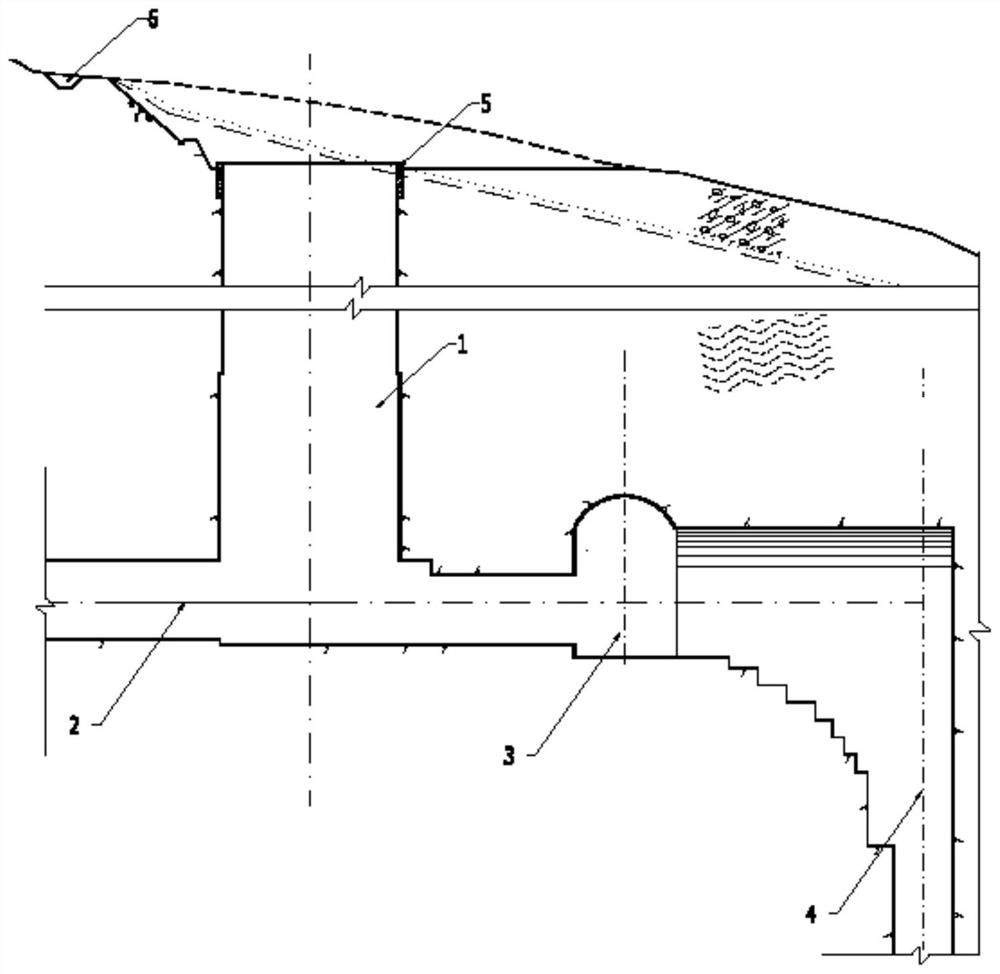

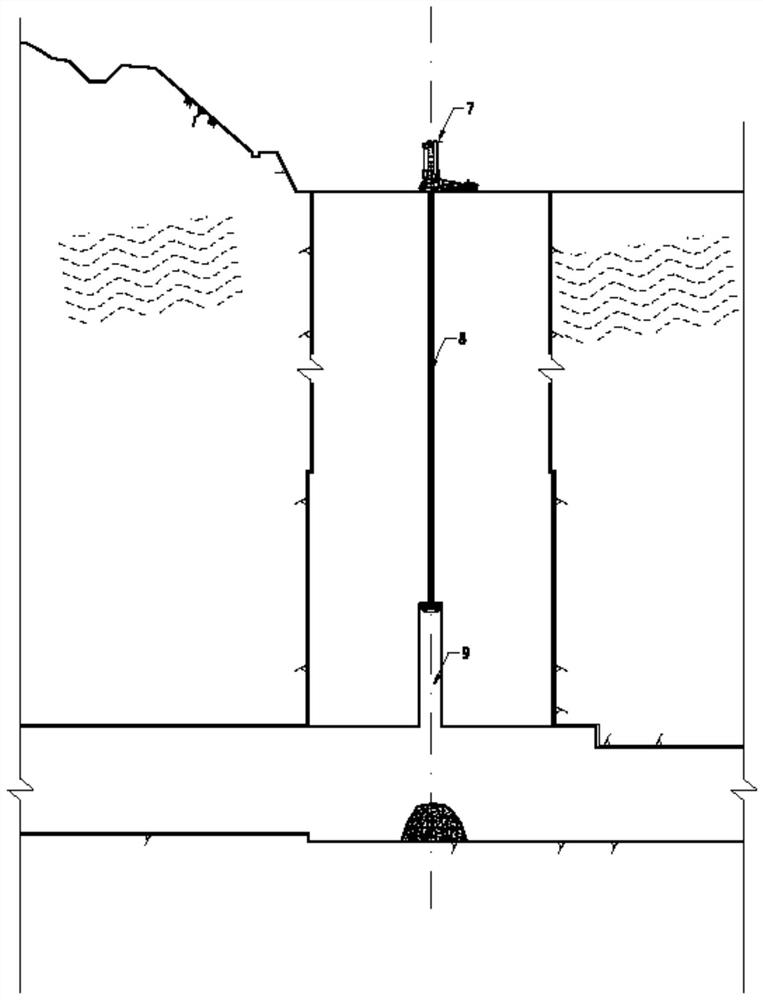

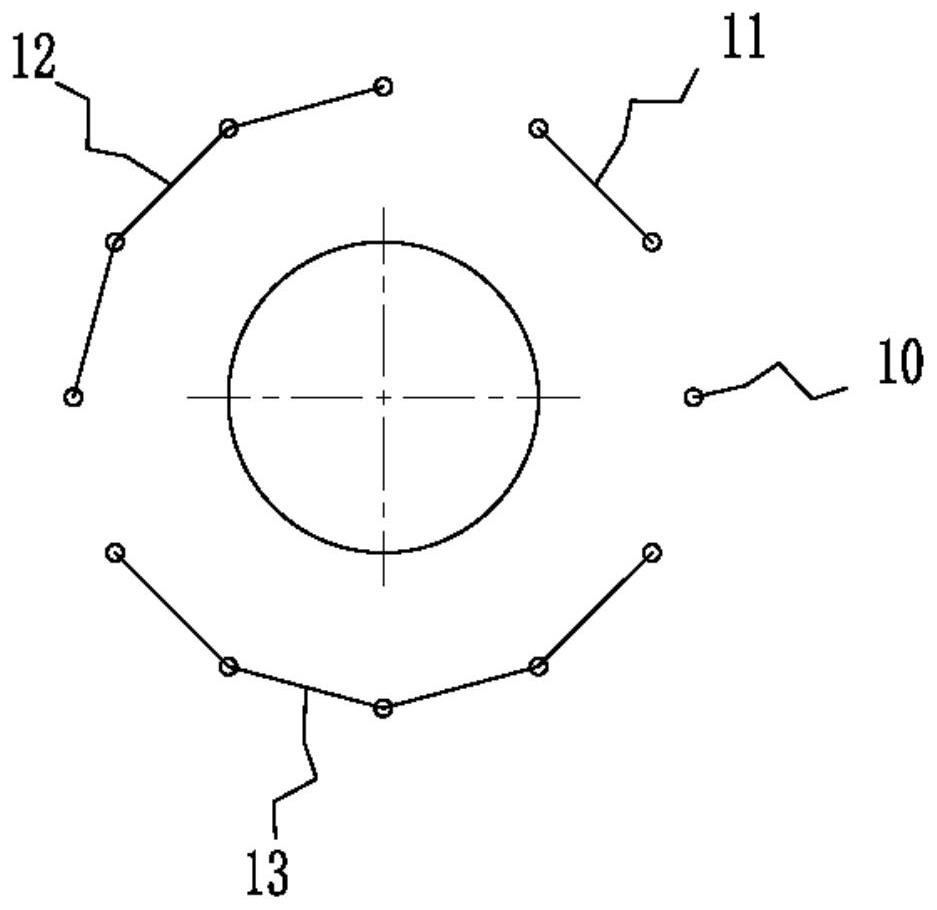

Construction method for rapidly expanding and excavating large-section surge shaft through one-time drilling and blasting of ultra-deep hole

A construction method and one-off technology, applied in blasting, water conservancy projects, hydropower stations, etc., can solve the problems of increased construction costs, small implementation space, high safety risks, etc., to save costs, reduce the amount of slag in holes, and protect people. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below, but the present invention is not intended to limit the invention in the scope of the present invention, and will be described in the art of the present invention without departing from the present invention. Any changes or changes that are easy to implement by those of ordinary skill will fall within the scope of the claims.

[0039] The present invention tries to the construction of the pressure regulating well of the MIDDLE BHOTEKOSHI Hydropower Station Project (MBKHP).

[0040] The Middle Bhotekoshi Hydropower Technology (MBKHP) is located in Sindhupalchowk District of Bagmati Zone of The Central, and the Northeast of Kathmandu 101km. Hydropower Station is a water-repellent power station, with a total installed capacity of 102MW, design flow rate 50.8m 3 / S, the water head is 235m. The water tunnel length is about 7 km.

[0041] The pressure regulating well is located above the DT7 + 116.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com