Sintering machine bogie wheels

A wheel and machine technology, which is applied in the field of sintering machine trolley wheels, can solve the problems of adverse effects on production efficiency of sintering machine trolleys, high maintenance cost of sintering machine trolley wheels, easy wear of rolling bearings, etc., so as to improve service life and reduce Maintenance cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

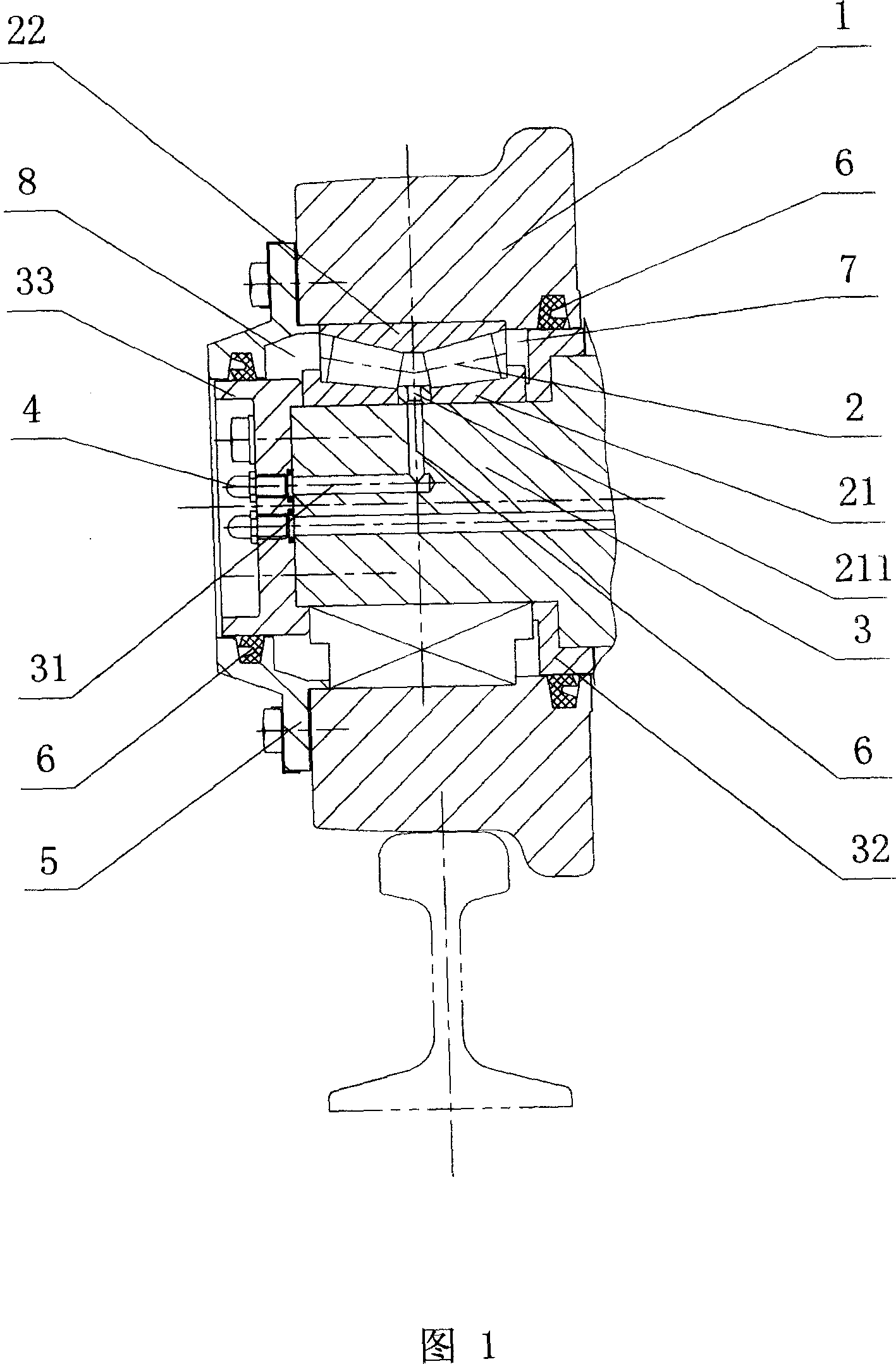

[0017] As shown in Figure 1, the trolley wheel of the sintering machine of the present invention comprises a wheel body 1, a bearing 2 and a trolley shaft 3, the bearing 2 is sleeved on the end of the trolley shaft 3, the wheel body 1 is sleeved on the bearing 2, and The feature is that the bearing inner ring 21 of the bearing 2 is provided with a lubricating port 211 , the trolley shaft 3 is provided with a grease passage 31 , one end of the grease passage 31 is provided with a grease nozzle 4 , and the other end communicates with the lubricating port 211 . The first shaft sleeve 32 is sleeved on the trolley shaft 3, and the second shaft sleeve 33 is installed at the end of the trolley shaft 3. The bearing inner ring 21 of the bearing 2 is positioned by the first shaft sleeve 32 and the second shaft sleeve 33, and the bearing The bearing outer ring 22 of 2 is positioned by the wheel body 1 and the axle end cover 5 installed on the wheel body 1. The grease nozzle 4 is mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com