Crtsiii type slab ballastless track track slab laying accuracy detection method

A technology of slab-type ballastless track and track slab, which is applied in the direction of tracks, track maintenance, roads, etc., can solve the problems of many technicians, low work efficiency, and cumbersome measurement process, so as to reduce workload, improve work efficiency, and improve ride comfort The effect of sexual precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further illustrate the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are for reference and description only, and are not intended to limit the protection scope of the present invention.

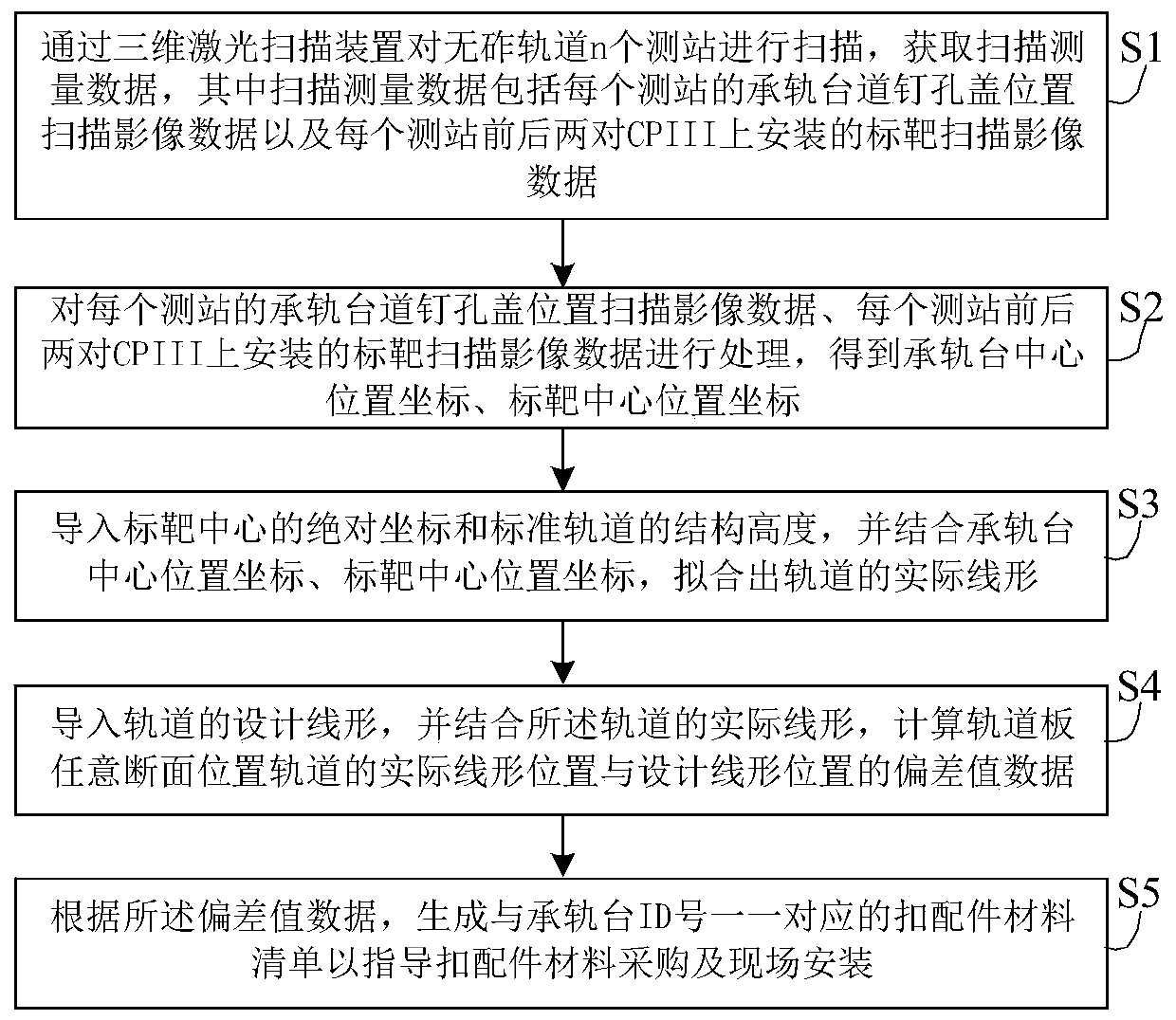

[0054] Such as figure 1 As shown, this embodiment discloses a CRTSIII type ballastless track track slab laying accuracy detection method, including the following steps:

