Acetylene tail gas recovery device for BDO production

A technology of acetylene tail gas and recovery device, which is applied in the direction of using liquid separation agent, absorption purification/separation, steam/steam condenser, etc., which can solve the impact of long-term stable operation of the system, inability to effectively remove inert gas, and acetylene purity cannot be guaranteed, etc. problems, to achieve the effects of easy availability, improved competitiveness, and reduced methanol replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The Examples described below illustrate the present invention in detail, but the present invention is not limited to the following Examples. The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

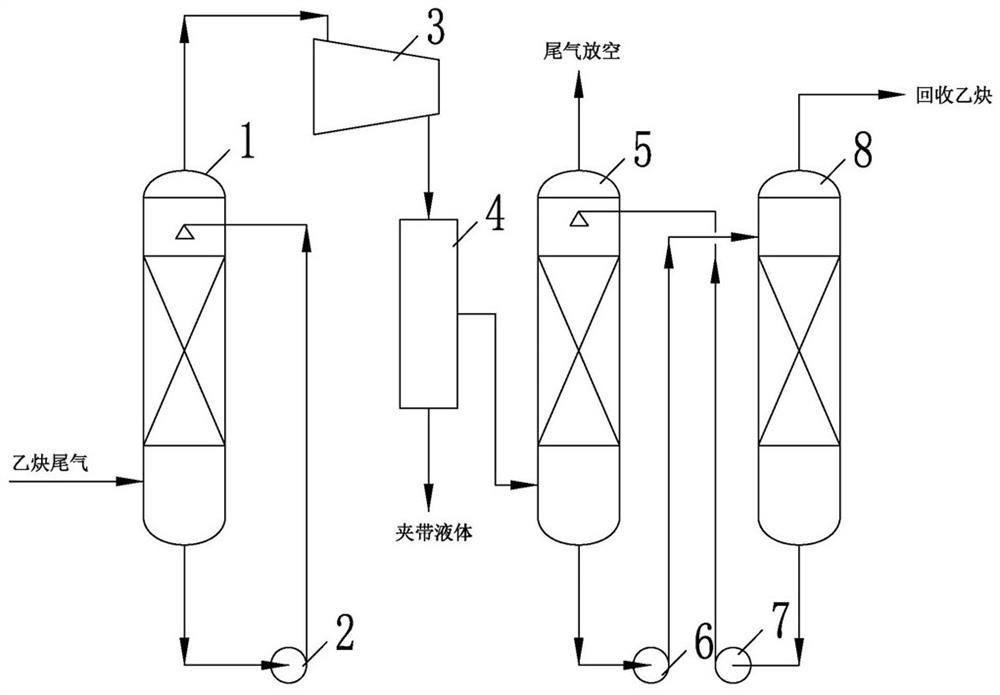

[0017] Such as figure 1 Shown, a kind of acetylene tail gas recovery device that is used for BDO production is characterized in that, comprises washing tower 1, tail gas compressor 3, dehydration system 4, absorption tower 5, regeneration tower 8, and described washing tower 1 bottom is provided with Acetylene tail gas pipeline, the bottom of the washing tower 1 is provided with a pipeline connected to the top nozzle through the washing tower circulation pump 2, the top of the washing tower 1 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com