Patents

Literature

48results about How to "Fully extended" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

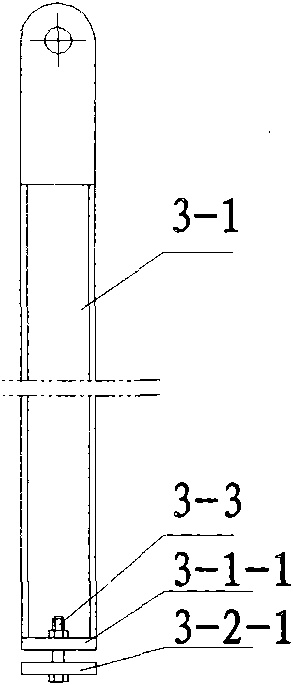

Method of energy cumulative presplitting and smoothsurface blasting and special device therof

ActiveCN101033932AIncrease profitEnhance blasting forceBlasting cartridgesBlastingBinding energyDetonator

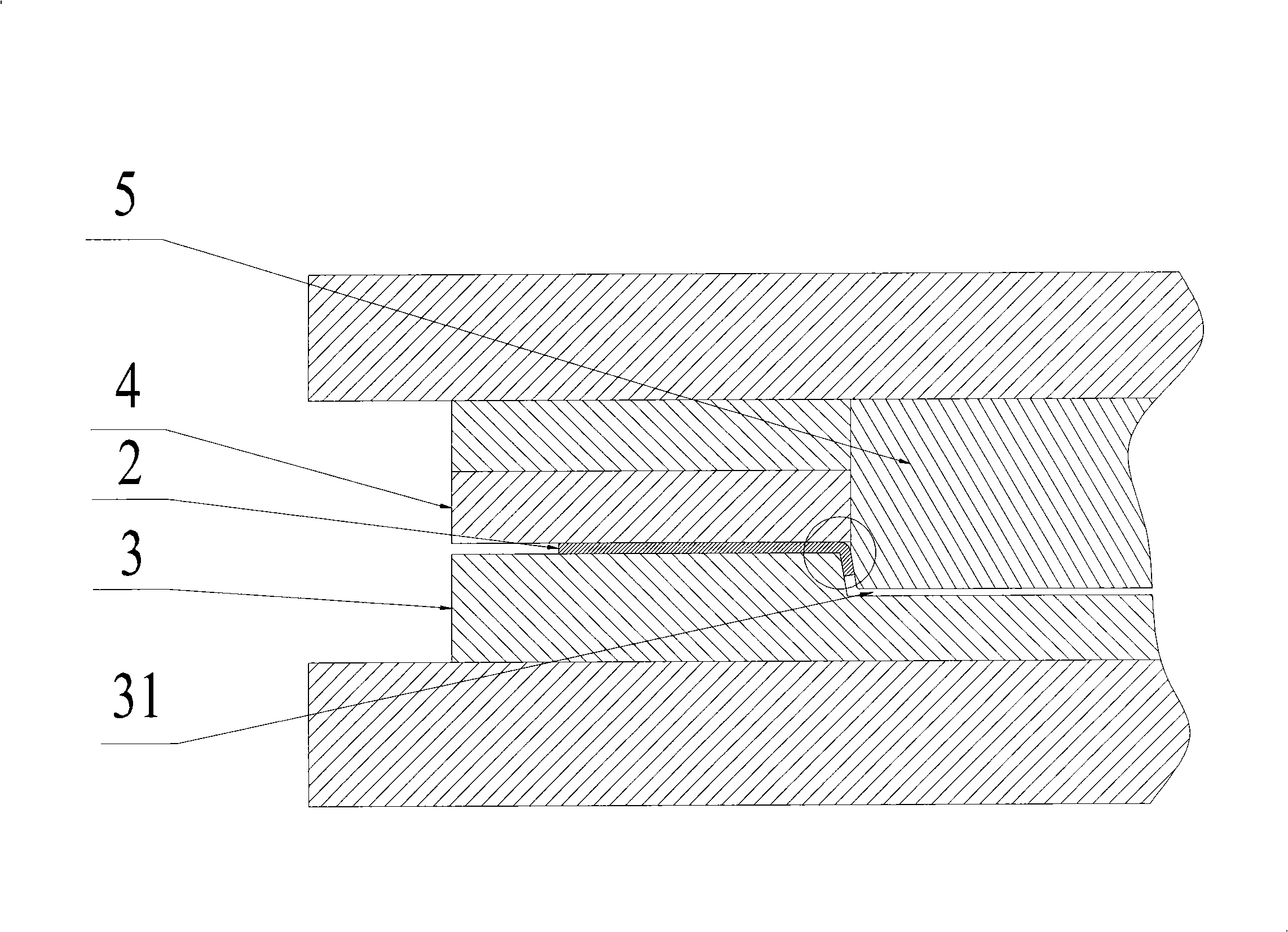

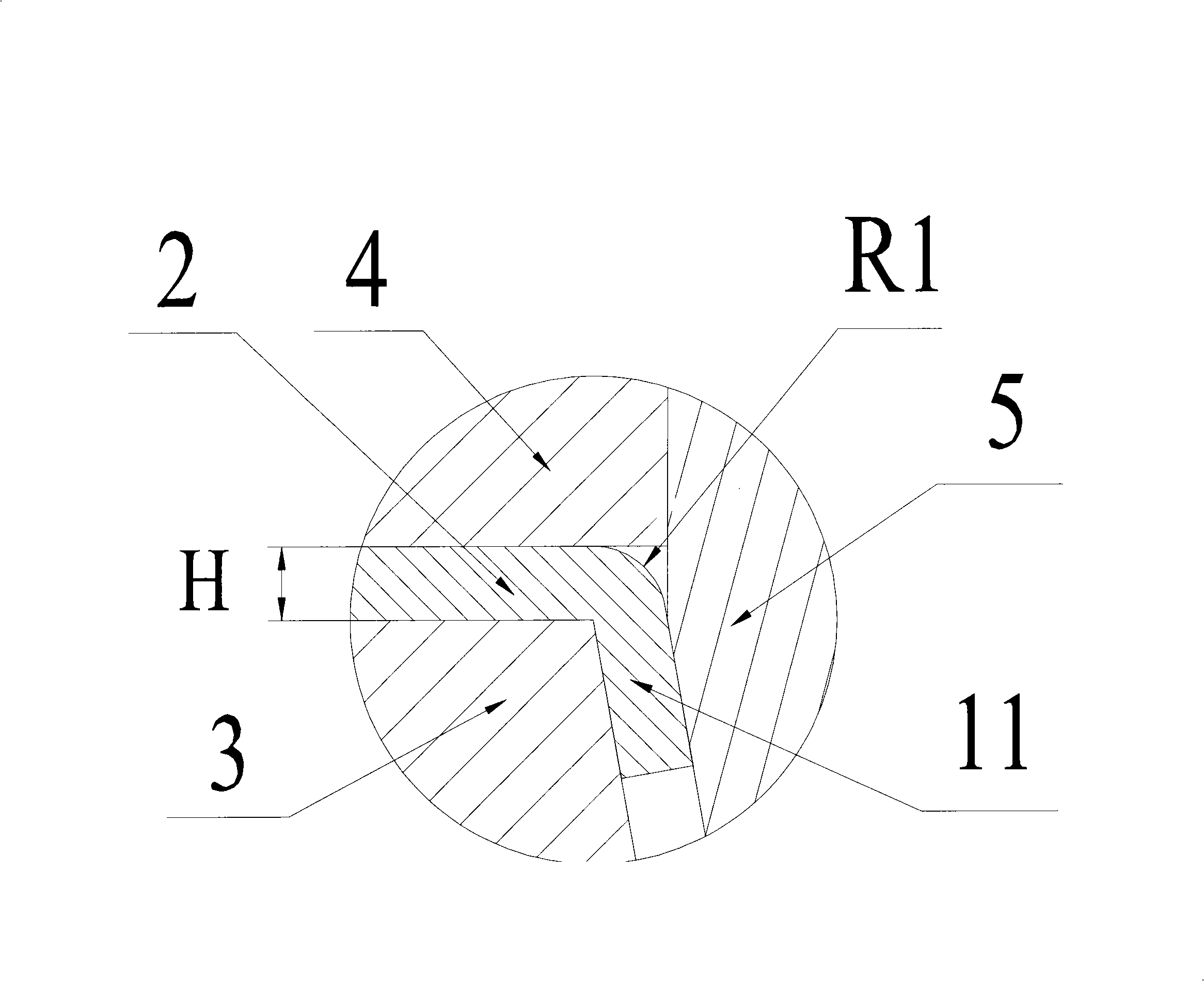

It is a special-purpose device used for two-directional energy-focusing and smooth blasting, post standard knot of multisection energy-gathering pipe which is in the double ''V'' shaped energy-accumulating groove which is set on the pipewall full of detonator, each post standard knot is linked with connection casing on which there is energy-accumulating groove, centering ring in the hole is noosed on the standard joint of the binding energy tube so that the center lines of the upper and the lower energy-gathering groove like V shape are in the same surface in the blasthole. Orifice centering rings of the two V- shaped central whose orientation is the same with V- shaped energy-gathering groove are set on the noose annulus wall at the ground end of energy -gathering pipe at orifice of blasthole, which makes the center line of each energy-gathering groove like a V shape forms a surface of centering and coinciding with blasting surface in each blasthole and among. After detonating explosive, make shaped charge jet spark along initial small crack that forms while the crack begins to form, then forms presplitting or smooth blasting surface, and finish energy-gathering presplitting and smooth blasting. The invention can enhance utilization ratio of demolishing energy and debase quantity of drilled holes, the influence of destroying rock mass kept down is little and the blasting surface is more level.

