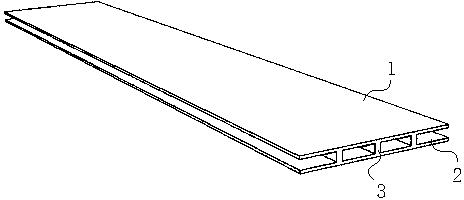

Explosive welding method of arranging multiple reinforcing ribs between large-area double-layer steel plates

A technology of explosive welding and reinforcing ribs, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as unreported, limited operating space, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention relates to an explosive welding method in which multiple reinforcing ribs are arranged between large-area double-layer steel plates, which is a two-stage explosive welding method. details as follows:

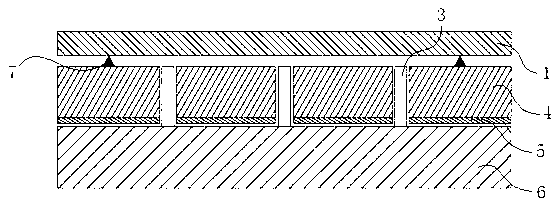

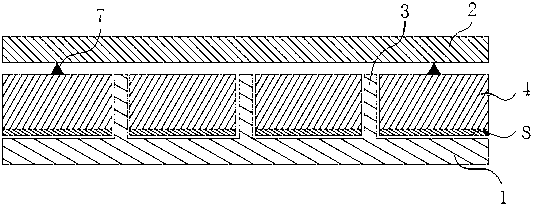

[0032] The first stage of explosive welding: the schematic diagram of the process device is attached figure 2 As shown, formwork 1 4, formwork 2 5 and reinforcing ribs 3 are spot-welded and fixed on the backing plate 6 respectively, and the backing plate 6 is placed on a dense sand pile (hereinafter referred to as the foundation), and a gap is placed on the formwork 1 4 Column 7, place the upper panel 1 on the gap column 7, charge explosive (emulsion explosive) on the upper surface of the upper panel 1, and carry out explosive welding; under the impact force of explosive welding, the upper panel 1 and the reinforcing rib 3 are welded into one The overall weld, the solder joints between the rib 3, template 1 4, template 2 5 and the backing plate 6 are all imp...

Embodiment 2

[0046] The invention relates to an explosive welding method in which multiple reinforcing ribs are arranged between large-area double-layer steel plates, which is a two-stage explosive welding method. details as follows:

[0047] The first stage of explosive welding: the schematic diagram of the process device is attached figure 2 As shown, formwork 1 4, formwork 2 5 and reinforcing ribs 3 are spot-welded and fixed on the backing plate 6 respectively, and the backing plate 6 is placed on a dense sand pile (hereinafter referred to as the foundation), and a gap is placed on the formwork 1 4 Column 7, place the upper panel 1 on the gap column 7, charge the upper surface of the upper panel 1 with explosive (emulsion explosive), and carry out explosive welding. The overall warpage of the welded material obtained in the first stage is controlled to not exceed 5%, so that the welded material can be explosively welded to the lower panel 2 in the second stage without correction.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com