Curved surface aerator and aeration method

A technology of aerator and curved surface, which is applied in the field of aeration equipment at the bottom of sewage and wastewater, can solve the problems of rubber vibration diaphragm aging, easy blockage, unstable operation, etc., and achieve the effect of solving unreliability, appropriate size, and uniform distribution of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

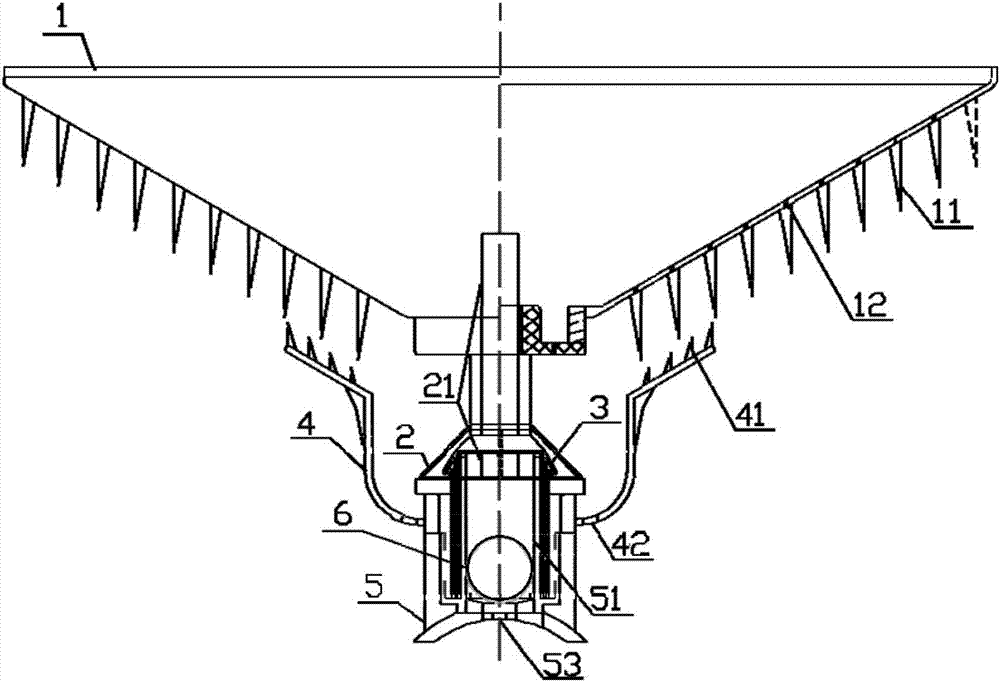

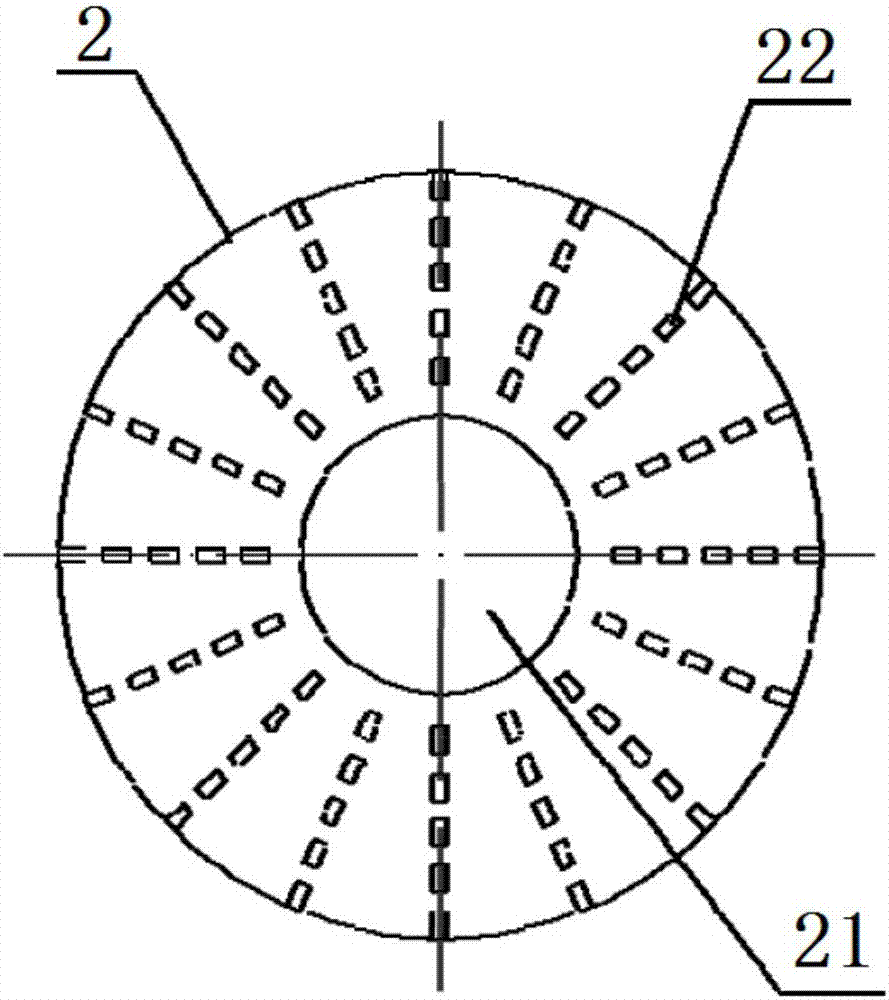

