A loading method for four vertical tail loads

A technology with four vertical tails and loads, which is used in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve the problems of increasing difficulty in the design of the test plan and on-site implementation, and achieve the convenience of applying loads in both directions of tension and compression. The effect of measuring and reducing the amount of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

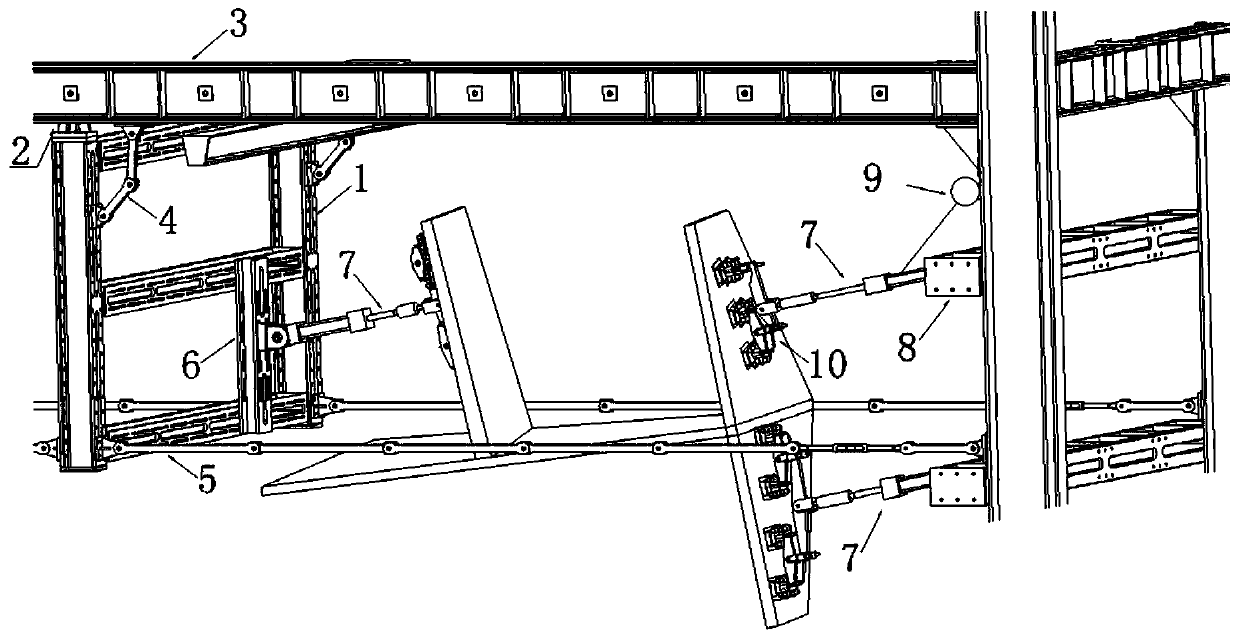

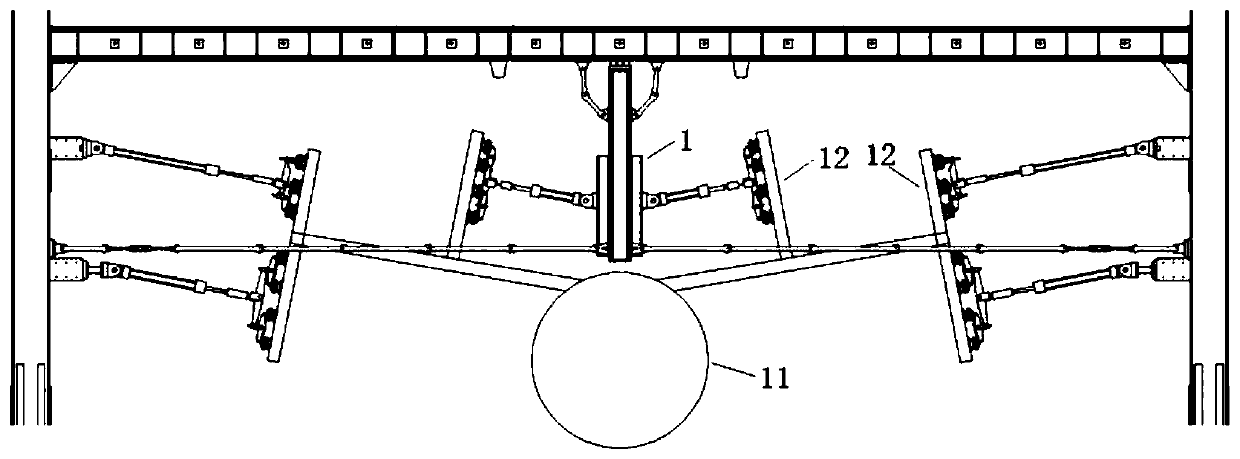

[0022] Below in conjunction with accompanying drawing, the present invention is further introduced, a kind of four vertical tail load loading method of the present invention, comprises the following steps:

[0023] Step 1: Install the vertical tail frame 1 between the inner vertical tails, and connect the upper ear 2 of the vertical tail frame 1 to the loading beam 3 through bolts, and the distance between the lower end of the vertical tail frame 1 and the rear fuselage of the aircraft is not less than 300mm ;

[0024] Step 2: The upper end of the vertical tail frame 1 is connected to the loading beam 3 through the upper end pull plate 4, and the lower end of the vertical tail frame 1 is connected to the lateral loading column through the lower end pull plate 5;

[0025] Step 3: Install the actuator fixing seat 6 on the corresponding position of the vertical tail frame 1 according to different test conditions, and install the actuator 7 on the actuator fixing seat 6 for loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com