Deep-buried tunnel blasting excavation effect control method

A control method and tunnel technology, applied in the field of geotechnical engineering, can solve the problems of retaining rock mass damage, network needs to be further optimized, and clamping effect is not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

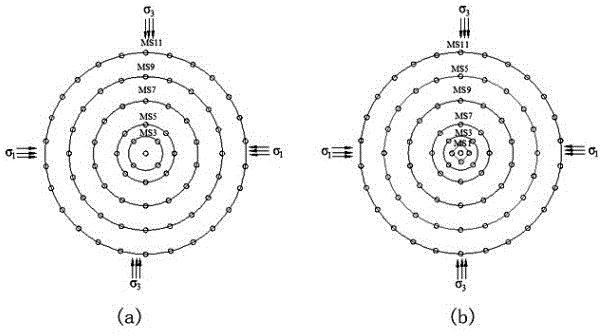

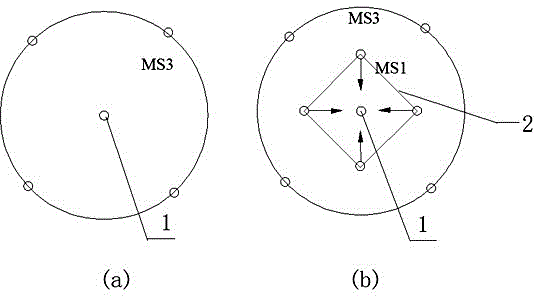

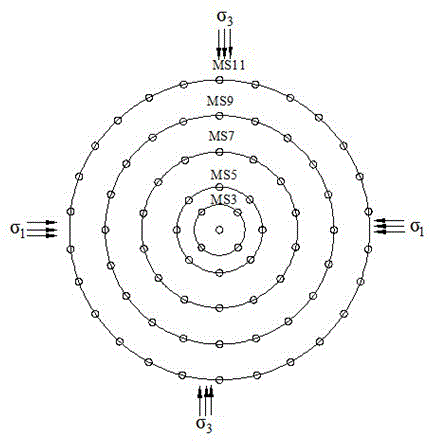

[0047] A deeply buried circular tunnel is excavated in an infinite mountain, the radius of the tunnel face is r=2.5m, and the horizontal initial ground stress σ of the face is 1 is the maximum principal stress, the vertical initial stress σ 3 For the minimum principal stress, the full-section blasting excavation is formed. The middle part of the face is cut with straight holes. From the inside to the outside, one circle of cut holes MS3, three circles of caving holes MS5~MS9, one circle of peripheral smooth blast holes MS11 are arranged in sequence on the excavated face. The conventional detonation networking method of , caving holes and smooth blast holes is: connect the blast holes into a circle to obtain 5 differential initiation sections of MS3, MS5, MS7, MS9 and MS11, see figure 1 shown.

[0048] If the detonation is carried out according to the above-mentioned networking, the detonation area of the cut section and the single-shot charge are too large, and the strain ...

Embodiment 2

[0052] See Figure 5 , a deep-buried city gate tunnel was excavated in an infinite mountain, the radius of the tunnel face r=2.5m, and the horizontal initial ground stress σ 1 is the maximum principal stress, and the vertical initial stress is σ 3 For the minimum principal stress, the full-section blasting excavation is formed. According to the drilling and blasting design scheme with the single shot charge as the core control index, the cutting holes MS3, the caving holes MS5~MS13 and the surrounding smooth blasting holes MS15~17 are arranged on the working surface. The conventional detonation networking method of surface blast holes is: connect the blast holes as Figure 5 MS3, MS5, MS7, MS9, MS11, MS13, MS15 and MS17 are shown as 8 differential initiation stages.

[0053] If the detonation is carried out according to the above-mentioned networking, the detonation area of the cut section and the single-shot charge are too large, and the strain energy is released violent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com