Owner:SINOHYDRO BUREAU 8 CO LTD

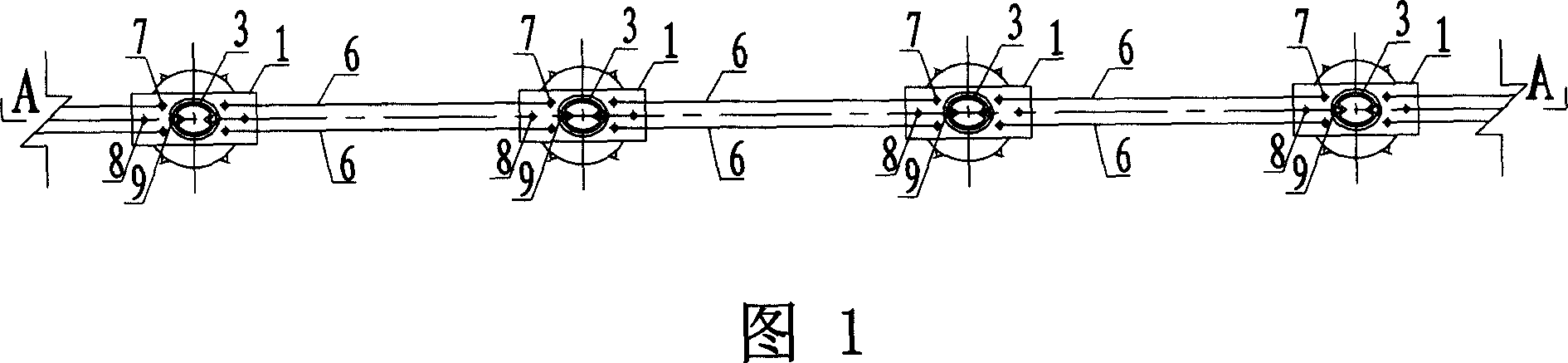

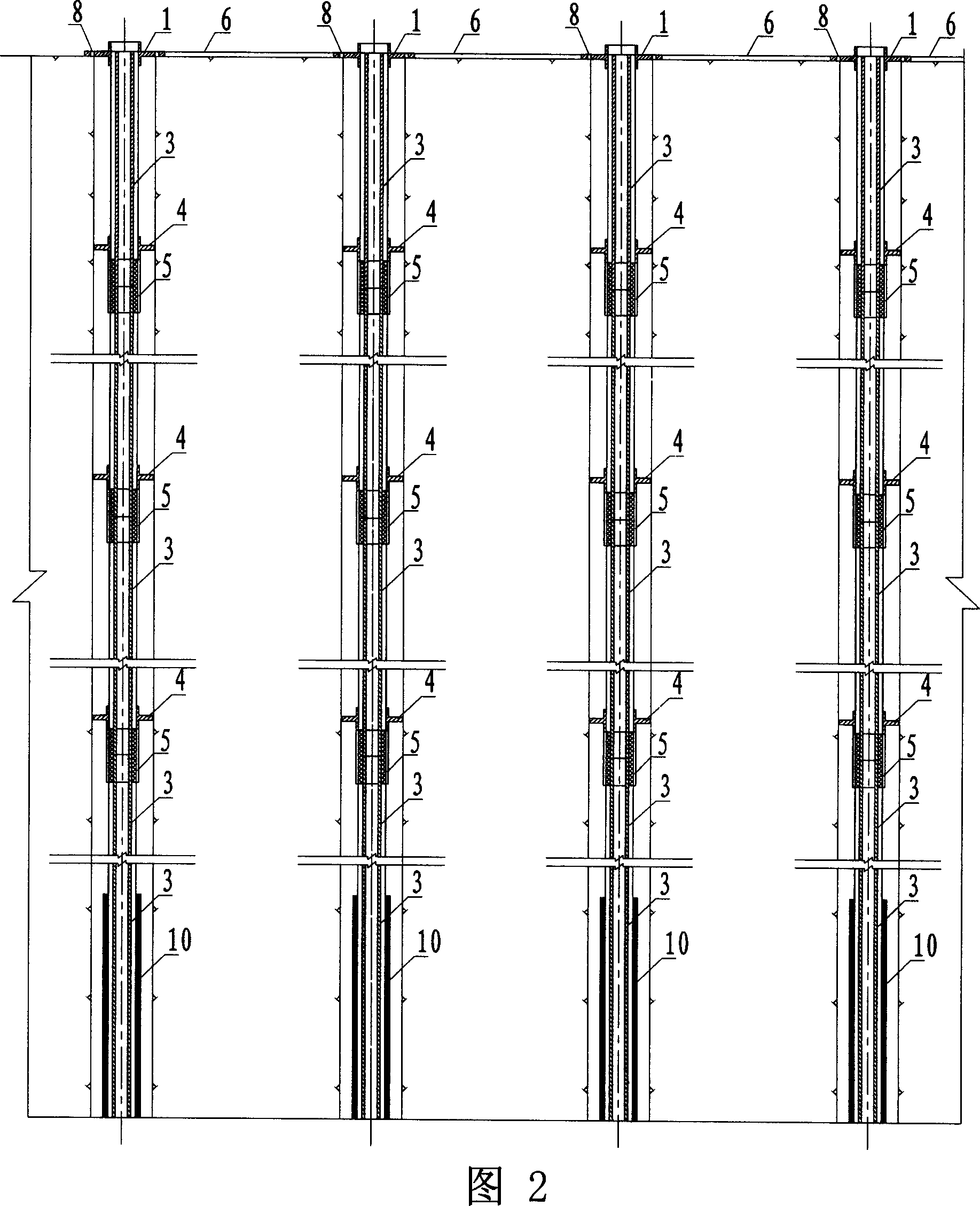

