Circumferential planar jet energy-gathering cutter and application method thereof

A technology of energy-concentrating cutters and planes, which is applied in the direction of blasting, etc., can solve the problems of increasing the cost of secondary blasting and mechanical crushing, affecting the progress and quality of the project, accelerating the wear and tear of electric protection equipment, etc., so as to save single blasting The effect of increasing the amount of explosives, improving the blasting effect, and reducing the cost of blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with embodiment.

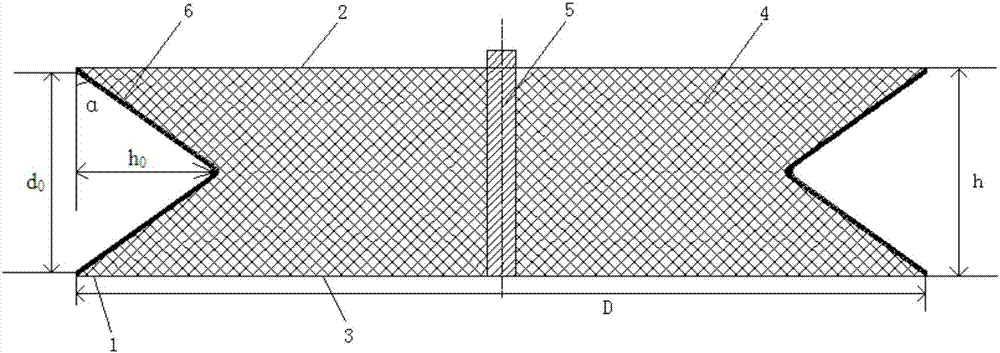

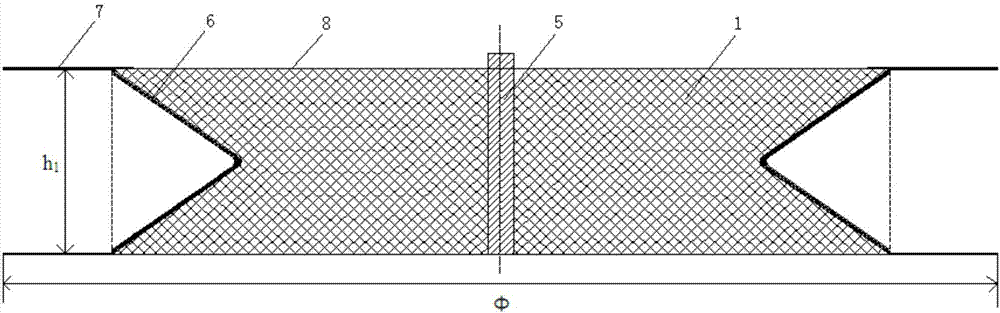

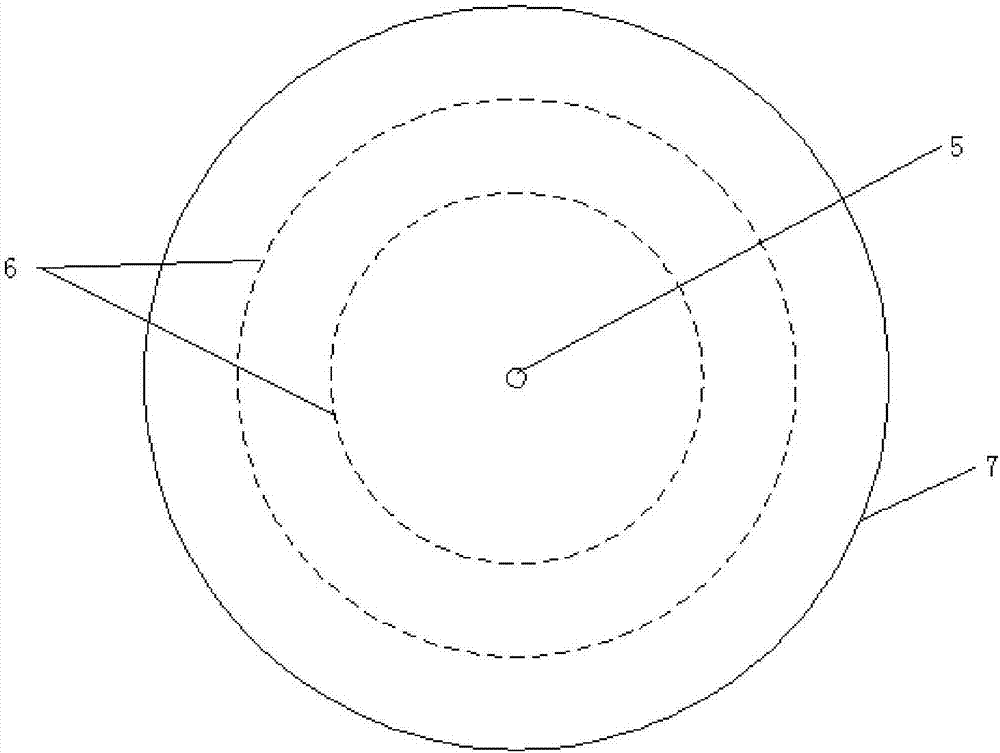

[0039] according to figure 1As shown, the present invention provides a circular plane jet energy-concentrating cutter, comprising: a ring body 1 made of metal, the upper end and the lower end of the ring body 1 are respectively provided with an upper end cover 2 and a lower end cover 3, and the upper end cover 2. A cavity structure is formed between the lower end cover 3 and the ring body 1. Explosives 4 are filled in the cavity, and a detonator tube 5 is inserted on the upper end cover 2 and the lower end cover 3. The ring body 1 The outer wall is provided with a V-shaped groove 6 along the horizontal direction, and the V-shaped opening of the V-shaped groove 6 faces the outside of the annular body. The V-shaped groove 6 is used as an annular energy-gathering cover on the annular body, and the opening of the V-shaped groove 6 The two ends of the end are connected to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com