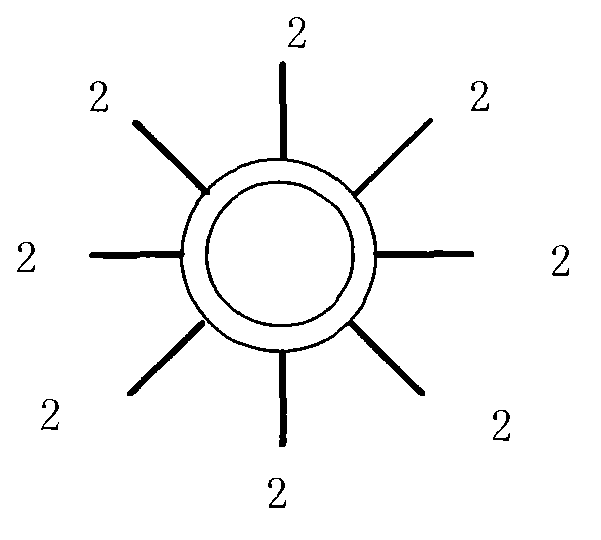

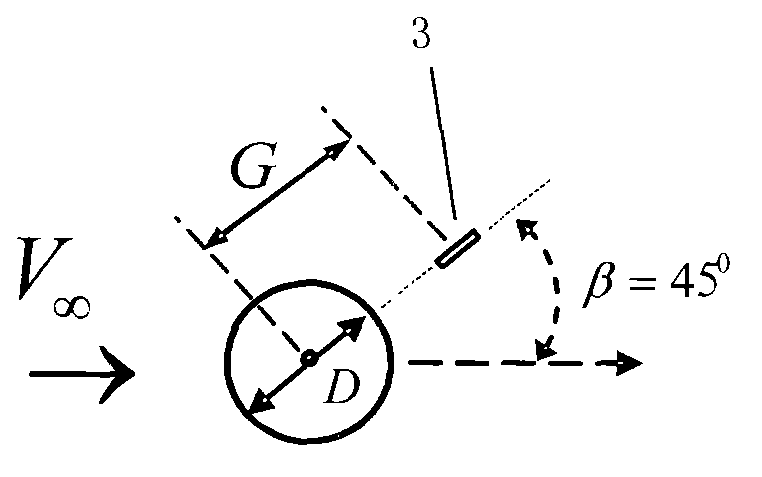

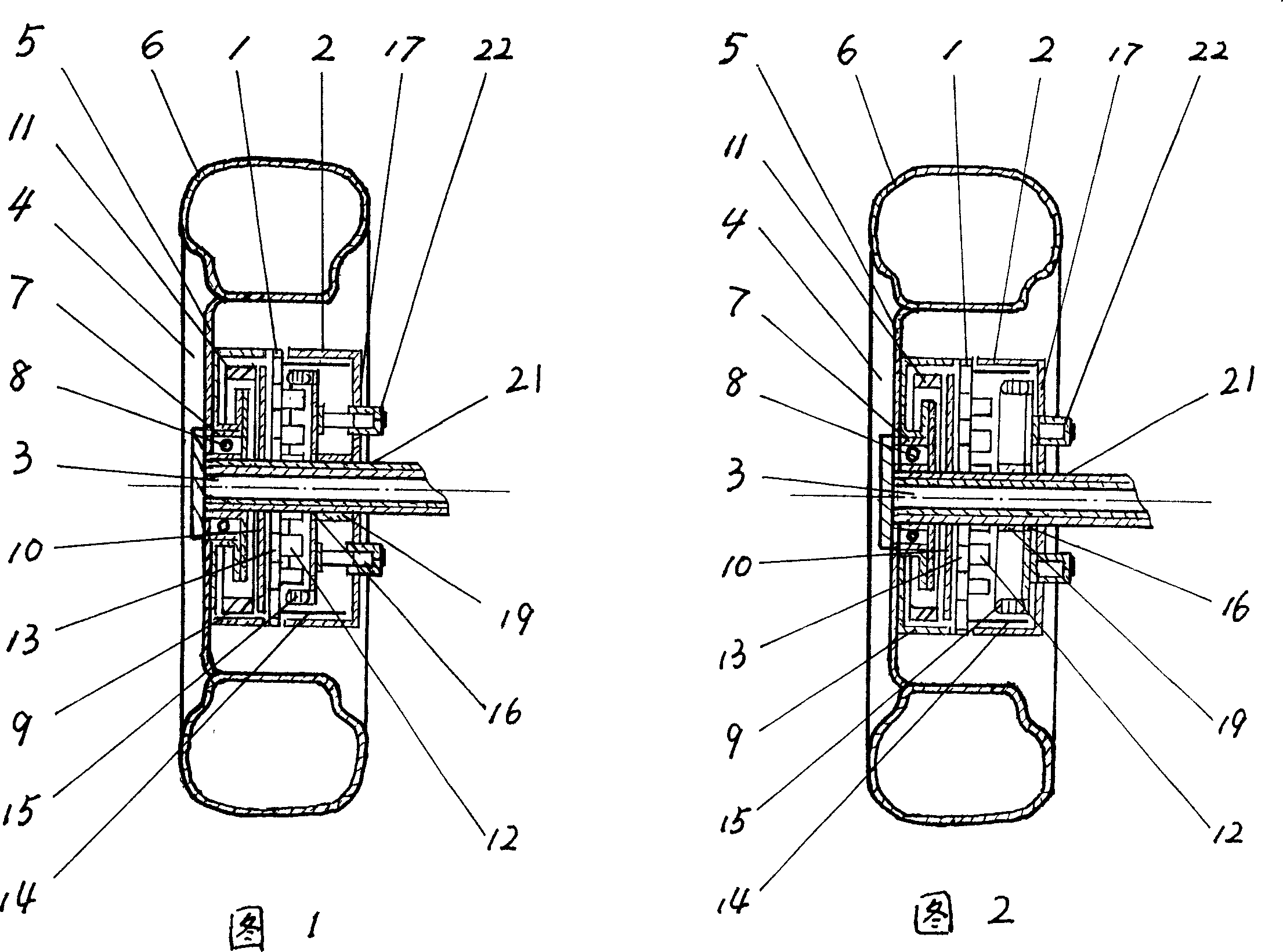

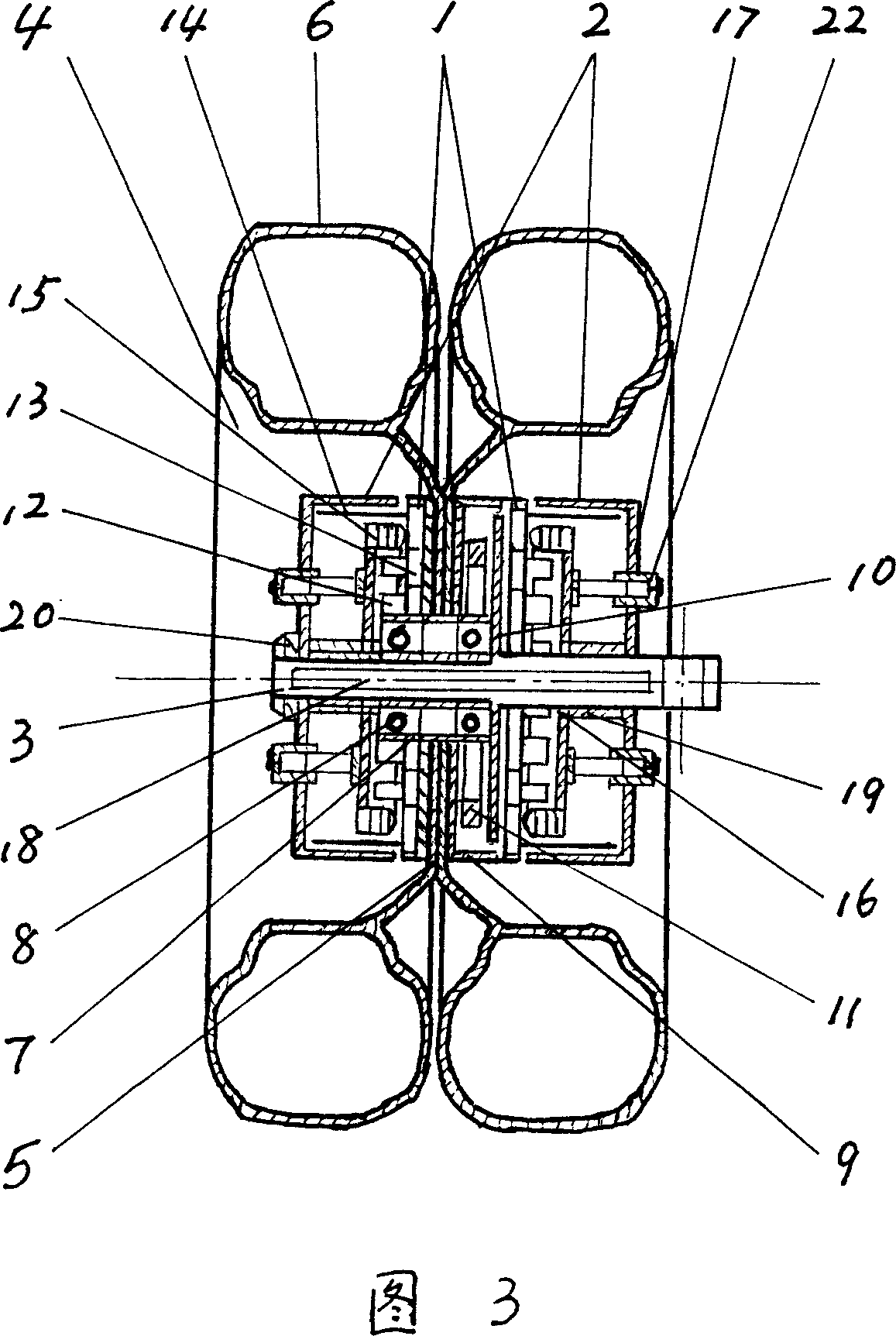

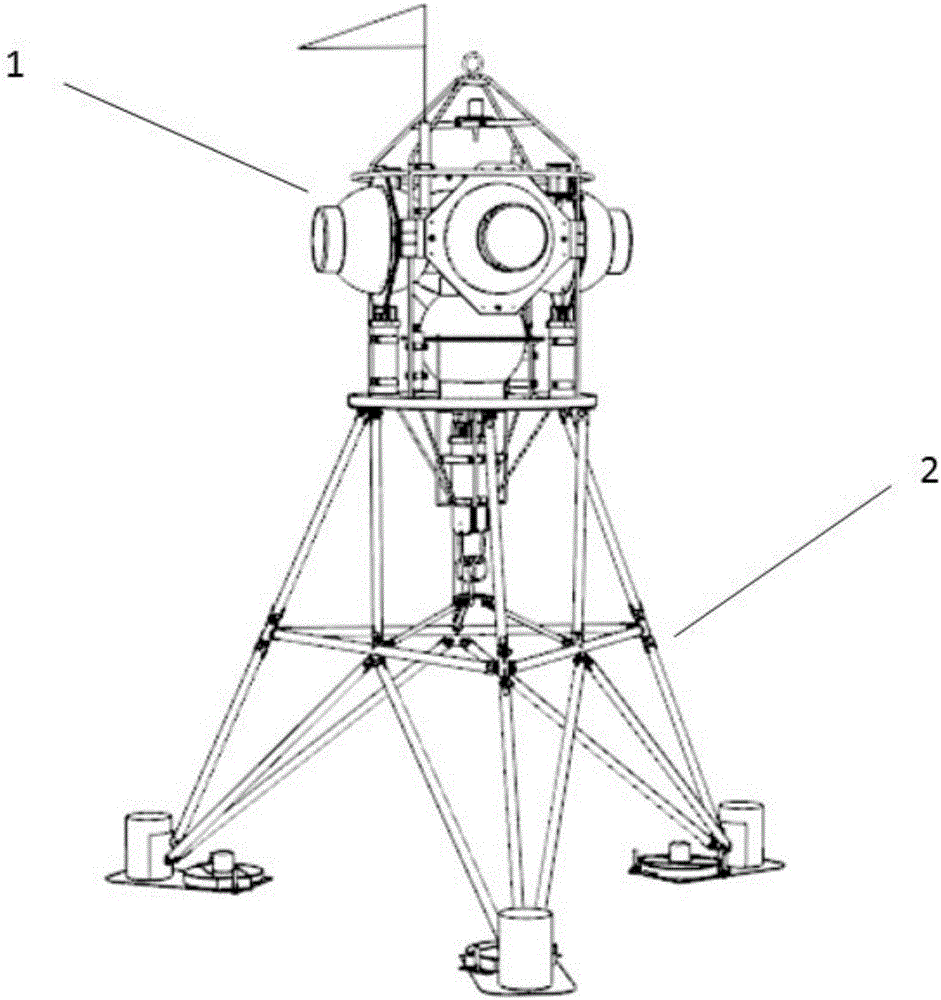

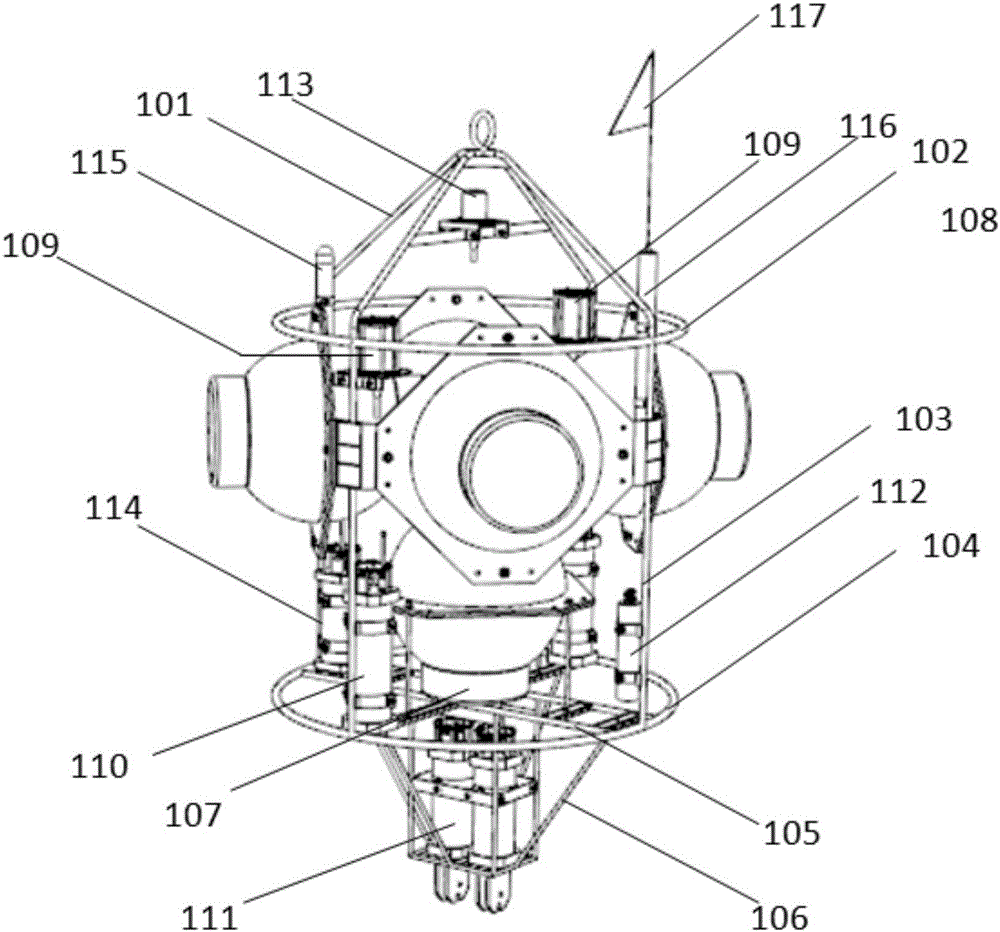

Vortex induced vibration method of subduction tower type construction

The invention discloses a vortex induced vibration method of a subduction tower type construction, eight pairs of rotary supporting rods and eight strips of cloth are arranged on the upper end and lower end of the tower type construction, the eight supporting rods (2) on the upper end are arranged in the shape of a Chinese character 'mi', namely included angles between adjacent two supporting rods are 45 degrees, the eight supporting rods (2) on the lower end are also arranged in a shaped of Chinese character 'mi', namely included angles between adjacent two supporting rods are 45 degrees, and each pair of two upper and lower supporting rods are located at the same vertical surface; stripes of cloth on one to three supporting rods which have a minus 45 degrees to a positive 45 degrees with a wind direction included angle are selected to lift as windy weather; at the premise of not changing structural basic shape, the vortex induced vibration method of the subduction tower type construction has the advantages of applying an easy, feasible and effective method to control and prevent a vortex from falling off, and achieving the purpose of vortex induced vibration.

