Parabola type long-service-life continuous casting submersed nozzle

A parabolic, long-life technology, used in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problem of aggravating the erosion and erosion of the inner wall of the submerged nozzle, poor resistance to molten steel and slag erosion, and continuous casting. Smooth progress and other issues, to achieve the effect of being beneficial to continuous casting operations, resisting corrosion of molten steel and slag, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

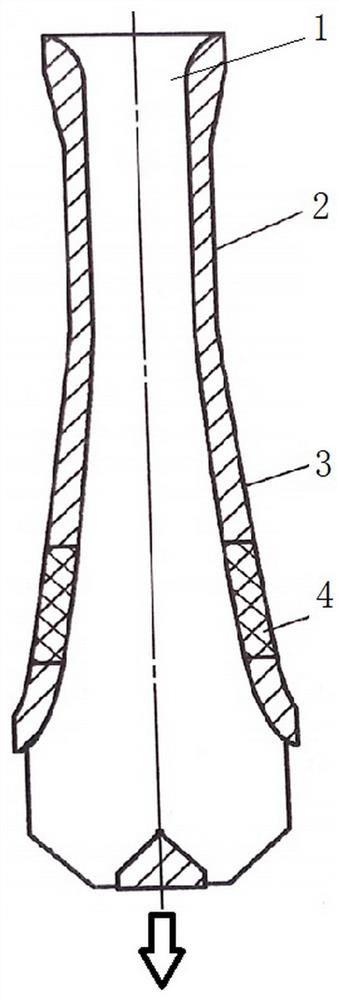

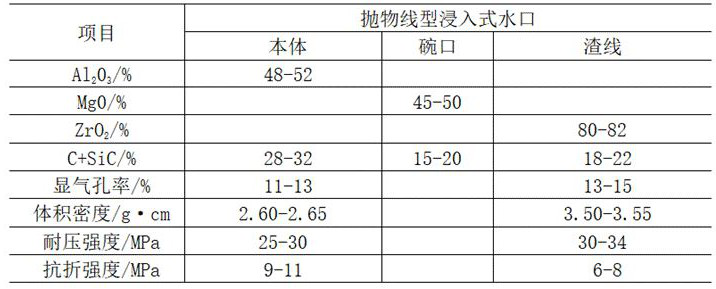

[0014] A parabolic long-life continuous casting submerged nozzle, such as figure 1 As shown, including the nozzle body, the top of the nozzle body is the bowl mouth part 1, the lower part of the nozzle body has a slag line part 4, and the nozzle body between the bowl mouth part 1 and the slag line part 4 is formed by the upper cylindrical body. 2 and the lower parabolic body 3, the inner peripheral wall of the cylindrical body 2 is cylindrical, and the inner wall curve of the parabolic body 3 is a parabola; the cylindrical body 2 and the parabolic body 3 contain a mass percentage of 48- 52 Al 2 0 3 , the inner peripheral walls of the two are respectively provided with a medium wear-resistant coating, and the wear-resistant coating is composed of a C+SiC mixture with a mass percentage of 28-32. The bowl mouth part 1 contains 45-50% of magnesium oxide, An upper wear-resistant coating is arranged on the inner peripheral wall of the bowl mouth part 1, and the upper wear-resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com