Preparation method of bacterial cellulose immobilized laccase POPs subduction material

A technology of bacterial cellulose and immobilized laccase, applied to biochemical equipment and methods, chemical instruments and methods, fixed on/in organic carriers, etc., can solve the problems of not seeing POPs reduction materials, etc., and achieve The structure is controllable, the application is promoted, and the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

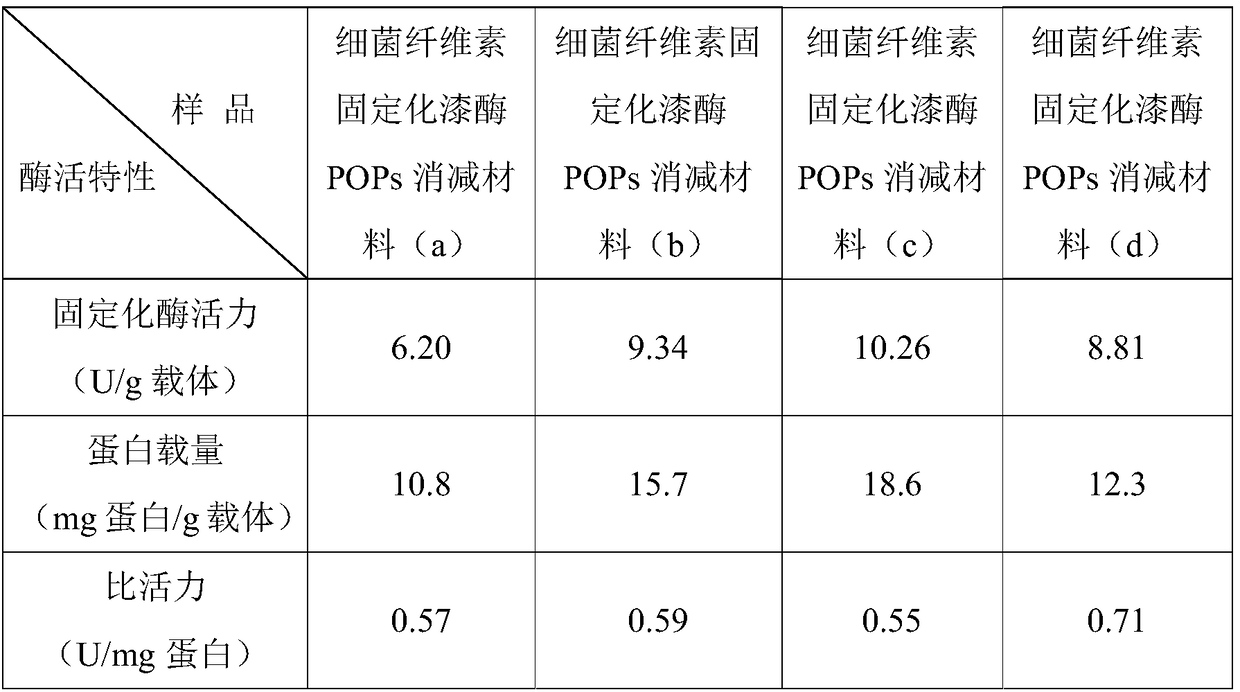

Embodiment 1

[0021] 1) Achromobacter was inoculated into the seed medium of pH 4.8 (by weight percentage, including: 30g / L glucose, 6g / L yeast extract, 10g / L peptone, 1g / L trisodium citrate, 2g / L magnesium sulfate ), under 26 ℃, 140r / min condition, carry out dynamic culture 36h days and make seed liquid, with the fermented medium of pH6.8 with the 15% inoculum of volume percentage, seed liquid is transferred to (by weight percentage, comprising: 30g / L glucose, 12g / L yeast extract, 12g / L tryptone, 2g / L sodium citrate, 2g / L magnesium sulfate, 2.7g / L Na 2 HPO 4 , 2g / L KH 2 PO 4 ), each 250mL Erlenmeyer flask contained 50mL of fermentation broth, cultured statically at 26°C for 8 days, and obtained a bacterial cellulose film on the upper layer of the culture broth;

[0022] 2) Take out the bacterial cellulose film obtained in step 1), rinse slowly with deionized water several times, remove the bacterial cells and residual culture medium on the surface of the film, and use a mass fraction o...

Embodiment 2

[0025]1) Inoculate Alcaligenes into the seed culture medium of pH 6.8 (by weight percentage, including: 30g / L glucose, 6g / L yeast extract, 10g / L peptone, 1g / L trisodium citrate, 2g / L magnesium sulfate ), under the conditions of 30°C and 160r / min, carry out dynamic culture for 30h to obtain the seed liquid, and transfer the seed liquid to the fermentation medium of pH 6 with the volume percentage 8% inoculum (in weight percentage, comprising: 30g / L Glucose, 12g / L yeast extract, 12g / L tryptone, 2g / L sodium citrate, 2g / L magnesium sulfate, 2.7g / L Na 2 HPO 4 , 2g / L KH 2 PO 4 ), each 250mL Erlenmeyer flask contained 70mL of fermentation broth, cultured statically at 30°C for 7 days, and obtained a bacterial cellulose film on the upper layer of the culture broth;

[0026] 2) Take out the bacterial cellulose film obtained in step 1), rinse slowly with deionized water several times, remove the bacterial cells and residual culture medium on the surface of the film, and use a mass fr...

Embodiment 3

[0029] 1) Inoculate the non-rhizobia into the seed culture medium of pH 5 (by weight percentage, comprising: 30g / L glucose, 6g / L yeast extract, 10g / L peptone, 1g / L trisodium citrate, 2g / L magnesium sulfate ), under 28 ℃, 200r / min condition, carry out dynamic culture 20h day and make seed liquid, with the fermented medium of pH 4.8 (in weight percentage, comprise: 30g / L Glucose, 12g / L yeast extract, 12g / L tryptone, 2g / L sodium citrate, 2g / L magnesium sulfate, 2.7g / L Na 2 HPO 4 , 2g / L KH 2 PO 4 ), each 250mL Erlenmeyer flask contained 60mL of fermentation broth, cultured statically at 27°C for 6 days, and obtained a bacterial cellulose film on the upper layer of the culture broth;

[0030] 2) Take out the bacterial cellulose film obtained in step 1), rinse slowly with deionized water several times, remove the bacterial cells and residual culture medium on the surface of the film, and use a mass fraction of 0.1mol / L NaOH solution in a water bath at 85°C Treat for 90 minutes u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com