Owner:CHINA JILIANG UNIV

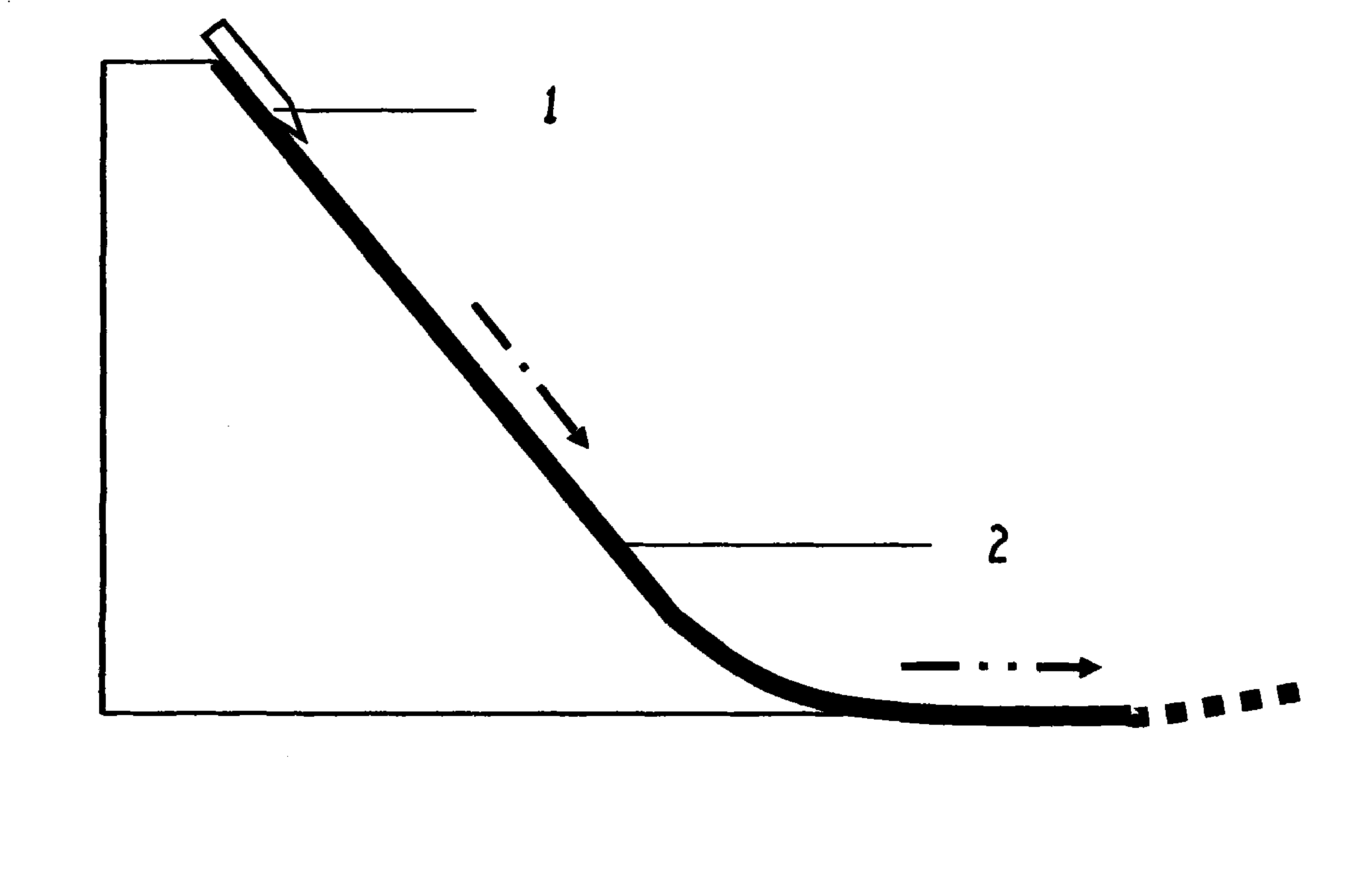

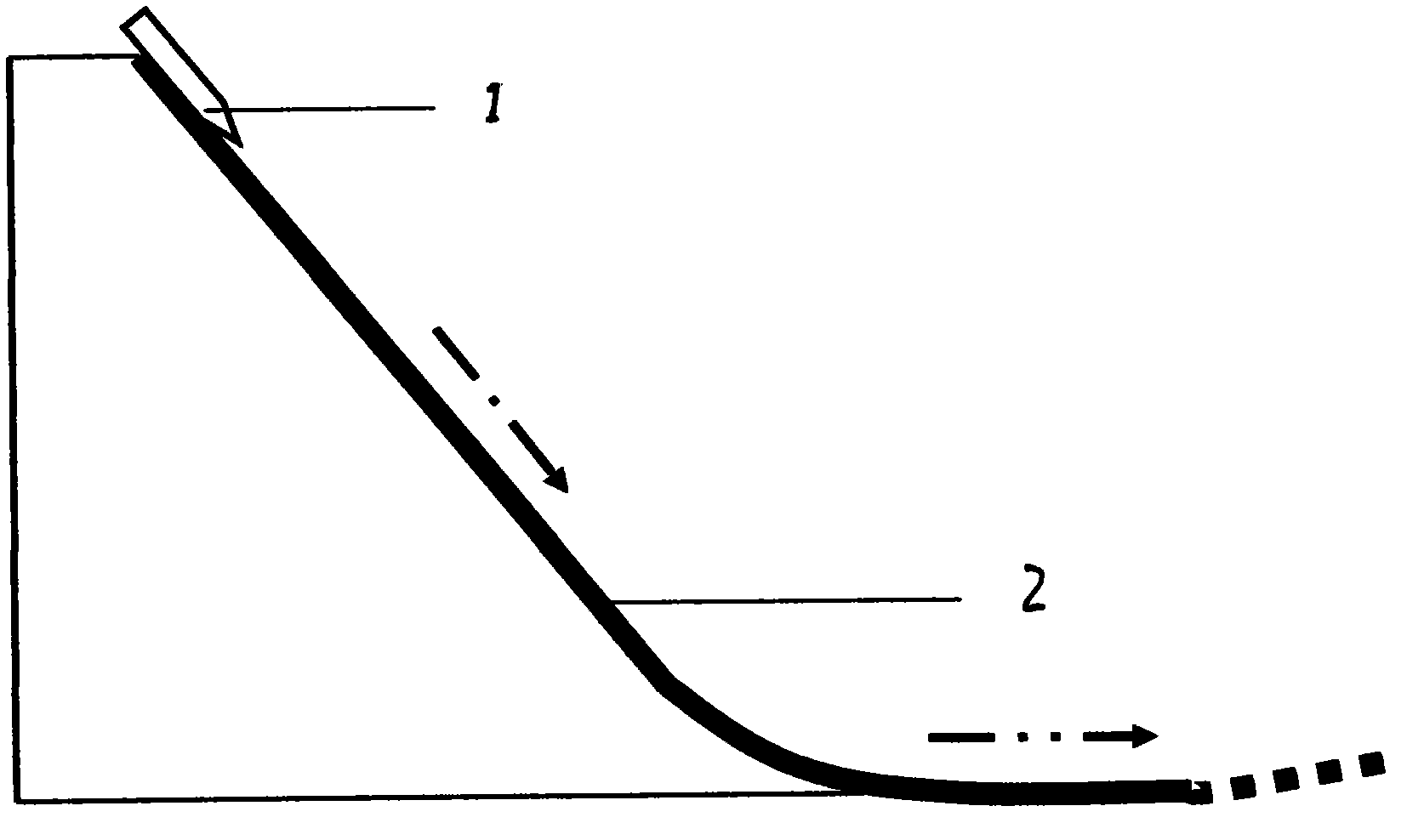

A method of using the aircraft's own gravity potential energy to make it dive and accelerate to achieve take-off

InactiveCN102267570AImprove and save consumptionEnergy efficient operational measuresLaunching/towing gearGravitational potentialRunway

The invention discloses a method for using the gravity potential energy of the aircraft itself to accelerate its dive and take off. It is to place the aircraft 1 at the upper end of the runway 2 extending obliquely or downwardly at a certain height, so that the operation of the aircraft 1 from a standstill to a take-off phase is to dive obliquely downward or downward from a high place at first. The runway 2 that supports or carries the accelerated running of the aircraft has a certain height, extends obliquely downward or downward, and has a certain bending arc in the longitudinal direction, and finally smoothly changes to extend horizontally or obliquely upward, and can immediately dive. The running direction is changed to run toward the horizontal direction or obliquely upward at high speed, and then the aircraft 1 leaves the runway by its own power to achieve the purpose of the aircraft 1 taking off. The invention can shorten the running distance and save a lot of fuel and energy during the take-off process of the aircraft.

Owner:雷宏

Natural mineral repairing agent

InactiveCN109761301AReduce CODEasy to operateWaste water treatment from animal husbandryBiological testingChemical oxygen demandTherapeutic effect

The invention provides a natural mineral repairing agent. The natural mineral repairing agent is prepared from the following main components of natural zeolite powder, kieselguhr and polymeric aluminum chloride. The natural mineral repairing agent provided by the invention takes natural minerals as the main components, the natural mineral repairing agent not only can be added in a dry powder form,but also can be used by adding water for dissolving, the operation is convenient, the natural mineral repairing agent is environment-friendly and cannot generate secondary pollution after use, a subduction function on bottom mud is obtained, desilting cost can be saved, the treatment effect is lasting, and recurrence is not easy; when the natural mineral repairing agent is used for treating fivekinds of surface water and aquaculture wastewater, pollutants such as COD (Chemical Oxygen Demand), ammonia nitrogen and total phosphorus in water can be rapidly reduced; the natural zeolite in the natural mineral repairing agent has very strong adsorption property on the ammonia nitrogen and is capable of removing 90 percent or above of ammonia nitrogen in the water, so that the natural mineral repairing agent has a very good purifying effect aiming at the water with overproof ammonia nitrogen.

Owner:HUANYA TIANJIN ENVIRONMENTAL PROTECTION TECH CO LTD

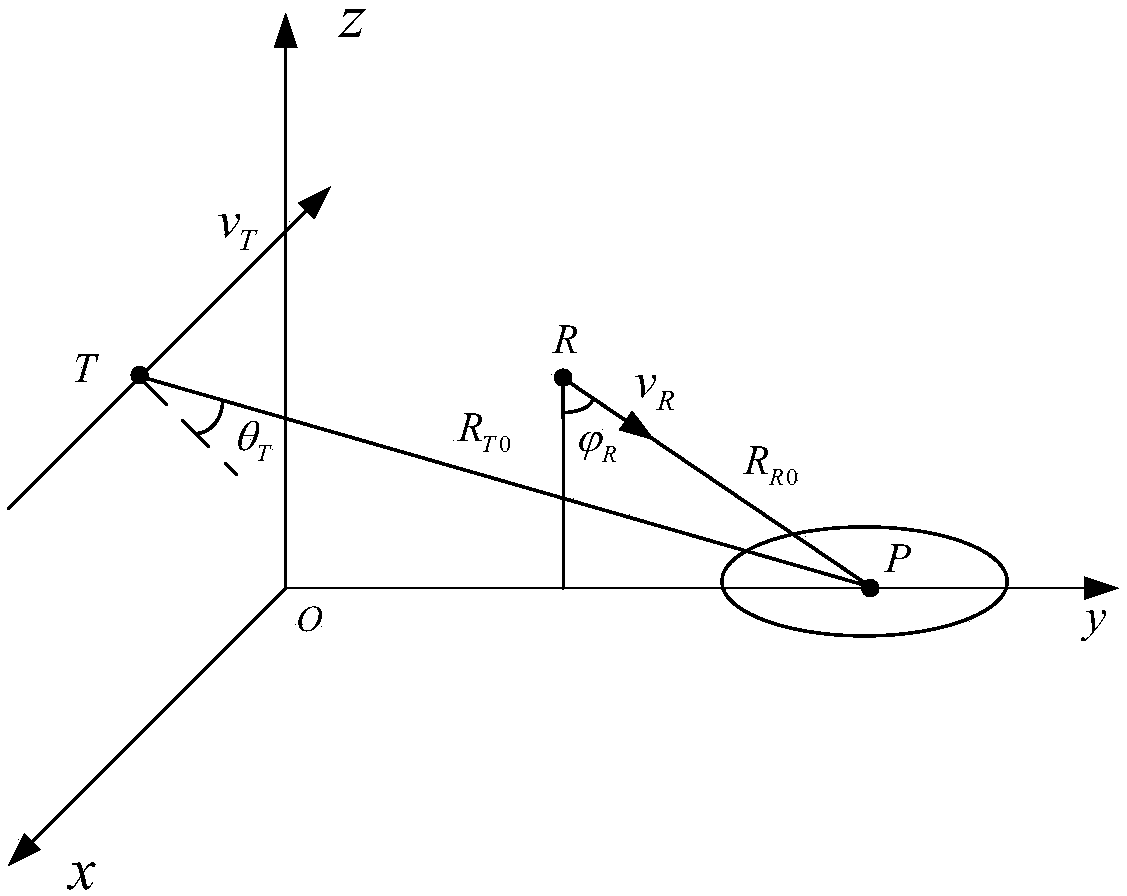

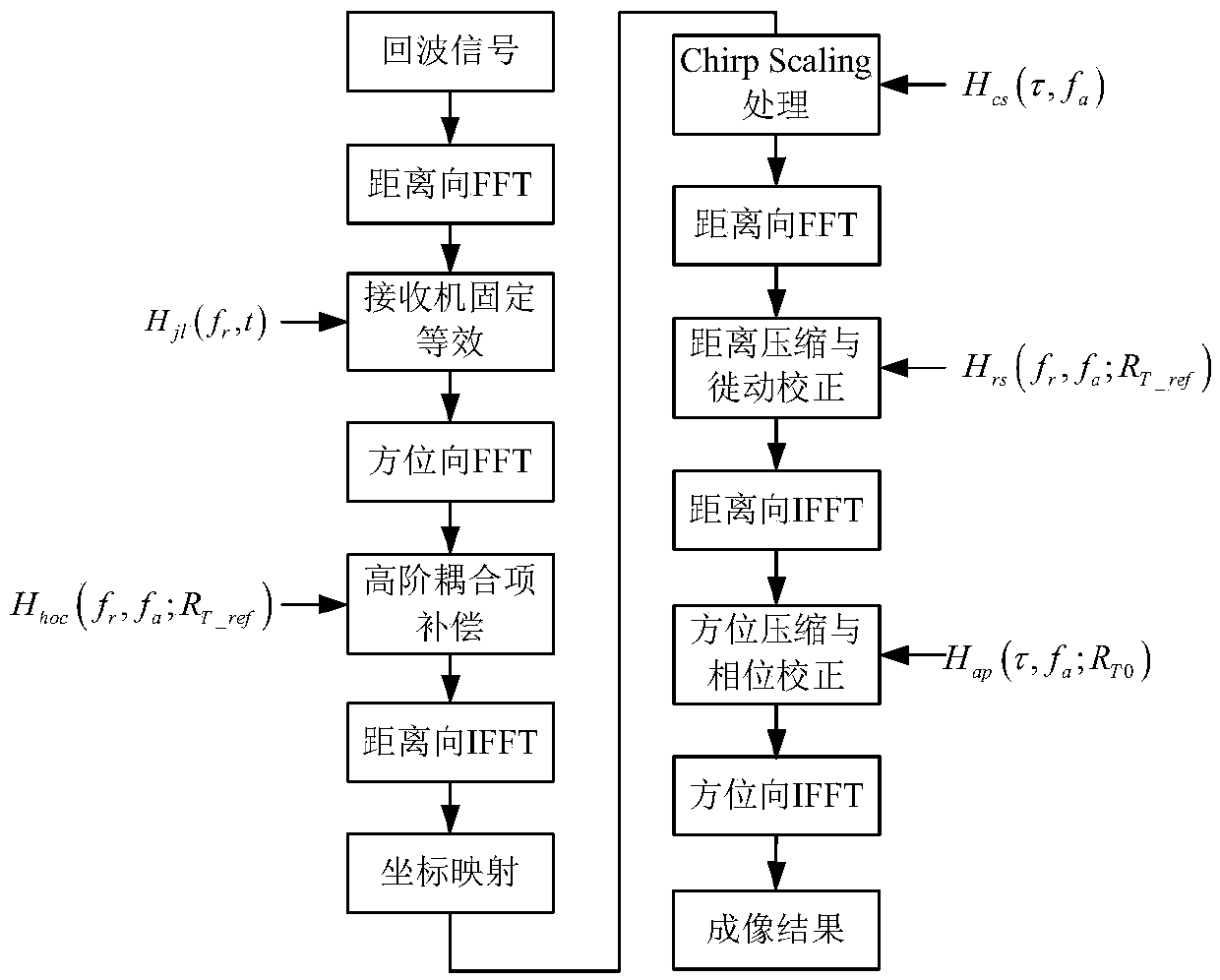

Bistatic forward-looking SAR imaging method in subduction mode

The invention discloses a bistatic forward-looking SAR imaging method in a subduction mode. The method comprises the steps: proposing an imaging model in which a reconnaissance plane cooperates with amissile, the track is vertical, and the missile performs a uniform diving attack; establishing a geometric model of an uniform diving bistatic forward-looking SAR; providing a model corresponding toslant range history; and proposing an imaging algorithm based on receiver fixed equivalent for characteristics of the slant range history. According to the method, the double missiles matching model adopts an action mechanism that a missile attack and a missile performs irradiation and imaging, and an irradiation missile is away from an imaging area.

