Patents

Literature

44results about How to "Reduce the amount of replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

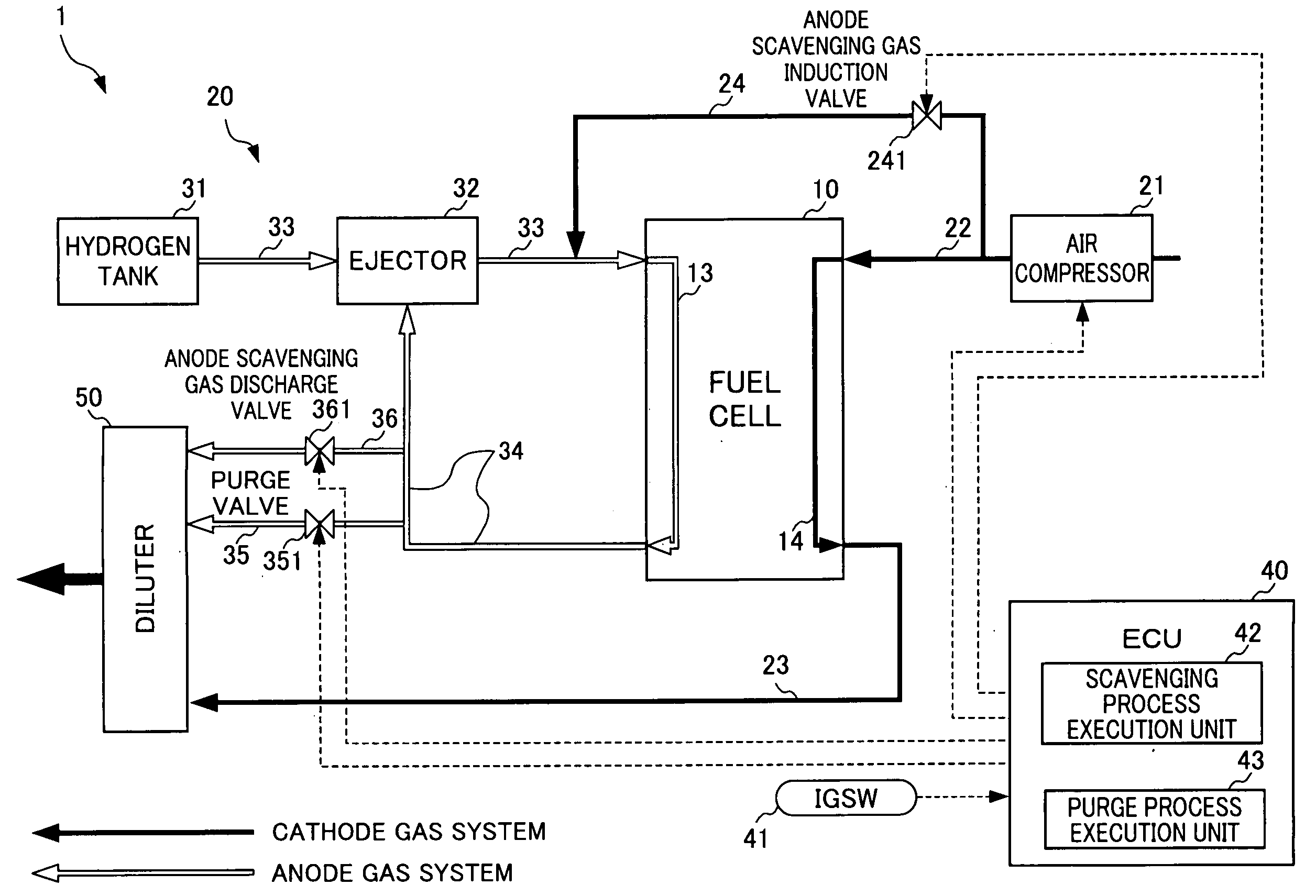

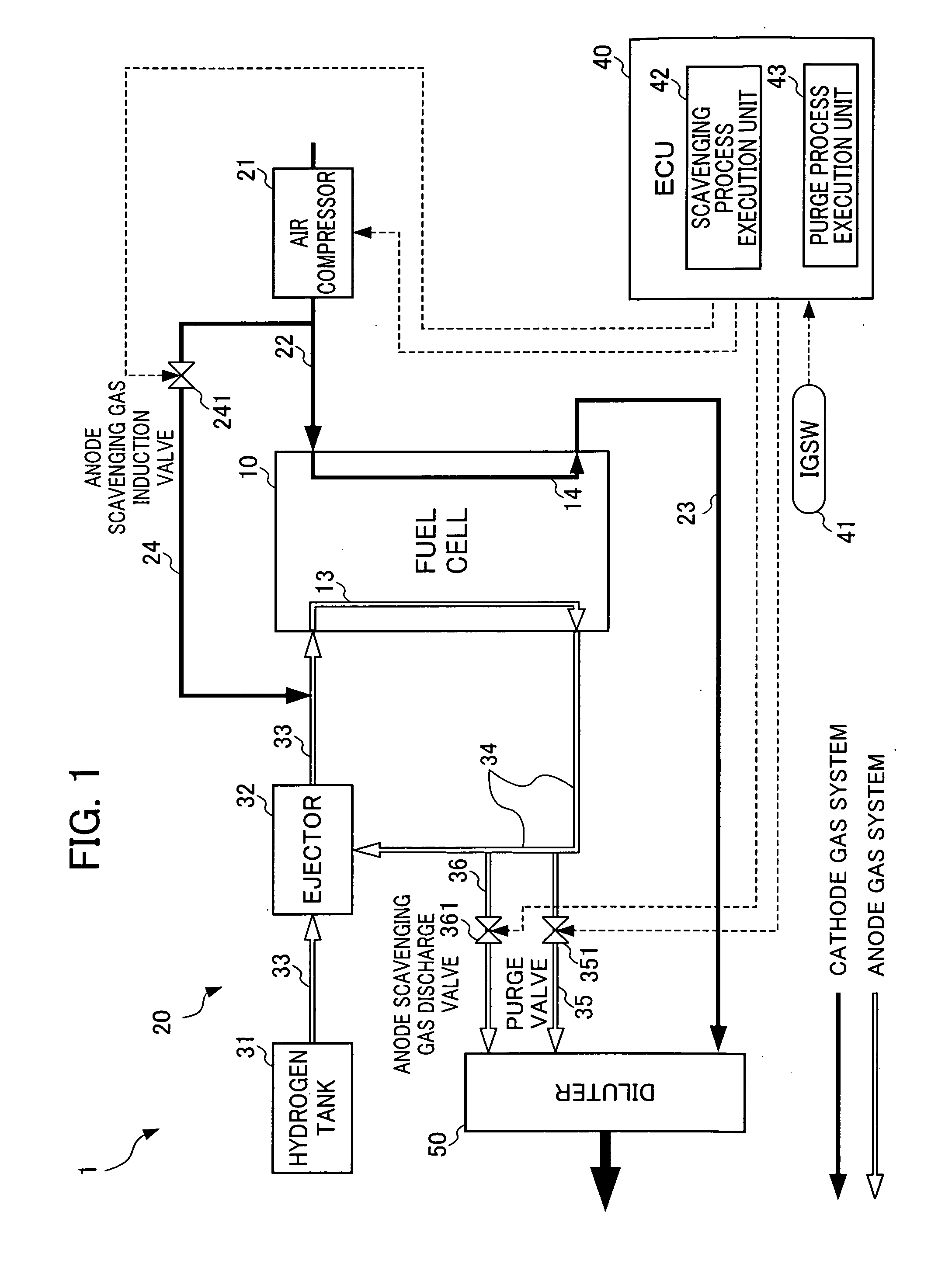

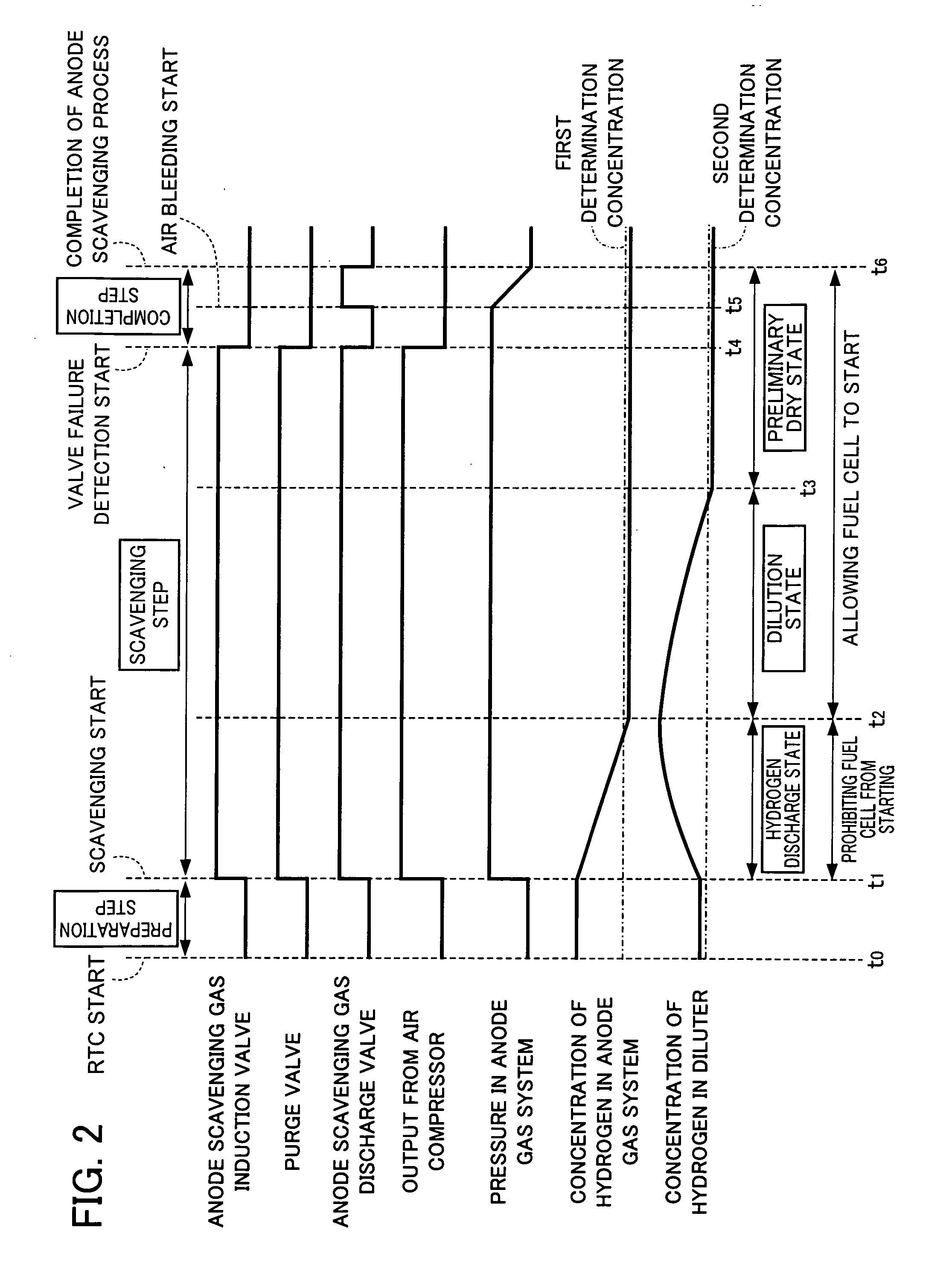

Fuel cell system and control method thereof

InactiveUS20090286116A1Fast startupStable generationFuel cell auxillariesAutomotive engineeringEngineering

The present invention provides a fuel cell system and a control method thereof that performs a scavenging process when the fuel cell is stopped, whereby stable electrical power production is ensured after startup, and faster startup is possible. The fuel cell system performs the scavenging process in which scavenging gas is supplied into an anode gas system when the fuel cell is stopped. When a startup request for the fuel cell is detected while the anode scavenging process is being performed, the concentration of hydrogen in the anode gas is detected, and then whether to continue the anode scavenging process and prohibit the fuel cell from starting, or to suspend the anode scavenging process and allow the fuel cell to start is determined based on this detected concentration of hydrogen in the anode gas system.

Owner:HONDA MOTOR CO LTD

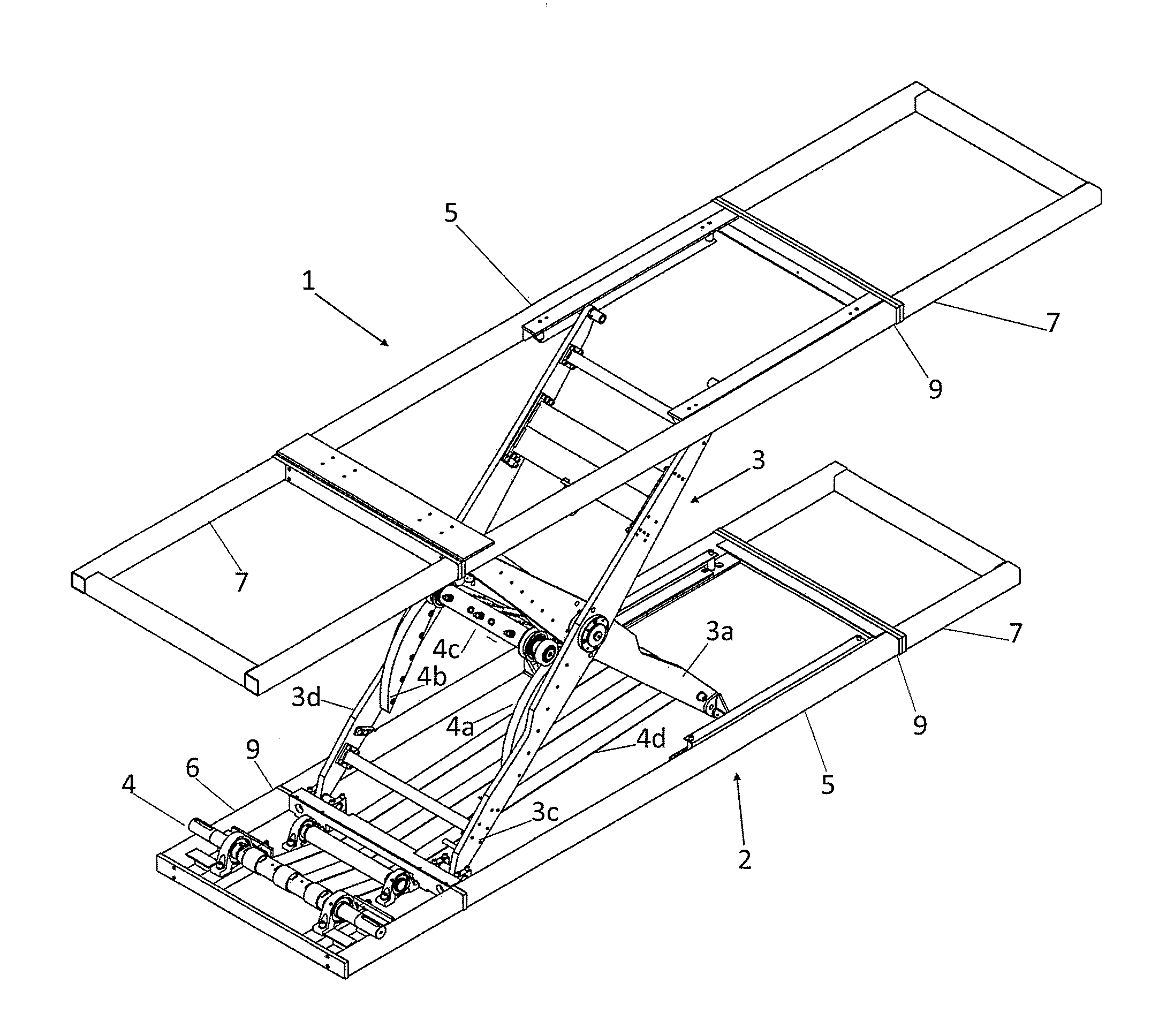

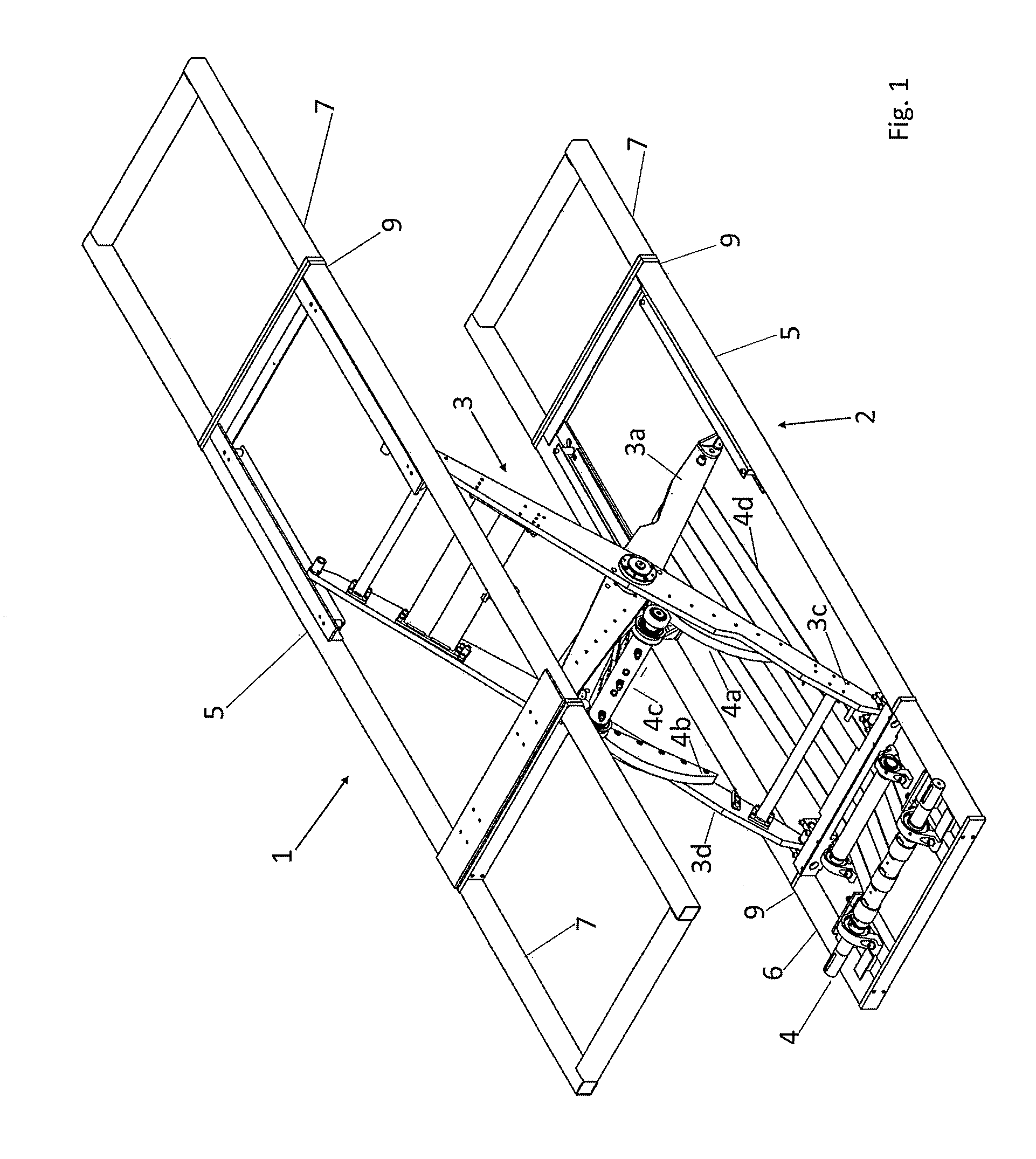

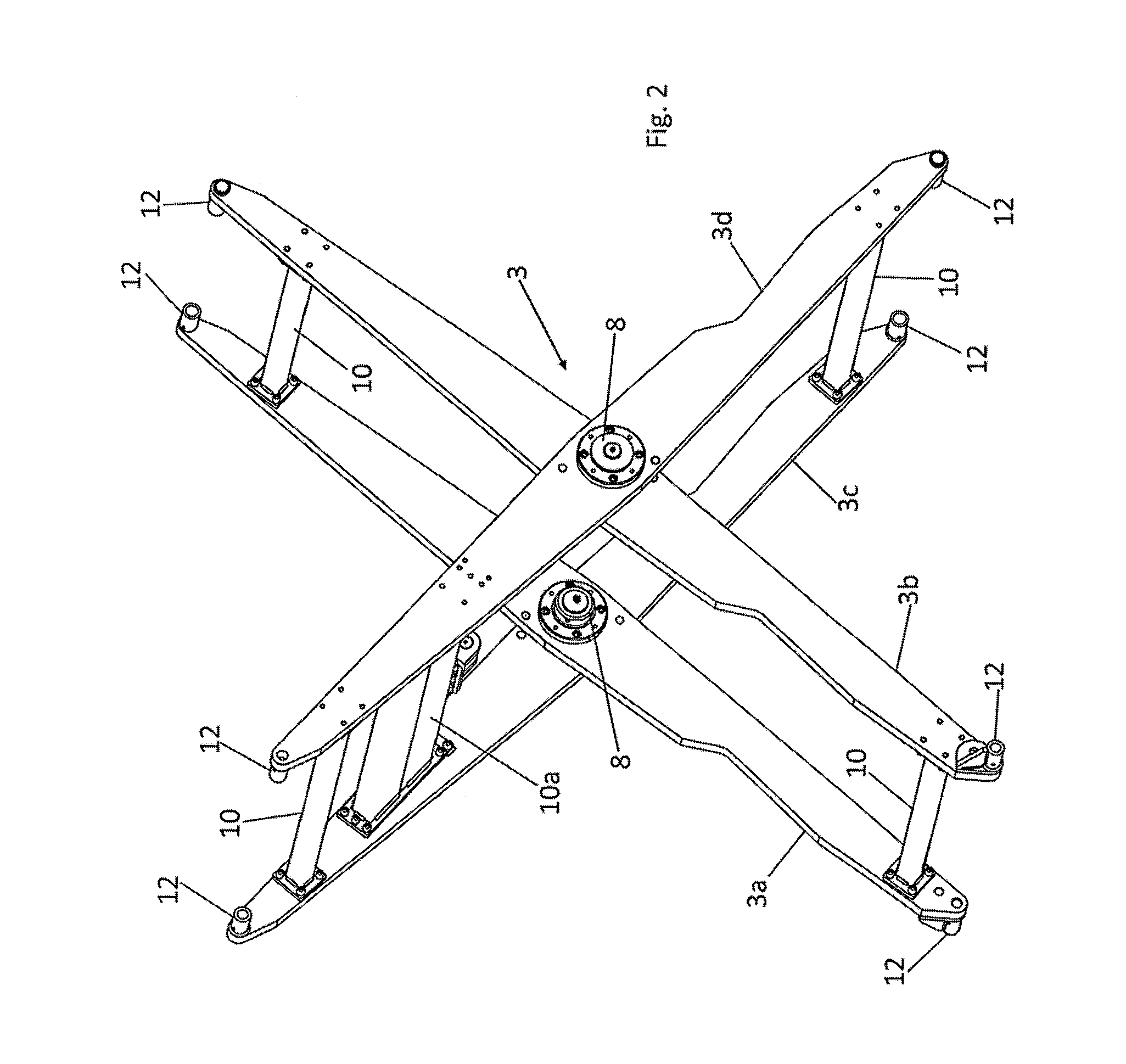

Scissors lifting table and method of assembling a scissors lifting table

A scissors lift comprises an upper frame module (1) and a lower frame module (2), a scissor mechanism (3) and a drive unit (4). The upper frame module (1) and the lower frame module (2) are connected by the scissor mechanism (3) in such a way that a lifting movement, by which the spacing between the upper frame module (1) and lower frame module (2) changes, is rendered possible. The scissors lift, particularly the upper frame module (1) and / or the lower frame module (2), have a central portion (5) to which extension 6 and / or 7 that are pre-produced in fixed sizes and are fitted together in the manner of a modular construction system to make a scissors lifting lift of desired size.