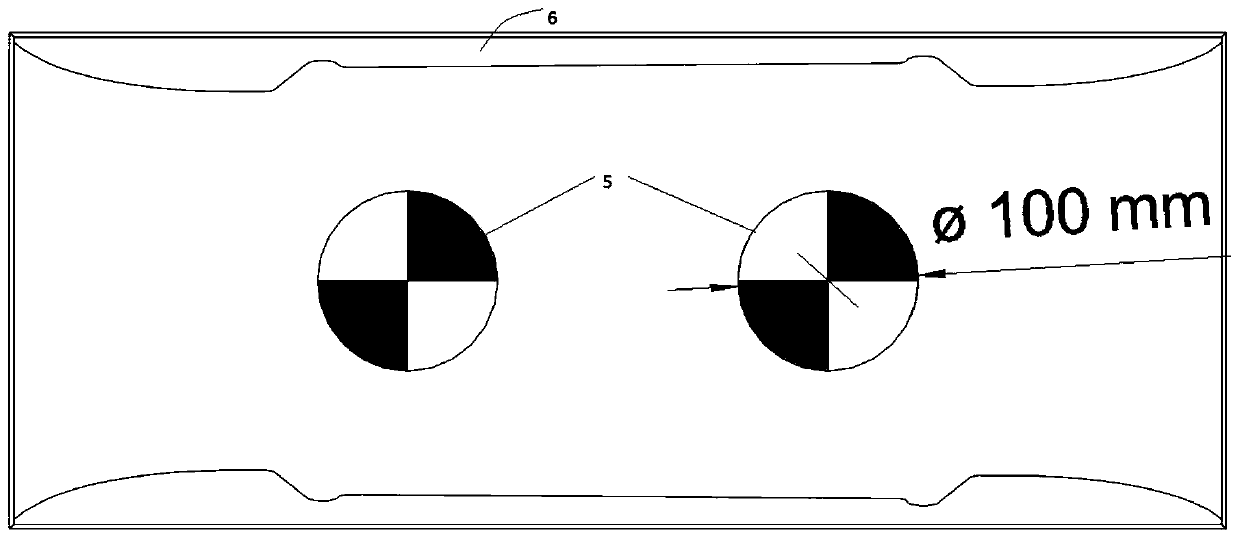

[0055] S1. Use a three-dimensional laser scanning device to scan n measuring stations on the ballastless track to obtain scanning measurement data, where the scanning measurement data includes the scanned image data of the position of the rail-supporting platform spike hole cover of each measuring station and the front and rear of each measuring station Scanning image data of two pairs of targets installed on CPIII;

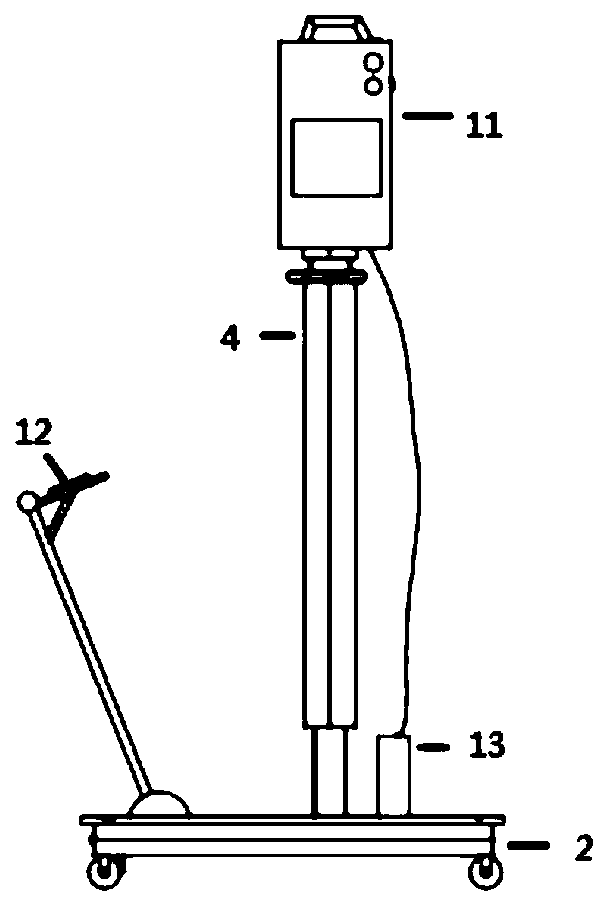

[0056] It should be noted that, if figure 2 As shown, the 3D laser scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com