Owner:江苏天域航空科技集团股份有限公司

Wheel power-generating device for retractable stator

InactiveCN1937364AGuaranteed normal consumptionReduce consumptionAuxillary drivesElectrodynamic brake systemsLow speedRoad surface

The generating set includes wheel rotor, stub stator, wheel axis, stator slide way, sliding rack, and clutch of stator. The wheel rotor is composed of wheels, rotor, fan or centrifugal wheel, and shield. Stub stator includes stator, end plates, and rectifier. One side of clutch of stator is installed on end plate, and the other end if installed on stator. Based on different instances, such as ascent load, operation at low speed, uncrowned road, or downhill load, the makes stator separate fro or combine to rotor automatically through control system. Thus, using energy of inertia and downward subduction force, the invention can generate electric energy without affecting speed and load. Features are: repetitive cycling power generation, saving energy, and lowing pollution. The generating set is applicable to hybrid motor vehicles, military vehicles, new type motorcycles, and bicycles, even train.

Owner:陈冠卿

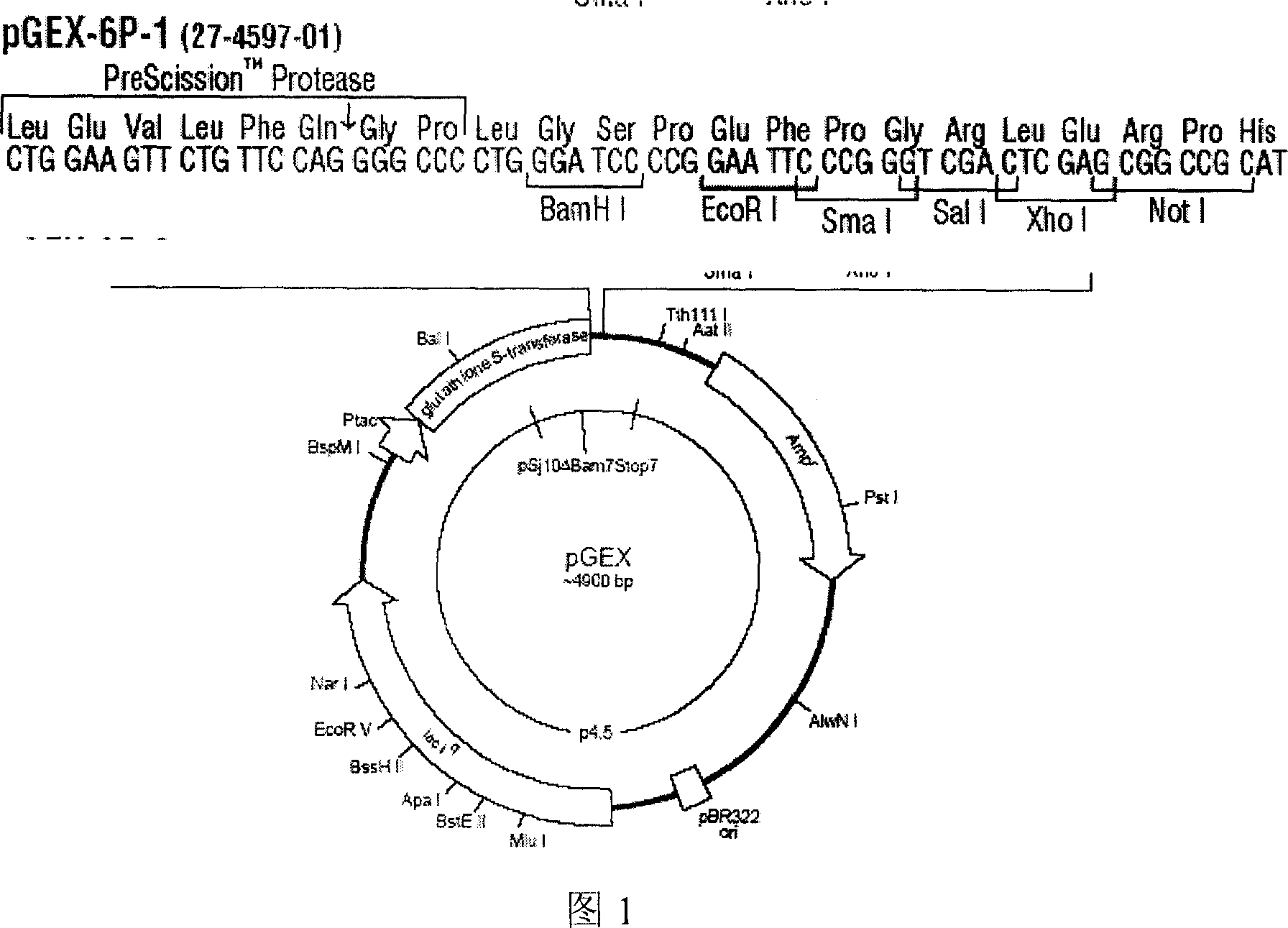

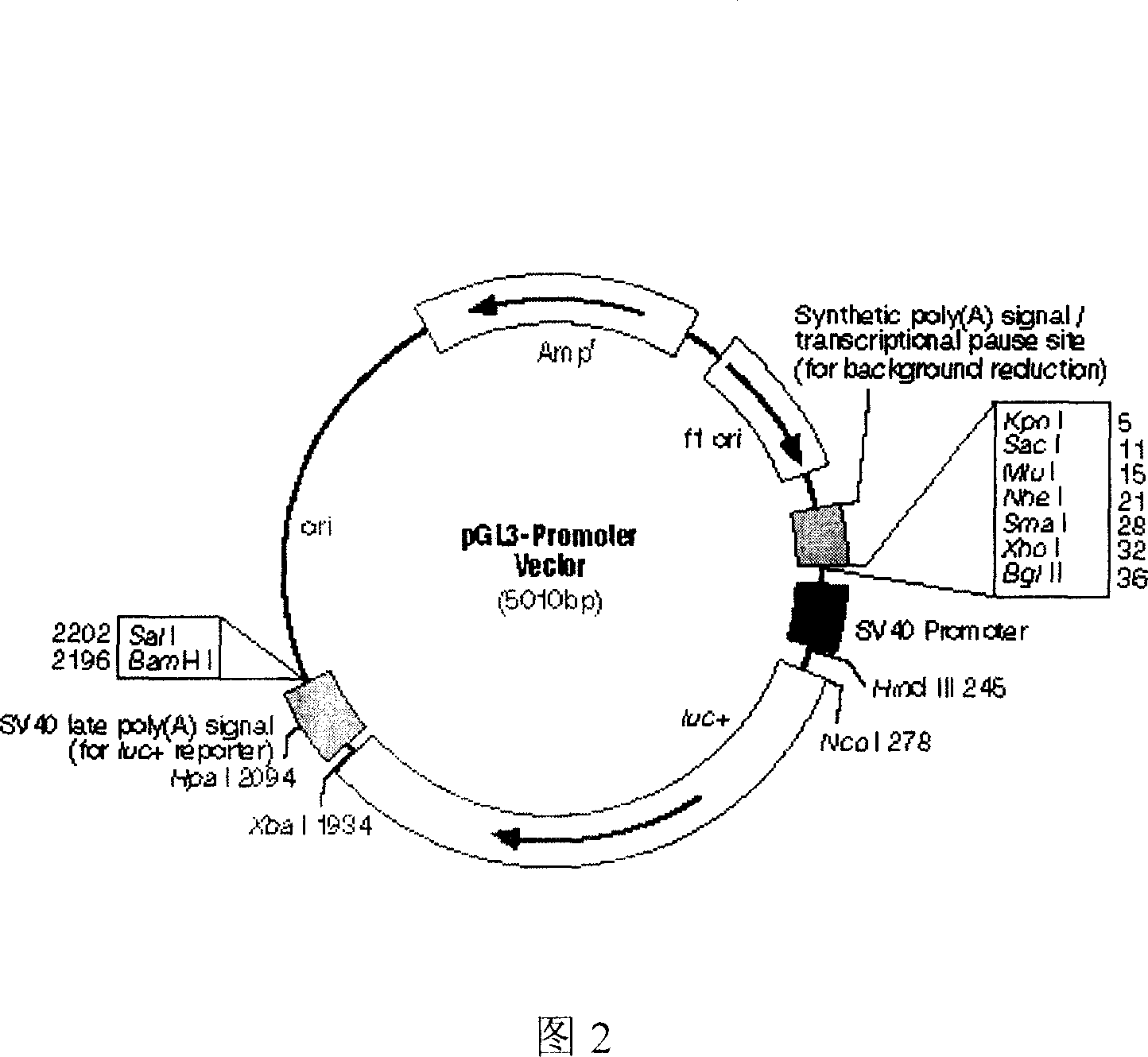

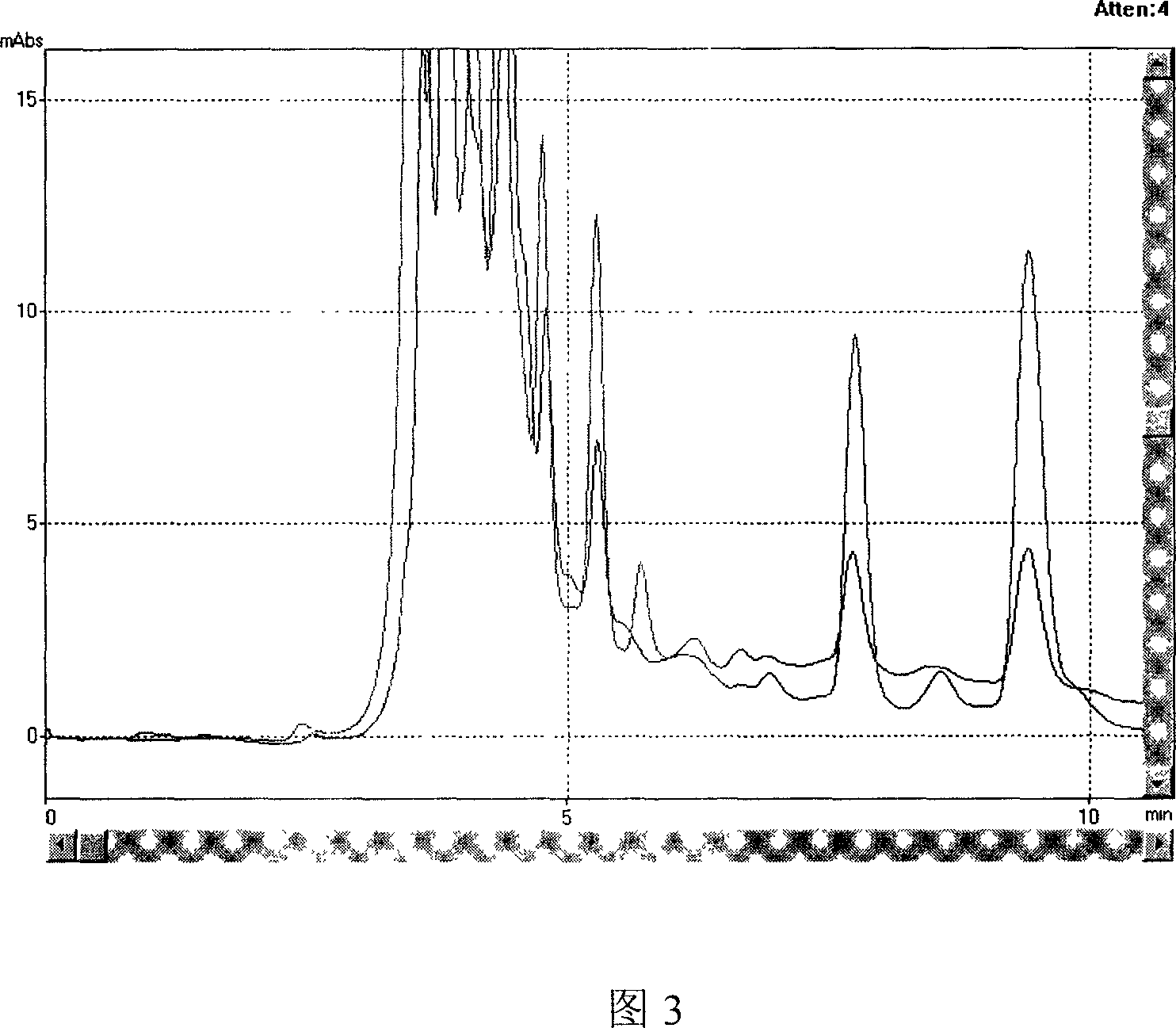

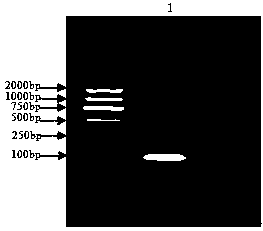

Gene sequence correlated with cordycepin biological synthesis

The present invention relates to cordycepin biosynthesis relevant gene and its application. Seven cordycepin biosynthesis relevant genes are cloned by means of suppression and subduction hybridizing (SSH) technology. They are named separately as chcs1, chcs2, chcs3, chcs4, chcs5, chcs6 and chcs7 and have cDNA sequence lengths of 760bp, 774bp, 713bp, 823bp, 746bp, 763bp and 890bp separately. Through constituting high efficiency plant expression converting vector containing the said genes, it is possible to increase the copy quantity of biosynthesis gene inside thallus and to raise the content of cordycepin aweto expresses for meeting the requirement in developing medicine.

