Method and system for calculating absolute machining surface shape of reflector

A calculation method and technology of a calculation system, applied in the field of optical detection, can solve problems such as no calculation method, only qualitative evaluation, and inability to build a detection optical path, so as to achieve the effect of convenient and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

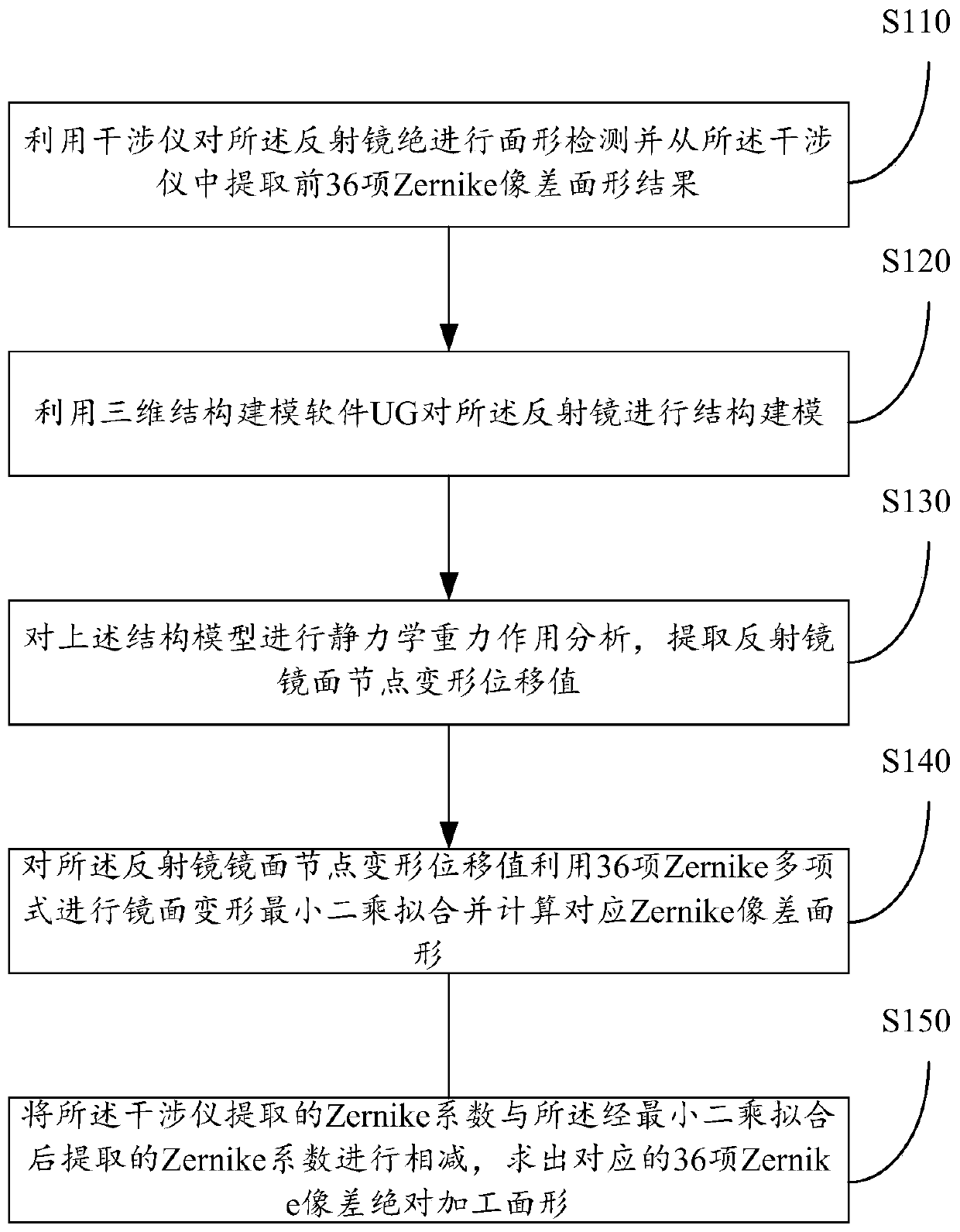

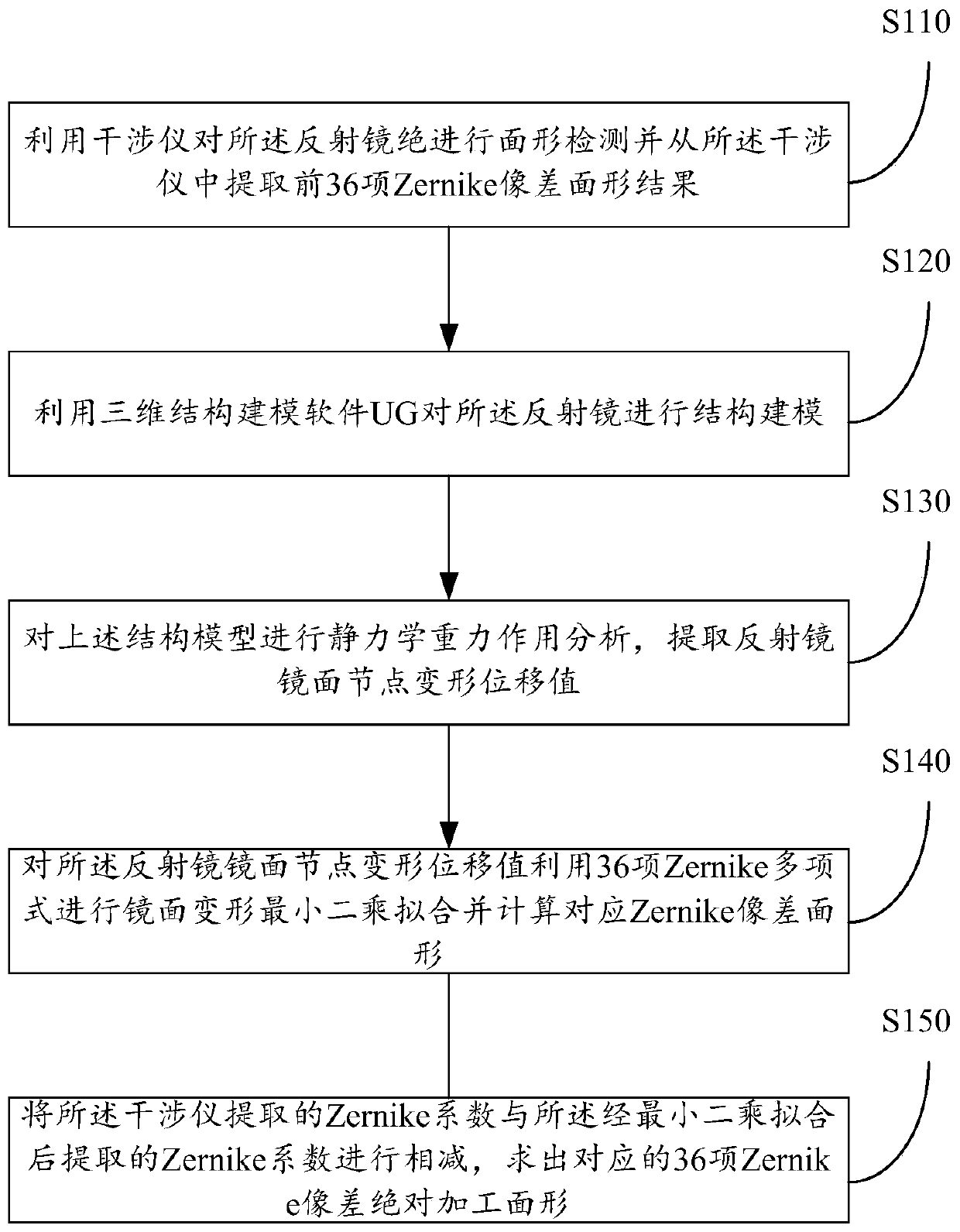

[0032] see figure 1 , the present invention provides a flow chart of the calculation method for the absolute processing surface shape of the mirror, including the following steps:

[0033] Step S110: Use the interferometer to detect the surface shape of the mirror and extract the first 36 Zernike aberration surface shape results from the interferometer, and record it as W opt=a 1 ·Z 1 +a 2 ·Z 2 +a 3 ·Z 3 +…+a 36 ·Z 36 , where W opt is the surface shape detected by the interferometer, Z i is the i-th Zernike polynomial, a i Zernike coefficients extracted for the interferometer.

[0034] It can be understood that the surface shape of the mirror can be expressed by using Zernike aberration. By placing the mirror to be inspected on the inspection tool, an optical inspection optical path is built, and the interferometer is used for surface inspection and the first 36 Zernike items are extracted from the interferometer. Aberration Surface Results.

[0035] In some prefe...

