VOCs waste gas treatment device

An exhaust gas treatment device and exhaust gas collection technology, applied in the field of environmental engineering, can solve problems such as unstable catalyst performance, secondary pollution of ozone, and increased operating costs, achieving good social and environmental benefits, less hazardous waste treatment, and reduced The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

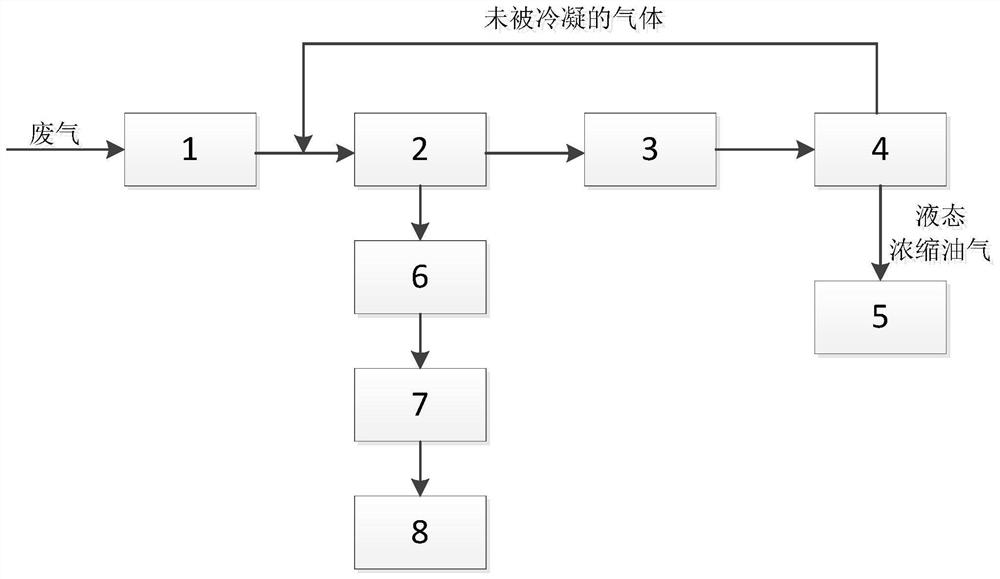

[0026] A VOCs waste gas treatment device 2, comprising a waste gas collection device 1, a waste gas treatment device 2, a condensation device 4, a safety device 7, an induced draft fan, an oil and gas collection device 5, a gas discharge device 8 and its connecting pipe fittings and an electric control system device;

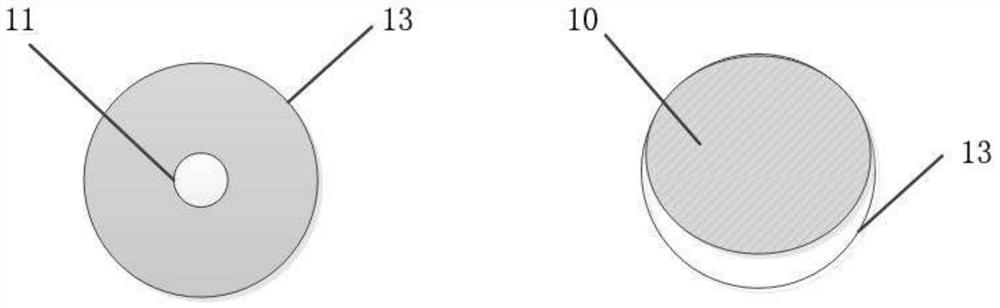

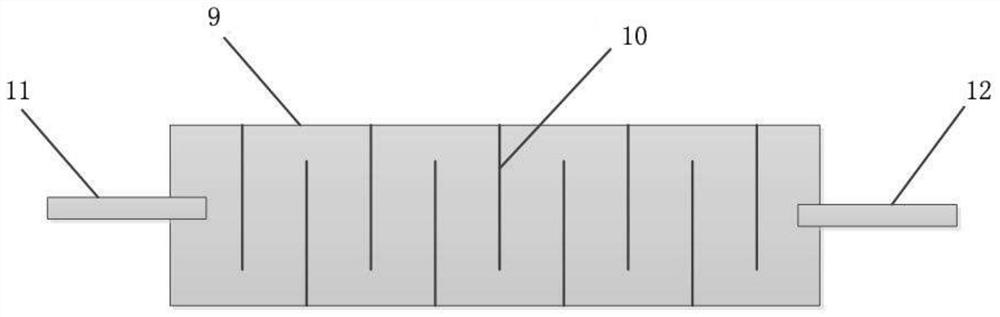

[0027] The waste gas collection device 1 is used to collect waste gas, and the outlet of the waste gas collection device 1 is connected to the waste gas treatment device 2, and the waste gas treatment device 2 is composed of a hollow outer cylinder structure skeleton and 1-n microstructures made of organic membranes. The filter tube 9 and the baffle plate 10 in the filter tube are composed of components; the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com