Owner:JONJEE HI TECH INDAL & COMML HLDG

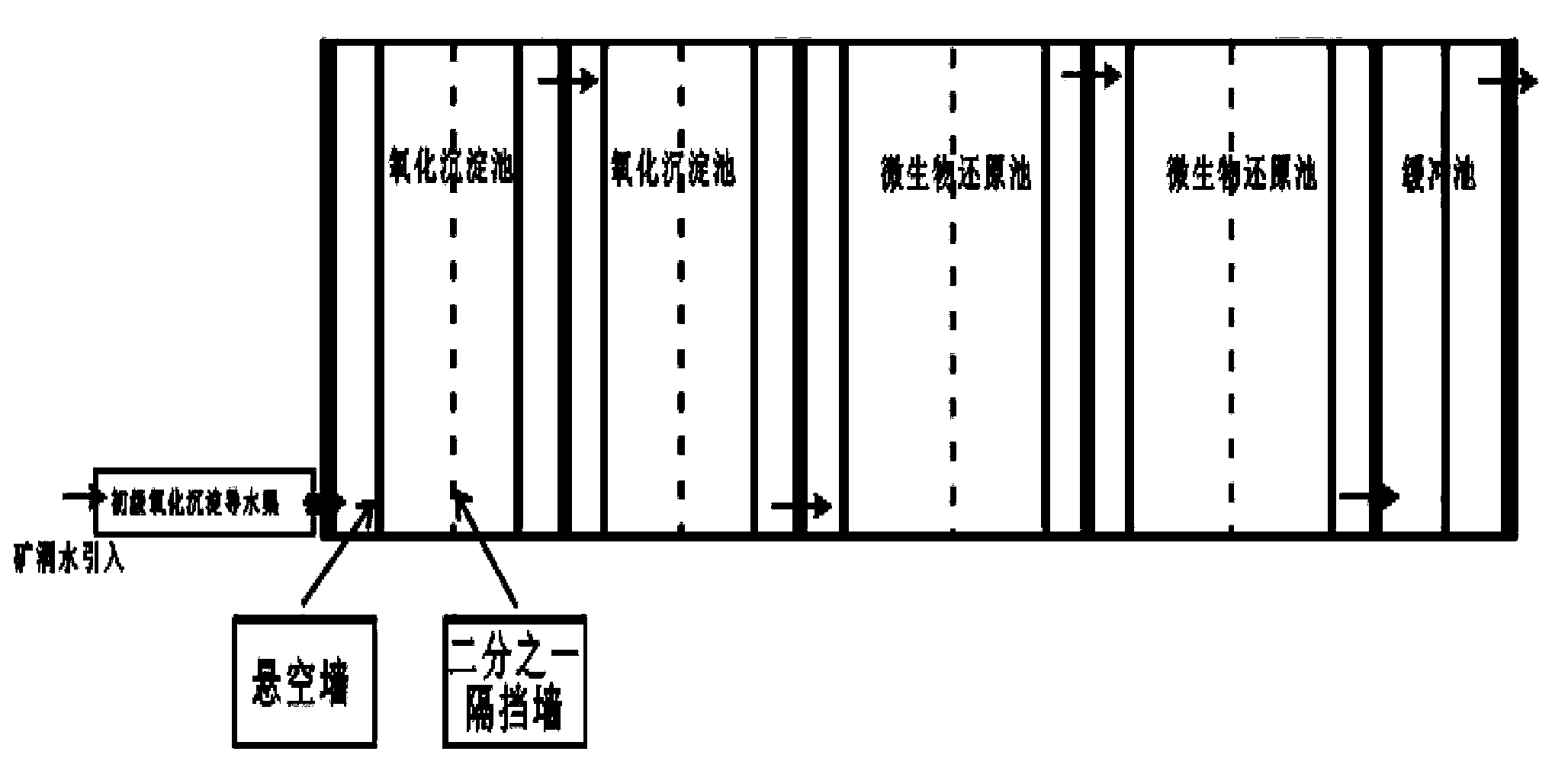

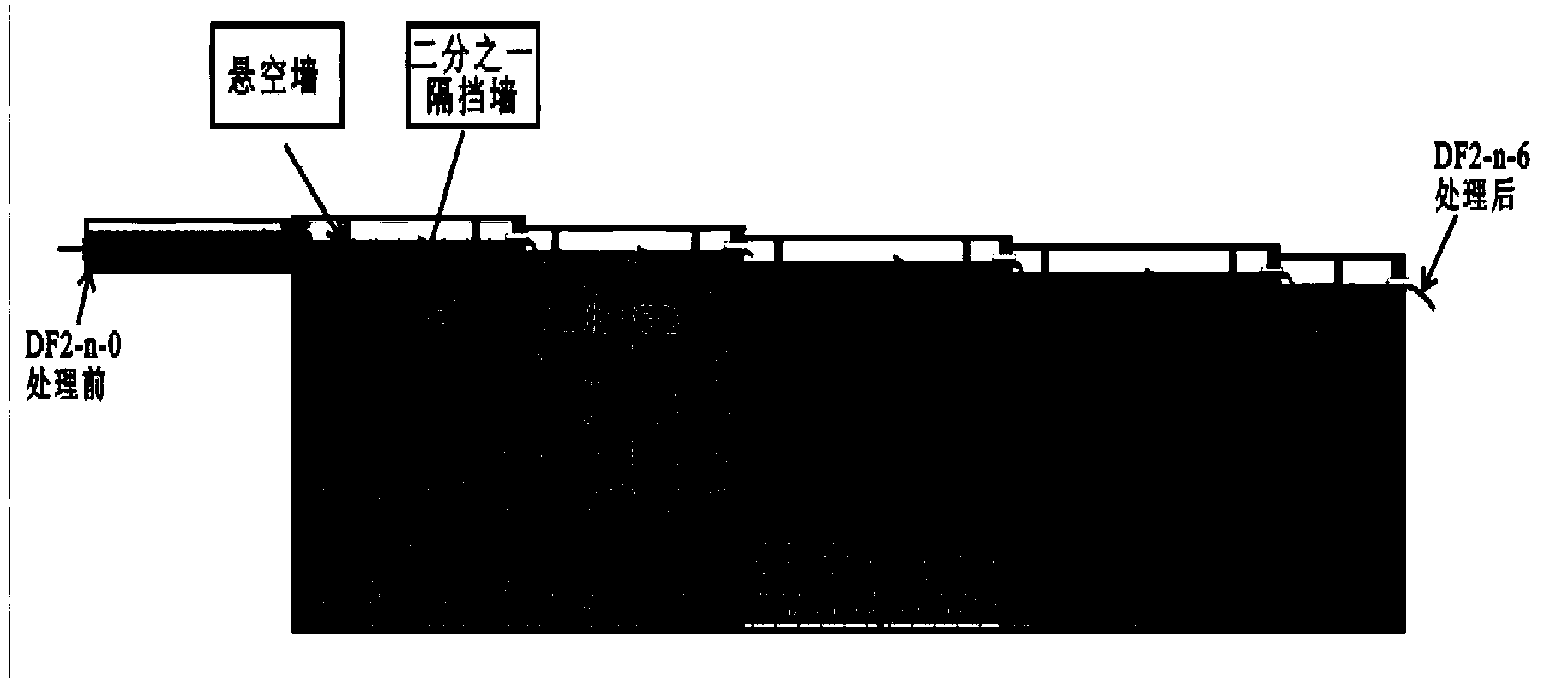

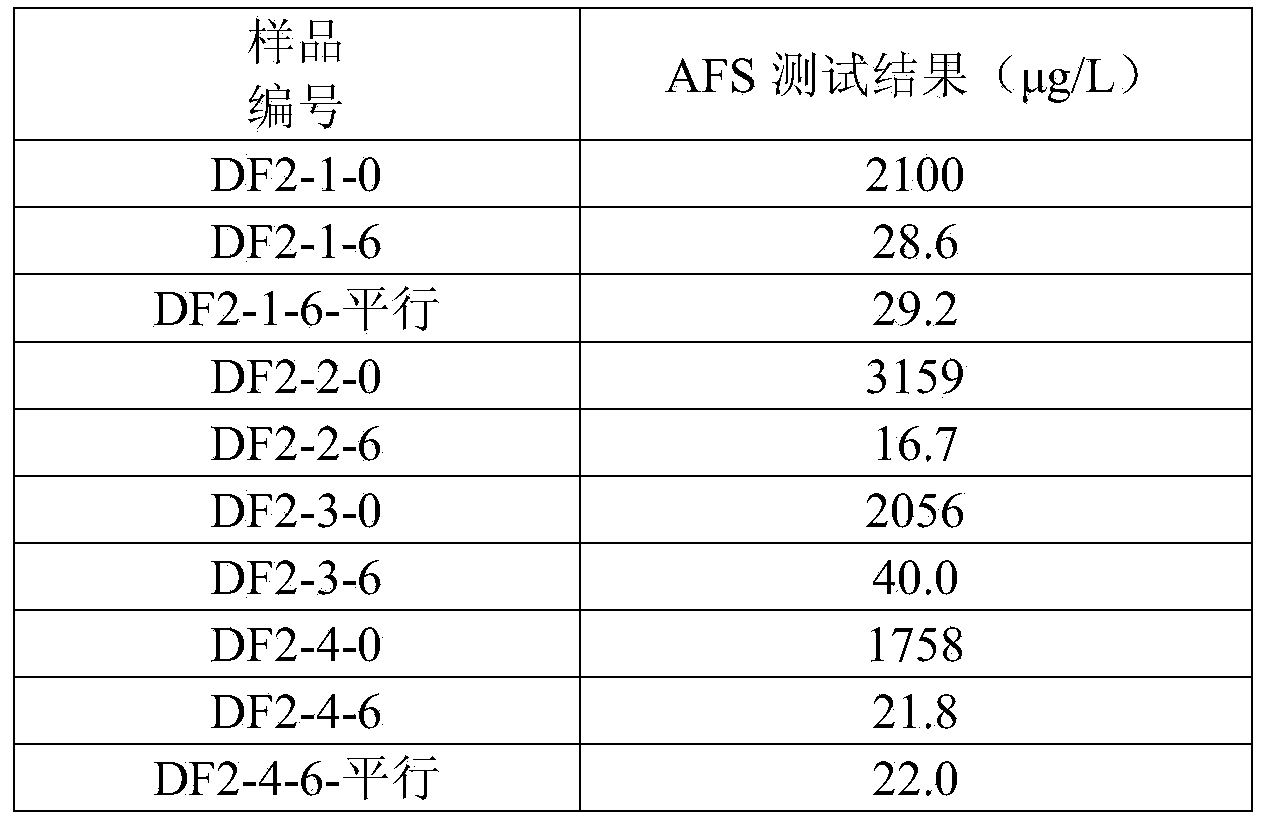

Apparatus and method for processing antimony ore acidic waste water

ActiveCN103819055AReduce SbRaise pHWaste water treatment from quariesMultistage water/sewage treatmentTO-18Wastewater