Owner:MOHR CHRISTOPH

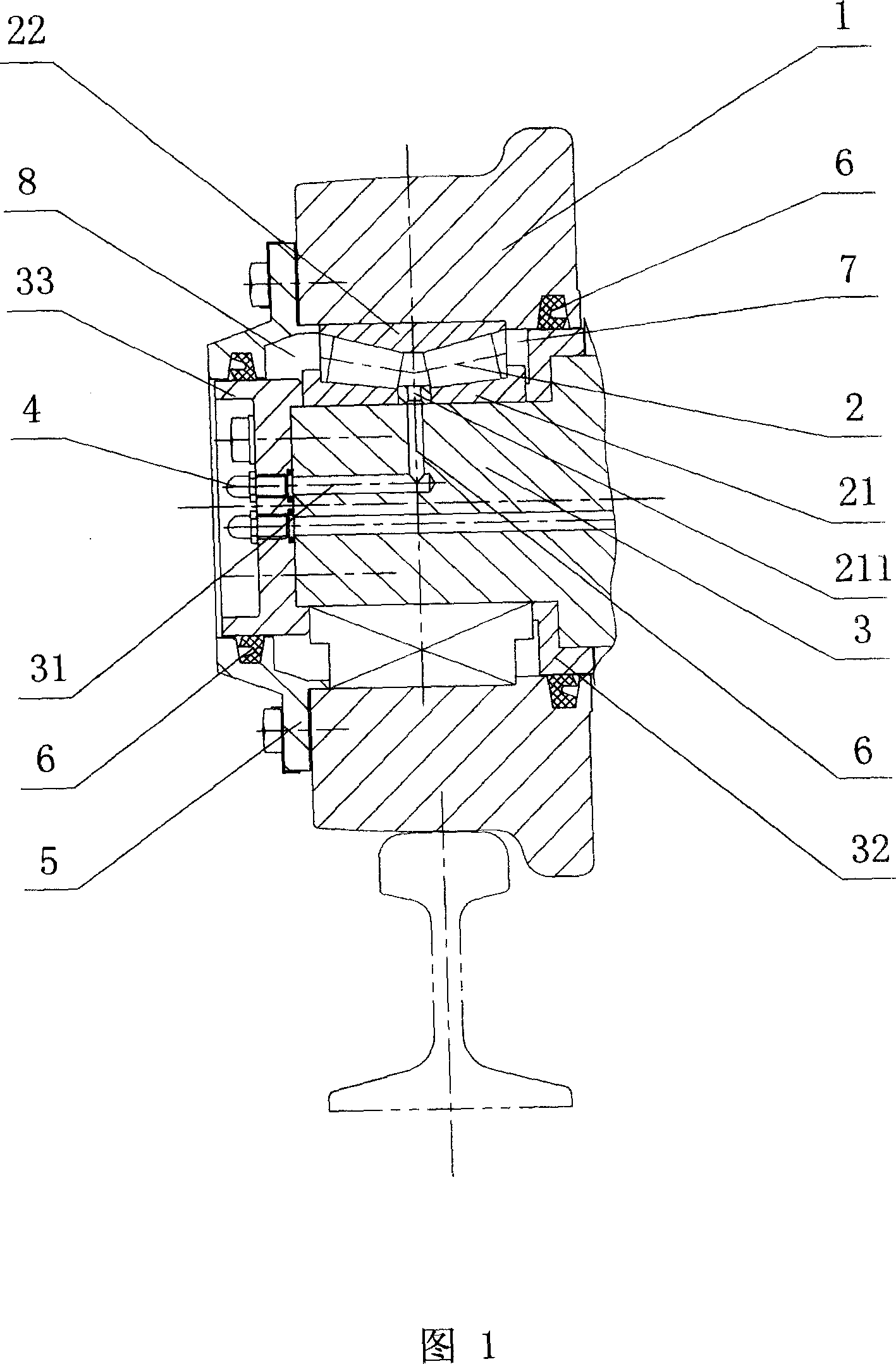

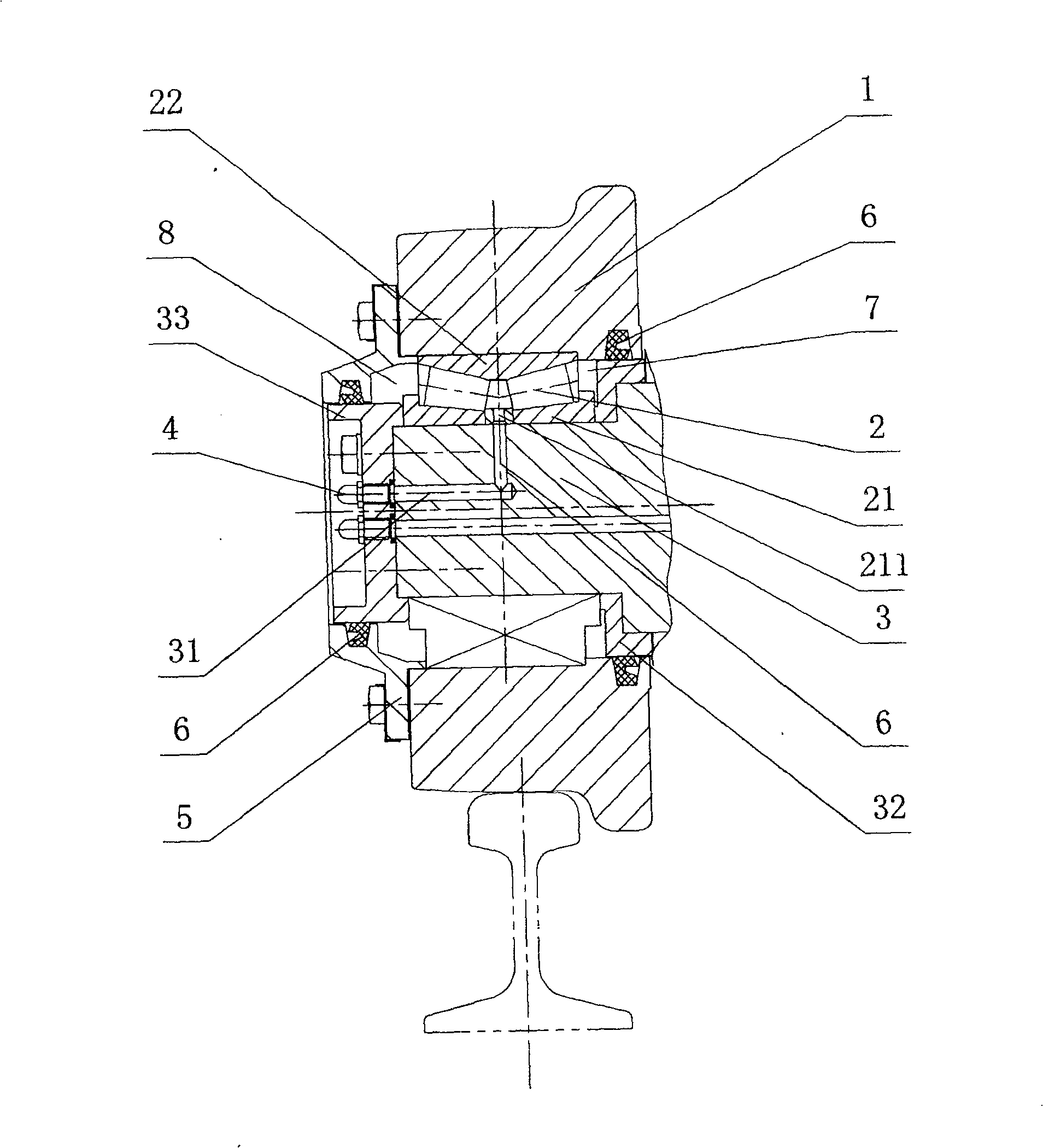

Sintering machine bogie wheels

The invention discloses wheels of loop wheel machine of sintering machine that can increase the service life of bearings, comprising wheel body, bearing, axles of loop wheel machine, bearing holder is set at the end of axle of loop wheel machine, the wheel body holder is installed on the bearings, and lubricating mouth is also set on the said bearings, and axles of loop wheel machine are equipped with grease channel, one end of the channel has a grease nipple, the other end connects the lubricating mouth.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Single-system one-step series-connected pressure swing adsorption process

The single system one-step series pressure swing adsorption process is characterized by that in the system formed from at least three adsorption towers the raw material gas is fed into X tower to make adsorption, the outputted off-test product gas is fed into Y tower to make adsorption and obtain qualified product gas, when the adsorbable component in the product gas will exceed standard, the output can be cut off, at this time X tower adsorption is completed, then other pressure swing adsorption steps are made; at the same time the raw material gas can be fed into Y tower to make adsorption, and its outputted off-test product gas can be fed into Z tower to make adsorption and outupt qualified product gas. Said operation can be circularly made, and can further raise utilization rate of adsorbent.

Owner:王玉

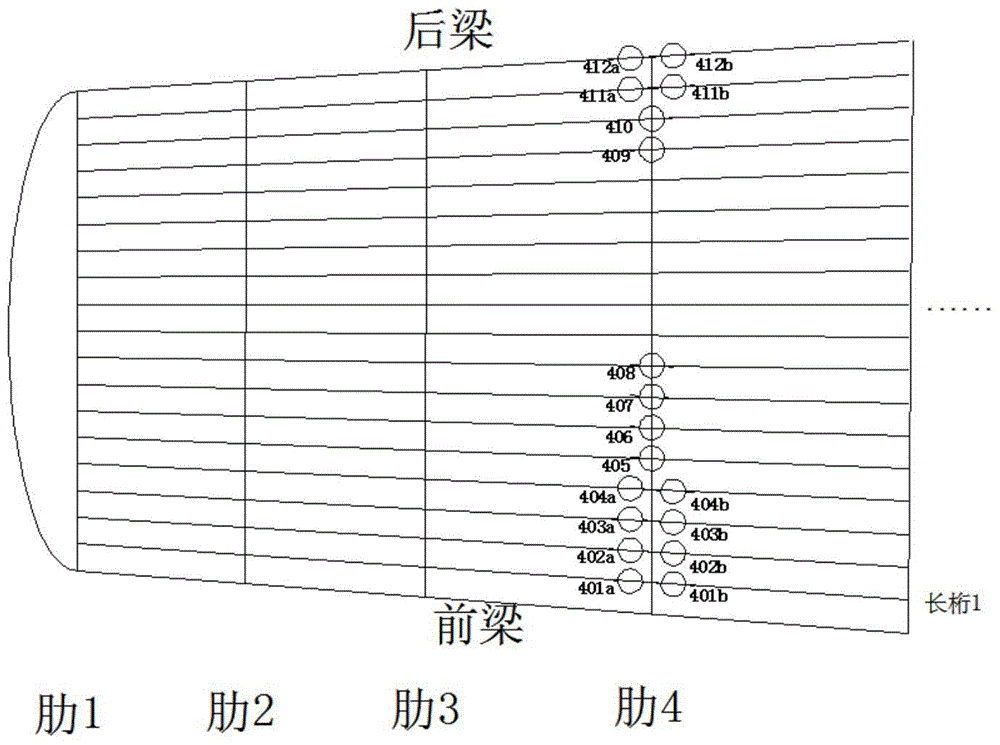

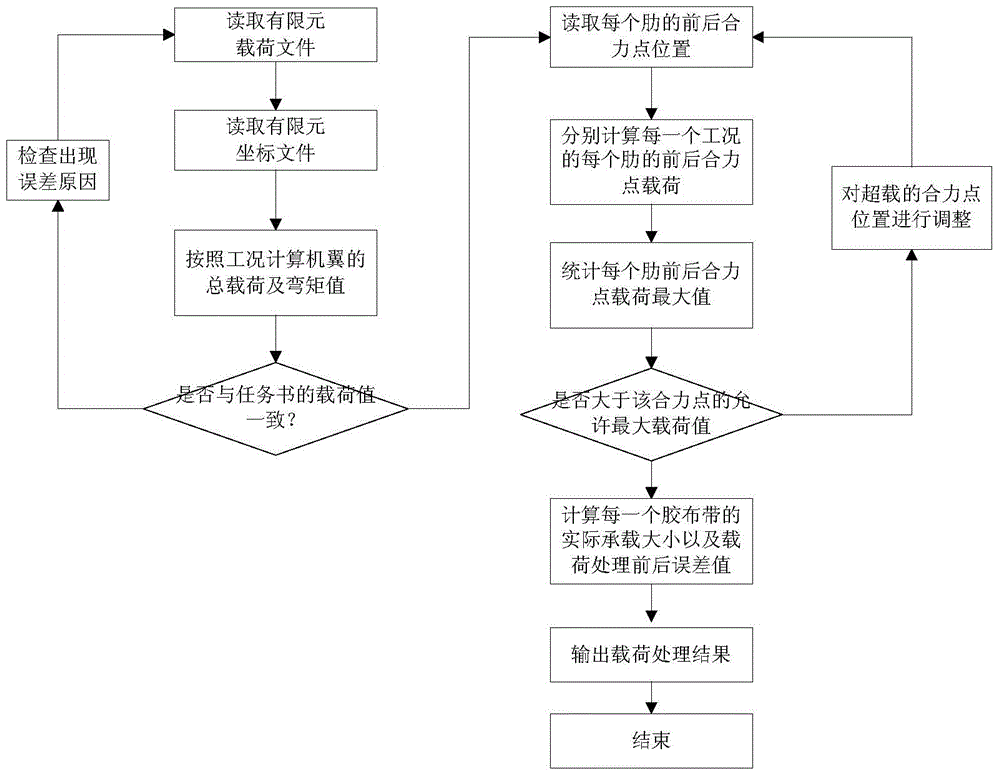

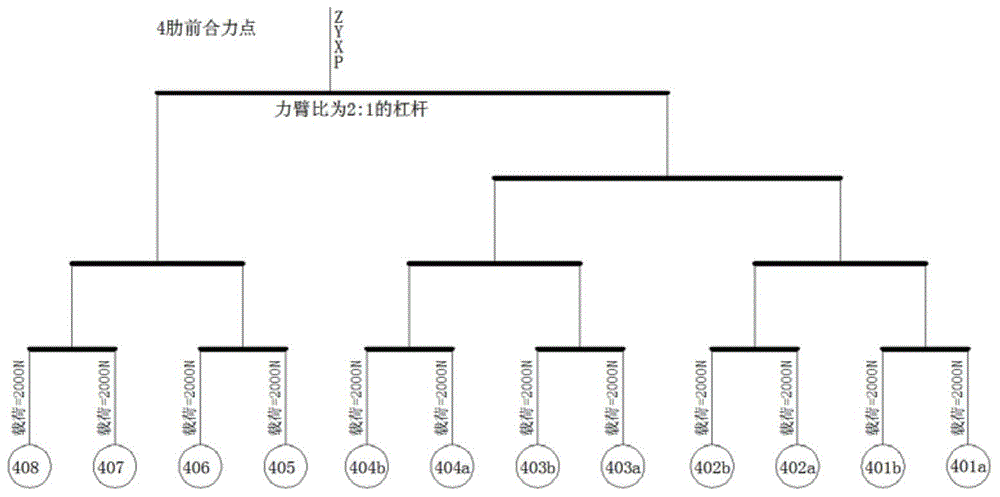

Double-beam type long straight wing load processing method

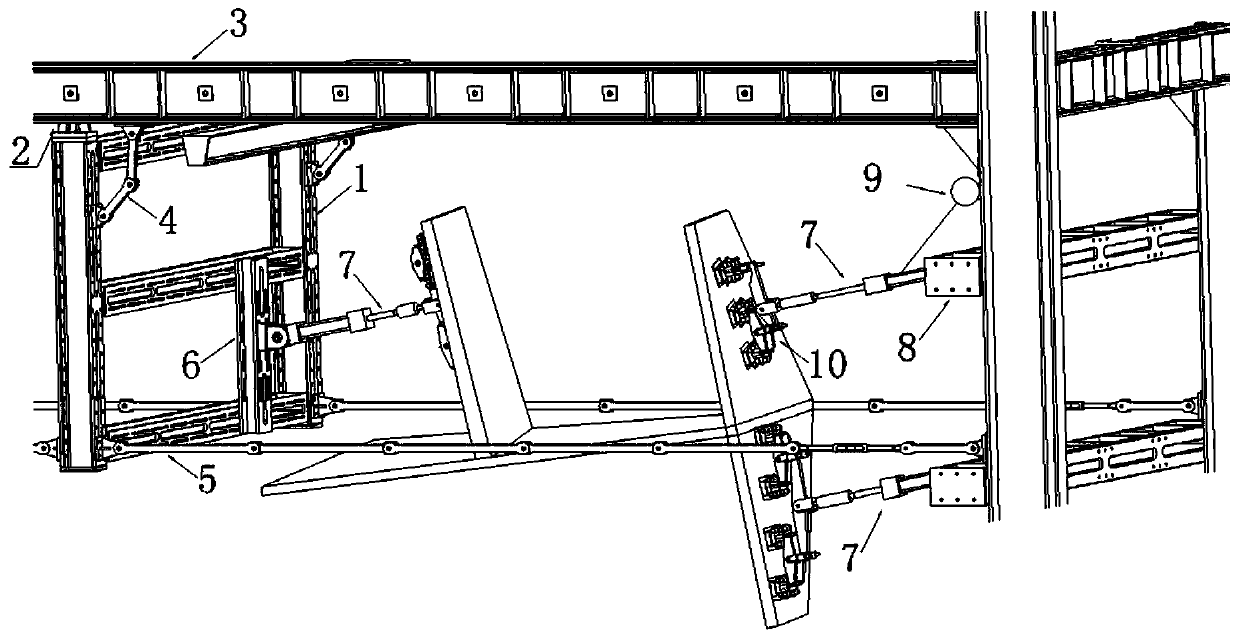

ActiveCN105716842AImprove accuracyImprove load handling efficiencyMachine part testingEngineeringResultant force

The invention provides a double-beam type long straight wing load processing method. The double-beam type long straight wing load processing method comprises the following steps: according to a finite element node number and position of each rib of a wing, selectively distributing adhesive tapes around the front beam and the back beam of each rib, wherein the load value of each adhesive tape is the maximum load value that the adhesive tape can bear; and according to the positions of the adhesive tapes of the front beam and the back beam of each rib, respectively calculating the lever end coordinates of the front beam and the back beam, and a load value that the lever system can bear, wherein the load value is the maximum bearing value of the lever system; the lever end coordinates of the front beam and the back beam of each rib are respectively the front resultant force point and the back resultant force point; and the lever systems for the front resultant force point and the back resultant force point are uniformly named as a special lever.