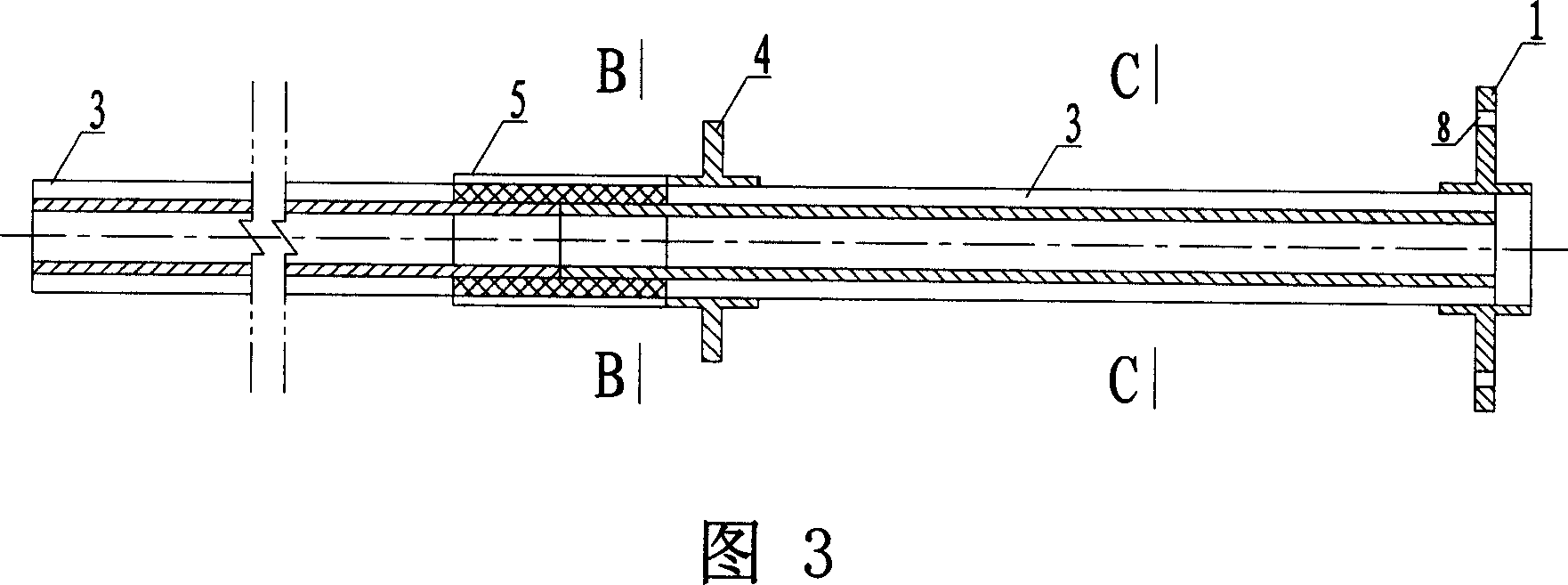

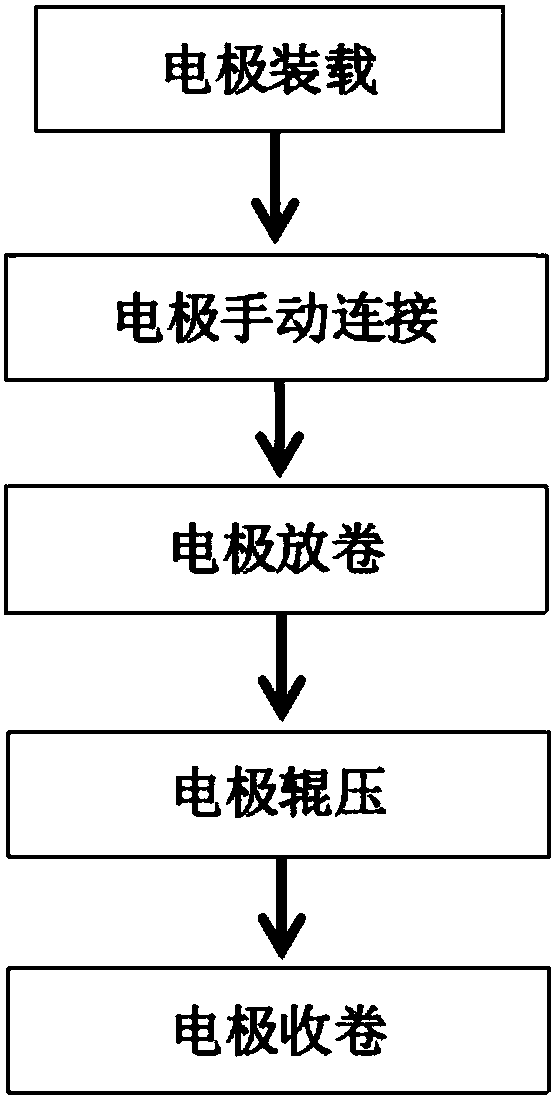

