Novel vertical deep ocean pipe with slug flow subduction

A deep-sea riser and slug flow technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as blocked pipelines, increased wellhead back pressure, pipeline vibration, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

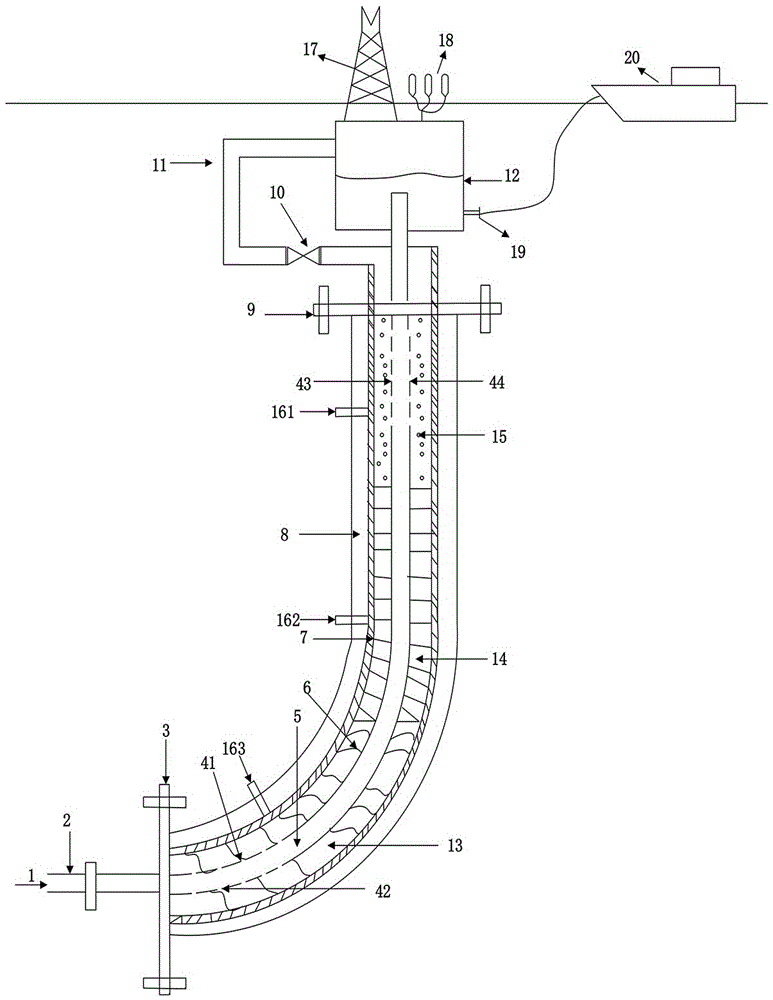

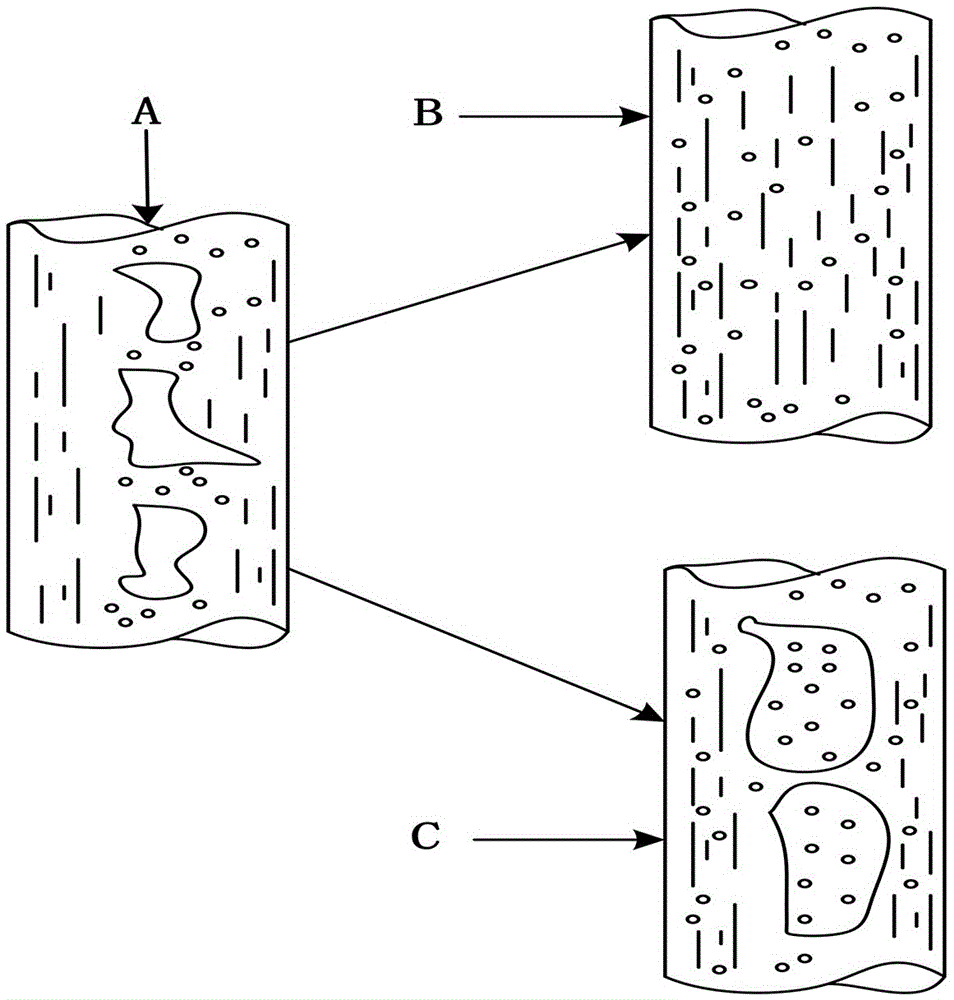

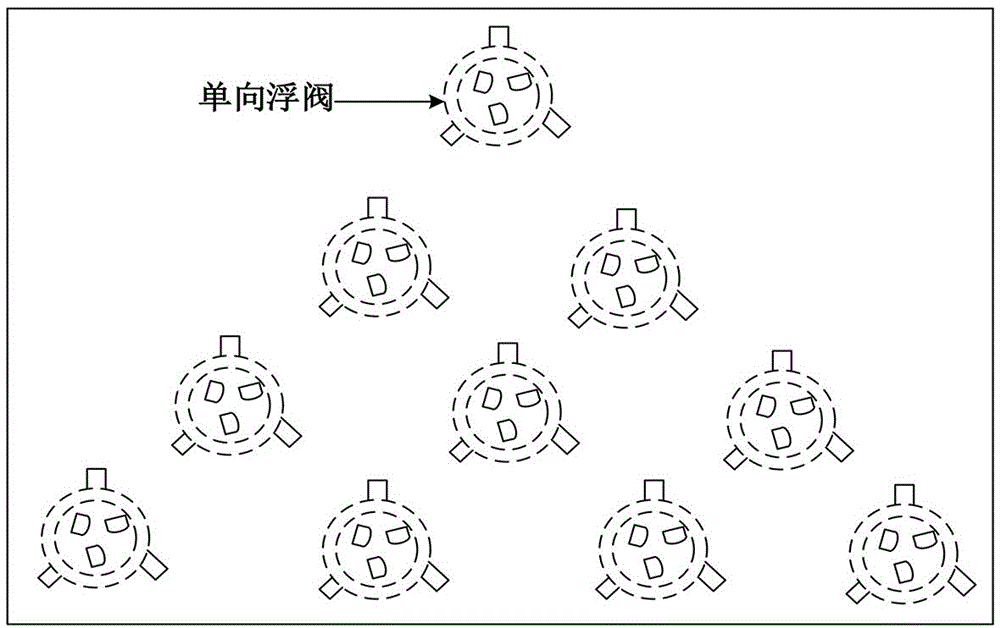

[0051] In this example, figure 1It is a schematic diagram of a new deep-sea riser structure with slug flow reduction, including oil-gas-water three-phase medium 1, production pipeline 2, blind flange 3, first communication hole 41, second communication hole 42, third communication hole 43, Fourth communication hole 44, inner pipe 5, outer pipe 6, insulation layer 7, heat insulation layer 8, connector 9, gas volume regulating valve 10, gas injection pipeline 11, floating separator 12, water phase 13, oil phase 14, Gas phase 15 , first pressure sensor 161 , second pressure sensor 162 , third pressure sensor 163 , flare tower 17 , buoy 18 , liquid phase outlet 19 , and oil storage vessel 20 .

[0052] The production pipeline 2 is connected to the inner pipe 5 through the blind flange 3, the oil-gas-water three-phase medium 1 enters the inner pipe 5 through the production pipeline 2, and the inner pipe 5 is connected to the floating separator 12 through the connector 9, The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com