Owner:CHINA AIRPLANT STRENGTH RES INST

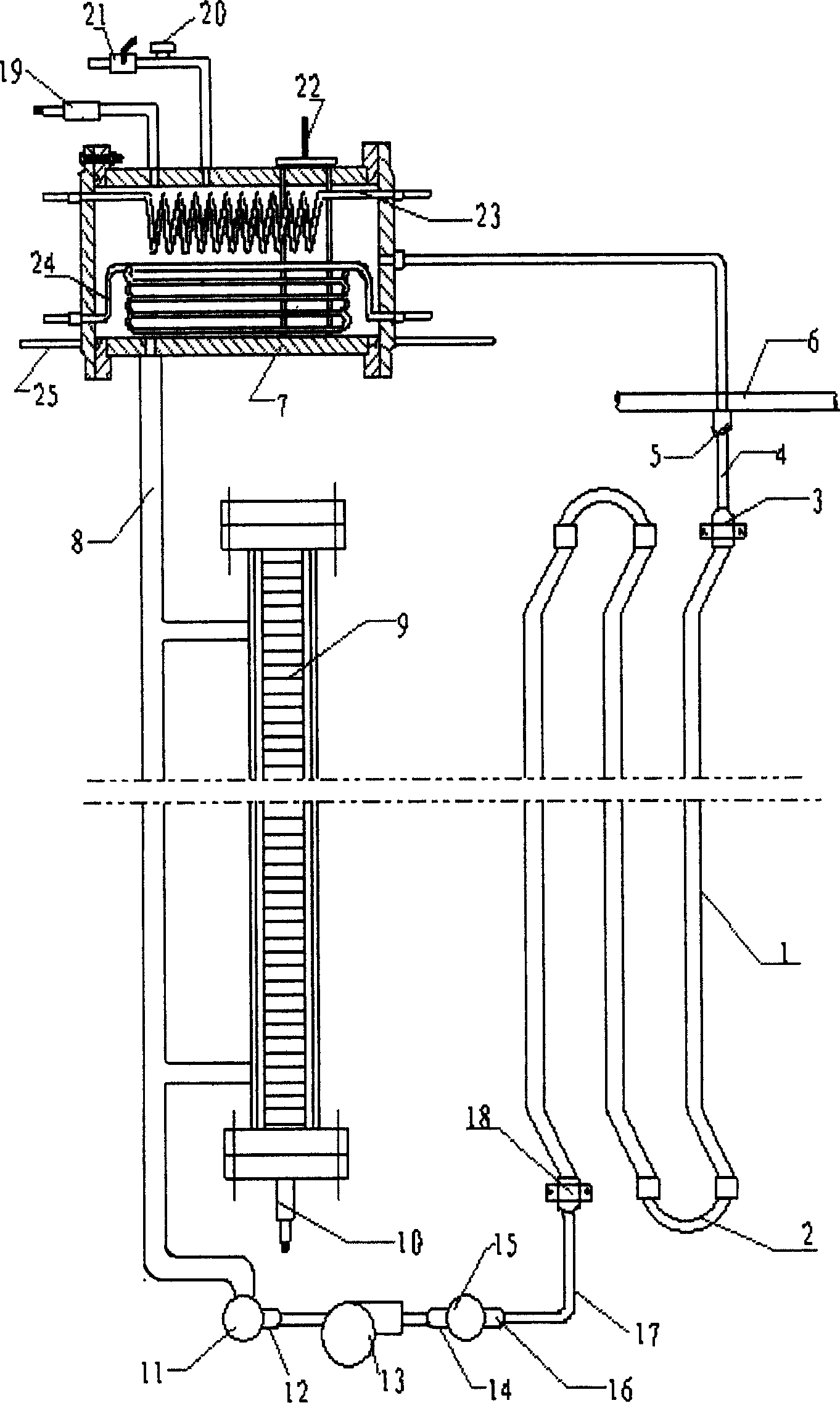

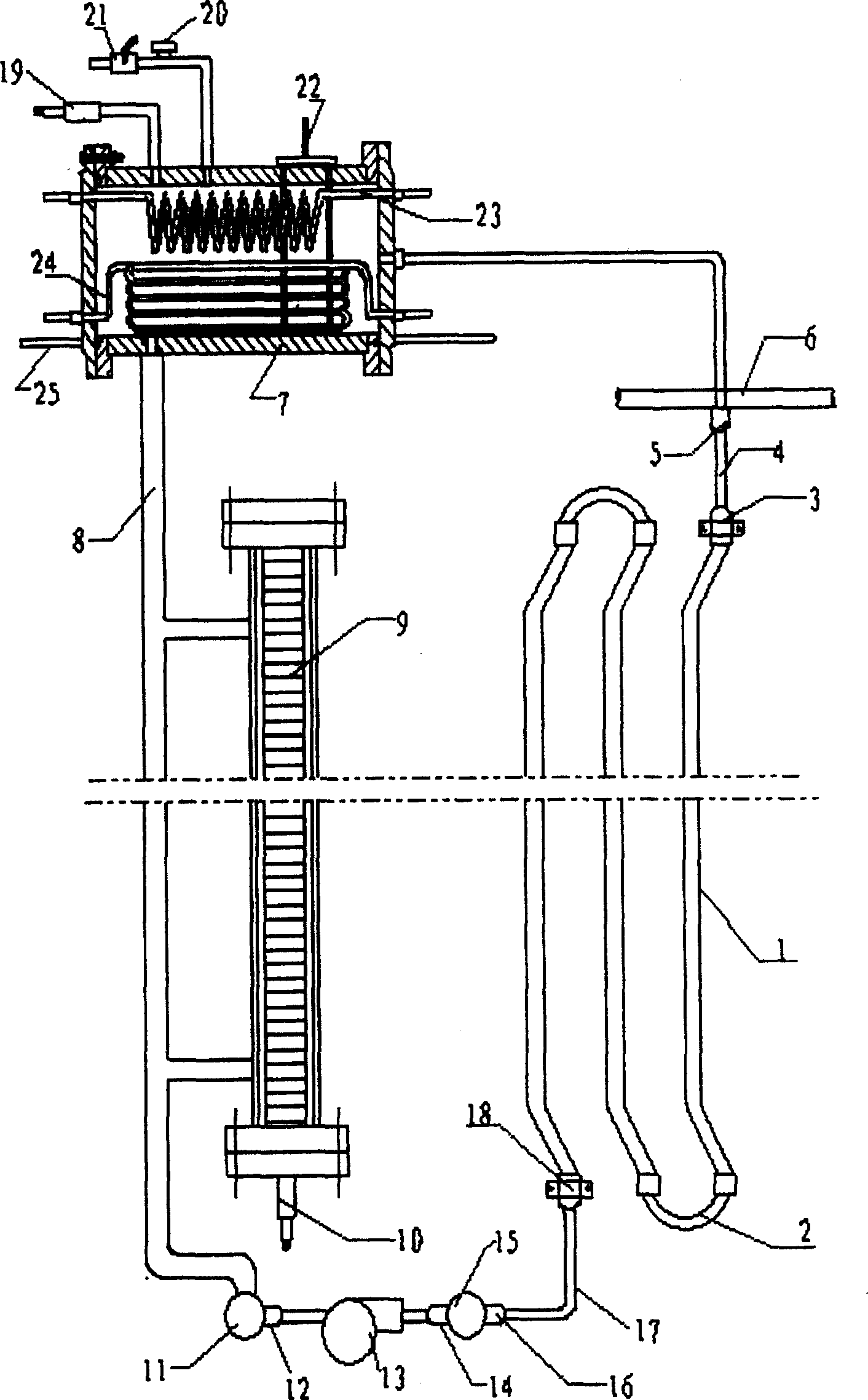

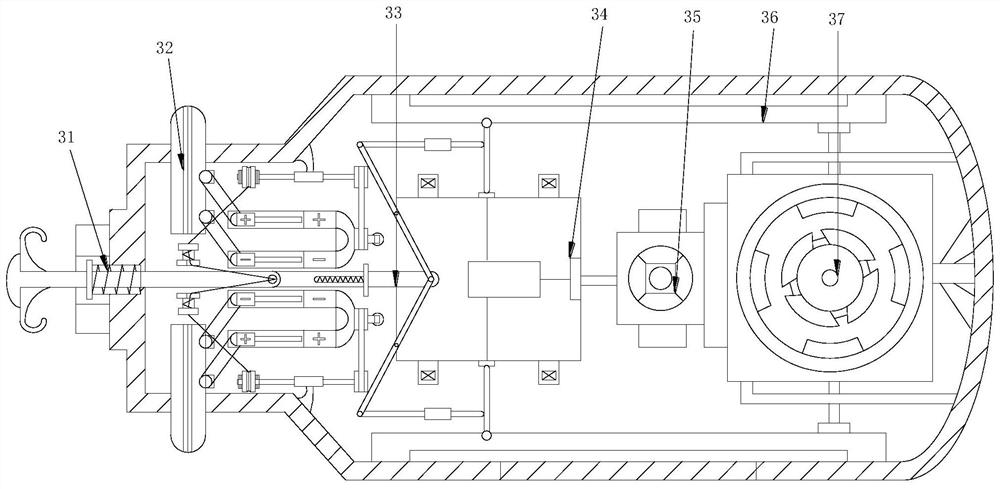

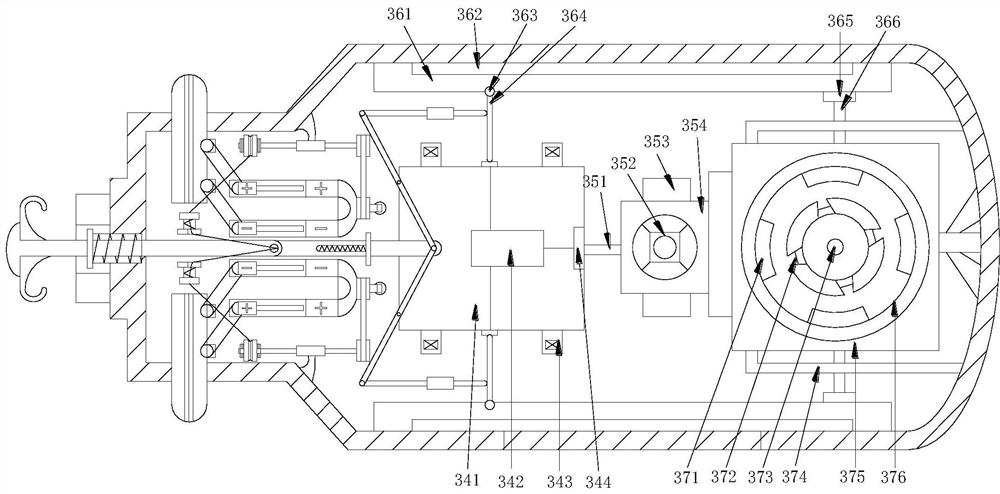

Forced circulation evaporation cooling device of hydraulic generator stator

InactiveCN1617426ARemarkable effectImprove insulation performanceCooling/ventillation arrangementSerial linePressure cycle

This invention relates to a cooling technology of motors providing a forcing circulation evaporation cooling device of a hydrogenrerator stator winding connection pipes connect the stator winding, a condenser, a pressure circulation pump and electro-hydraulic separation joints to an evcaporation cooling loop filled with evaporation cooling medium and a pressure circulation pump forcing the circulation of the evaporation cooling medium is also in the loop, every line-rod set consisting hollow heads and solid leads in the stator winding contains odd N serial line-rods, two leading out ends of the line rod set are connected with the up and down insulation lead pipes by the electro-hydaulic separation joints, several line-rod sets and a condenser constitute an independent evaporation cooling loop.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