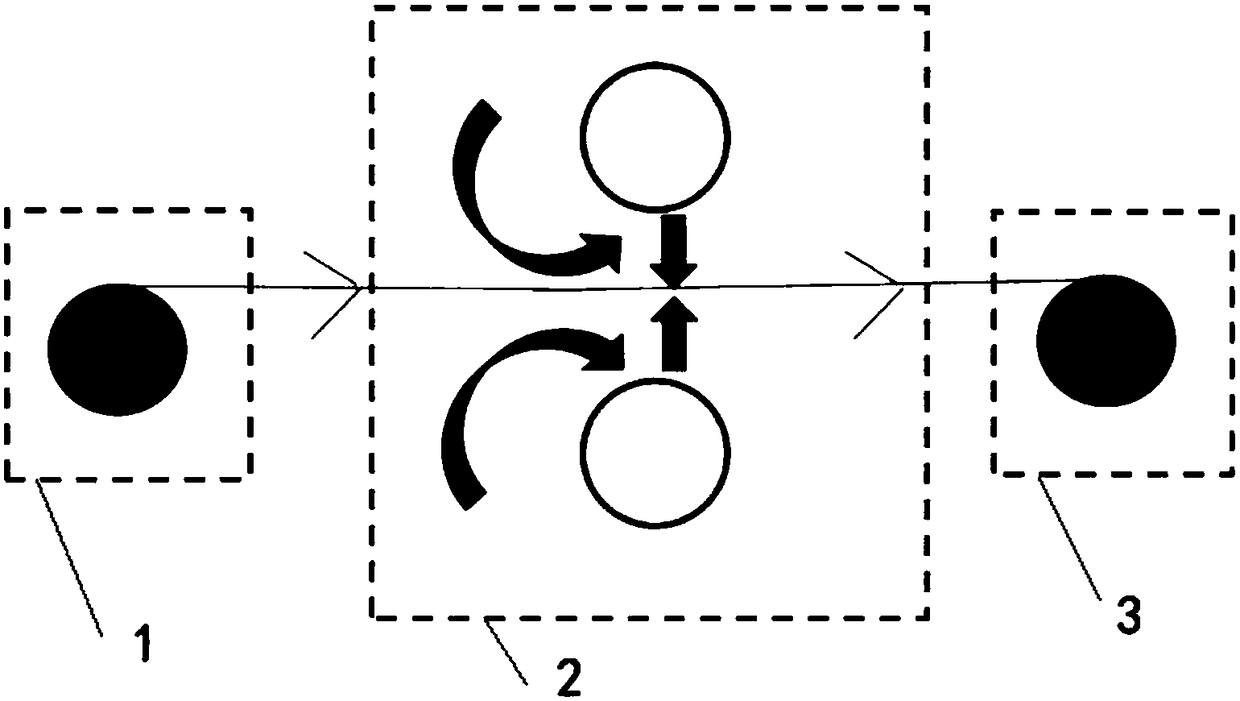

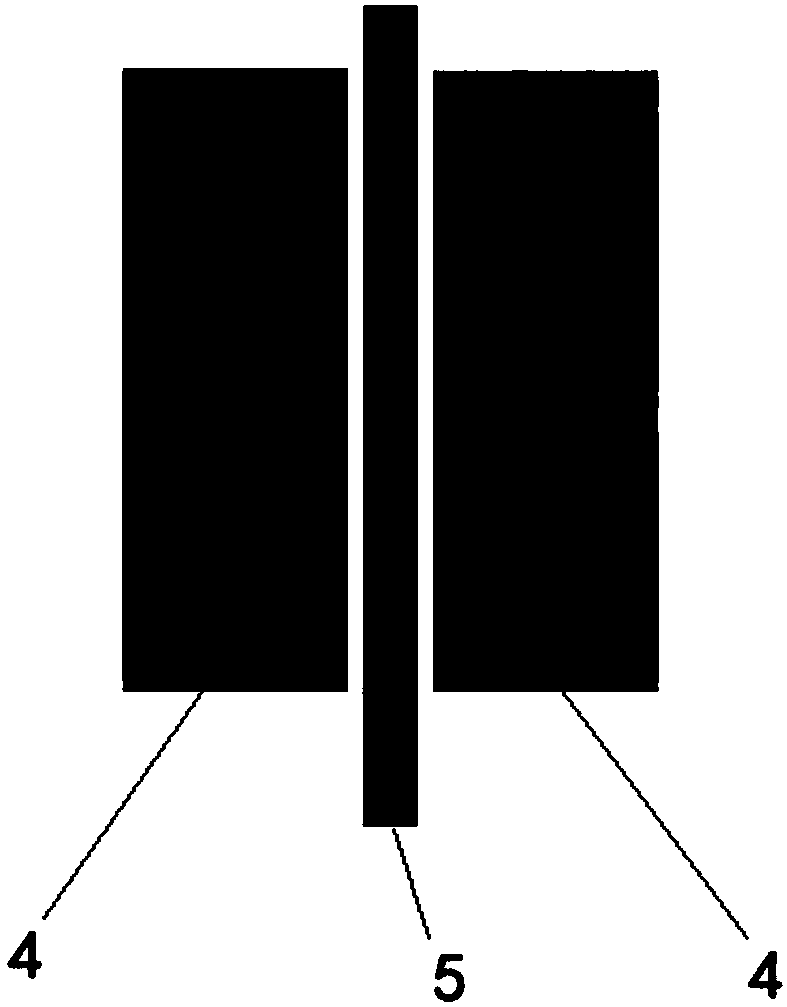

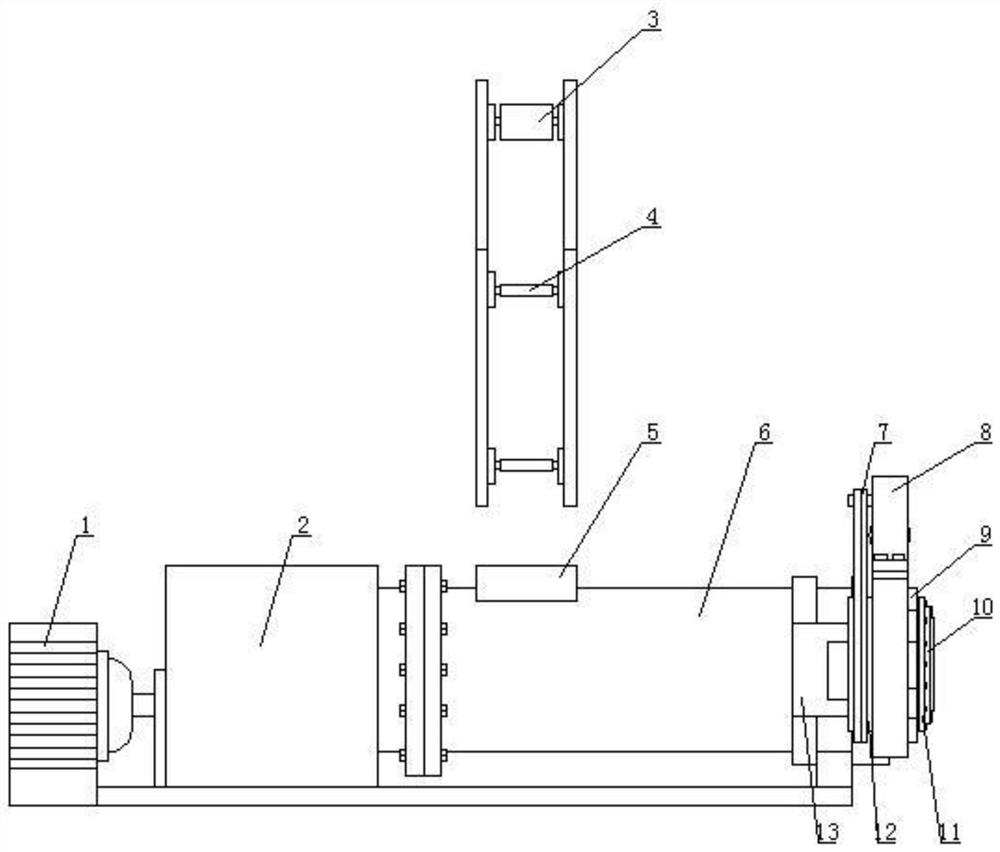

