Explosion stoping method for horizontal ore pillar of sublevel caving mining method

A mining method and ore pillar technology, which is applied in the blasting mining field of horizontal ore pillars in the stage mining method, can solve the problems of poisonous and harmful gas damage, high ore dilution rate, and high operation risk, so as to avoid overexplosion, Guaranteed packing quality and low risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] A blasting recovery method for horizontal ore pillars in a stage mine mining method is implemented according to the following steps:

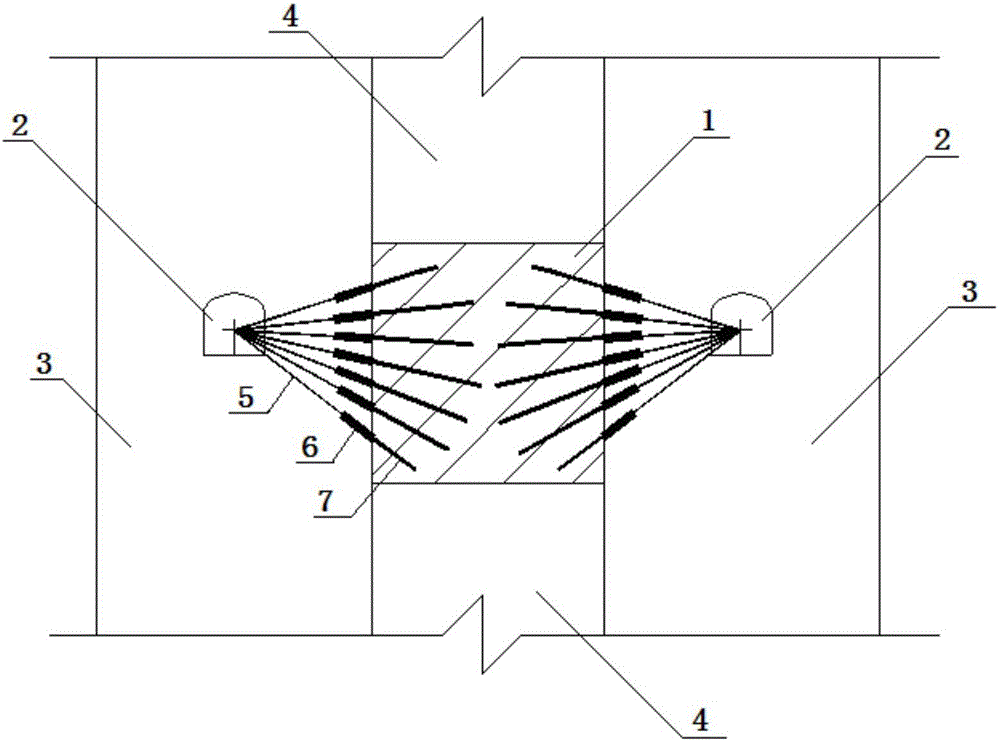

[0015] ①Drilling fan-shaped medium-deep holes: such as figure 1 As shown, the mining roadway in the vertical pillar 3 on both sides of the horizontal ore pillar 1 left after returning to the mining house by the stage mine method is used as the rock drilling roadway 2, and the rock drilling roadway 2 on both sides goes to the horizontal ore pillar 1 respectively. Drill a row (7 in total) of medium-deep holes in one direction to form two rows of medium-deep holes on the left and right. The medium-deep holes in the same row are fan-shaped to form fan-shaped medium-deep holes. The apex of the fan is located on the center line of the rock drilling roadway. The direction of the fan-shaped medium-deep holes is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com