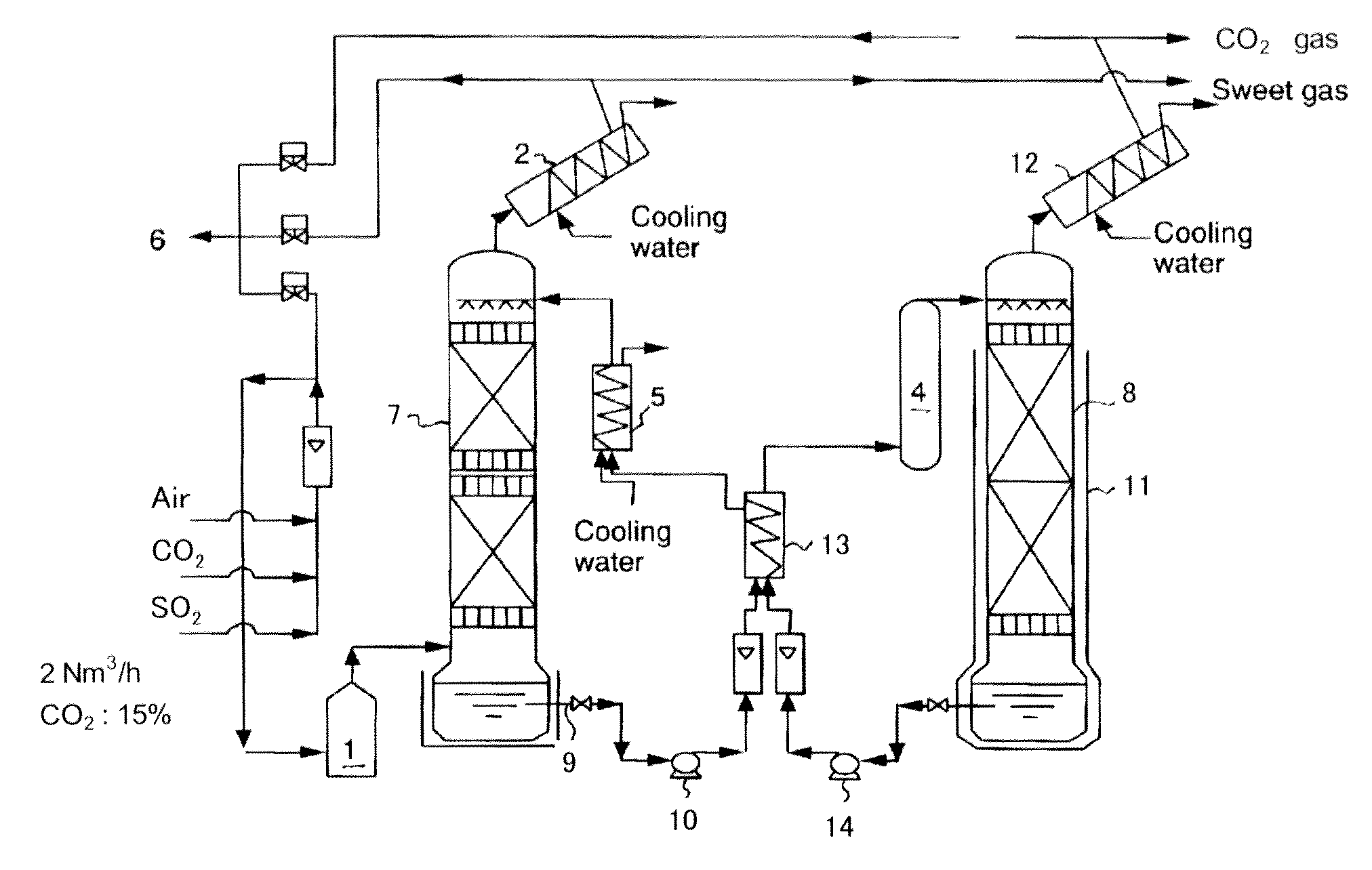

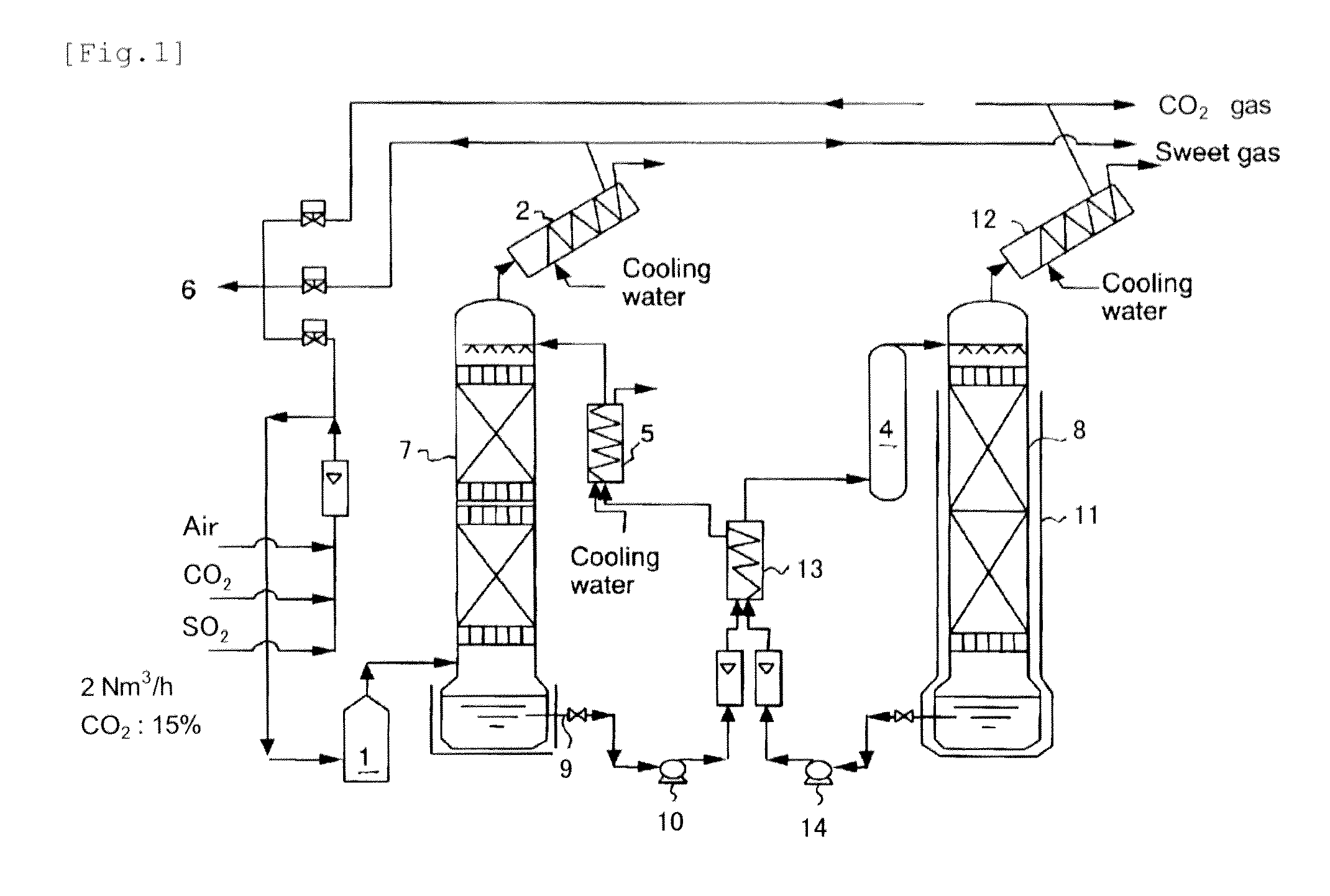

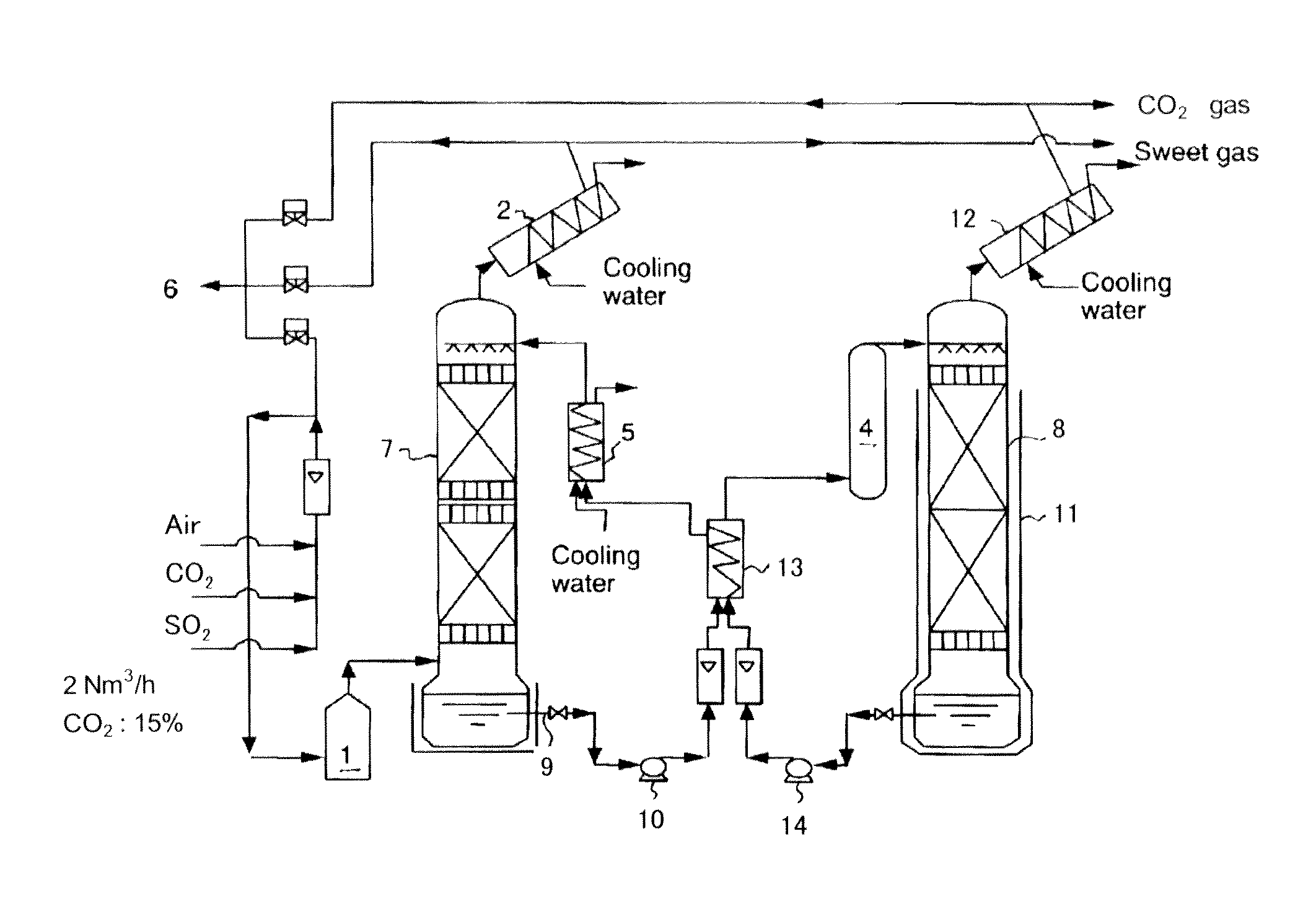

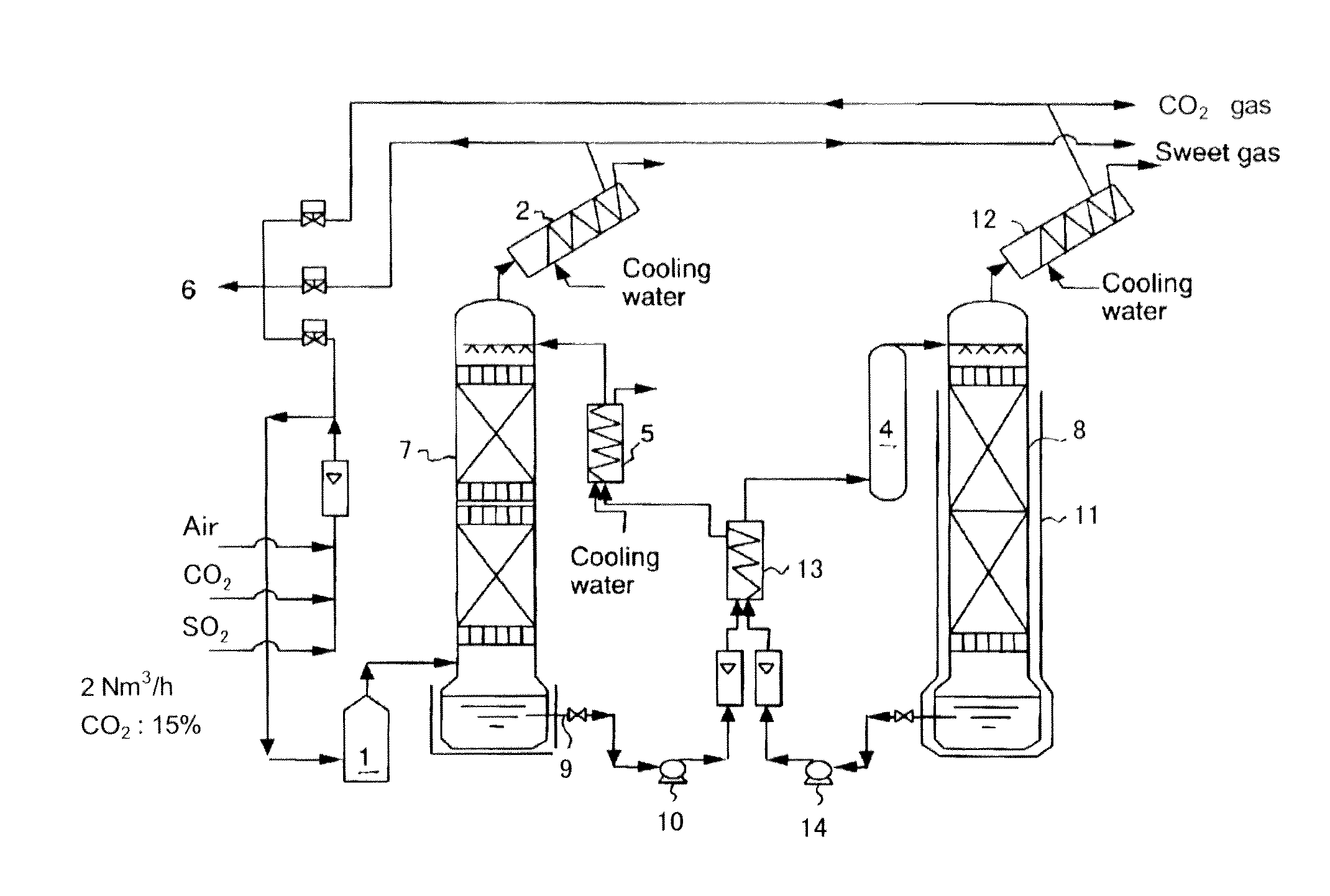

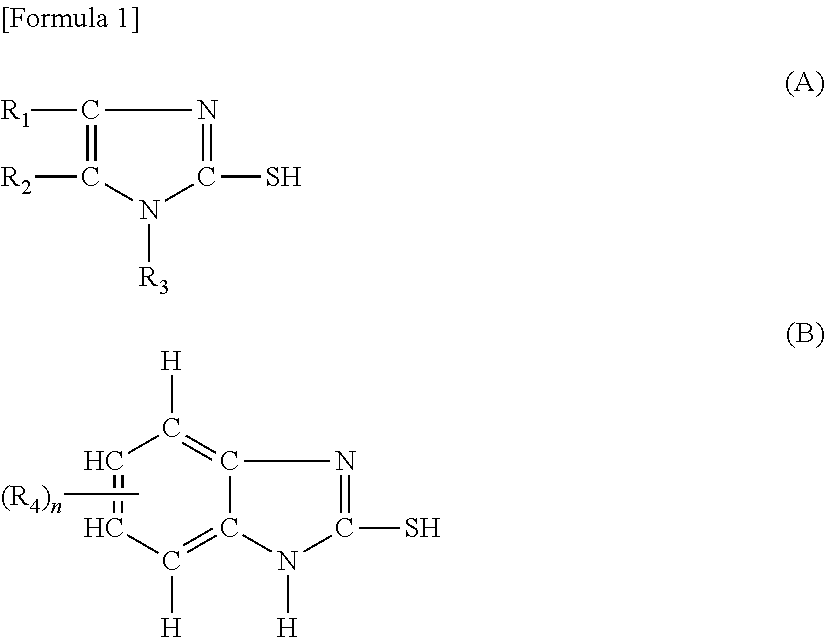

Carbon dioxide-absorbing solution and method of recovering carbon dioxide

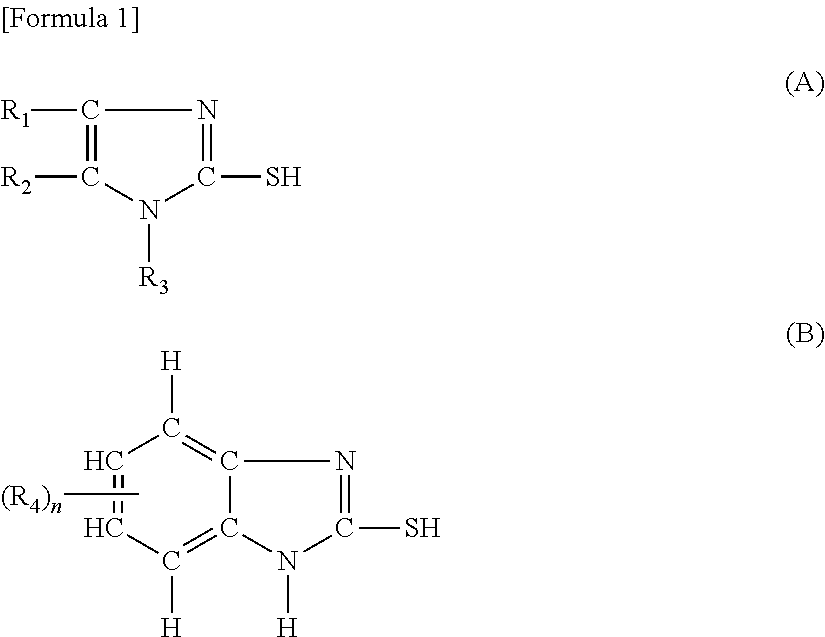

ActiveUS20120308469A1Replacement amount thereof be reduceDecrease in amountGas treatmentOther chemical processesChemistryAlkanolamine

A method of recovering carbon dioxide, including bringing gas to be processed containing carbon dioxide (CO2) and oxygen into contact with the CO2-absorbing solution according to Claim 1 in an absorption column to form a CO2-rich solution; subsequently circulating the solution in a regeneration column to thermally release and recover CO2 and recirculating the absorbing solution as a CO2-poor solution inside the absorption column; and performing heat exchange between the solution being delivered from the absorption column to the regeneration column and the solution recirculated from the regeneration column to the absorption column, wherein an alkanolamine aqueous solution containing a silicone oil and / or an organosulfur compound represented by the Formula (A) or (B) is added to the solution inside the absorption column and / or the solution recirculated from the regeneration column to the absorption column to adjust the composition of the absorbing solution inside the absorption column so as to include the alkanolamine in an amount of 30% by weight or more and 60% by weight or less, the organosulfur compound in an amount of 0.01% by weight or more and 2% by weight or less, and the silicone oil in an amount of 5 ppm by weight or more and 100 ppm by weight or less.

Owner:MITSUBISHI POWER LTD

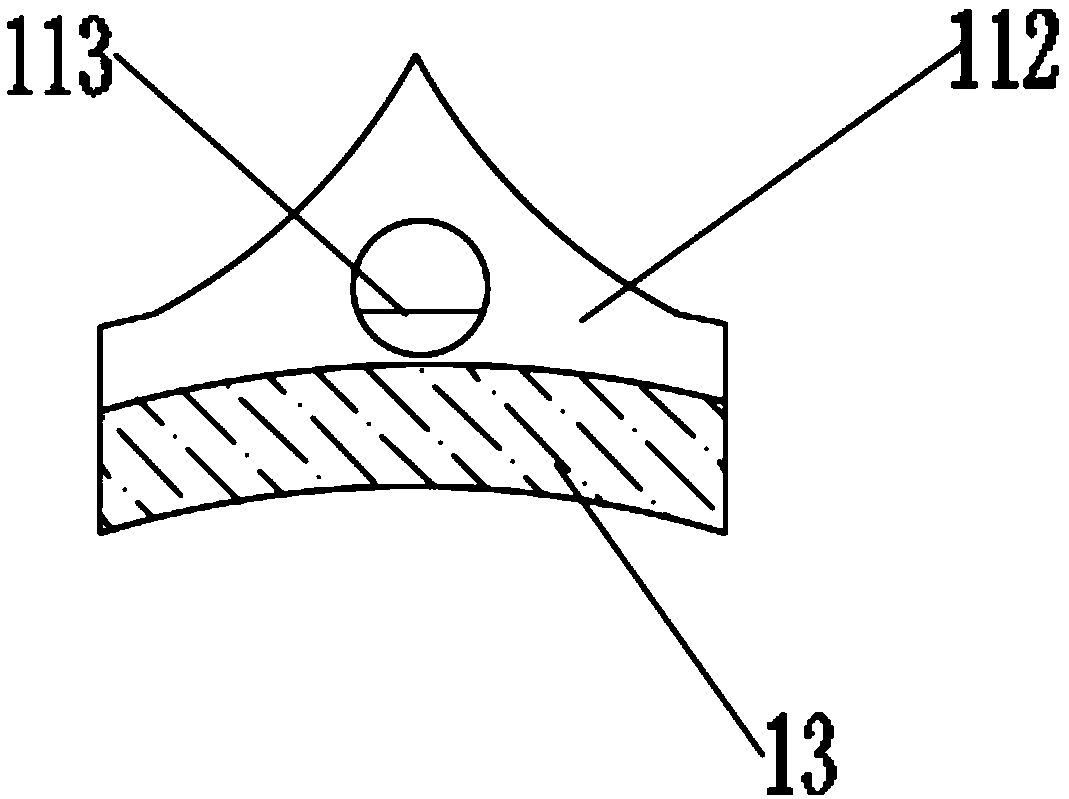

Sintering machine bogie wheels

ActiveCN100516743CReduce maintenance costsAvoid damageCharge manipulationFurnace typesBogieAgricultural engineering

The invention discloses a sintering machine trolley wheel which can improve the service life of the bearing. The sintering machine trolley wheel comprises a wheel body, a bearing, and a trolley axle. The bearing is sleeved on the end of the trolley axle, and the wheel body is sleeved on the bearing. Above, the bearing is provided with a lubricating port, the axle of the trolley is provided with a grease channel, one end of the grease channel is provided with a grease nozzle, and the other end communicates with the lubricating port.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

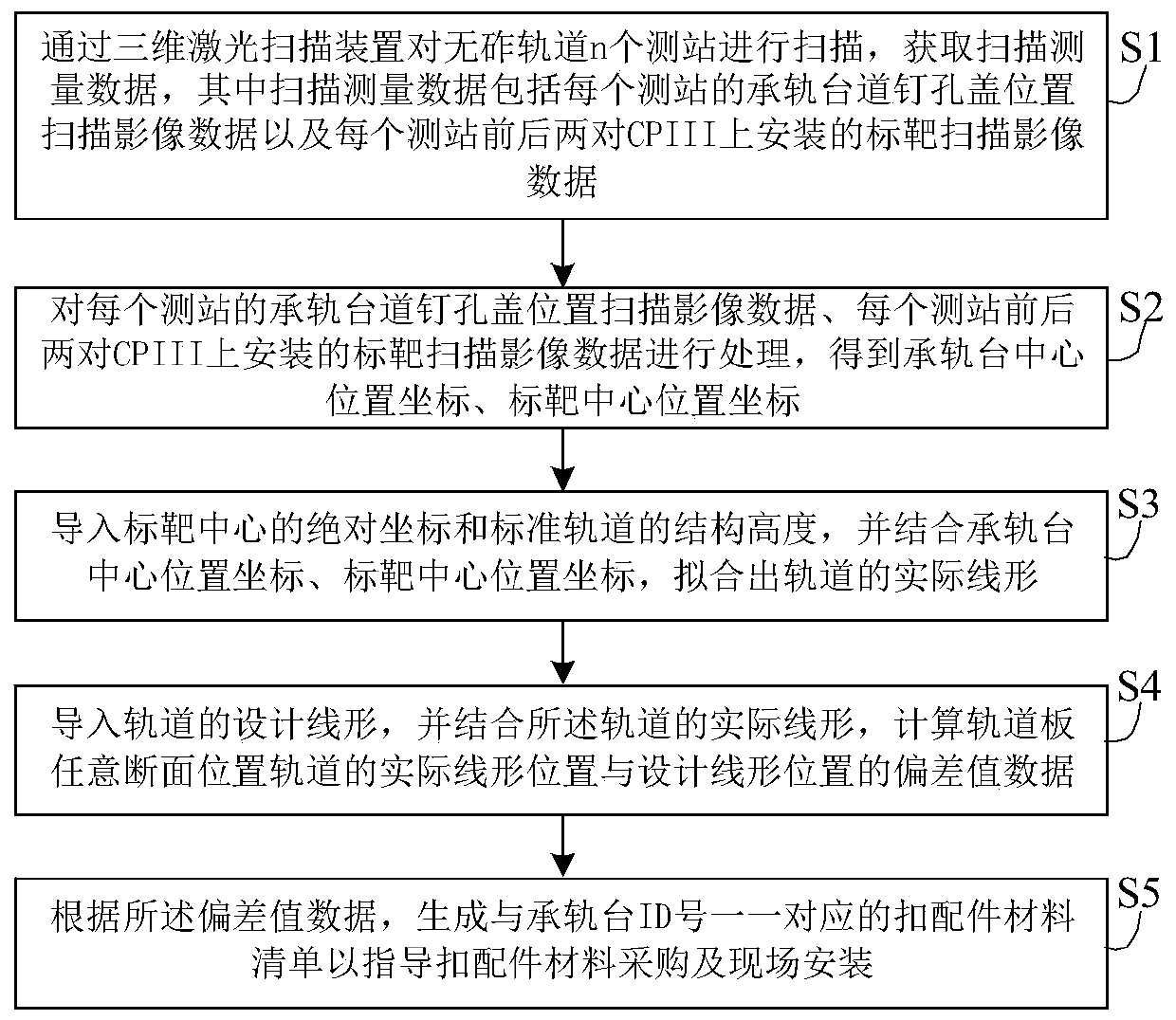

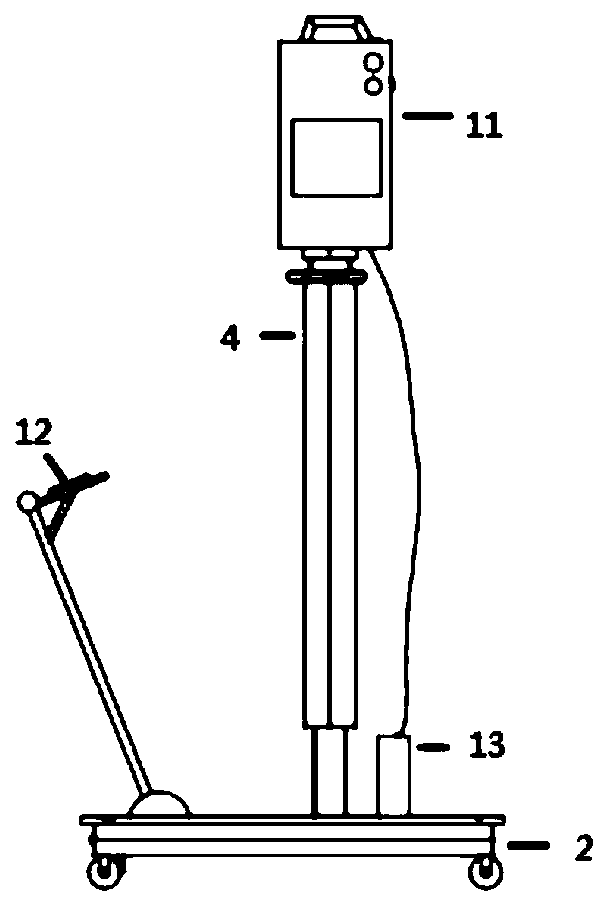

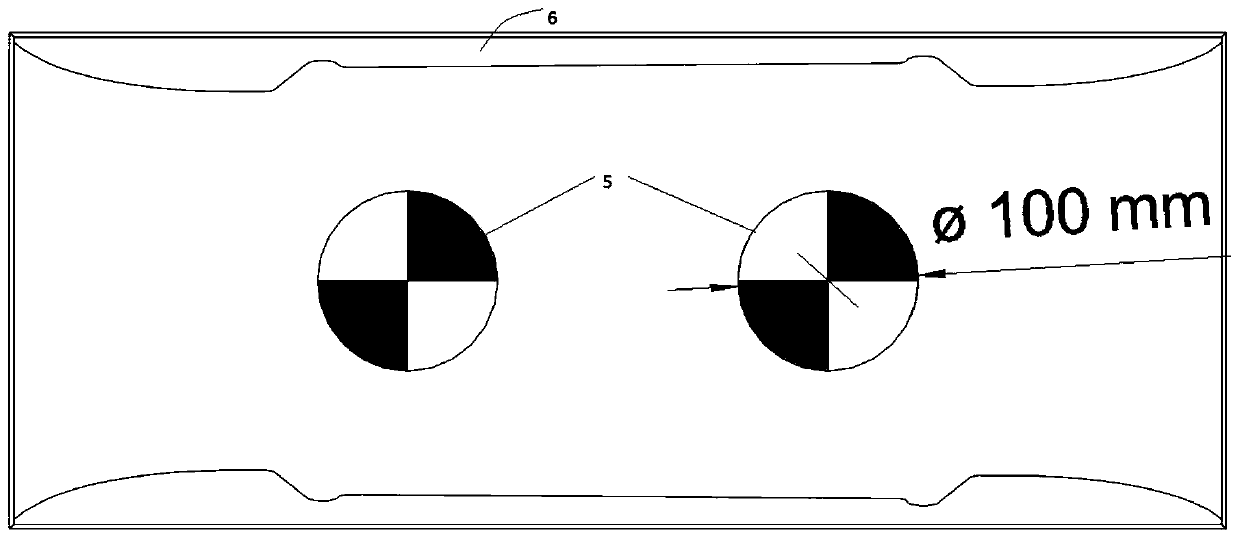

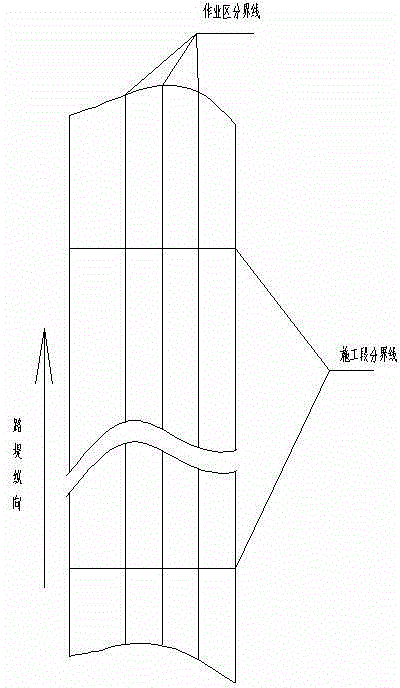

Crtsiii type slab ballastless track track slab laying accuracy detection method

ActiveCN108149535BImprove Ride AccuracyReduce fine-tuning workloadMeasuring apparatusLaser scanningRecognition algorithm

The invention discloses a laying precision detecting method of a CRTSIII plate-type ballastless-track track board, and belongs to the technical field of track construction. The laying precision detecting method comprises the following steps that scanning data of n detecting stations of the ballastless track are obtained through a three-dimensional laser scanning device; track bearing table position scanning data of each detecting station, scanning data of targets mounted on the two pairs of CPIII on the front and rear of each detecting station are processed by using a grayscale recognition algorithm, the track bearing table center position coordinates and the target center position coordinates are obtained; the absolute coordinate of a CPIII net and the structure height of a standard trackare guided into, and an actual line shape of the rack is fitted; the designed line shape of the track and the curve segment track super high value are guided into, deviation value data of the actualline shape position and the designed line shape position of the track at any section position of the track board are calculated; and a material list of fastener parts corresponding to the track bearing table ID numbers in a one-to-one mode is generated according to the deviation value data. The laying precision detecting method improves the work efficiency of CPISIII plate retest, reduces the replacement rate of the standard fastener parts, and saves the cost.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP +1