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

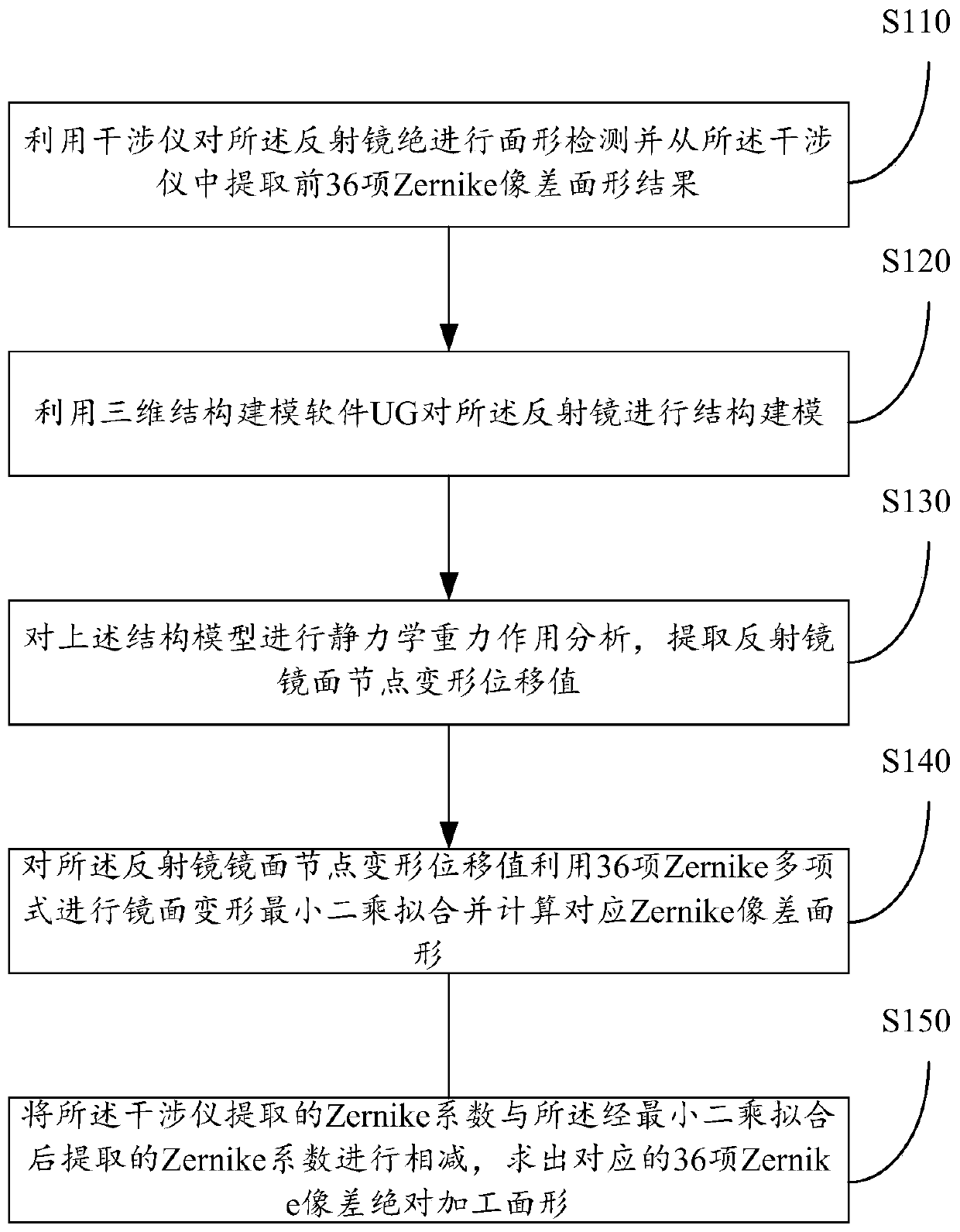

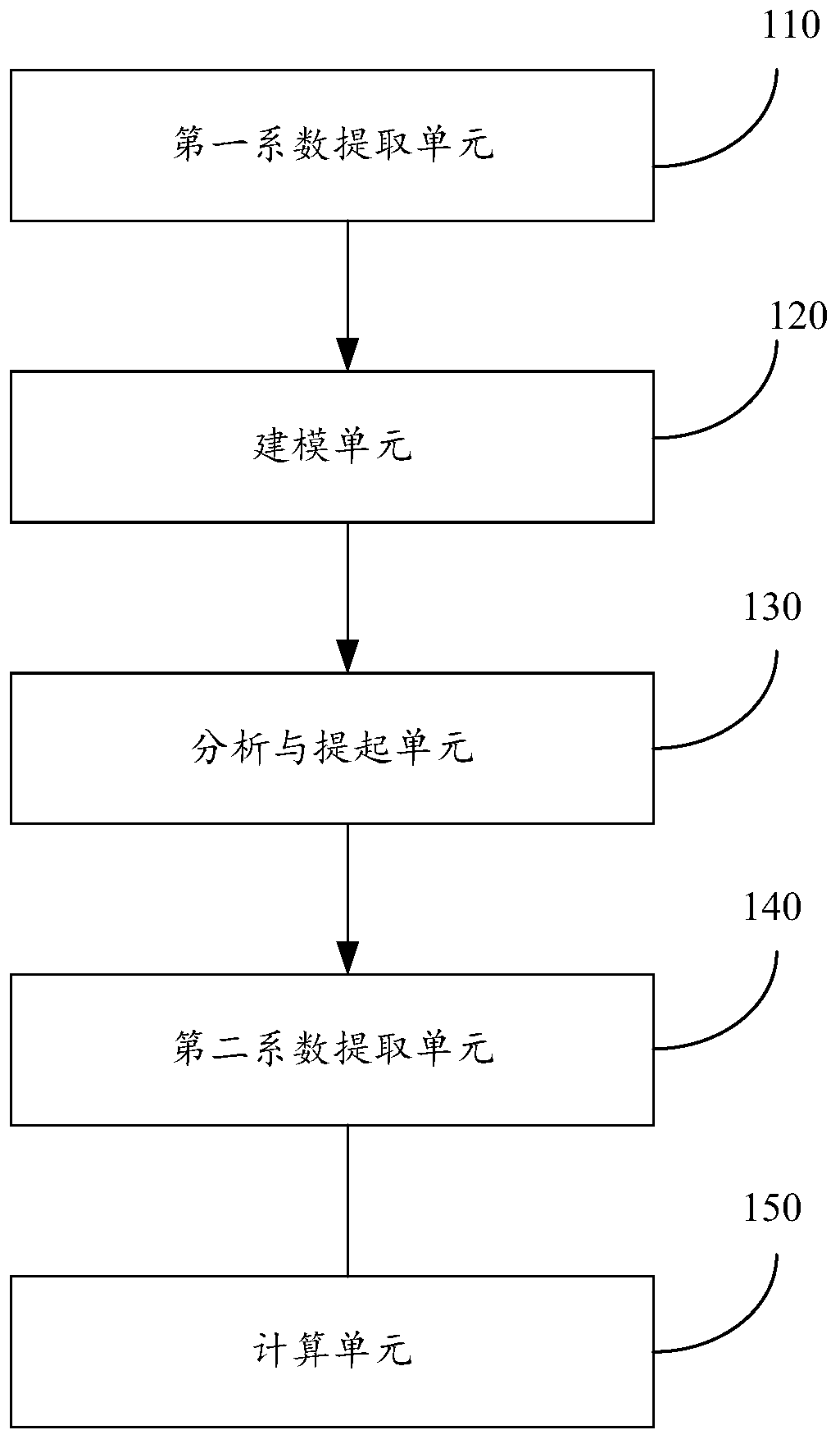

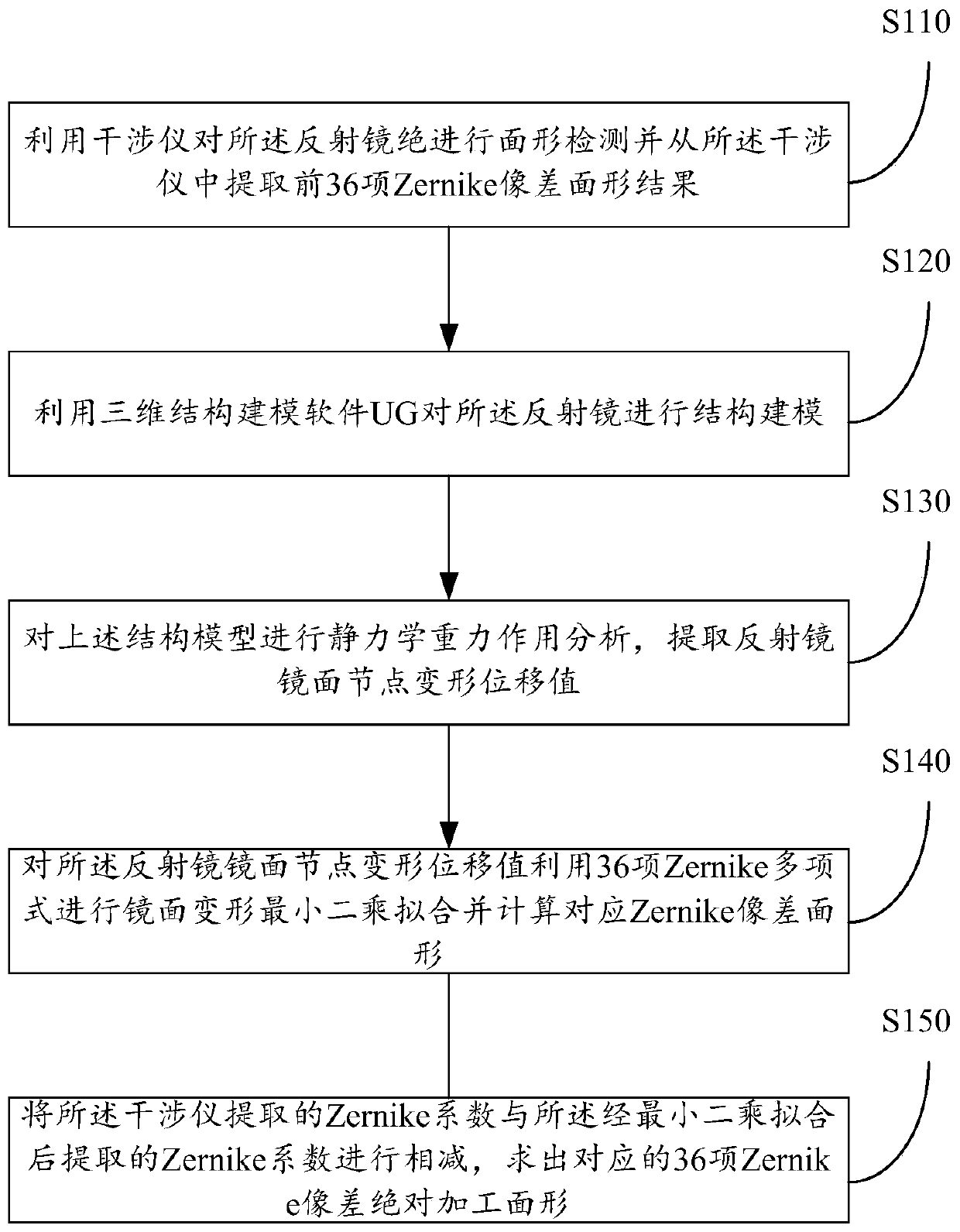

Method and system for calculating absolute machining surface shape of reflector

ActiveCN109708590AAccurate calculationEase of evaluationUsing optical meansFinite element methodEngineering

The invention provides a method and system for calculating an absolute machining surface shape of a reflector. Subduction can be performed on a Zernike aberration detection result of an interferometerduring detection and a result which is calculated by a finite element method and fitted with Zernike aberration under the state, so that a mirror absolute machining surface shape can be obtained. Through the provided with the method and system, the separation of surface shape error caused by the support in a mirror detection surface shape result can be realized, so that the mirror machining surface shape and mirror support surface shape can be better evaluated; and in addition, through the adoption of the provided method and system, accurate calculation on a reflector surface shape under complex working conditions can be conveniently achieved through the extracted mirror machining surface shape.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

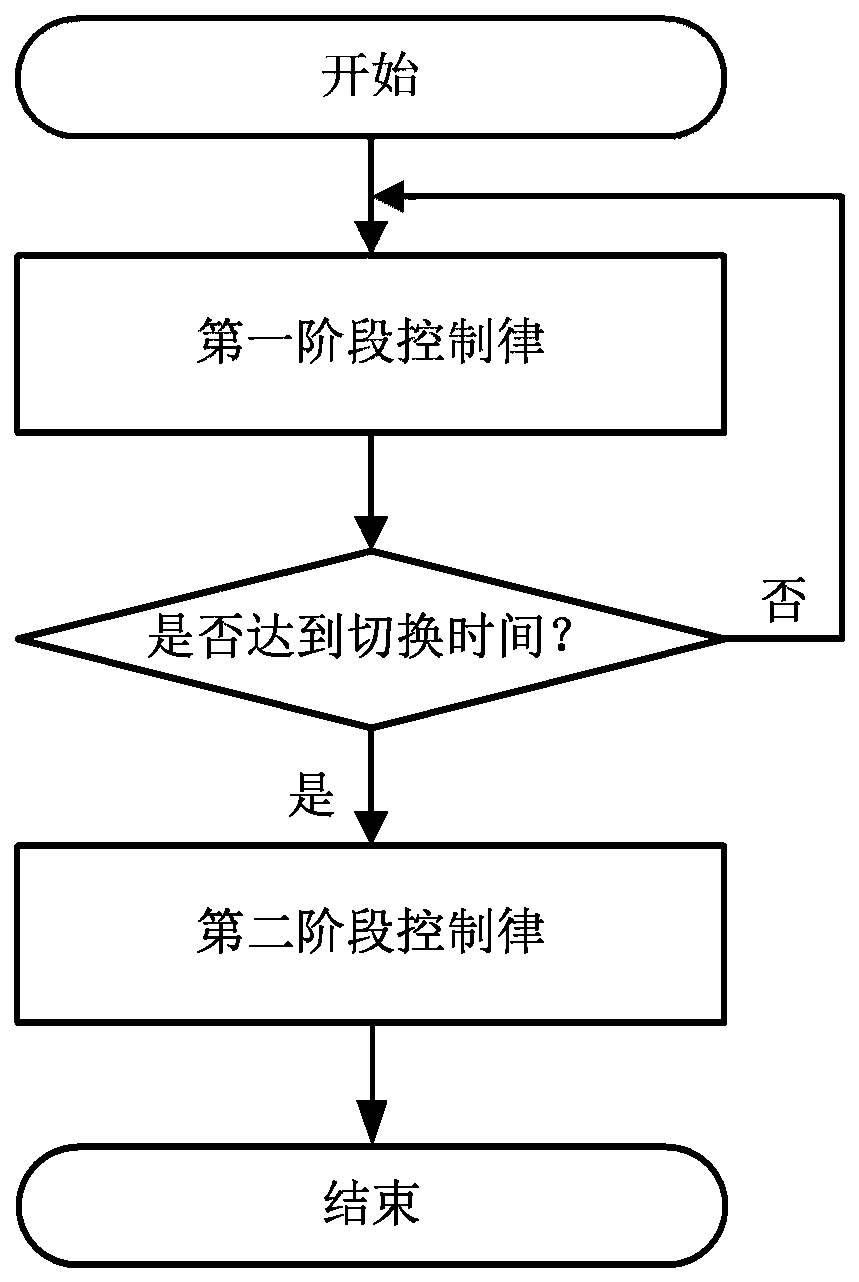

Unmanned aerial vehicle time-division control method

The invention provides an unmanned aerial vehicle time-division control method. The control method comprises the following steps: executing a first stage control law; judging whether reaches switchingtime, continuously executing the first stage control law if the switching time is not reached, and executing the second stage control law if reaching the switching time. For the dynamics and kinematics characteristics of the unmanned aerial vehicle by changing to a level flight stage from the subduction stage, the total design requirement of the unmanned aerial vehicle is combined, the maximum speed and the maximum overload value limit are considered, so that the speed and the overload of the unmanned aerial vehicle are changed in an allowable change by designing the switching time of the first stage control law and the second stage control law and the change rate of a posture instruction in the first stage control law, thereby guaranteeing the posture gentle transition and flight security of the unmanned aerial vehicle. The control method is simple in shape, low in computation complexity and convenient for engineering realization.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