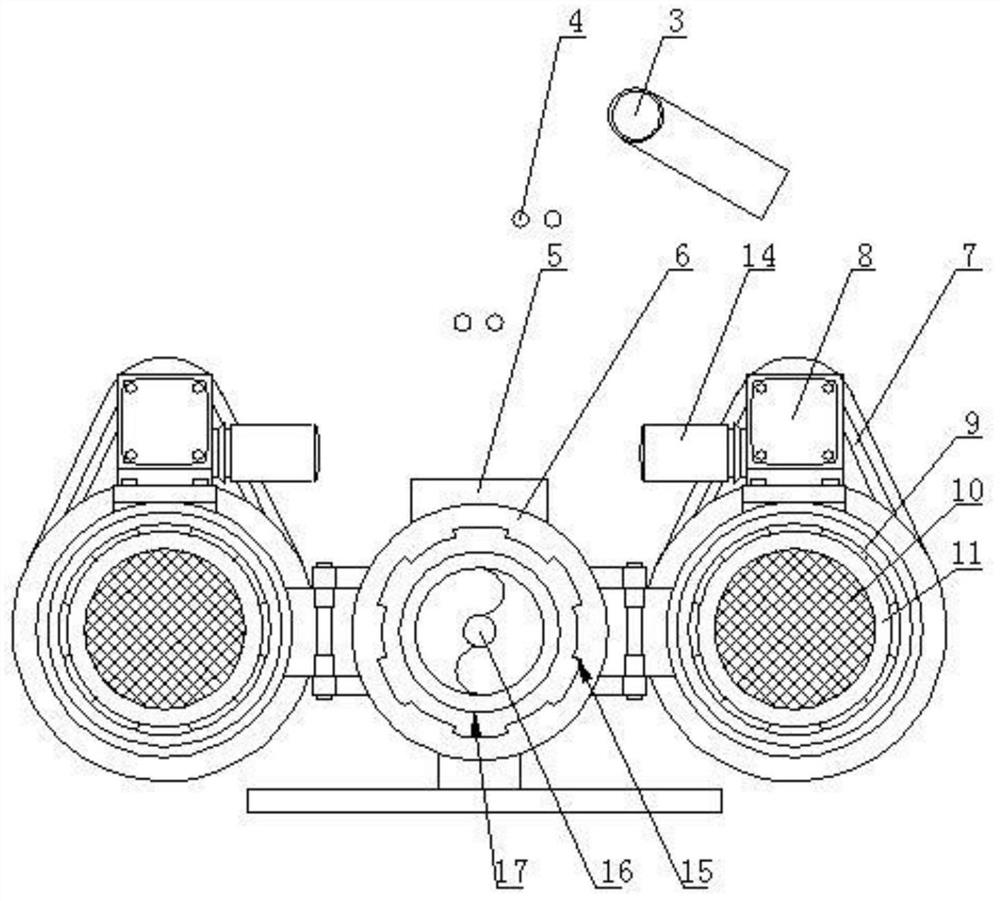

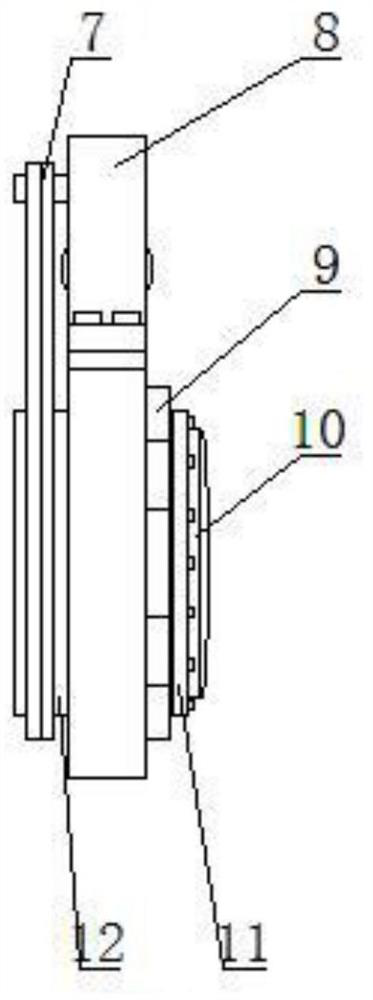