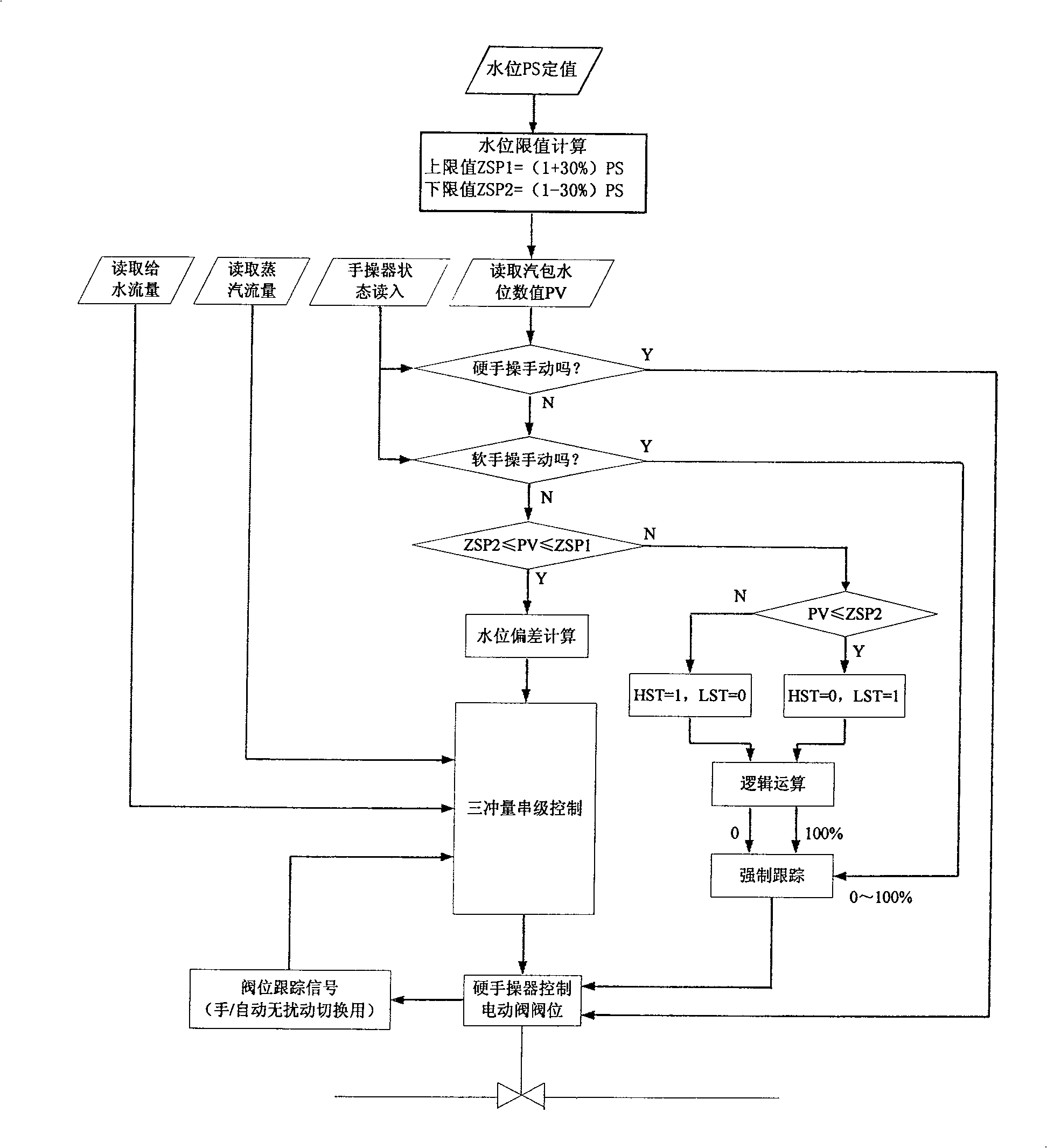

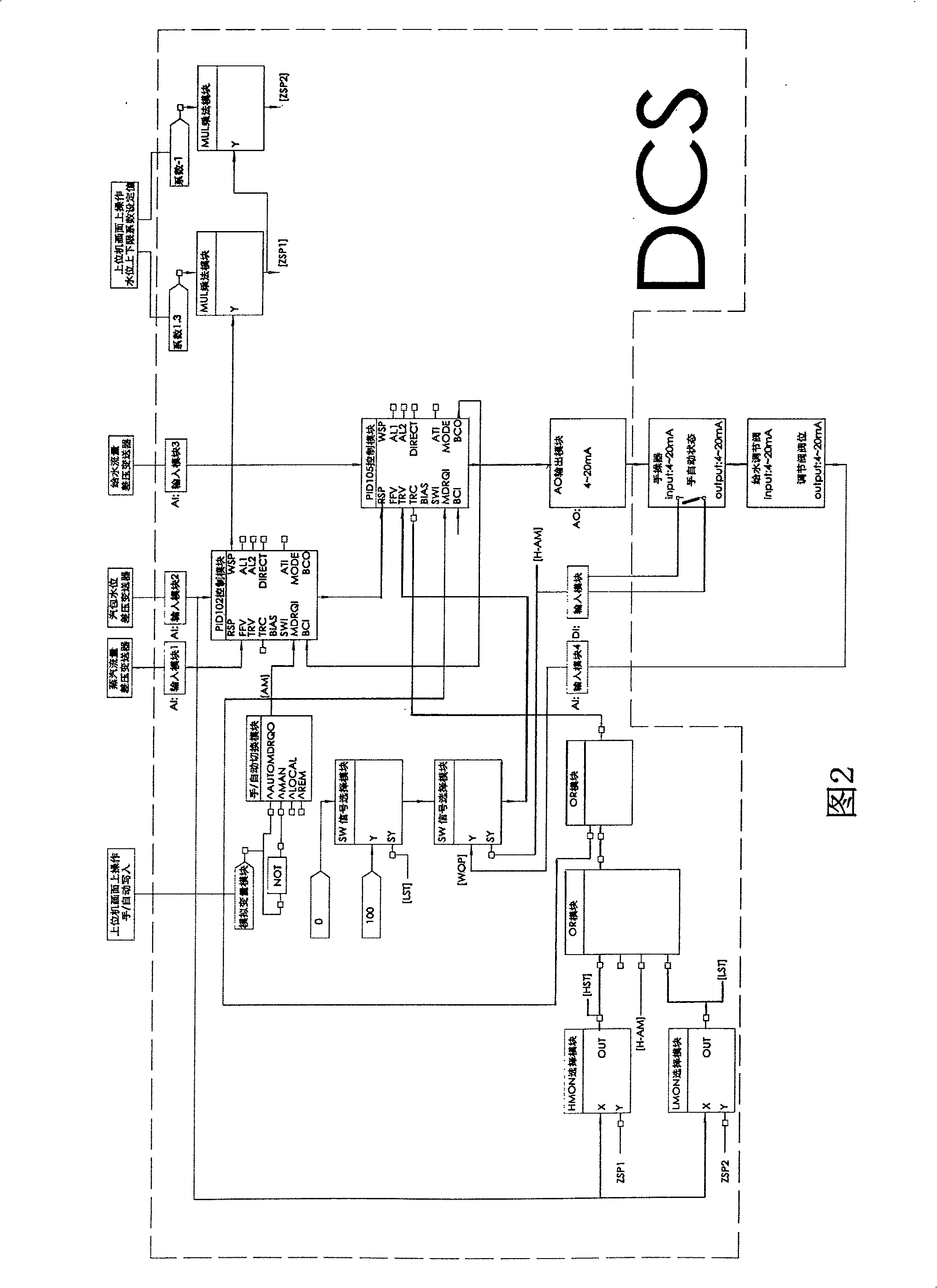

Control method of boiler water level and its control system

InactiveCN100535513CGuaranteed safe operationReduce maintenance workloadWater feed controlLimit valueElectric control

A boiler water level control method and its control system, based on the principle of three-impulse cascade control, controls the valve position of the feed water regulating valve; the control system can also compare the upper and lower limit values of the water level from the steam drum with the water level tracking value respectively The signal directly controls the full closing and full opening of the water supply regulating valve. The boiler water level control system working in the above method is composed of three-impulse transmitters for steam drum water level, steam flow rate and feed water flow rate, controller, upper computer, hand operator and electric water feed regulating valve. , The selection module and the comparison module are used to calculate the upper limit value and the lower limit value of the water level, set the limit valve position, and judge the state of the water level exceeding the limit. The system responds quickly and has a high level of automation, reducing labor intensity and ensuring safe operation of the boiler.

Owner:SHANGHAI HONGJIAN AUTOMATION EQUIP

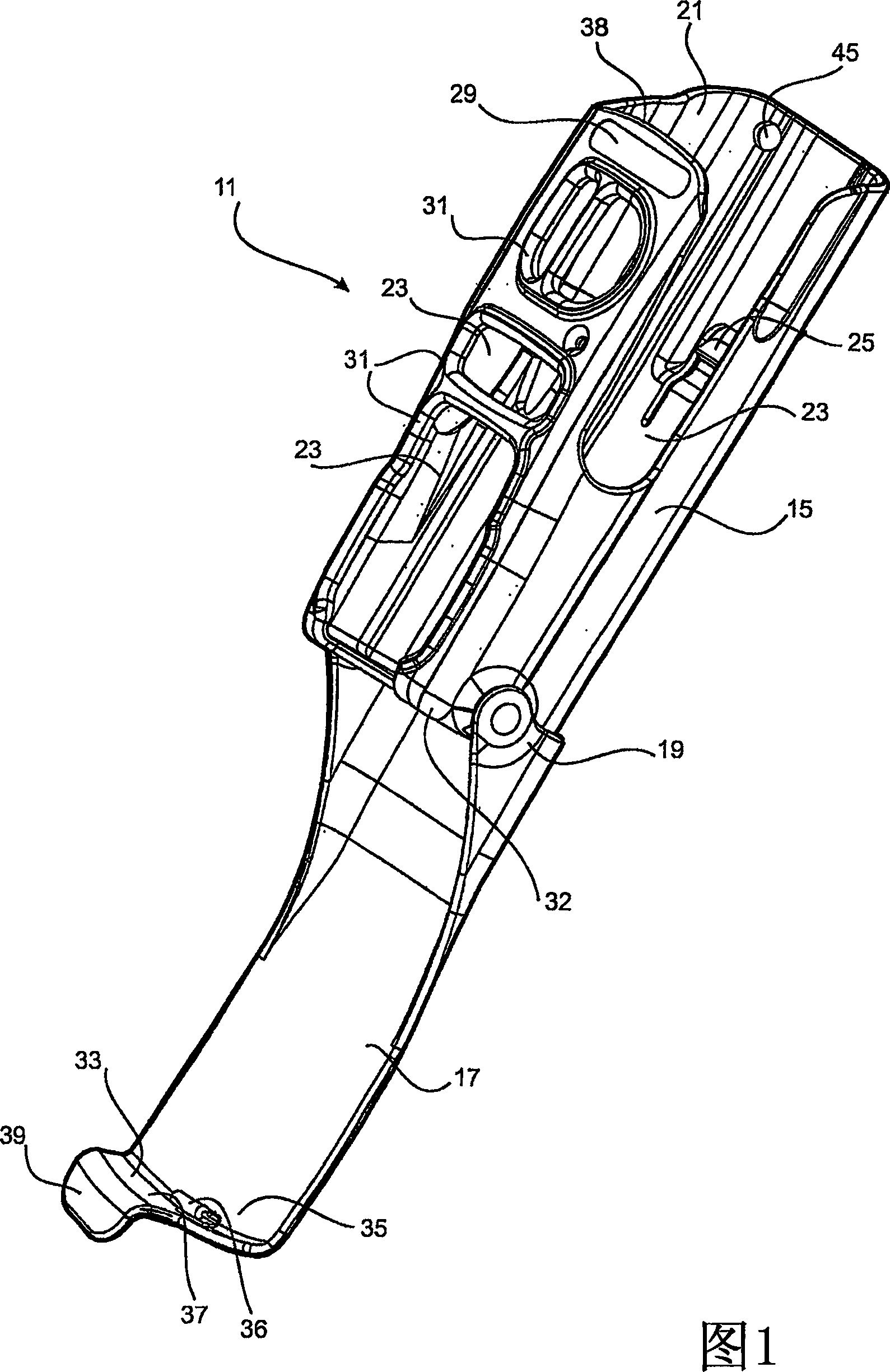

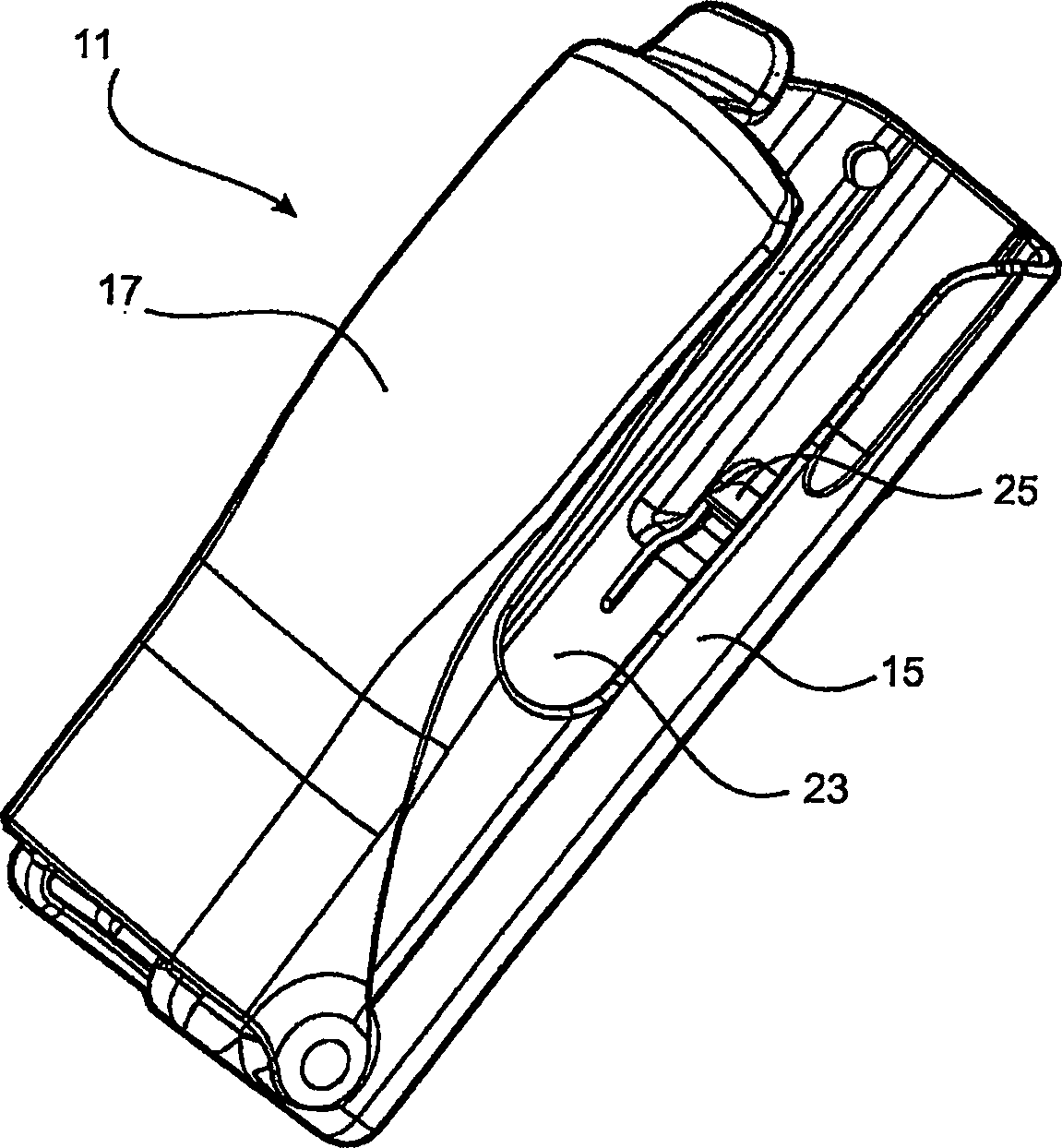

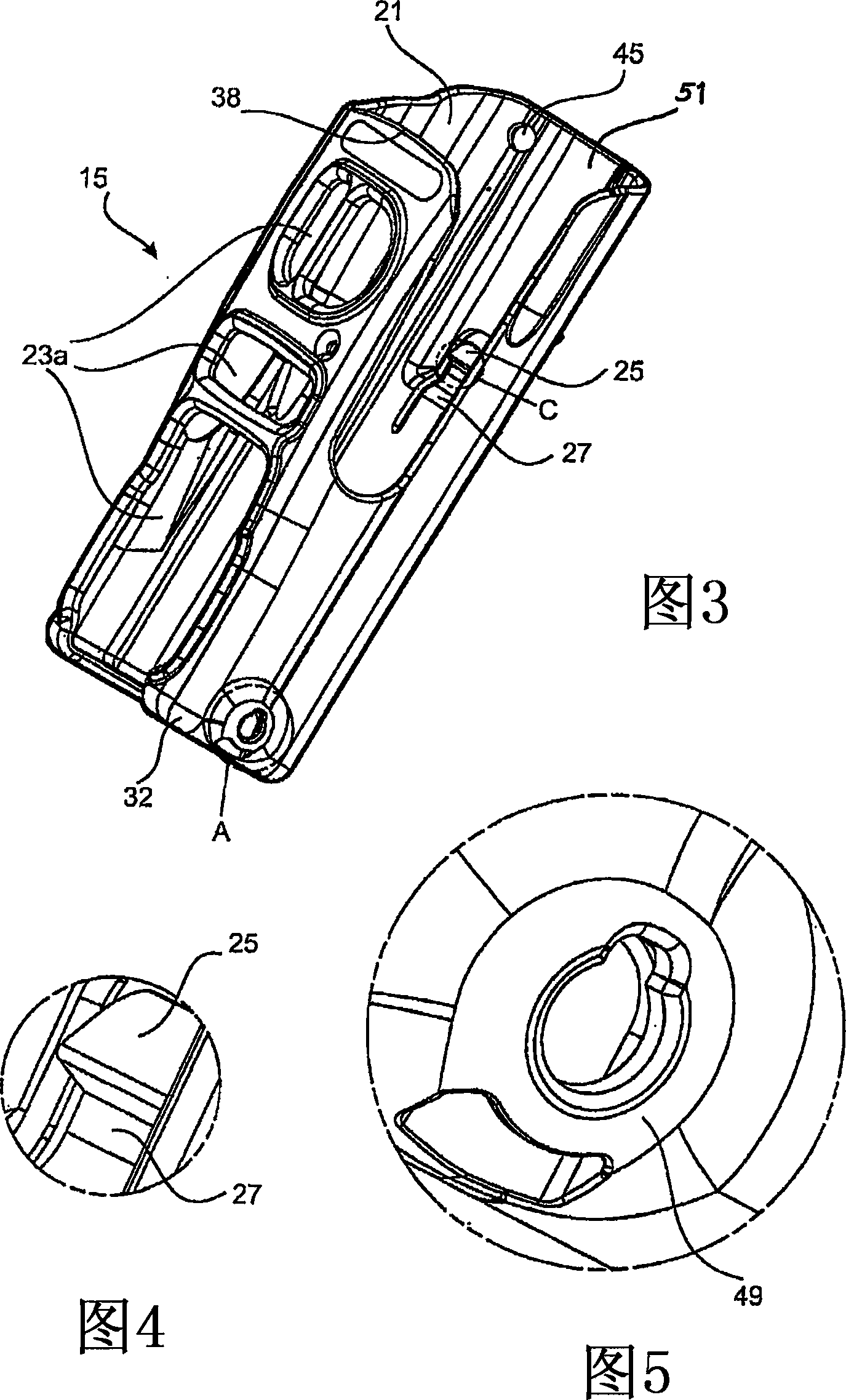

Protective shroud

InactiveCN1883183AReduce maintenanceReduce the amount of replacementTravelling carriersHoldersBiomedical engineeringCommunication device

A shroud (11) for protecting a communication device, the shroud (11) comprises a receptacle (15) having an opening (21) to receive the device. The receptacle (15) is adapted to releasably retain the device therein. The shroud (11) is movable between a closed condition and an open condition, wherein in the open condition the communication device is fully operable, while in the closed condition the communication device is substantially protected from damage.

