Double-beam type long straight wing load processing method

A processing method and beam-type technology, which is applied in the field of load processing and loading of wing box sections in the static strength test of full-scale aircraft structures, can solve the problems of large load processing workload, many lever loading stages, and low load processing efficiency. , to achieve the effect of improving the effective utilization rate, reducing the number of processing and replacement, and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

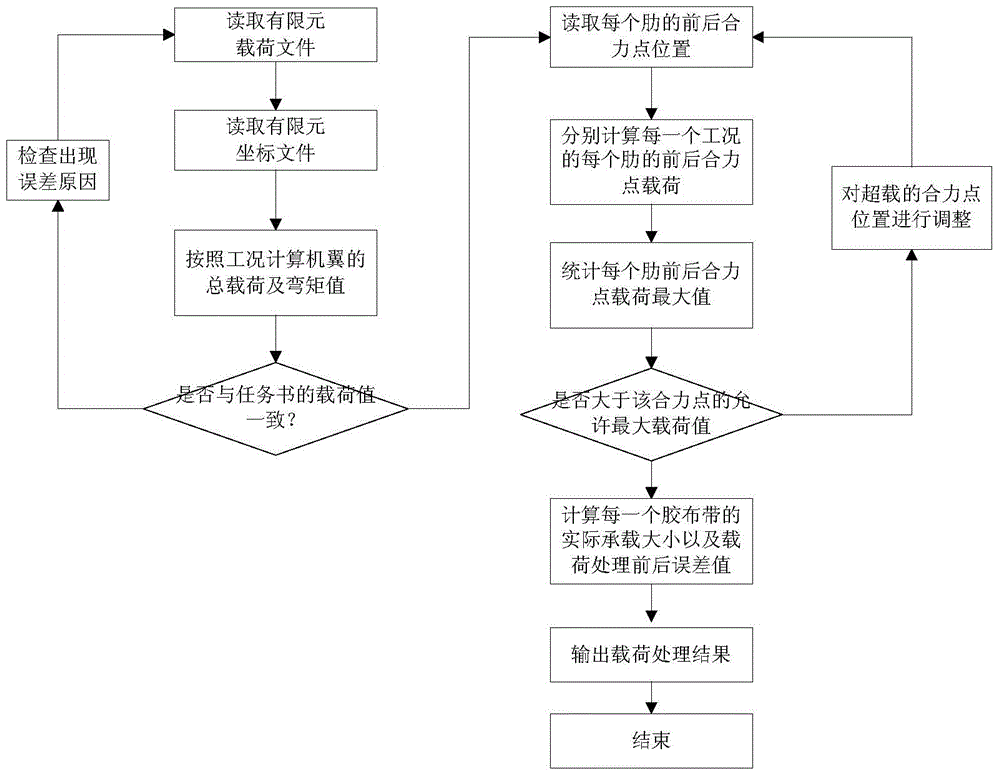

[0018] The flow chart of realizing the load processing of double-spar long straight wing with computer program is as follows: figure 2 shown.

[0019] The program is divided into two parts: data verification and data processing. All calculation programs are completed using VC++.

[0020] The present invention provides a kind of double beam type long straight wing load processing method, it is characterized in that, comprises the following steps:

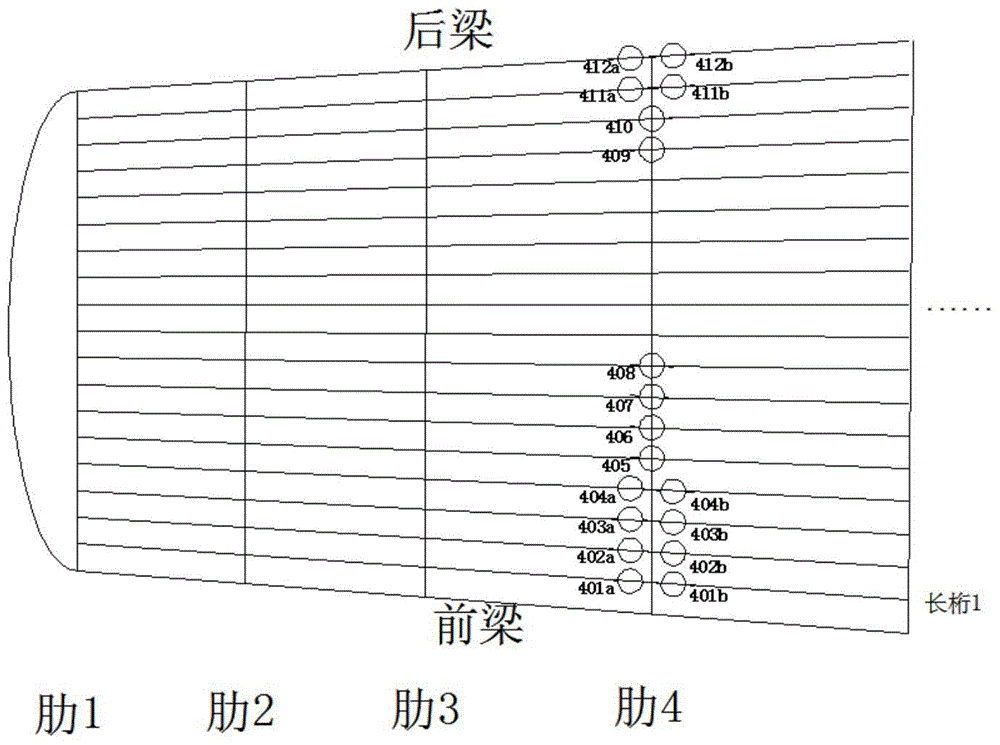

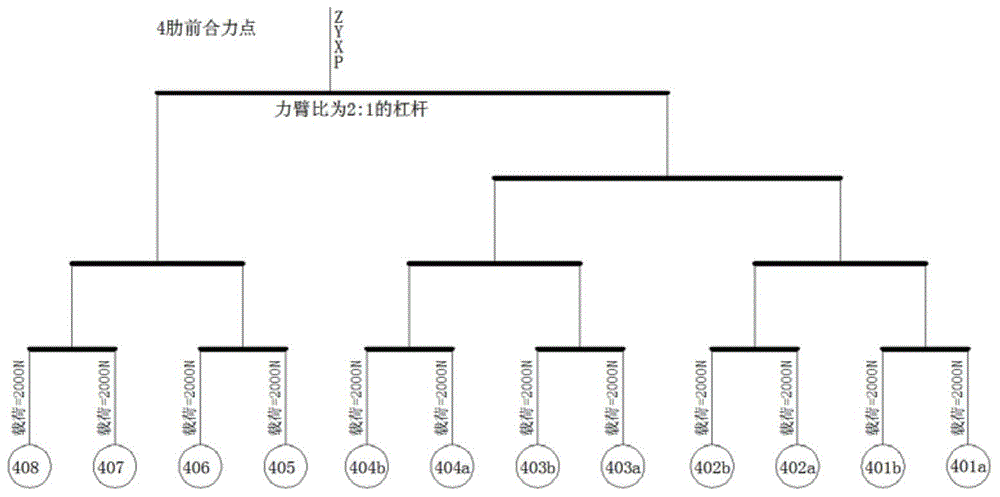

[0021] 1) According to the finite element node number and position of each rib of the wing, tapes are selectively arranged near the front and rear beams of each rib, such as figure 1 As shown, the load value of each tape is the maximum load value that the tape can bear, and then calculate the lever end coordinates of the front beam and rear beam and their lever system according to the tape position and tape load value of each rib front beam and rear beam The load value that can be tolerated is called the maximum load value of its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com