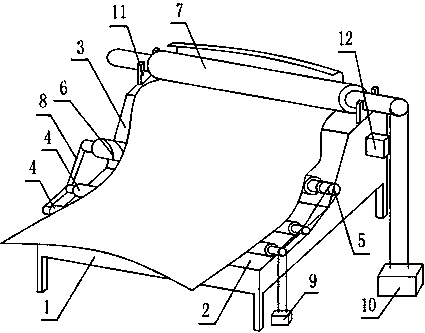

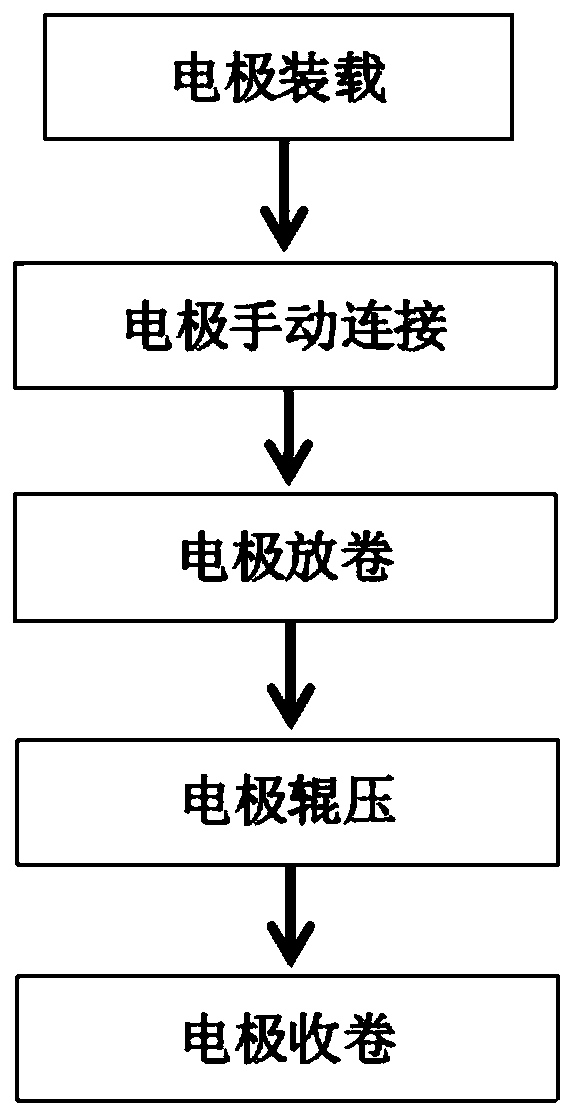

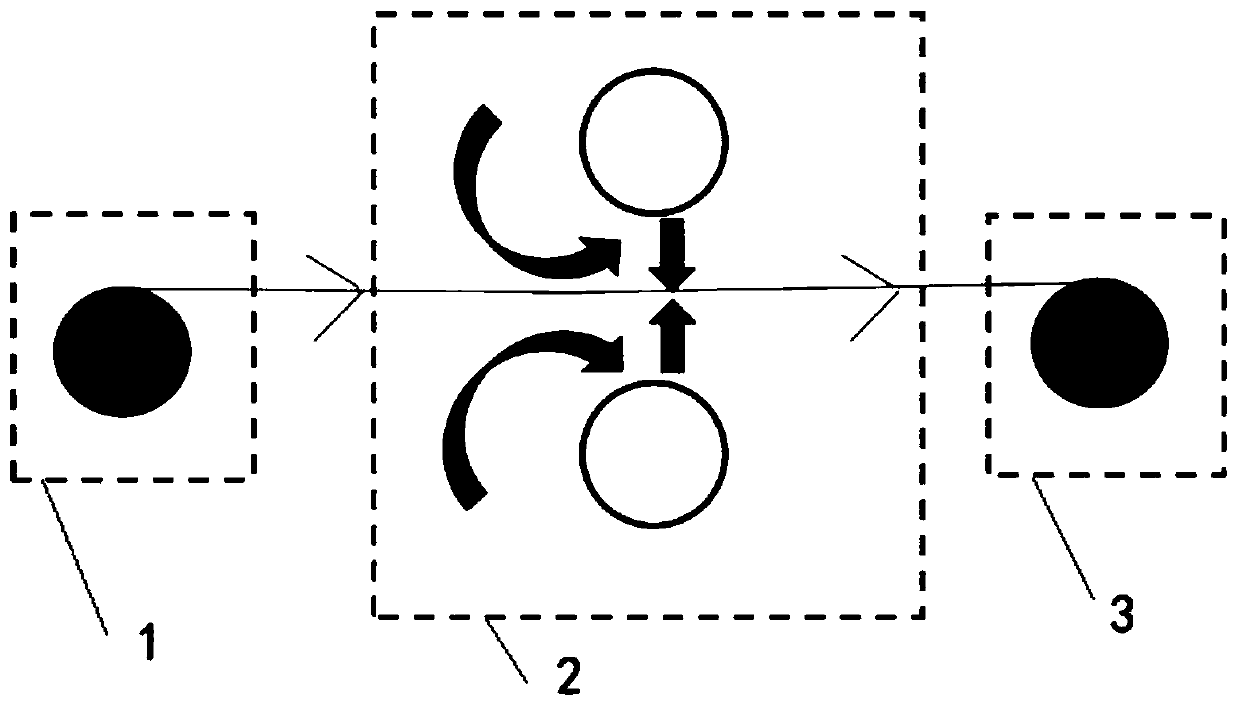