Owner:SENTINEL GARDENS

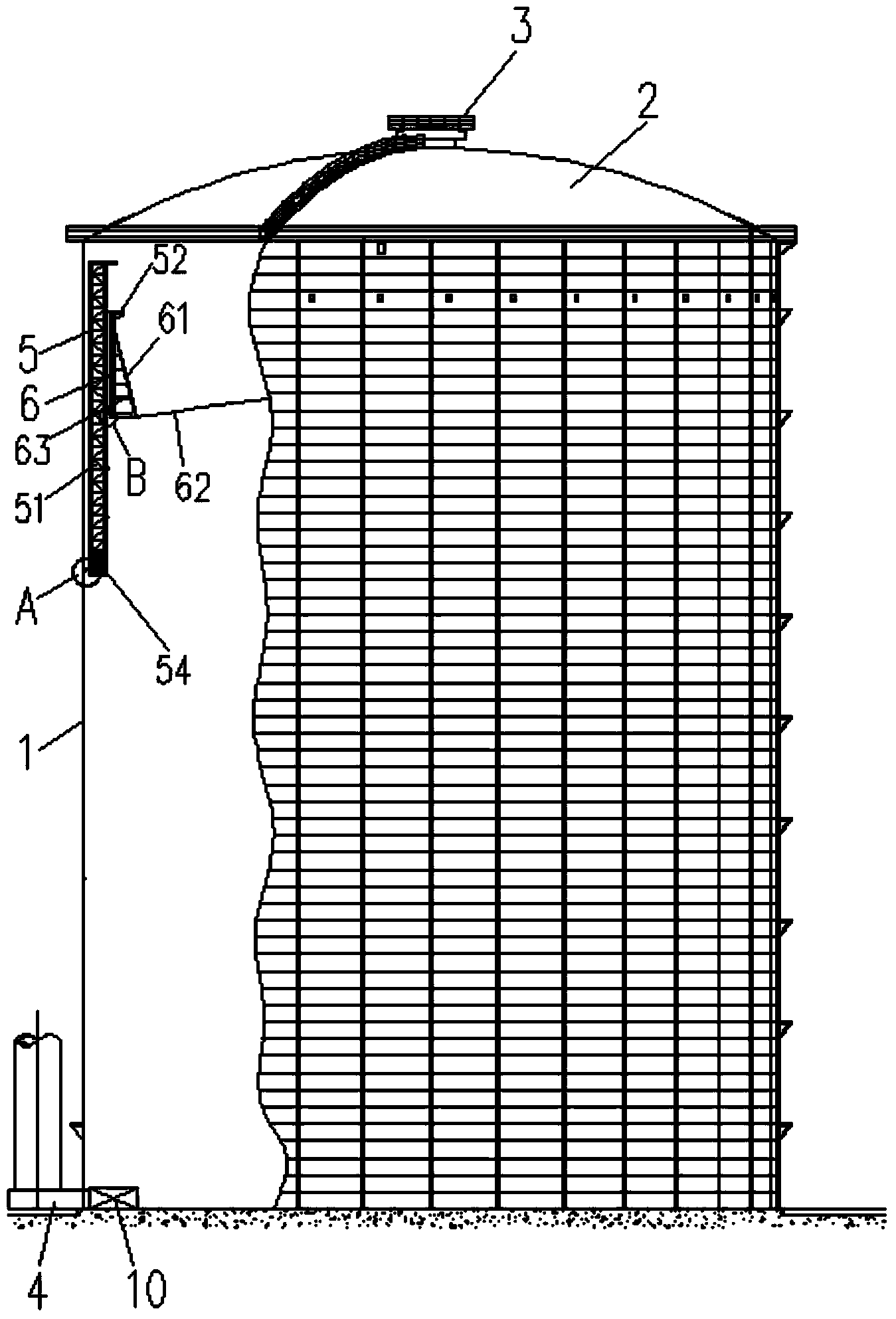

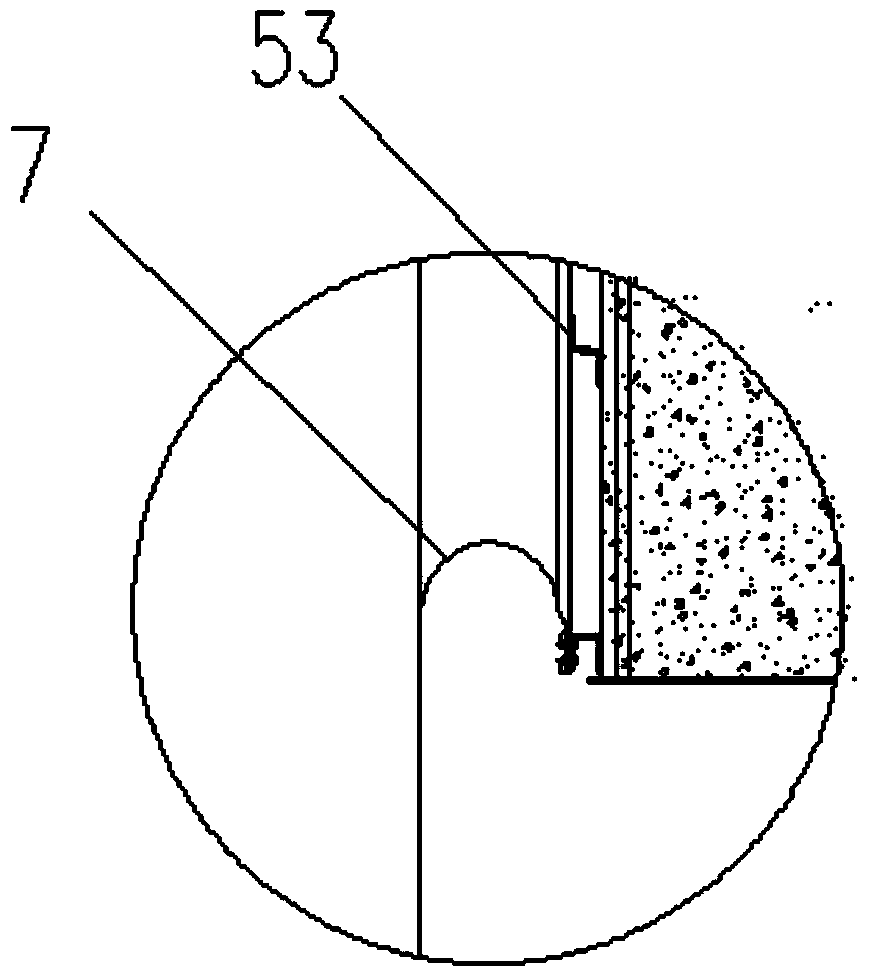

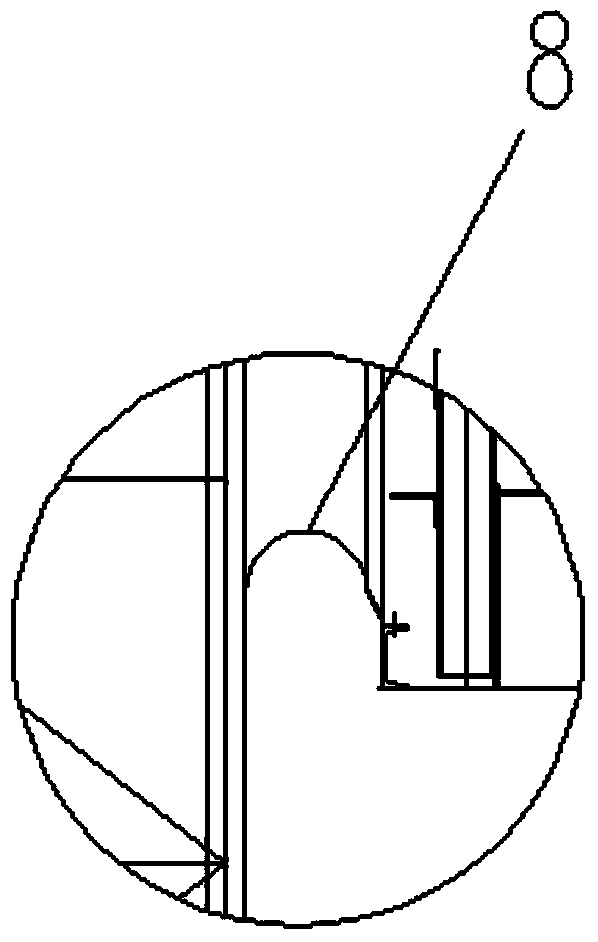

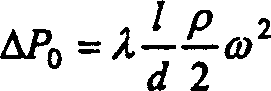

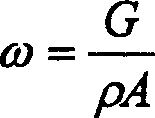

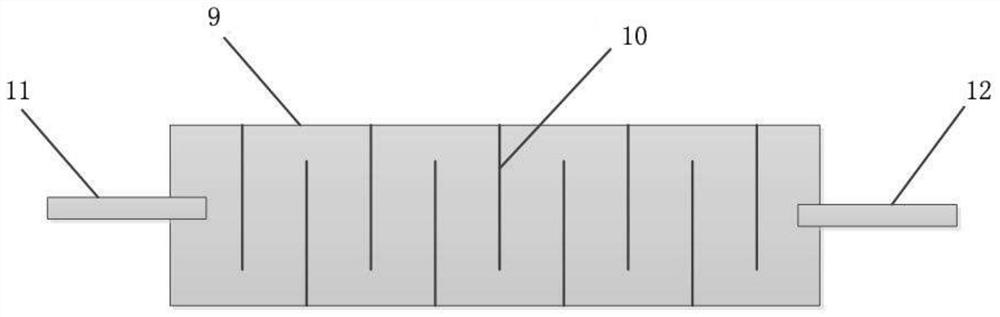

Sliding type H-type piston coal gas tank and sliding type H-type piston thereof

ActiveCN103629520AImprove the ability to withstand work pressureReduce steel consumptionVariable capacity gas holdersNitrogenEngineering

The invention discloses a sliding type H-type piston coal gas tank and a sliding type H-type piston thereof. The sliding type H-type piston coal gas tank comprises a coal gas tank barrel, wherein a roof deck and a ventilation clerestory are arranged at the top of the coal gas tank barrel; a gas inlet is formed at the bottom of the coal gas tank barrel; the coal gas tank barrel is internally provided with a sliding type H-type piston which can slide along the inner wall; the sliding type H-type piston comprises a piston rail frame which can slide along the inner wall of the coal gas tank barrel; the inner wall of the piston rail frame is provided with a sliding type liner piston arch capable of sliding along the inner wall of the piston rail frame; the sliding type liner piston arch comprises a liner piston, a piston plate and a piston plate supporting truss; a rubber sealing film is arranged between the sliding type H-type piston and the inner wall of the coal gas tank barrel; and a liner rubber sealing film is also arranged between the sliding type liner piston arch and the inner wall of the piston rail frame. According to the sliding type H-type piston coal gas tank and the sliding type H-type piston thereof, an outer pressure calculation height of a piston cylinder can be reduced, the steel consumption amount of the piston is reduced, the displacement amount of nitrogen is reduced and the displacement time of the nitrogen is shortened.

Owner:CISDI ENG CO LTD

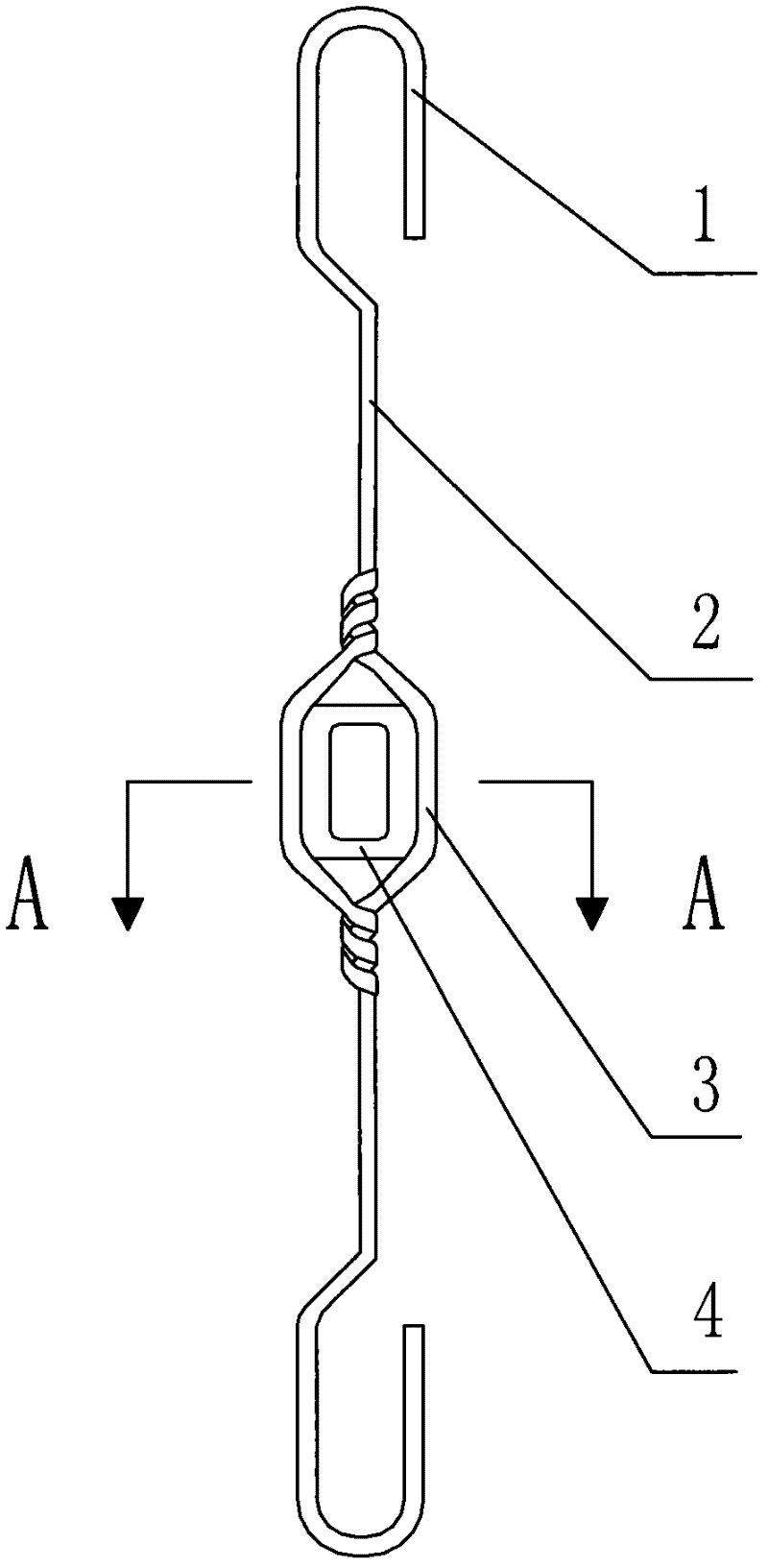

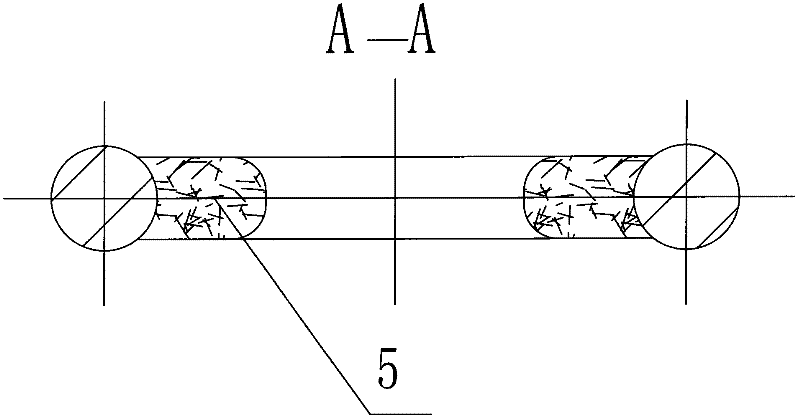

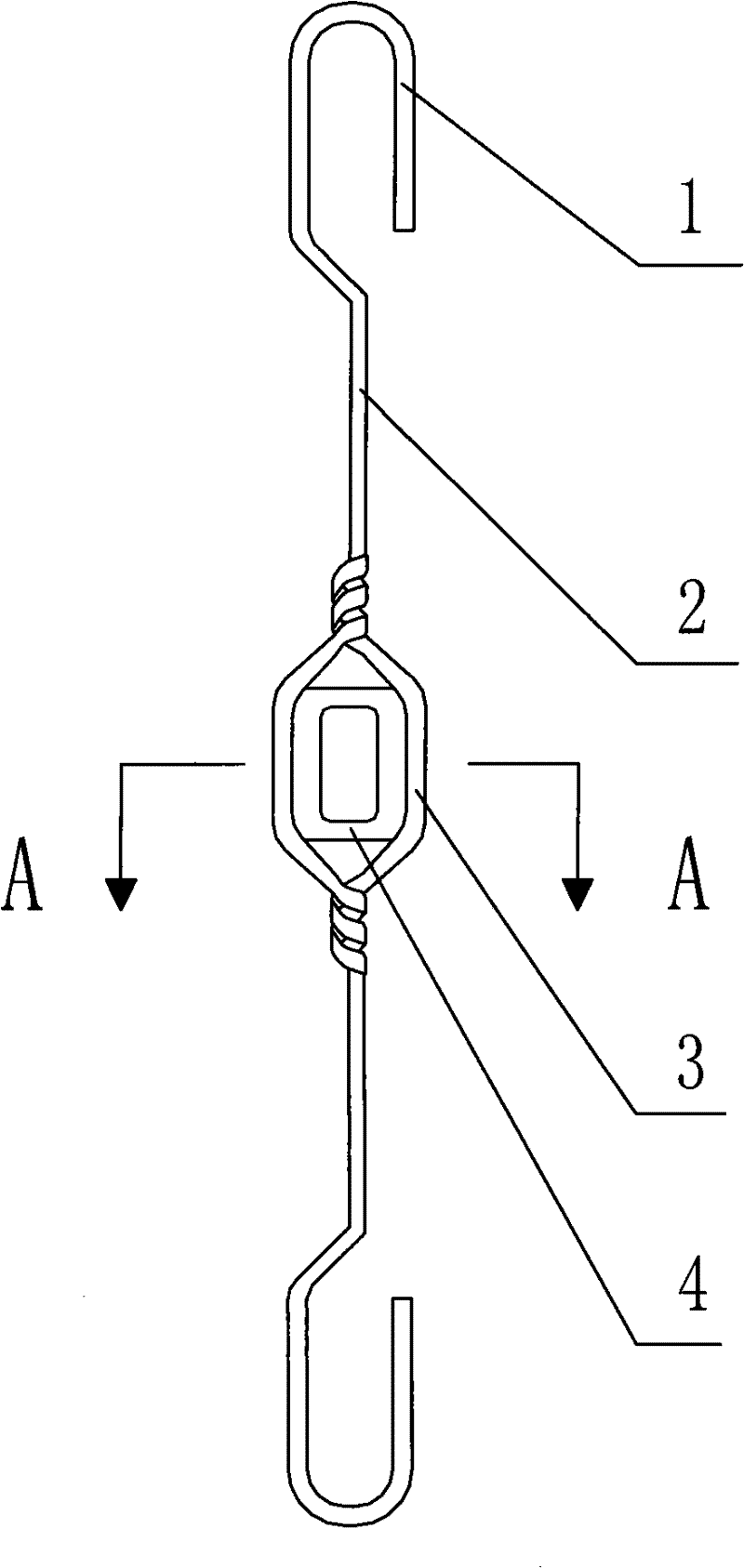

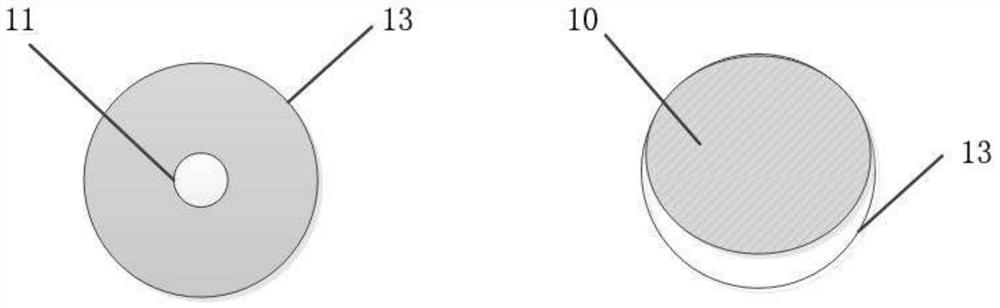

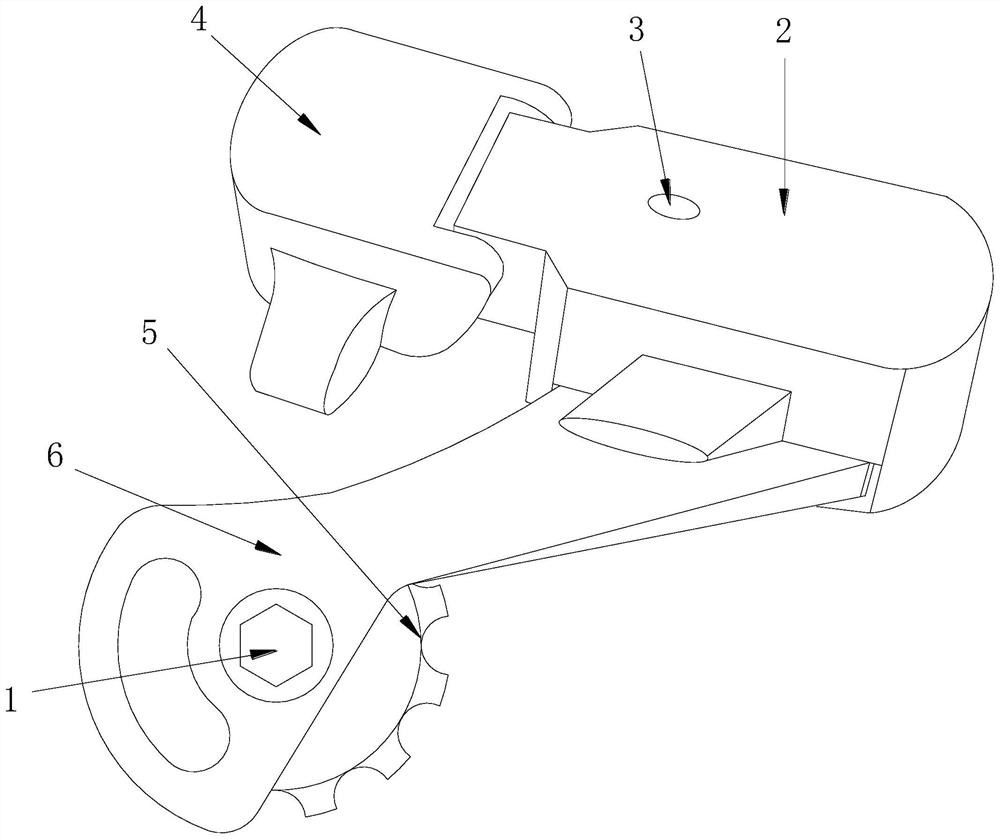

Wear resistant palm fiber

InactiveCN102477607AReduce the amount of replacementImprove wear resistanceCircular loomsHealdsWear resistantEconomic benefits

The invention relates to the field of textile accessories and especially to a wear resistant palm fiber for a matched circular weaving machine. The wear resistant palm fiber comprises a palm fiber fixing hook, a drawing metal line and a fiber threading hole, wherein, a wear resistant loop is clamped in the fiber threading hole, an outer ring of the wear resistant loop is provided with a groove matched with an inner ring of the wear resistant loop, and the wear resistant loop is made of a manganese steel alloy material. According to the invention, the wear resistant loop is clamped in the fiber threading hole, which enables wear resistance of the fiber threading hole to be substantially improved and the service life of the palm fiber to be prolonged; and the wear resistant palm fiber has an improved structure, so when the palm fiber is worn, it only needs to replace the wear resistant loop without replacing the whole palm fiber, thereby lowering down production cost and improving economic benefits.

Owner:曾华良

Variable-pressure adsorption method using auxiliary system

A pressure-variable adsorption process with auxiliary system features use of a primary adsorption-regeneration cyclic system composed of two or more adsorption towers and an additional adsorption-regeneration cyclic system also composed of two or more adsorption towers. The charge gas is input to the said primary system which outputs the components difficult to be adsorbed. When the content of the components easily adsorbed in the primary system is going to go beyond the standard value, its output is switched to the said additional system. It can simulatenious obtain high-purity easily adsorbed components and difficultly adsorbed components with high output rate and low cost.

