Sliding type H-type piston coal gas tank and sliding type H-type piston thereof

A sliding type, gas tank technology, applied in the field of gas tank, can solve the problems of increasing the labor intensity of production units, increasing unsteady factors, and large piston steel consumption, reducing calculation height, reducing replacement time, and reducing steel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

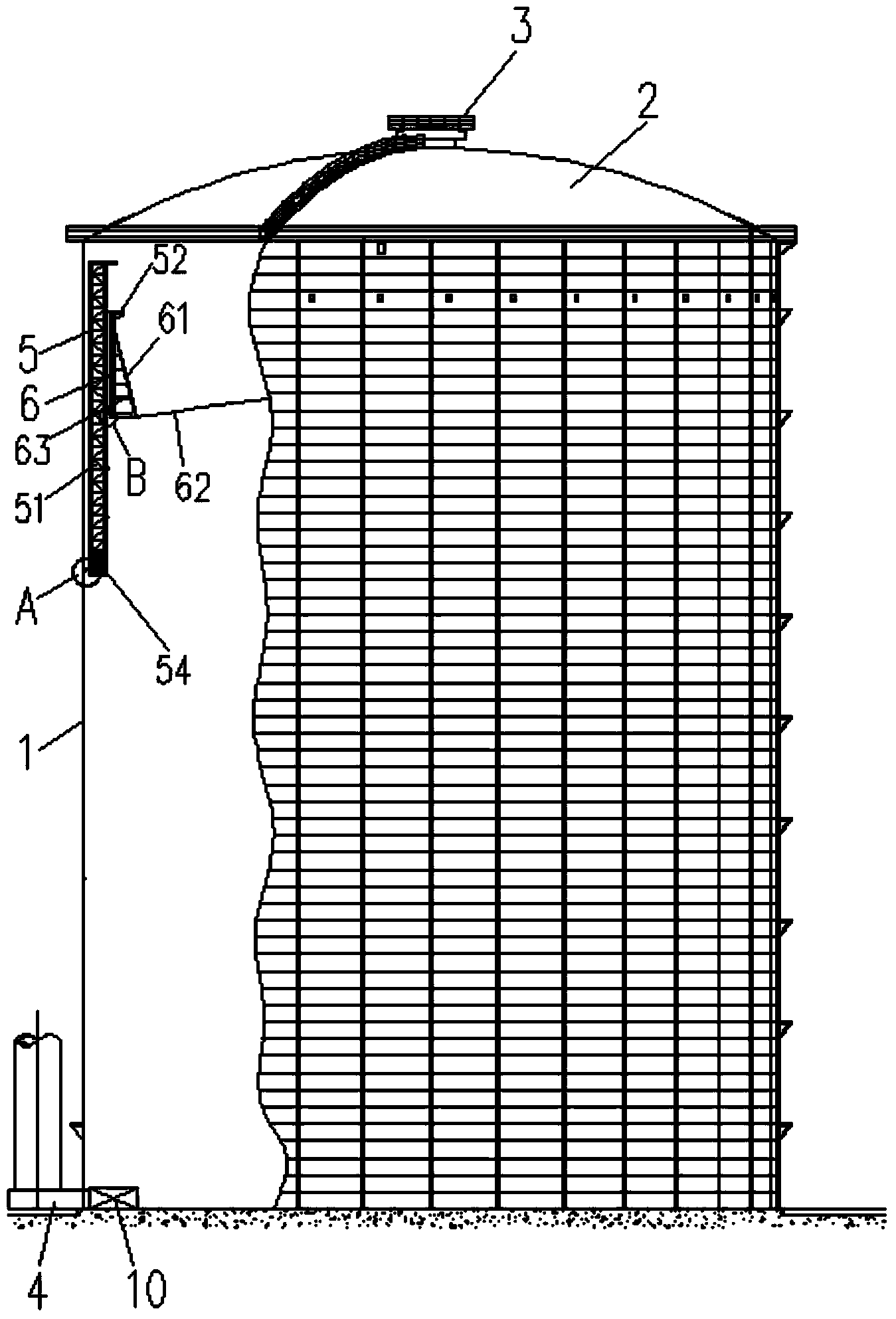

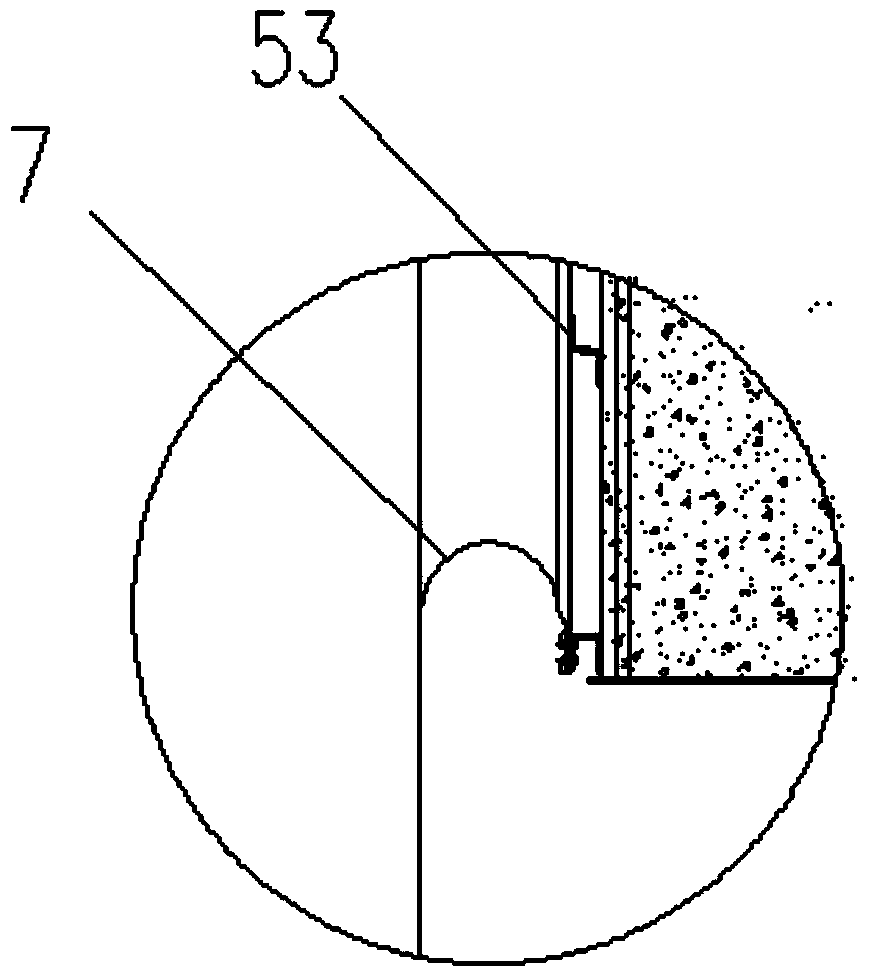

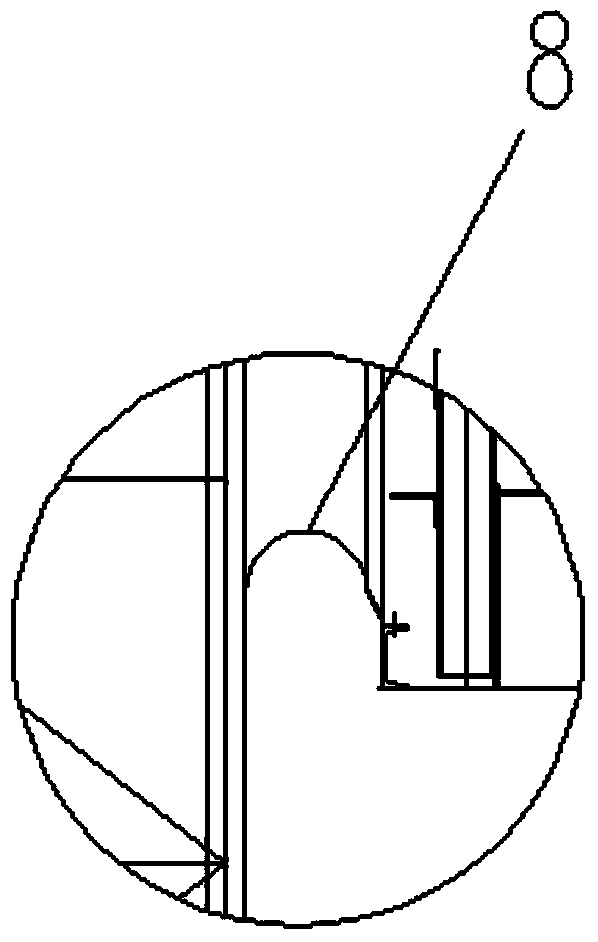

[0026] As shown in the figure, a sliding type H-type piston gas cabinet includes a gas cabinet cylinder 1, a roof plate 2 and a ventilation floor 3 are arranged on the top of the gas cabinet cylinder, and a gas tank is provided at the bottom of the gas cabinet cylinder. The inlet and outlet 4, the gas holder barrel is also provided with a sliding H-type piston 5 that can slide along its inner wall, and the sliding H-type piston includes a piston fence frame 51 that can slide along the inner wall of the gas holder barrel. The inner wall of the piston fence frame is provided with a sliding inner tank piston arch 6 that can slide along it, and the top of the piston fence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com