Embodiment 2

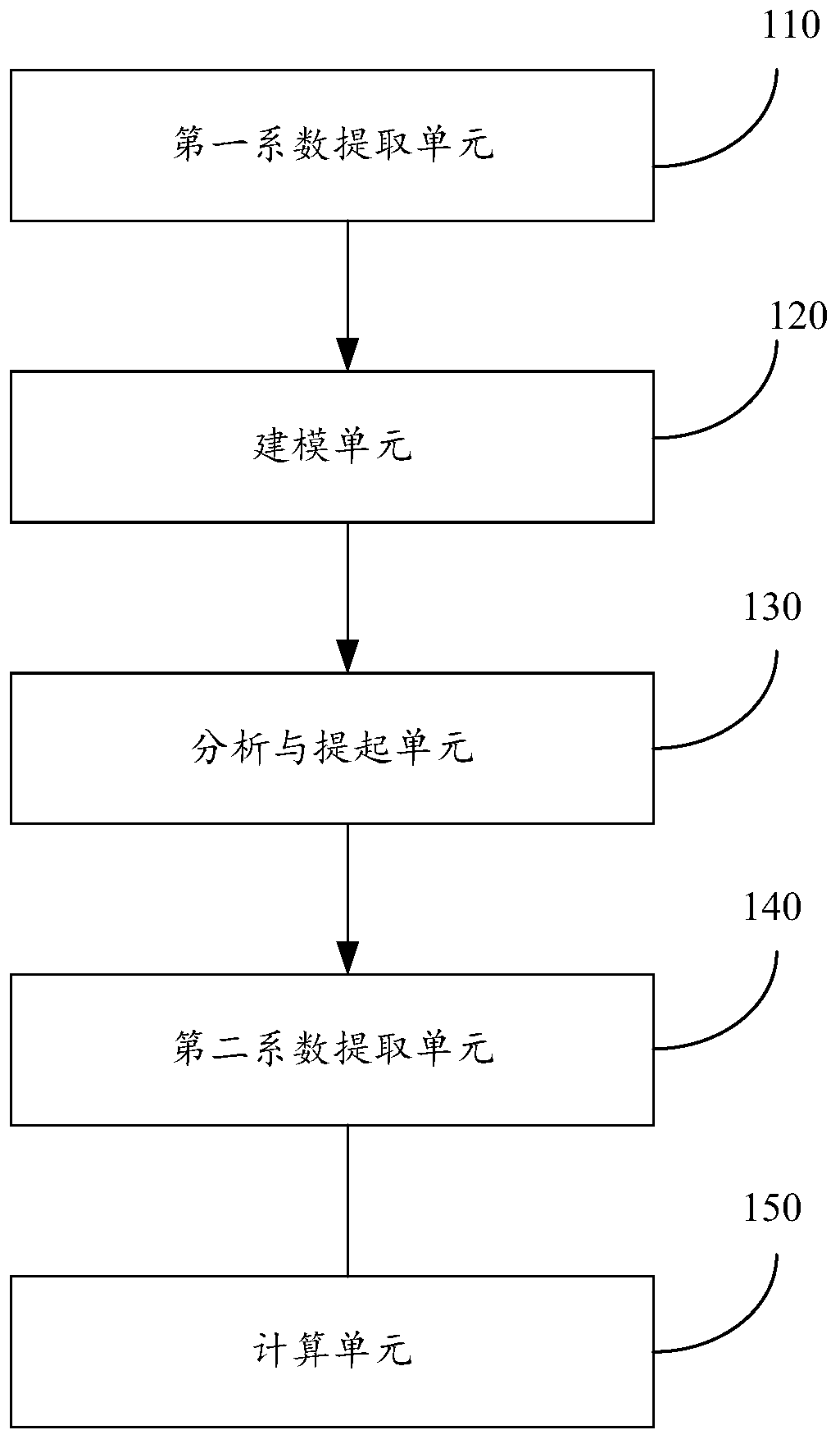

[0045] see figure 2 , the present invention provides a structural schematic diagram of a computing system for the absolute processing surface shape of a mirror, including:

[0046] The first coefficient extraction unit 110: use the interferometer to detect the surface shape of the mirror and extract the first 36 Zernike aberration surface shape results from the interferometer, and denote it as W opt =a 1 ·Z 1 +a 2 ·Z 2 +a 3 ·Z 3 +…+a 36 ·Z 36 , where W opt is the surface shape detected by the interferometer, Z i is the i-th Zernike polynomial, a i Zernike coefficients extracted for the interferometer.

[0047] It can be understood that the surface shape of the mirror can be expressed by using Zernike aberration. By placing the mirror to be inspected on the inspection tool, an optical inspection optical path is built, and the interferometer is used for surface inspection and the first 36 Zernike items are extracted from the interferometer. Aberration Surface Result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com