Owner:王玉

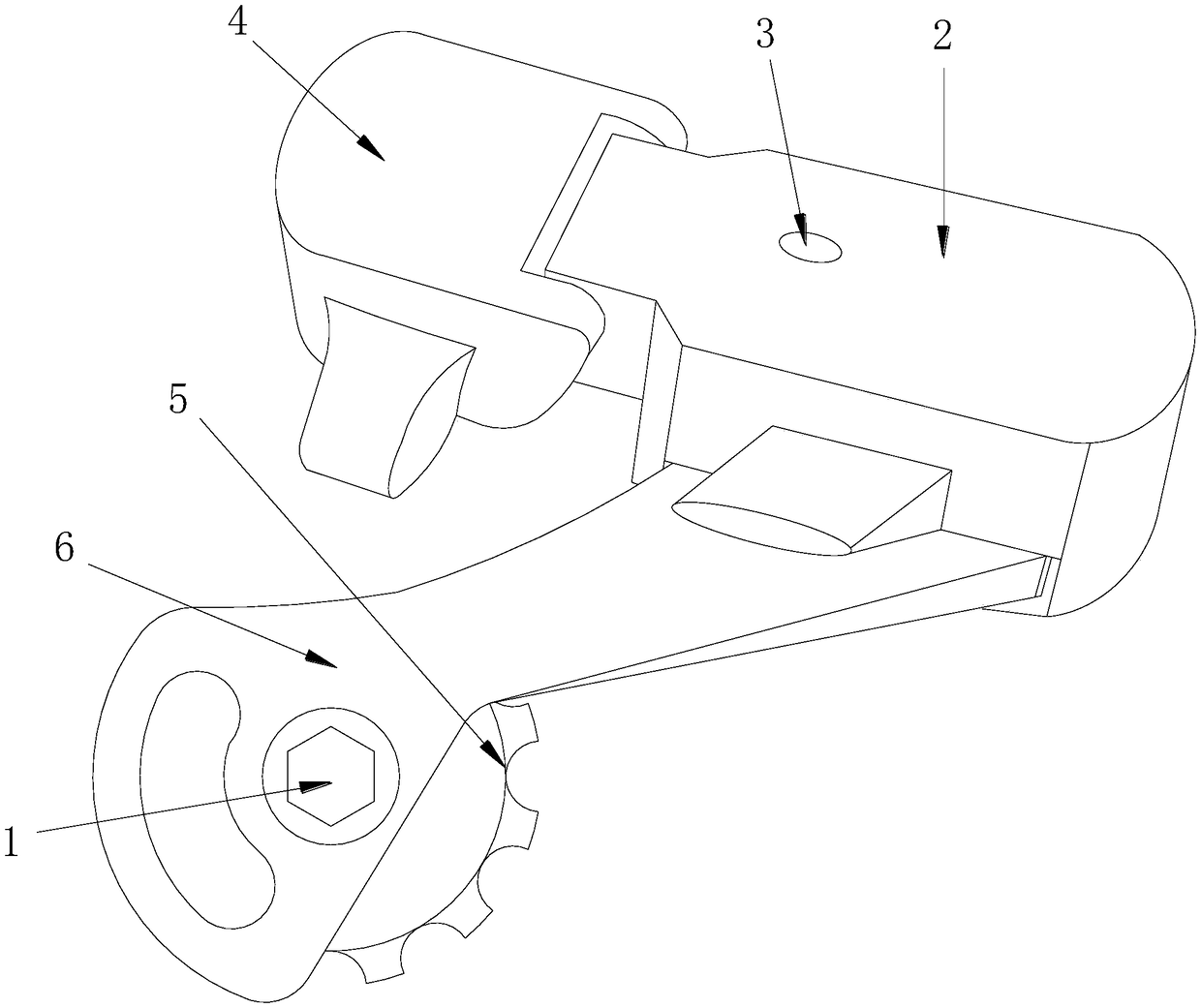

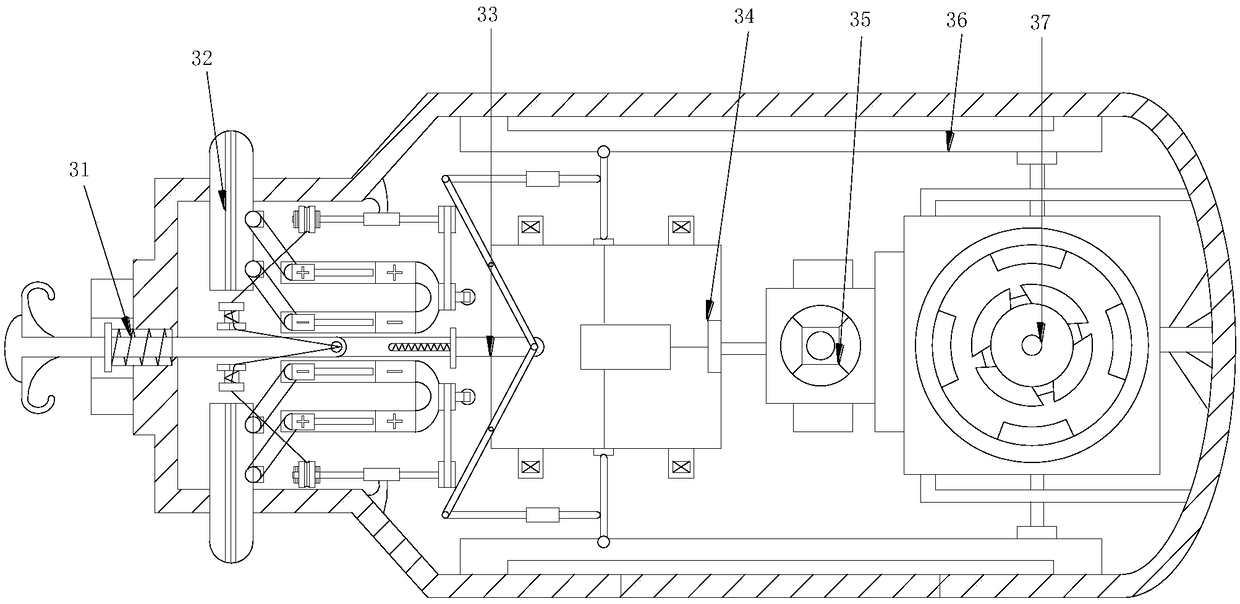

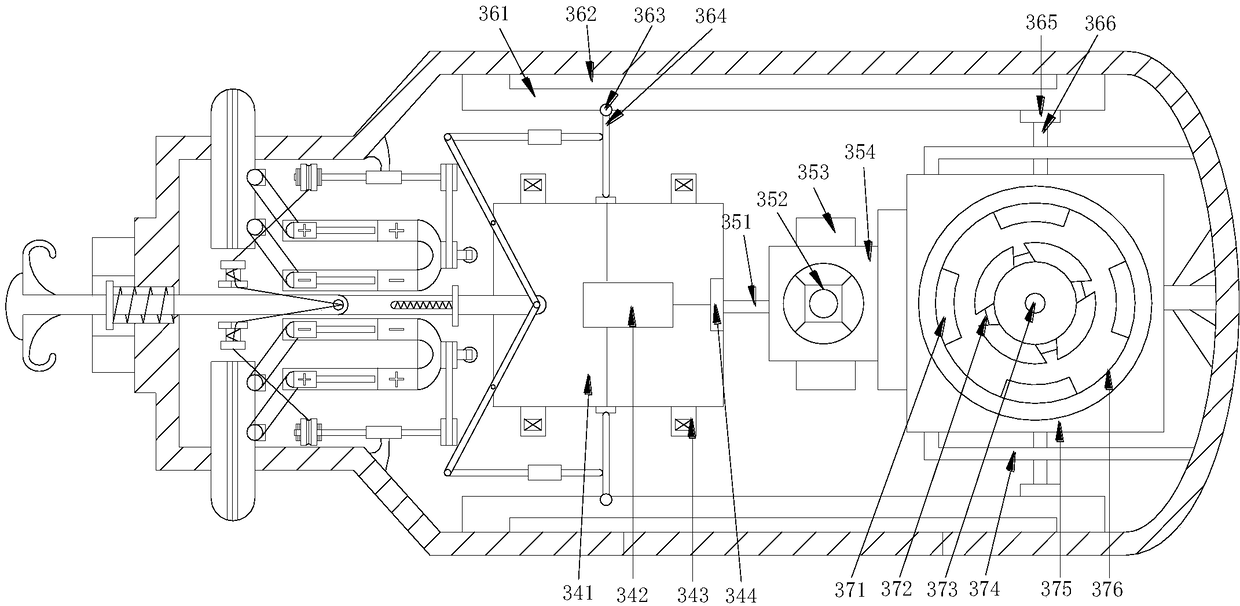

Transmission control device based on big data management mode

InactiveCN109050780AReduce the amount of replacementAvoid wastingChain/belt transmissionElectricityAutomatic transmission

The invention discloses a transmission control device based on a big data management mode, the structure comprises a lock nut, waterproof housing, Transmission control, fixed head, Variable speed seatplate, the transmission control unit is integrally mounted inside the waterproof housing in an embedded manner, the invention mainly utilizes the double-contact hair-generating mechanism, abduction positioning mechanism, co-actuated control mechanism, CONDUCTIVE MECHANISM FOR RECEIVING PROCESSING, main power output mechanism, power storage mechanism, power generating mechanism, the transmission adopts the double-contact generating mechanism, abduction positioning mechanism, the cooperating electric control mechanism cooperates with each other to carry out integral split-type fixing, when theinternal parts are damaged, the whole part can be removed and repaired only by operation of the two-contact mechanism, The energy is converted and stored by the power storage mechanism and the power generation mechanism, and the power supply of the automatic transmission is realized by the mutual cooperation of the receiving and processing conductive mechanism and the main force output mechanism.

Owner:温永宁

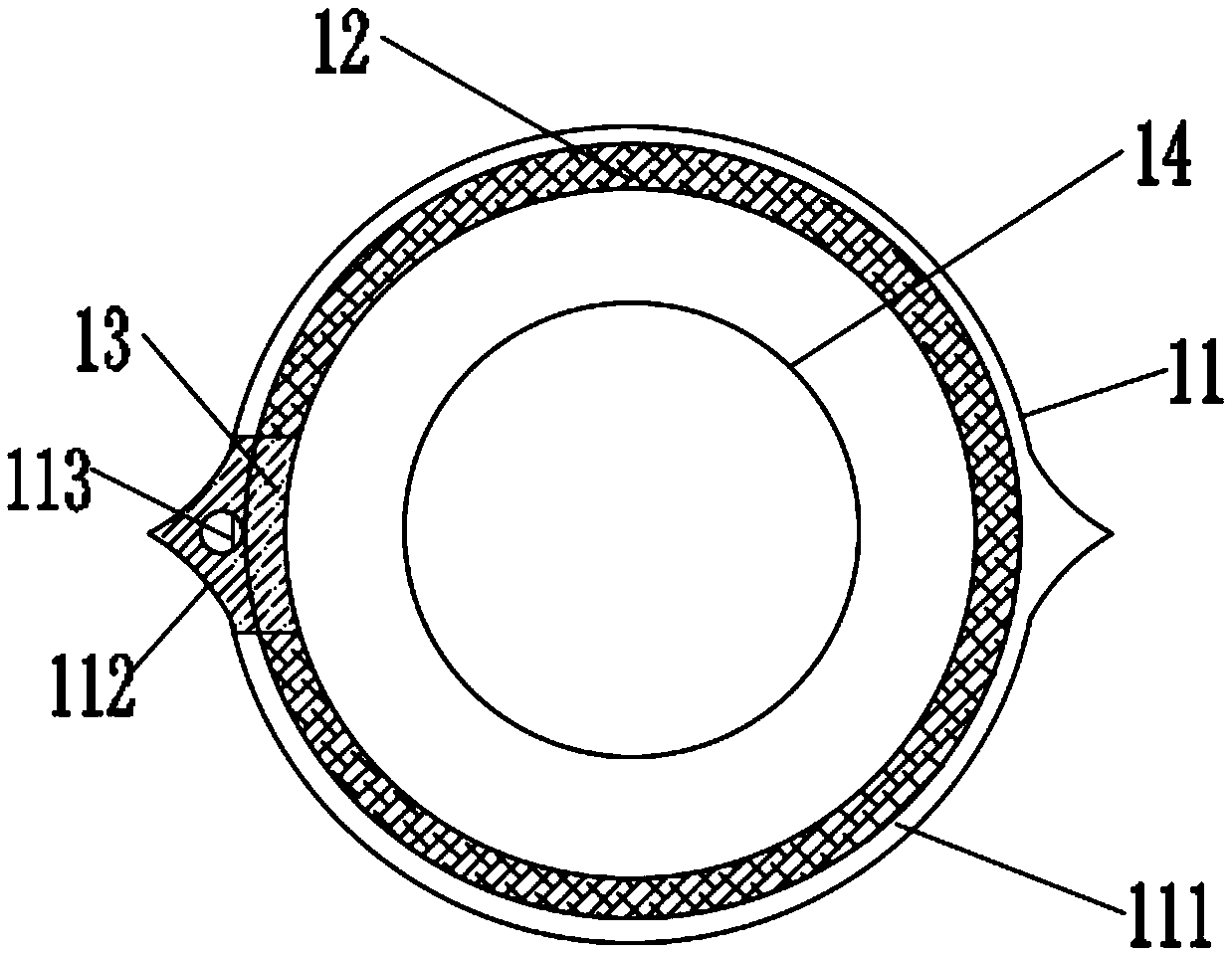

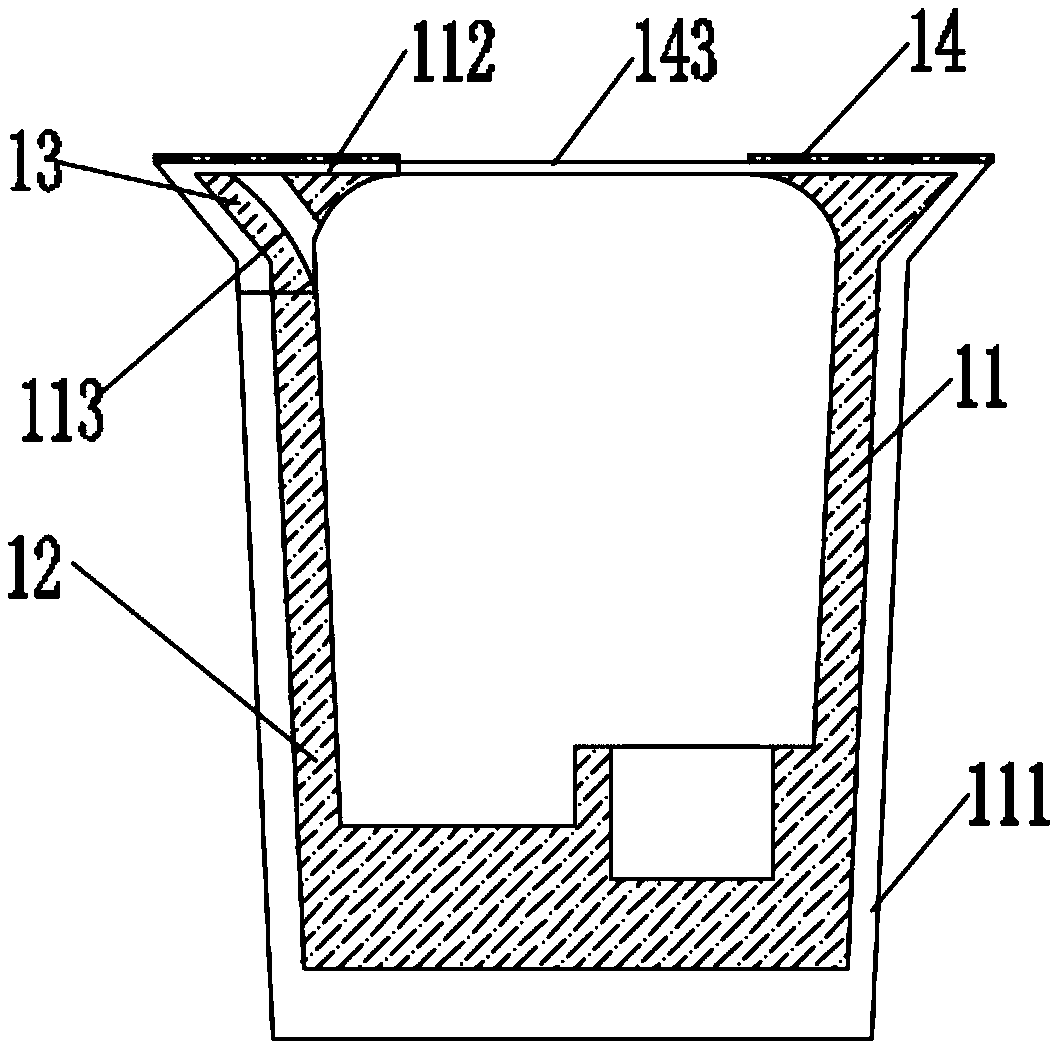

Casting ladle and device for preparing nodular cast iron

InactiveCN108838383AReduce the amount of replacementReduce manufacturing costMelt-holding vesselsEconomic benefitsDuctile iron

The invention provides a casting ladle and a device for preparing nodular cast iron. The casting ladle comprises a shell, a first fire-retarding portion and a second fire-retarding portion. The shellcomprises a ladle body and a ladle nozzle. The first fire-retarding portion is attached to the inner surface of the ladle body. The second fire-retarding portion is attached to the inner surface of the ladle nozzle. With the casting ladle and the device for preparing nodular cast iron, the problem that a fire-retarding portion of a ladle nozzle of an existing casting ladle is corroded badly, and the cost of replacement is high. Because the first fire-retarding portion is attached to the inner surface of the ladle body, and the second fire-retarding portion is attached to the inner surface of the ladle nozzle, the ladle body and the fire-retarding portion of the ladle nozzle are cast independently, the ladle nozzle can be replaced independently, operation is more convenient and quick, the production efficiency is improved, and the economic benefit is good.

Owner:西峡县众德汽车部件有限公司

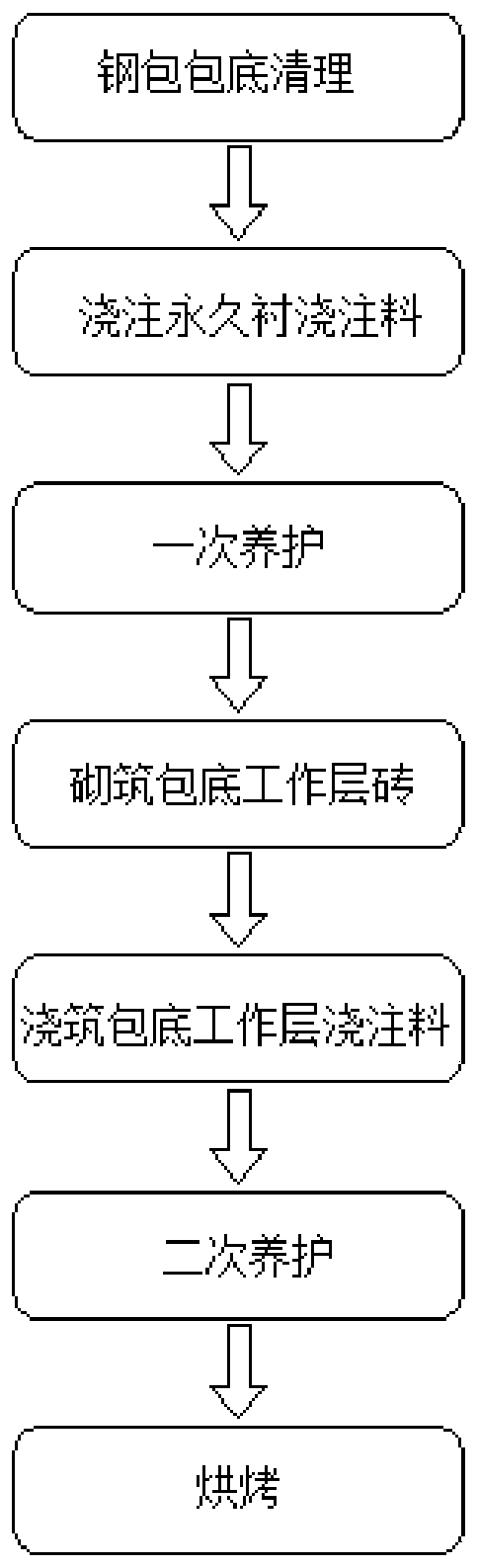

Carbon-free steel ladle composite ladle bottom constructing technology

The invention provides a carbon-free steel ladle composite ladle bottom constructing technology. The technology is applied to guarantee that the ladle bottom repairing difficulty and the repairing cost are reduced while a ladle bottom is safely used. The carbon-free steel ladle composite ladle bottom constructing technology comprises the following steps that a ladle bottom is cleaned, pouring of perpetual lining casting materials is carried out, maintaining is carried out, pouring of ladle bottom working layer casting materials is carried out, maintaining is carried out, ladle bottom working bricks are constructed, and baking is carried out; and the technology is used for constructing the ladle bottom, the first-layer perpetual lining casting materials can achieve the aims of guaranteeingthe ladle bottom safety and the thermal insulation and heat preservation effect, the second-layer ladle bottom working layer casting materials guarantee the using safety of the repaired ladle bottom,and the third-layer carbon-free prefabricated bricks can be locally replaced and mended by replacing damaged parts. The steel ladle bottom using safety, the ladle bottom repairing difficulty and ladlebottom repairing cost have contradiction all the times, the three-layer refractory material structures of the composite ladle bottom well solve the problems.

