Plating solution for electroplating Ni/graphene compound heat conduction film on surface of substrate

A graphene composite, thermally conductive film technology, applied in electrolytic coatings, coatings, etc., can solve the problems of shortened instrument life, slow heat dissipation, easy peeling, etc., and achieve the effect of improving thermal conductivity, improving wettability and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

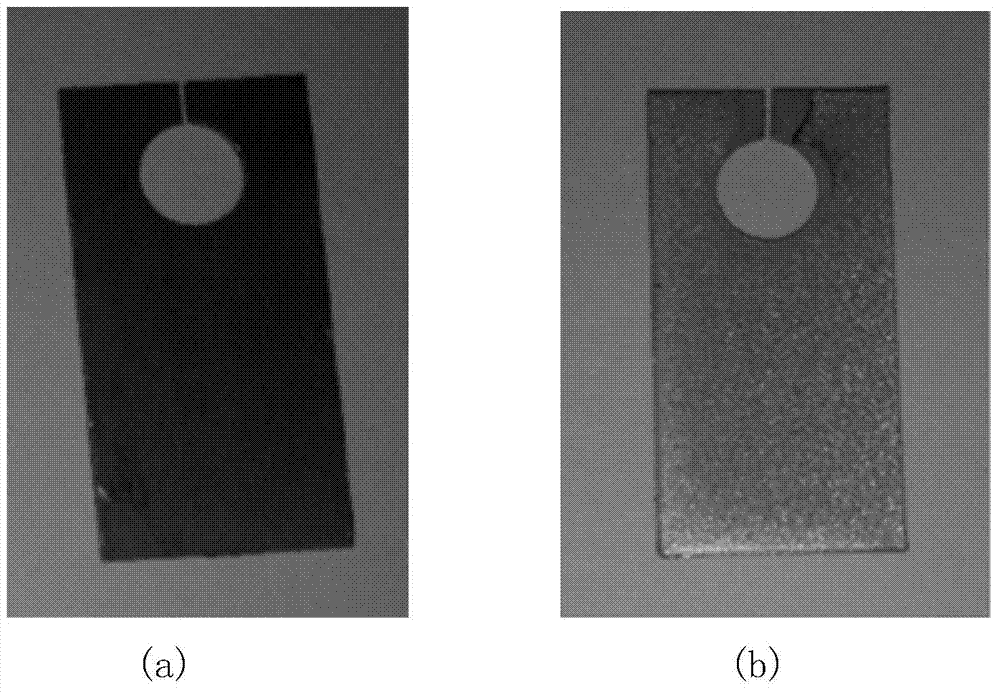

[0022] 1) Use 304 stainless steel sheet as the substrate (substrate such as figure 1 As shown in (a), after testing, the thermal conductivity of the substrate is 17W / (m K)), and the substrate is pretreated, specifically, acetone room temperature ultrasonication for 10min→chemical degreasing→hot water (70℃) Cleaning → cold water washing at room temperature → etching → cold water washing at room temperature → activation and pre-plating at room temperature → cold water washing at room temperature; where:

[0023] In the chemical degreasing operation: the chemical degreasing liquid is composed of sodium hydroxide (25g / L), sodium carbonate (35g / L), sodium phosphate dodecahydrate (35g / L) and OP emulsifier (4g / L), and then Degreasing at a temperature of 90°C for 10 minutes;

[0024] Etching operation: The etching solution is composed of sulfuric acid (98%, 100ml / L), nitric acid (68%, 100ml / L) and hydrofluoric acid (40%, 100ml / L), and then soaked at room temperature (25°C) 10min;

...

Embodiment 2

[0036] 1) Using 304 stainless steel flakes as the base material (the thermal conductivity of the base material is 17W / (m K) after testing), the base material is pretreated, specifically acetone room temperature ultrasonic 10min → chemical degreasing → hot water (70 ℃) Cleaning → cold water washing at room temperature → etching → cold water washing at room temperature → activation and pre-plating at room temperature → cold water washing at room temperature; where:

[0037] In the chemical degreasing operation: the chemical degreasing liquid is composed of sodium hydroxide (25g / L), sodium carbonate (35g / L), sodium phosphate dodecahydrate (35g / L) and OP emulsifier (4g / L), and then Degreasing at a temperature of 90°C for 10 minutes;

[0038]Etching operation: The etching solution is composed of sulfuric acid (98%, 100ml / L), nitric acid (68%, 100ml / L) and hydrofluoric acid (40%, 100ml / L), and then soaked at room temperature (25°C) 10min;

[0039] In activation and pre-plating ope...

Embodiment 3

[0046] 1) Using 304 stainless steel flakes as the base material (the thermal conductivity of the base material is 17W / (m K) after testing), the base material is pretreated, specifically acetone room temperature ultrasonic 10min → chemical degreasing → hot water (70 ℃) Cleaning → cold water washing at room temperature → etching → cold water washing at room temperature → activation and pre-plating at room temperature → cold water washing at room temperature; where:

[0047] In the chemical degreasing operation: the chemical degreasing liquid is composed of sodium hydroxide (25g / L), sodium carbonate (35g / L), sodium phosphate dodecahydrate (35g / L) and OP emulsifier (4g / L), and then Degreasing at a temperature of 90°C for 10 minutes;

[0048] Etching operation: The etching solution is composed of sulfuric acid (98%, 100ml / L), nitric acid (68%, 100ml / L) and hydrofluoric acid (40%, 100ml / L), and then soaked at room temperature (25°C) 10min;

[0049] In activation and pre-plating op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com