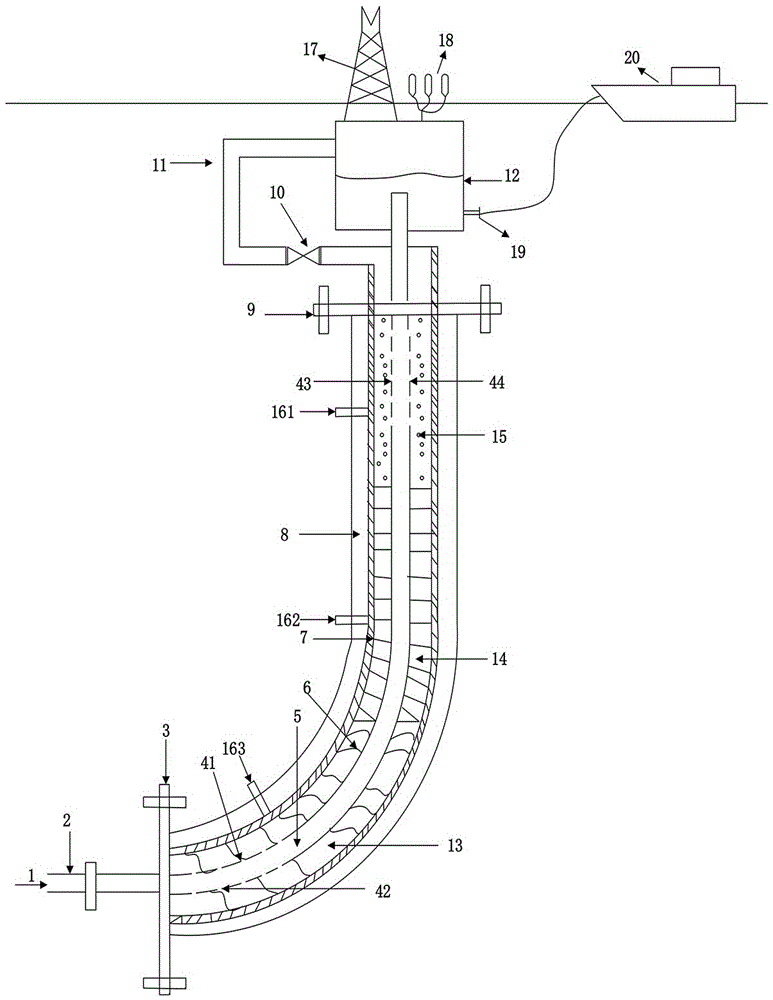

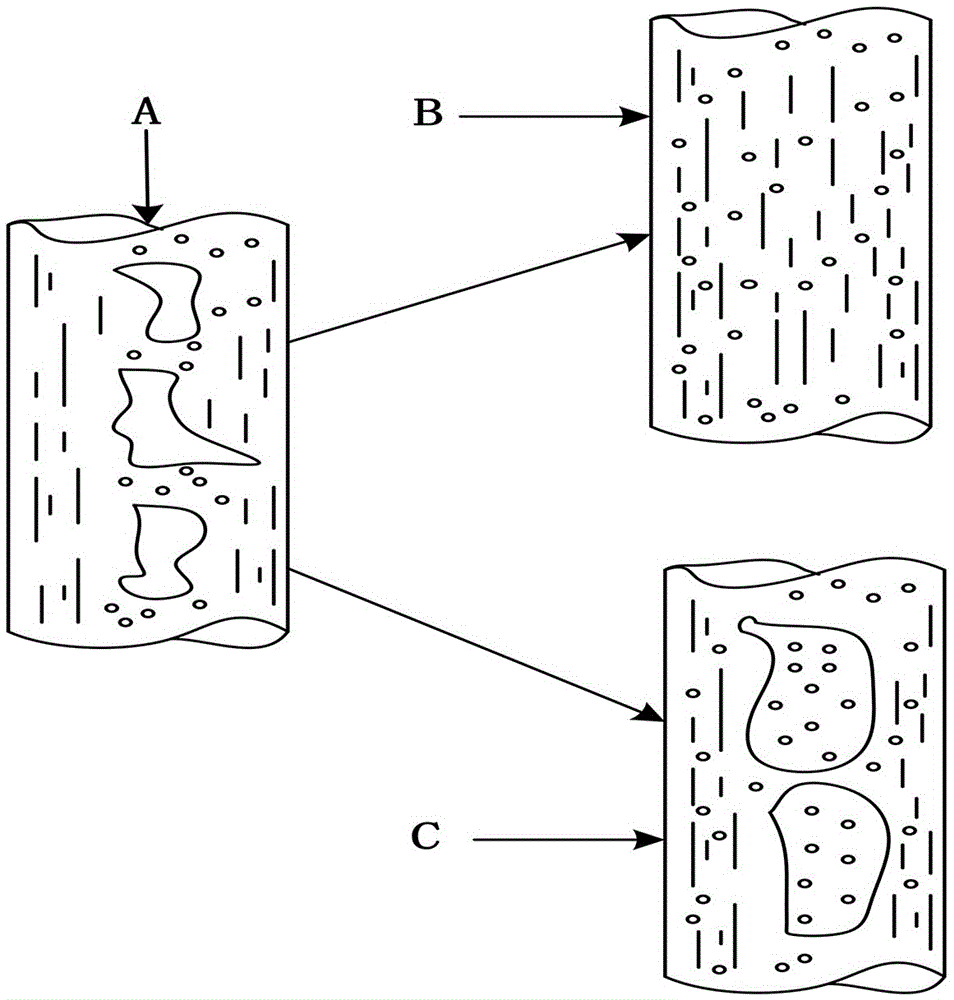

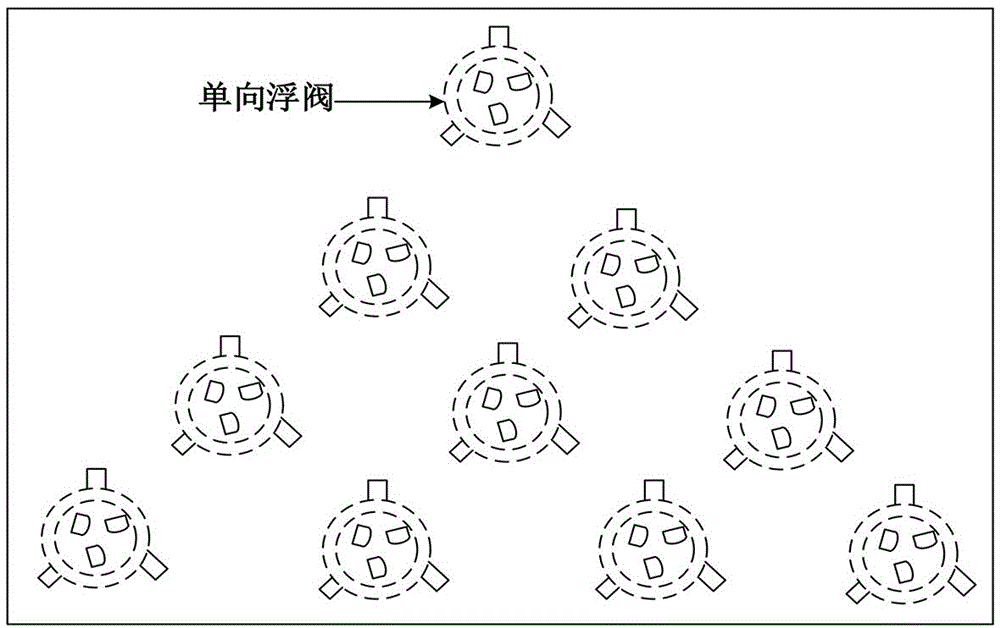

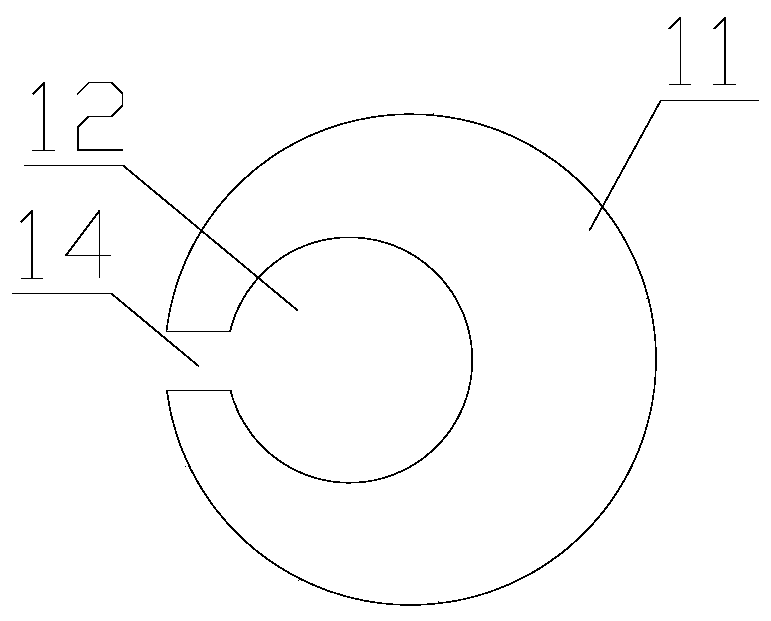

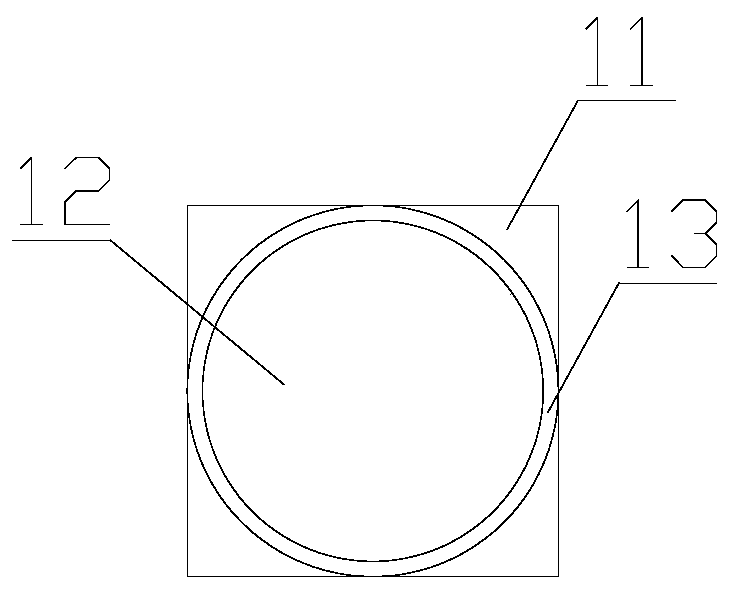

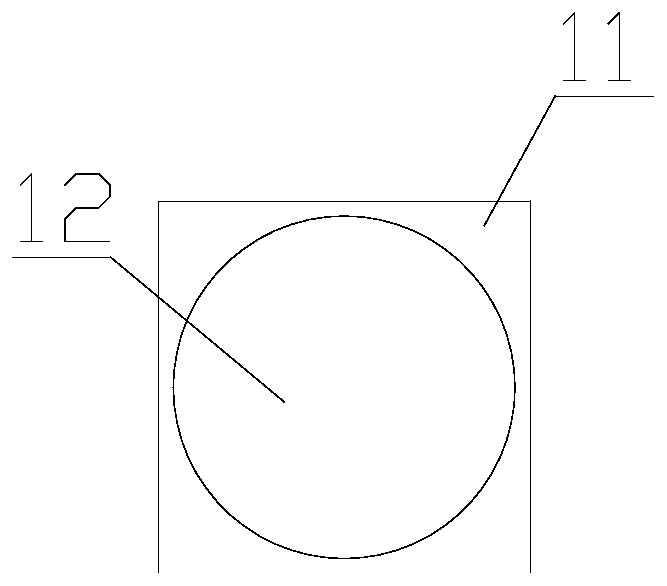

Novel vertical deep ocean pipe with slug flow subduction

The invention relates to a novel vertical deep ocean pipe with slug flow subduction. The novel vertical deep ocean pipe with slug flow subduction integrates multiple functions such as slug flow trapping, gas lifting of the bottom part of the vertical pipe, gas-liquid separating of the top part of the vertical pipe, and online monitoring of pressure in the vertical pipe into a whole; an inner pipe and an outer pipe of the vertical pipe are designed; a certain number of communicating holes with definite size are formed in the bottom part and the top part of an inner pipe wall, so that pressure balance of the inner pipe and the outer pipe is kept; one-way floating valves are designed on the communicating hole parts in the top part of the inner pipe wall, so that a fluid of the outer pipe one-way enters the inner pipe; a gas lifting system is designed, and gas enters the inner pipe through communicating holes on an outer pipe wall, so that the density, the speed and the length of a slug flow are changed, and the slug flow subduction under different working conditions is realized; a floating type separator on the top part of the vertical pipe is designed, so that an oil-gas separation effect is produced; and a pressure on-line monitoring system is designed, and pressure sensors are arranged on the bottom part, the middle part and the upper part of the vertical pipe, so that the pressure change in the vertical pipe is monitored in real time, and a basis is provided for gas lifting gas flow regulation.

Owner:SOUTHWEST PETROLEUM UNIV

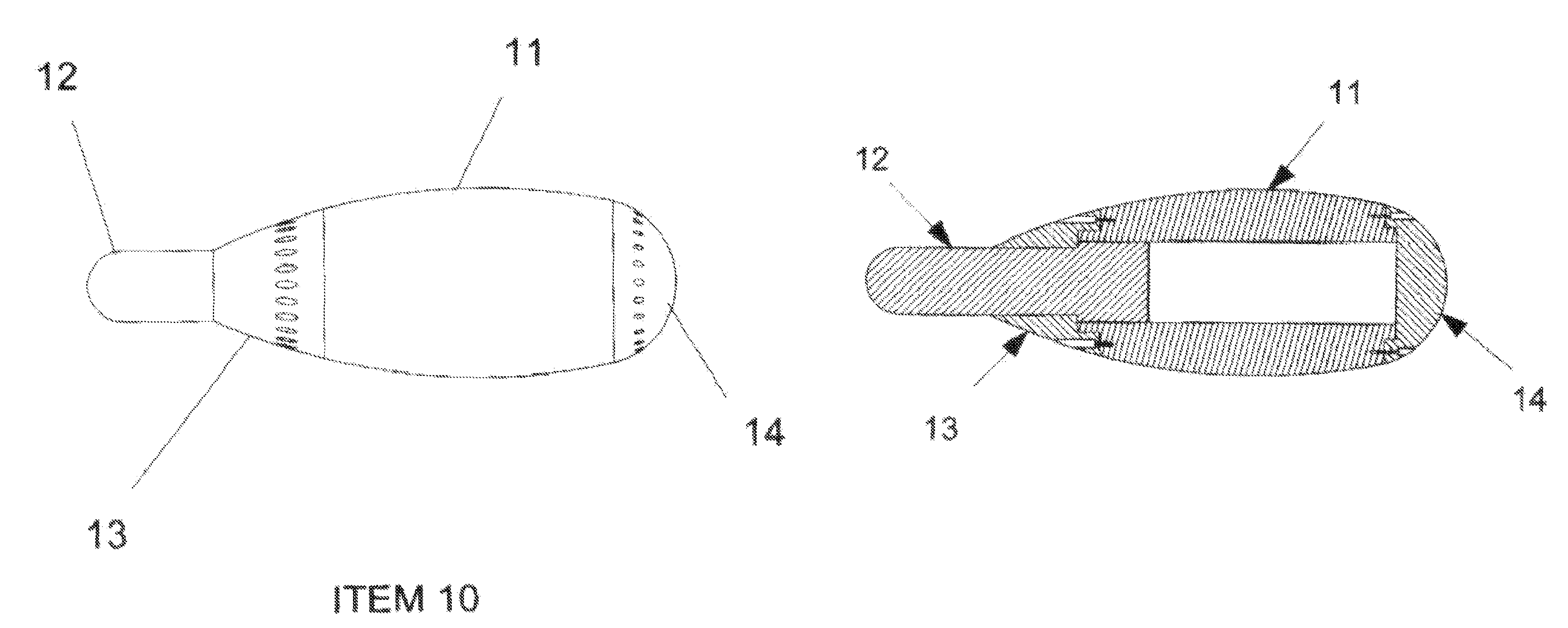

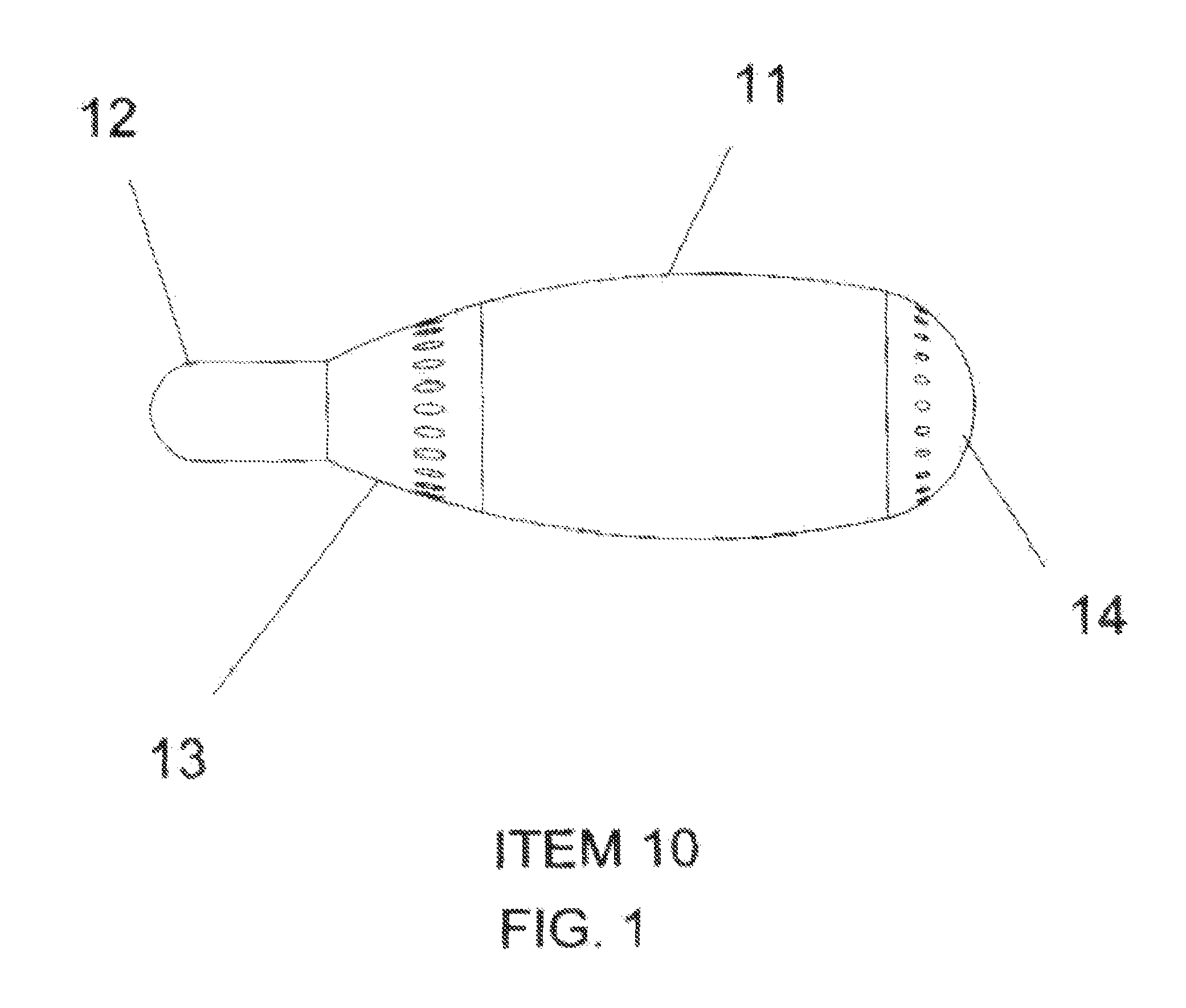

Method and apparatus for permanent and safe disposal of radioactive waste

InactiveUS7525112B2Rule out the possibilityNuclear engineering problemsNuclear engineering solutionsOcean bottomRemote control

A method of disposing of radioactive waste comprising the steps of: providing a pressure-equalizing container; filling the pressure-equalizing container with radioactive waste; and burying the waste filled container in a subduction fault region of the earth's crust. For a preferred embodiment of the process, the waste filled containers are buried in the mud on the ocean floor in a subduction fault region. Preferably, the containers are placed on the ocean side of the fault, rather than the continental shelf side. The pressure-equalizing container is preferably fabricated from stainless steel, with a lead seal, although containers fabricated from ceramic materials may also be used. The waste-filled containers are transported by ship to the area above a subduction fault, and an unpressurized, remote-controlled “submarine crawler” takes a number of containers to the ocean floor and buries them there, individually, in the mud or sediments.

Owner:GENERAL ELECTRIC CO

Screening method and application of aptamer for detecting acute promyelocyte leukemia

The invention provides an aptamer specifically combining acute promyelocyte leukemia HL-60 cells, and further provides a screening method and a clinical application of the aptamer. According to the screening method, six types of aptamers with different sequences are screened, and combining capacity among the aptamers and the acute promyelocyte leukemia HL-60 cells is different. The screening method includes the steps: synthesizing random single-strand DNA (deoxyribonucleic acid) libraries and primers; performing Cell-SELEX screening; performing library amplification; preparing a DNA single-strand library; repeating multiple screening and subduction screening; detecting stability after screening; detecting specificity of the aptamers.