Owner:北京利尔高温材料股份有限公司

Forced circulation evaporation cooling device of hydraulic generator stator

InactiveCN1293691CRemarkable effectImprove insulation performanceCooling/ventillation arrangementSerial linePressure cycle

This invention relates to a cooling technology of motors providing a forcing circulation evaporation cooling device of a hydrogenrerator stator winding connection pipes connect the stator winding, a condenser, a pressure circulation pump and electro-hydraulic separation joints to an evcaporation cooling loop filled with evaporation cooling medium and a pressure circulation pump forcing the circulation of the evaporation cooling medium is also in the loop, every line-rod set consisting hollow heads and solid leads in the stator winding contains odd N serial line-rods, two leading out ends of the line rod set are connected with the up and down insulation lead pipes by the electro-hydaulic separation joints, several line-rod sets and a condenser constitute an independent evaporation cooling loop.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

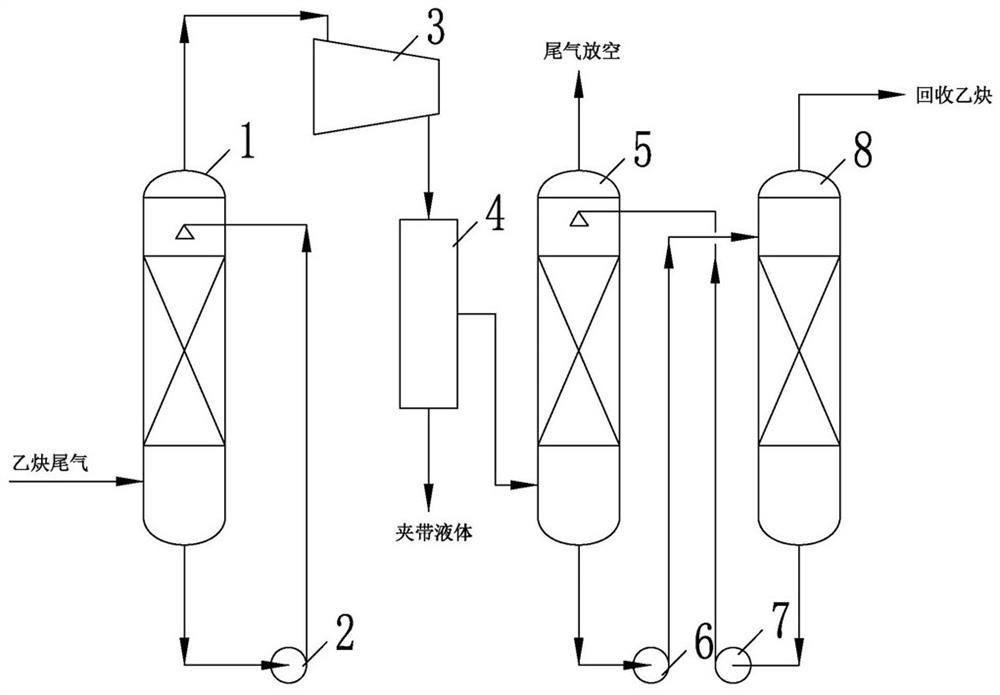

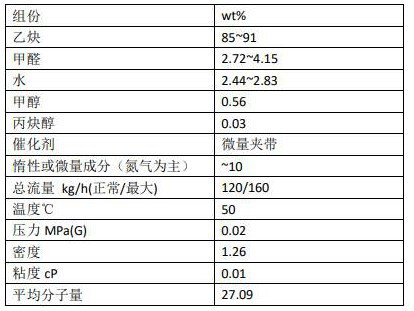

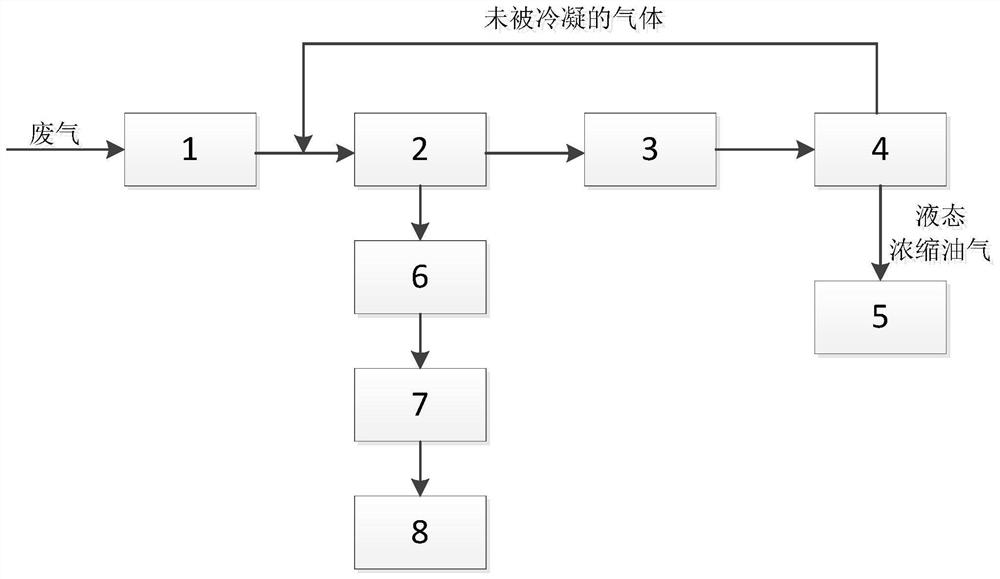

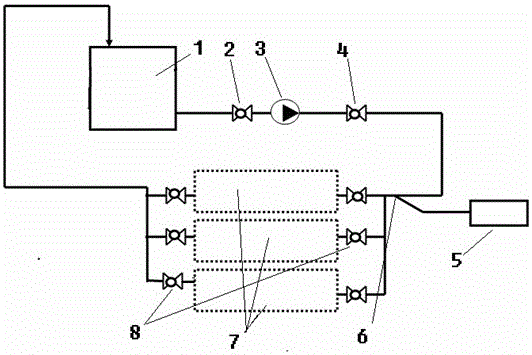

Acetylene tail gas recovery device for BDO production

PendingCN113694698AReduce the amount of replacementExtended operating cycleUsing liquid separation agentSteam/vapor condensersPhysical chemistryAcetylene

The invention discloses an acetylene tail gas recovery device for BDO production, and solves the problems of large methanol replacement amount and incapability of long-period stable operation in the existing BDO production technology. Acetylene tail gas from an ethynylation reaction system is washed by a washing tower, then enters a tail gas compressor, is pressurized, passes through a liquid removal system, enters an absorption tower after water and other small liquid drops are removed, tail gas subjected to low-temperature methanol absorption is fed into an acetylene torch, rich liquid enters a regeneration tower to be regenerated, and tower bottom regeneration liquid returns to the absorption tower to be recycled. Recycled acetylene is obtained from the tower top. The method is simple in process, convenient to operate, low in methanol replacement amount, good in device operation stability and high in competitiveness.

Owner:河南润能科技有限公司

Construction process of composite ladle bottom of steel ladle

ActiveCN110449568ATake security into considerationConsider heat insulationMelt-holding vesselsBrickMaterials science

The invention discloses a construction process of a composite ladle bottom of a steel ladle. The construction process comprises the following specific construction process flows of cleaning the ladlebottom of the steel ladle; pouring a permanent lining castable; carrying out primary curing; building a working layer brick of the ladle bottom; pouring a working layer castable of the ladle bottom; and carrying out secondary curing and baking. According to construction process of the composite ladle bottom of the steel ladle, the ladle bottom is divided into three layers, namely the first layer of the ladle bottom permanent lining, the second layer of a working layer aluminum-magnesium-carbon brick layer and the third layer of a ladle bottom castable layer, wherein the first layer of the permanent lining castable can ensure the safety of the ladle bottom and heat insulation, the second layer of the ladle bottom working layer brick ensures the safe use of the repaired ladle bottom, and thethird layer of the ladle bottom castable protects the ladle bottom working brick.

Owner:北京利尔高温材料股份有限公司

Carbon dioxide-absorbing solution and method of recovering carbon dioxide

ActiveUS8741245B2Reduce the amount of replacementPrevent oxidationGas treatmentOther chemical processesOrganosulfur compoundsCo2 absorption

A method of recovering carbon dioxide, includes bringing gas to be processed containing carbon dioxide (CO2) and oxygen into contact with the CO2-absorbing solution in an absorption column to form a CO2-rich solution; circulating the solution in a regeneration column to thermally release and recover CO2 and recirculating the absorbing solution as a CO2-poor solution inside the absorption column; and performing heat exchange between the solution being delivered from the absorption column to the regeneration column and the solution recirculated from the regeneration column to the absorption column, wherein an alkanolamine aqueous solution containing a silicone oil and / or an organosulfur compound is added to the solution inside the absorption column and / or the solution recirculated from the regeneration column to the absorption column to adjust the composition of the absorbing solution inside the absorption column.

Owner:MITSUBISHI POWER LTD

VOCs waste gas treatment device

InactiveCN112657321ASolve the pollution of the environmentImprove economyDispersed particle separationAir quality improvementFiltrationPipe fitting

The invention relates to a VOCs waste gas treatment device which comprises a waste gas collecting device, a waste gas treatment device, a condensing device, a safety device, an induced draft fan, an oil gas collecting device, a gas discharging device, a connecting pipe fitting of the gas discharging device and an electric control system device. The waste gas collecting device is connected with the waste gas treatment device, and the waste gas treatment device is composed of a hollow outer cylinder structure framework, an organic membrane micro-filtration pipe and a filter pipe inner baffle plate; the waste gas treatment device is connected with the condensing device through a first induced draft fan and is connected with the safety device through a second induced draft fan; the organic membrane micro-filtration pipe and the filter pipe inner baffle plate are arranged in the hollow outer cylinder structure framework in parallel, and the filter pipe inner baffle plate is perpendicular to the pipe wall of the organic membrane micro-filtration pipe to form crossed and alternate fan-shaped channels in the organic membrane micro-filtration pipe. By arranging the baffling concave-convex plate structure with the large specific surface area, organic components in the VOCs waste gas can be rapidly adsorbed, and are fully adsorbed and filtered by the organic membrane on the filter pipe, so that the purpose of effectively removing VOCs is achieved.

Owner:江苏国态环保集团有限公司

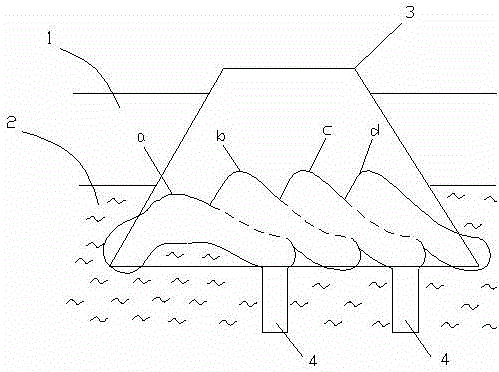

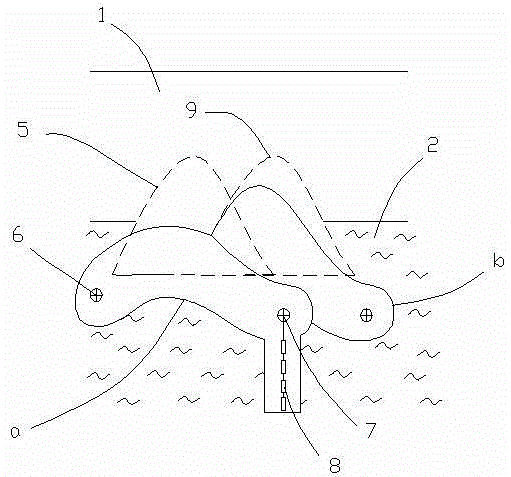

Horizontal explosive compaction land reclamation road building method

InactiveCN104631249AAvoid pile upReduce the amount of replacementRoadwaysClimate change adaptationEcological environmentContinuous operation

The invention discloses a horizontal explosive compaction land reclamation road building method. In the method, the construction efficiency can be improved by adopting the continuous operation in the same operation area between the adjacent construction sections and sequence operation in different operation areas; during explosion operation, a pile foundation is formed by arranging a pile foundation explosive bag, and the silt displacement amount can be decreased by utilizing bearing force provided by the pile foundation; the horizontal explosive compaction land reclamation road building method has the beneficial technical effects that the construction efficiency is high, the engineering quantity is less, the explosive amount can be effectively reduced, and the high damage to the ecological environment can be avoided.

Owner:陈绍文 +6

Environment-friendly composite material

The invention relates to the technical field of composite materials, in particular to an environment-friendly composite material which comprises silicon dioxide aerogel, aramid fibers, glass fibers, tetraethoxysilane, silicon carbide, diepoxypropane ethyl ether, vinyl resin, an initiator, an accelerant and a reinforcing agent. The preparation method comprises the following specific steps: adding silicon dioxide aerogel, aramid fiber and glass fiber into an emulsifying machine, filtering, evaporating excessive water, adding tetraethoxysilane, silicon carbide and diepoxypropane ethyl ether into a crusher, crushing, cleaning, mixing with vinyl resin for later use, and performing extrusion molding to obtain the composite material. And finally, mixing the mixture in each stage, filtering, drying, dehydrating, and extruding to form. Through comparison of a finished product experiment result and an existing finished product experiment result, the finished product is more durable than the existing finished product and is more difficult to damage, so that the replacement amount is reduced, the cost of a user is reduced, and the device is more environment-friendly.

Owner:宿迁北棠智能科技有限公司

Transmission control structure based on big data management mode

InactiveCN109050780BReduce the amount of replacementAvoid wastingChain/belt transmissionAutomatic transmissionControl engineering

Owner:温永宁

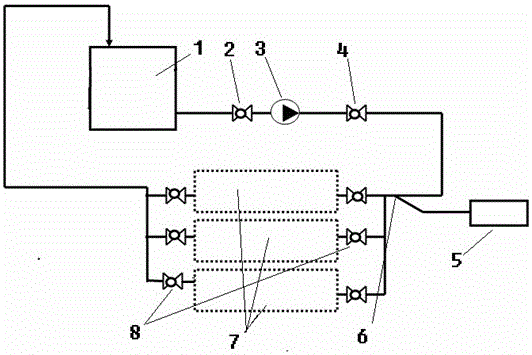

A method for circular flushing of carbon steel pipes in a fine cooling system

ActiveCN104722542BReduce the amount of replacementQuick and efficient completionHollow article cleaningForeign matterEngineering

The invention relates to a method and a device for circularly flushing carbon steel pipes of a refined cooling system. The device is characterized by comprising a cleaning box, cleaning pump inlet ball valves, a cleaning pump, a cleaning pump inlet ball valve, a high-pressure air source, a matching device, a cleaning unit, a temporary stop valve, an eccentric reducing tube and a reducing tube, wherein the cleaning box is connected to the cleaning pump through a pipe; the cleaning pump inlet ball valves are arranged on pipes at two ends of the cleaning pump; the high-pressure air source and the matching device are arranged at positions close to an inlet of a cleaning pipe, so that cleaning liquid can be subjected to matching in real time, and the flowing speed and the flowing state of the cleaning liquid are adjusted; and the cleaning unit and the temporary stop valve can be selected according to the diameters of pipes, and an optimum effect can be achieved. By the eccentric reducing tube, foreign matters are prevented from being stopped and jammed, and the circumstance that the foreign matters are stored at a joint is avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A Construction Technology of Carbon-free Steel Ladle Composite Ladle Bottom

ActiveCN108971471BReduce the amount of replacementSave resourcesMelt-holding vesselsComposite constructionBrick

The invention proposes a carbon-free steel ladle composite bottom construction process. The application of the technology not only ensures the safe use of the bottom, but also reduces the difficulty of repairing the bottom and reduces the repair cost. A carbon-free steel ladle composite bottom construction The process includes the following steps: cleaning the bottom, pouring the permanent lining castable, curing, pouring the castable for the working layer of the bottom, curing, building bricks for the working layer of the bottom, baking, using the present invention to construct the bottom, the first layer of permanent The lining castable can play the role of ensuring the safety of the bottom of the package and heat insulation. The castable of the second layer of the bottom working layer ensures the safety of the repaired bottom of the package. The third layer of carbon-free prefabricated bricks can be partially replaced and repaired. There has always been a contradiction between the safety of ladle bottom use and the bottom repair and bottom repair cost. The three-layer refractory structure of the composite bottom has solved this problem very well.

Owner:北京利尔高温材料股份有限公司

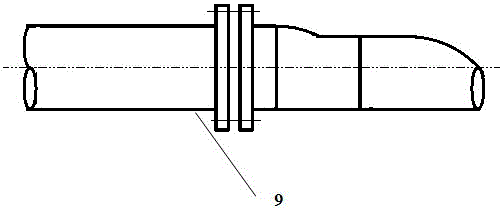

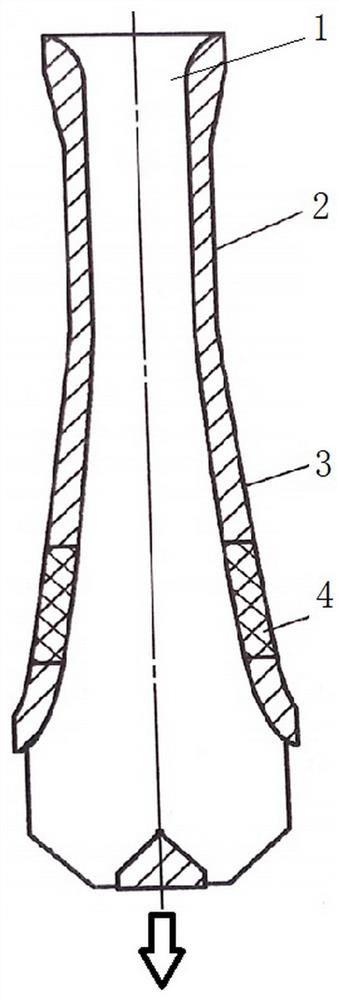

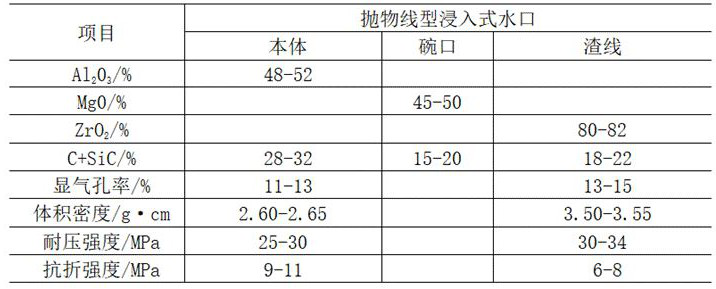

Parabola type long-service-life continuous casting submersed nozzle

The invention discloses a parabolic long-life continuous casting submersed nozzle which comprises a nozzle body, the top of the nozzle body is a bowl opening portion, the lower portion of the nozzle body is provided with a slag line portion, and the nozzle body between the bowl opening portion and the slag line portion is composed of a cylindrical body on the upper portion and a parabolic body on the lower portion. 48-52% by mass of Al203 is contained in the cylinder body and the parabola-shaped body, wear-resistant coatings are arranged on the inner circumferential walls of the cylinder body and the parabola-shaped body respectively, the wear-resistant coatings are composed of 28-32% by mass of C + SiC mixture, 45-50% by mass of magnesium oxide is contained in the bowl opening part, a wear-resistant coating is arranged on the inner circumferential wall of the bowl opening part, and the wear-resistant coatings are composed of 20-30% by mass of magnesium oxide. A wear-resistant coating is arranged on the inner circumferential wall of the slag line part, the wear-resistant coating is composed of 15-20% by mass of a C + SiC mixture, 80-82% by mass of ZrO2 is contained in the slag line part, the wear-resistant coating is arranged on the inner circumferential wall of the slag line part, and the wear-resistant coating is composed of 18-22% by mass of a C + SiC mixture.

Owner:XINJIANG BAYI IRON & STEEL

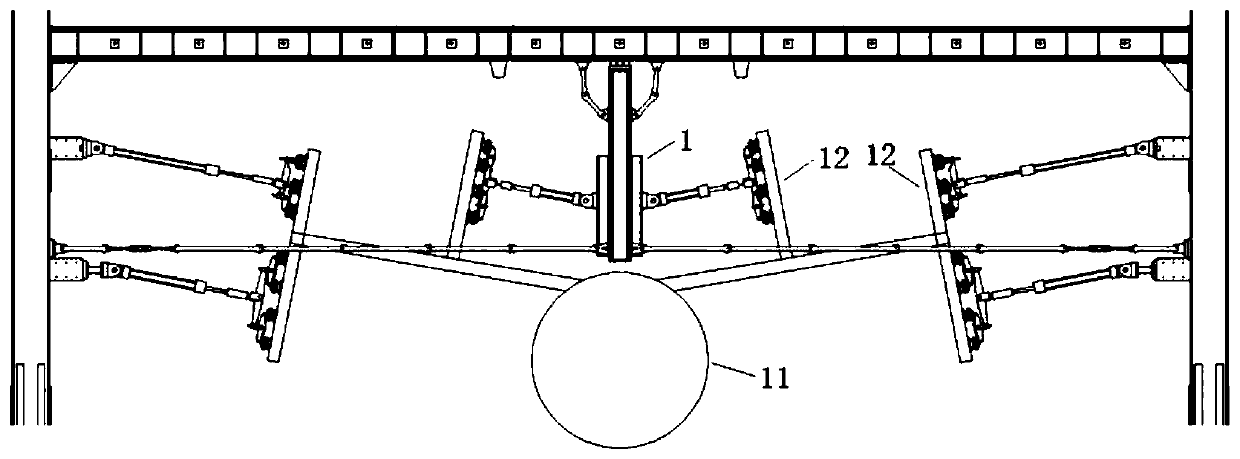

A loading method for four vertical tail loads

ActiveCN109655245BSimple designResolve Spatial InterferenceMachine part testingClassical mechanicsStructural engineering

The invention discloses a four-vertical-fin load loading method which comprises the following steps: 1) installing a vertical fin frame between inner vertical fins, connecting a single lug at the upper end of the vertical fin frame to a loading cross beam, and enabling the distance between the lower end of the vertical fin frame and a rear fuselage of an aircraft to be not less than 300mm; (2) theupper end of the vertical fin frame being connected with a loading cross beam through an upper end pull plate, and the lower end of the vertical fin frame being connected with a lateral loading standcolumn through a lower end pull plate; 3) installing an actuating cylinder fixing seat at a position corresponding to the vertical fin frame; 4) installing an actuating cylinder base at a position corresponding to the lateral loading cross beam of the vertical fins; 5) connecting the actuating cylinder with a loading cross beam by using a manual hoist, adjusting the actuating loading to meet therequirement by adjusting the manual hoist, and connecting the actuating cylinder with a vertical fin end lever; and (6) repeating the steps (2) to (5) to install the vertical fin loading equipment onthe other side. The four-vertical-fin load loading method can realize bidirectional tension and compression loading of vertical fin loads, and can avoid the spatial interference problem between the loading equipment and between the loading equipment and a test piece.

Owner:CHINA AIRPLANT STRENGTH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com