[0042] A curved surface aerator, its structure includes an inverted umbrella-shaped curved surface disk 1, an umbrella-shaped rotary cutter 2, an inverted cup cover 3, an air-water contact cylinder 4, a seat body 5, a non-return body 6, and the like.

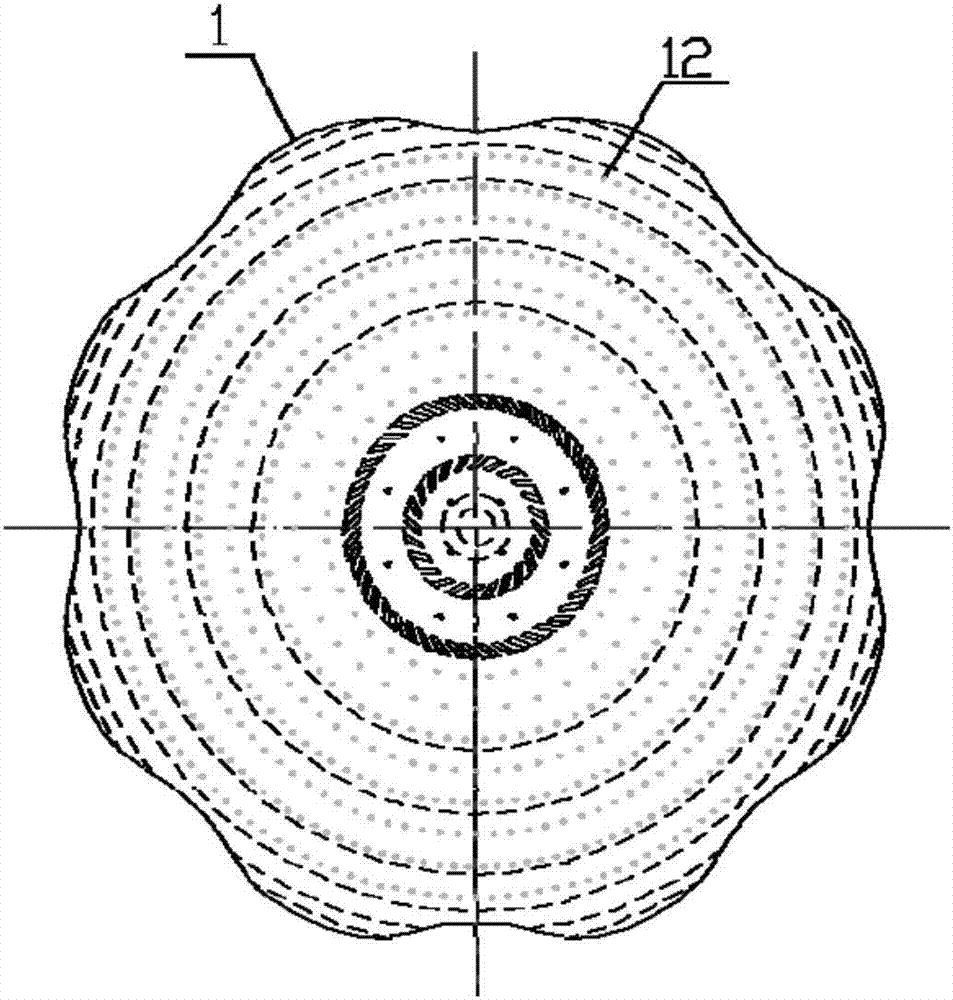

[0043] The inverted umbrella-shaped curved surface disk 1 is a symmetrical curved arc inverted umbrella-shaped disk surface. Several triangular cone teeth 11 are arranged under the disk surface, and the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com