Owner:BEIHUA UNIV

Rubber-particle sound insulation pad

A rubber particle soundproof pad is prepared by mixing the following raw materials in parts by weight: 50-150 parts of cement, 500-1000 parts of waste rubber powder, 20-50 parts of rubber powder, 1-5 parts of MC, and 1-5 parts of fiber. The invention has the following advantages: excellent sound insulation performance, convenient and quick construction, and effective mitigation of hollowing and cracking of floor cushions. Due to the good flexibility and elasticity of the waste rubber powder, it has an excellent reduction effect on the noise generated by the impact on the floor. The invention can be carried out on the construction site. After the mixed finished product is evenly mixed with water, the working surface can be pumped by mechanization, and the mechanical spray gun can be used to spray evenly on the floor of the building. The construction is convenient and fast, and the labor intensity is reduced. After the construction of the present invention is completed, when the composite light aggregate or foamed concrete is constructed on it, the bonding performance with the cushion material can be increased, thereby reducing or alleviating the hollowing and cracking of the cushion and the sound insulation layer.

Owner:张永利

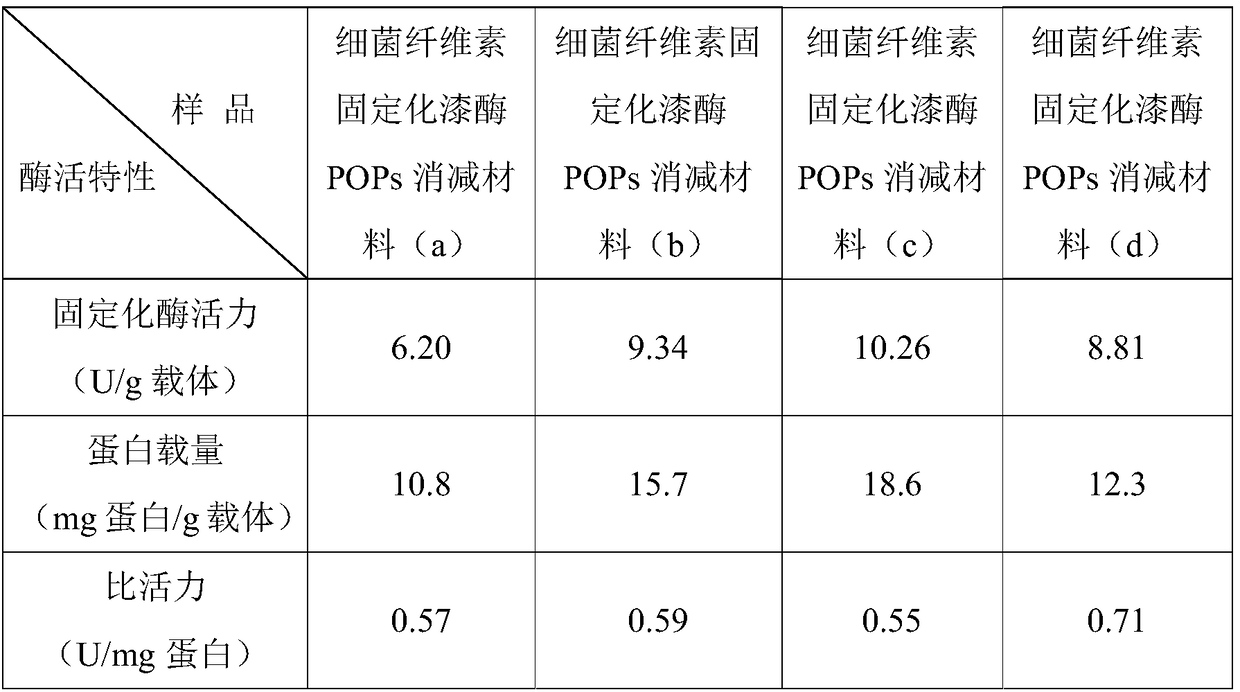

Preparation method of bacterial cellulose immobilized laccase POPs subduction material

InactiveCN108866034AEasy to degradeHigh purityOxidoreductasesOn/in organic carrierWater bathsFreeze-drying

The invention discloses a preparation method of a bacterial cellulose immobilized laccase POPs subduction material. The preparation method is characterized by comprising the following steps: transferring an inclining bacterial strain into a seed culture medium, performing the dynamic culture, then performing the transferring static culture, and obtaining a bacterial cellulose membrane film; processing 0.1 percent NaOH in a water bath, flushing by using deionized water until the neutrality, freeze drying, and obtaining a cellulose dry membrane; and finally preparing the immobilized laccase material by adopting an adsorption-cross linking method, wherein the immobilized laccase material can be used for processing a durability organic pollutant in natural water. The method is simple in operation, safe, environment-friendly and high in controllability. By adopting the bacterial cellulose film prepared in the invention, the laccase can be safely and efficiently immobilized, the enzyme activity can be maximally kept, the problems of the traditional free laccase for degrading the POPs pollutants in the water such as severe loss, difficulty in reusability and the like can be avoided, and the POPs in the natural water can be efficiently and safely degraded and eliminated.

Owner:ZHEJIANG SCI-TECH UNIV

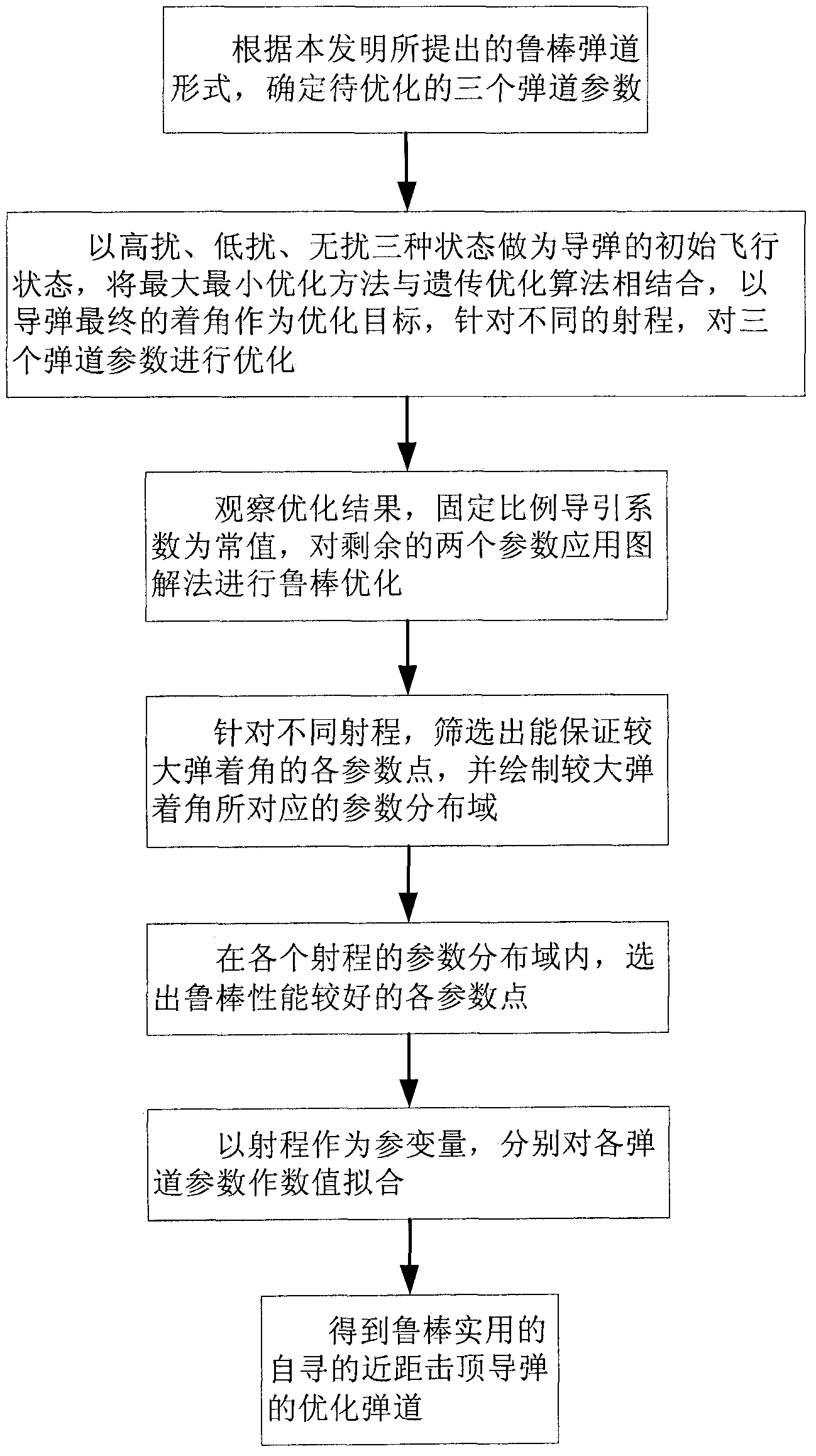

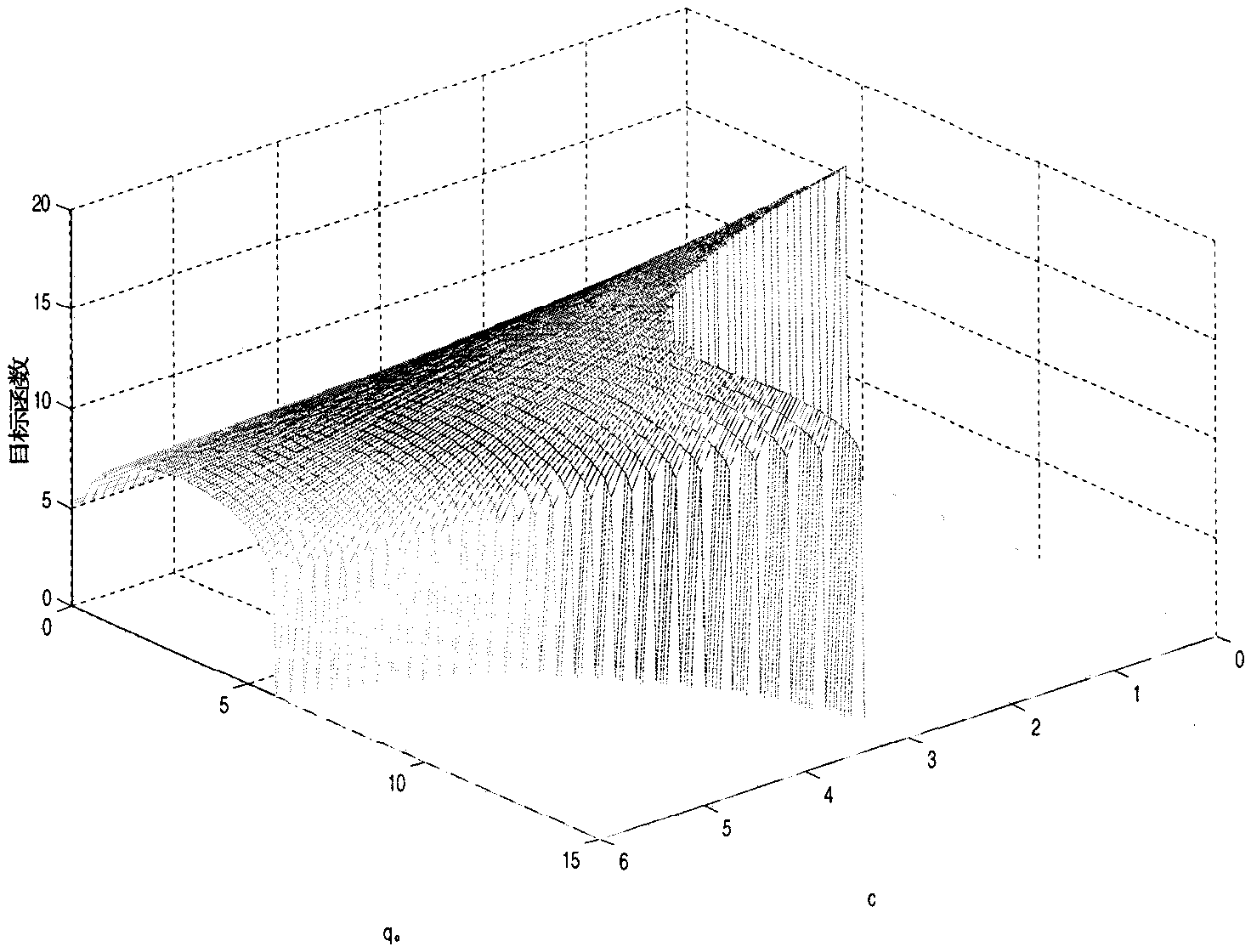

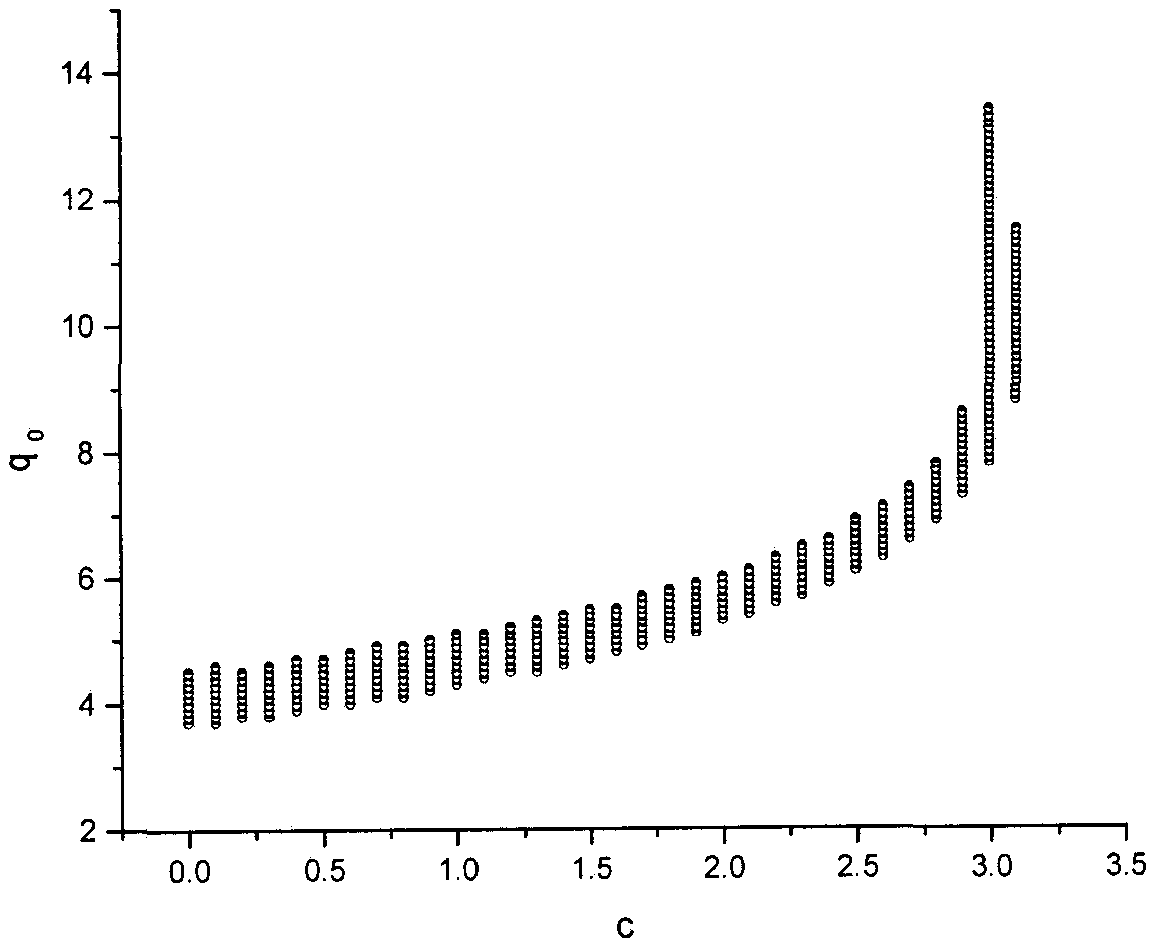

A Robust Trajectory Design and Optimization Method for Self-seeking Short-Range Topping Anti-Tank Missile

InactiveCN105659894BImprove robustnessBig angleSelf-propelled projectilesComplex mathematical operationsTechnology in Star TrekProjectile

The invention relates to a trajectory design and optimization method, in particular to a method for robust trajectory design and parameter optimization of short-distance topping anti-tank missiles, and belongs to the technical field of missile trajectory design. A self-seeking short-distance topping anti-tank missile robust ballistic design and optimization method of the present invention solves the optimal problem of the short-distance topping performance of the image self-seeking anti-tank missile, and then the present invention can be used under constraint conditions And from the initial disturbance situation, a robust ballistic form of image self-seeking short-distance topping anti-tank missile is determined, and the program control section adopts the attitude command form θ c = θ 0 -cq; at line of sight angle q 0 As the starting control condition of the final proportional guidance; the coefficient of the final proportional guidance is N. The ballistic designed by this method is not only robust and practical, but also has near-optimal performance, and can realize dive attack and precise strike at a relatively short target distance. The present invention can be widely used in the ballistic design of self-seeking anti-tank missiles Among them, it has important military application prospects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Vibration isolation piles and vibration isolation row of piles adopting vibration isolation piles

PendingCN109972669AImprove the vibration isolation effectImprove subtractive effectRailway tracksProtective foundationEngineeringNoise reduction

The invention belongs to the technical field of sound insulation and noise reduction equipment, and particularly relates to vibration isolation piles and a vibration isolation row of piles adopting the vibration isolation piles. Each vibration isolation pile includes a pile body, a cavity structure is arranged in each pile body, and a cavity in each pile body forms a vibration isolation cavity ofthe corresponding vibration isolation pile. The vibration isolation piles are arranged around a vibration source during use, when vibration waves pass through the vibration isolation piles, vibrationcan be subtracted in the vibration isolation cavities, and according to different types of the vibration waves, the positions and numbers of the vibration isolation cavities can be adjusted accordingly; and thus, the subduction effect of the vibration waves can further be improved, and the vibration isolation effect of the vibration isolation pipes is improved.

Owner:广州市泰宇科技发展有限公司

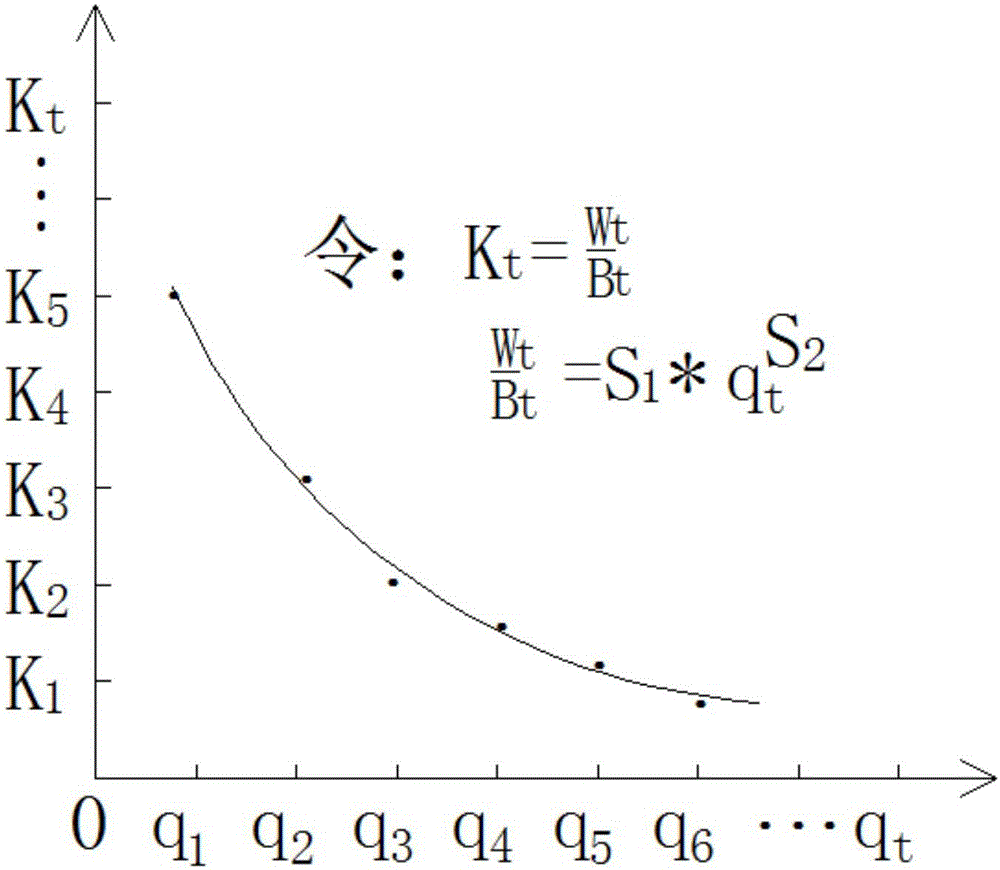

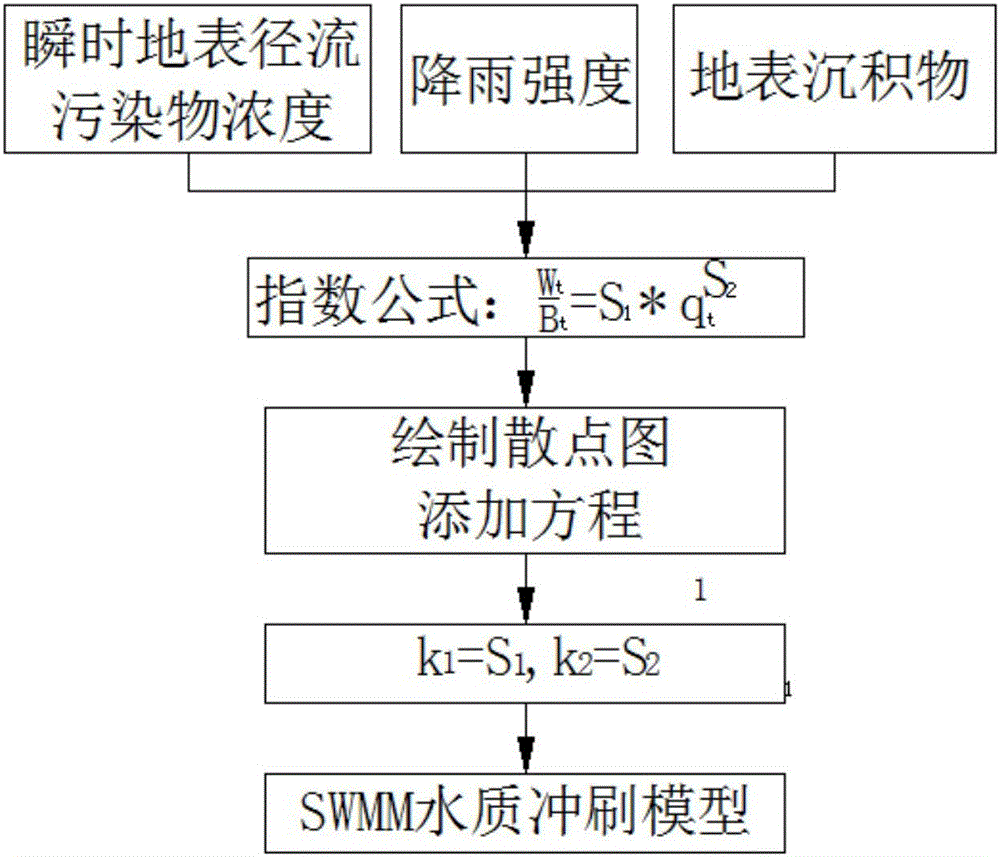

Method for determining SWMM water quality scouring model parameter

ActiveCN106682271AAvoid accidental errorsSolve certain problemsGeneral water supply conservationDesign optimisation/simulationWater qualitySurface runoff

The invention relates to a method for determining an SWMM water quality scouring model parameter and belongs to the crossing fields of municipal engineering and environmental engineering crossing and the like. First surface runoff water samples are obtained through a surface runoff sampling device, surface runoff water samples at different moments are obtained at the same interval time, pollutant concentration Wt is detected, and the rainfall intensity value qt at the moment t is recorded; a pollutant deposition load value is obtained by combination with detection of earth surface deposition collected in dry days, a unit area pollutant deposition amount initial value undergoes scouring subduction at the moment t to obtain a remaining pollutant cumulant Bt, and Bt, Wt and qt values at different moments in a rain are substituted into an index scouring function formula; each scattered point is drawn through the excel, a tendency chart and a tendency function are added, and values of S1 and S2 are obtained from the tendency function formula. By comparison of engineering practice monitoring results and model simulation results, water quality parameter obtaining correctness is found, and it is indicated that the method has scientificity and practical values.

Owner:BEIJING UNIV OF TECH

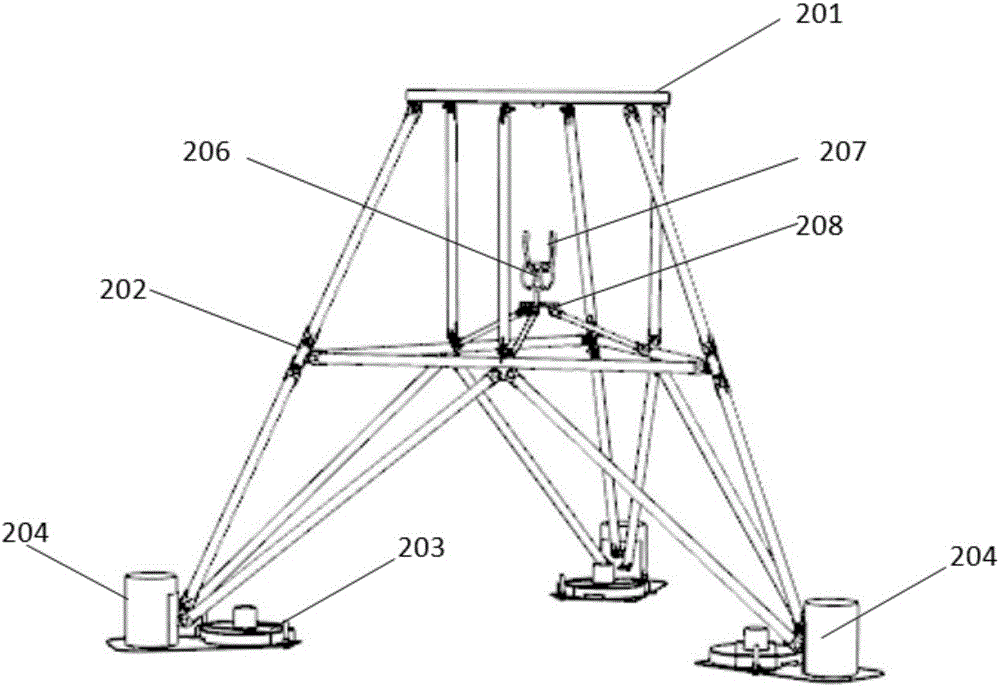

Seabed relative geodesic method

ActiveCN105911591ARealize relative geodesic functionGain speedSeismology for water-covered areasOcean bottomRelative motion

The invention discloses a seabed relative geodesic method, comprising steps of putting a plurality of subbottom observation platforms to seabed preset positions to constitute an observation net, realizing a relative geodesic function of each base station through performing continuous observation and self-contained storage on a relative distance between the base stations and varying data so as to obtain change of relative motion speed, displacement and vertical displacement of the base stations, calculating coupling coefficients of various segments of a subduction zone by combining with land GPS data, analyzing stress accumulation statuses of various segments of the subduction zone and estimating earthquake occurrence possibility and earthquake magnitude. The seabed relative geodesic method can perform long term accurate observation and recording on seabed horizontal and vertical deformation and provides the basis to the possibility of the earthquake occurrence in the subduction zone.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

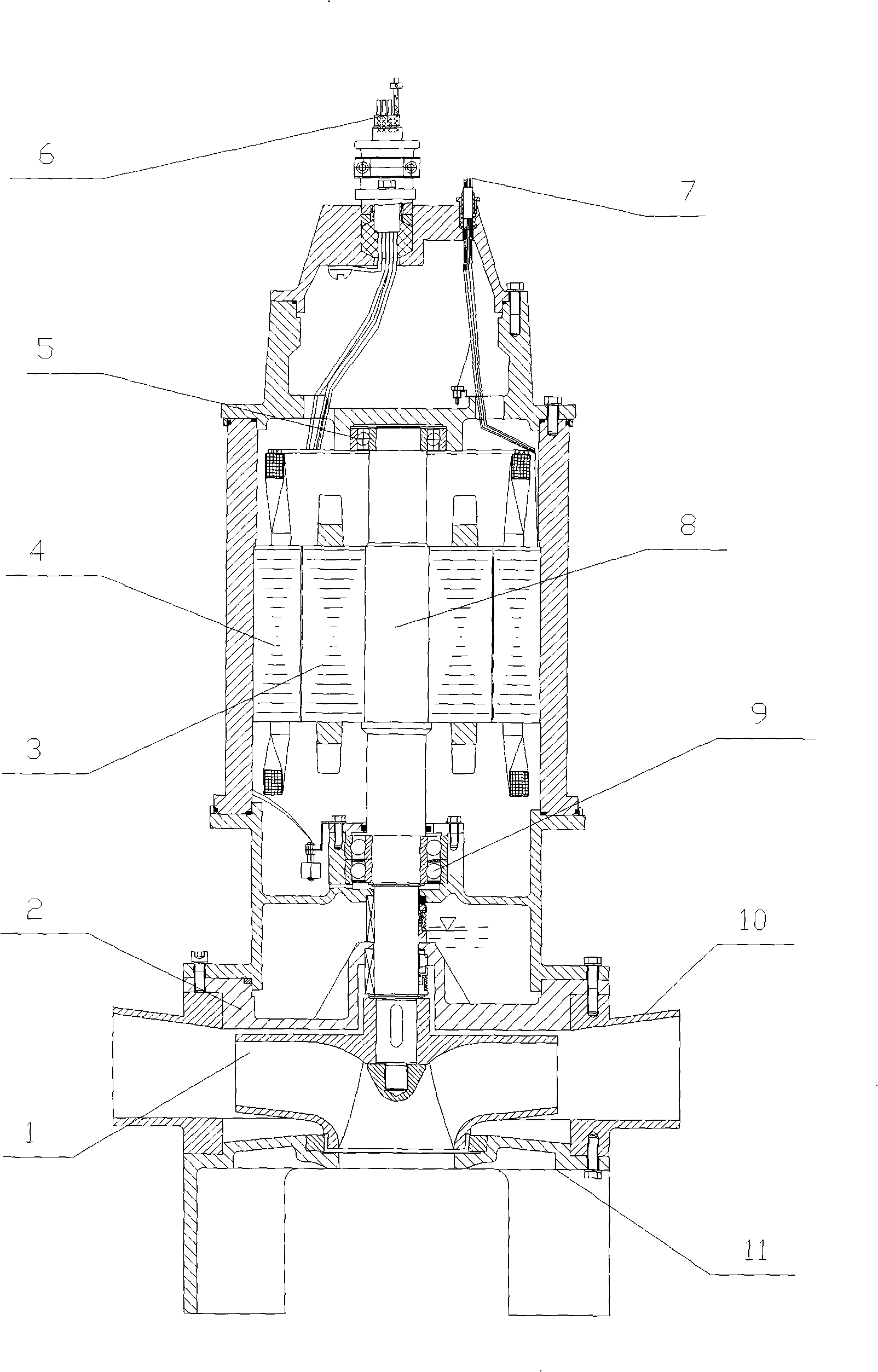

Submergence pump with multiple outlets

InactiveCN101408200AImprove efficiencyReduce the overall heightPump componentsPump installationsEngineeringMechanical engineering

The invention relates to a multi-outlet subduction-typed pump. The outlet of the pump is designed into a multi-outlet form, thereby playing the role of replacing an exit guide vane and improving the efficiency of the pump; moreover, the height of the pump is slightly lower than the height of the same pump with the guide vane.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com