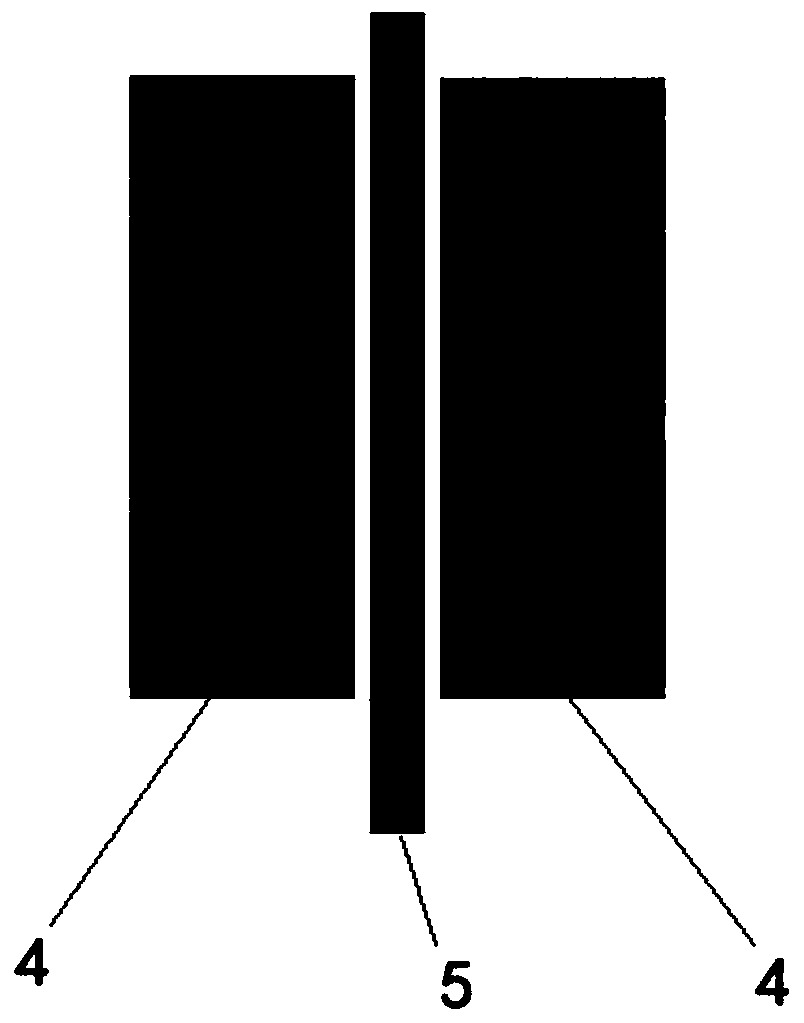

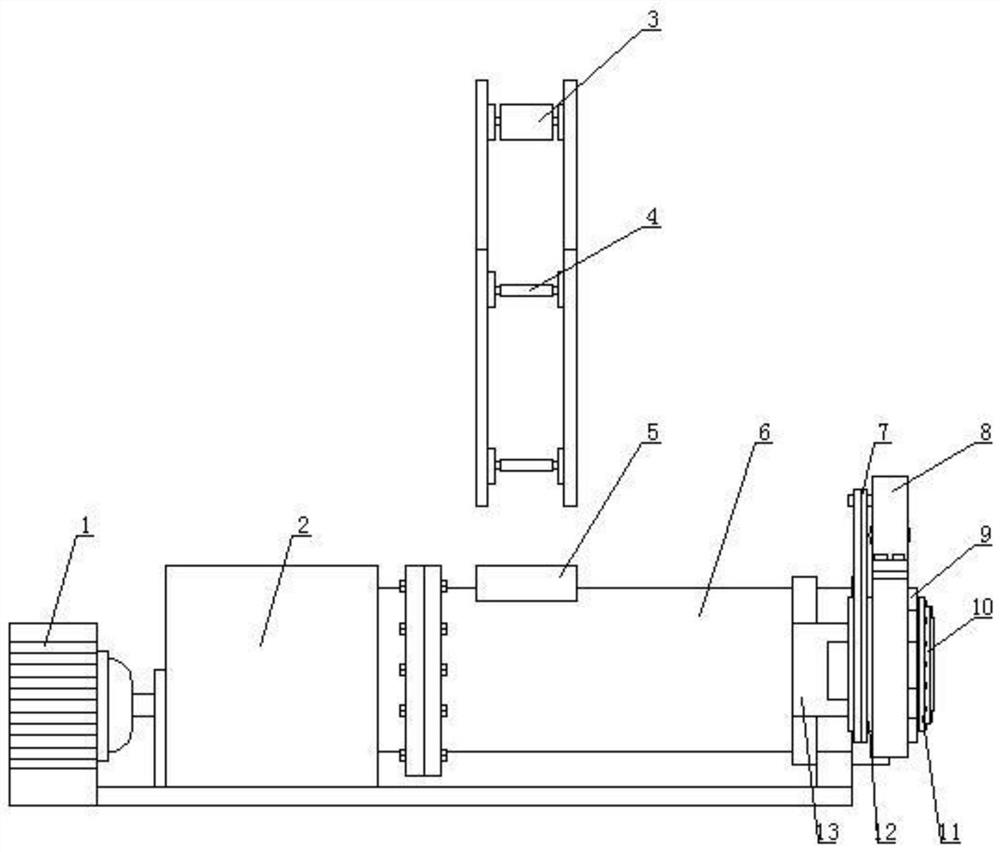

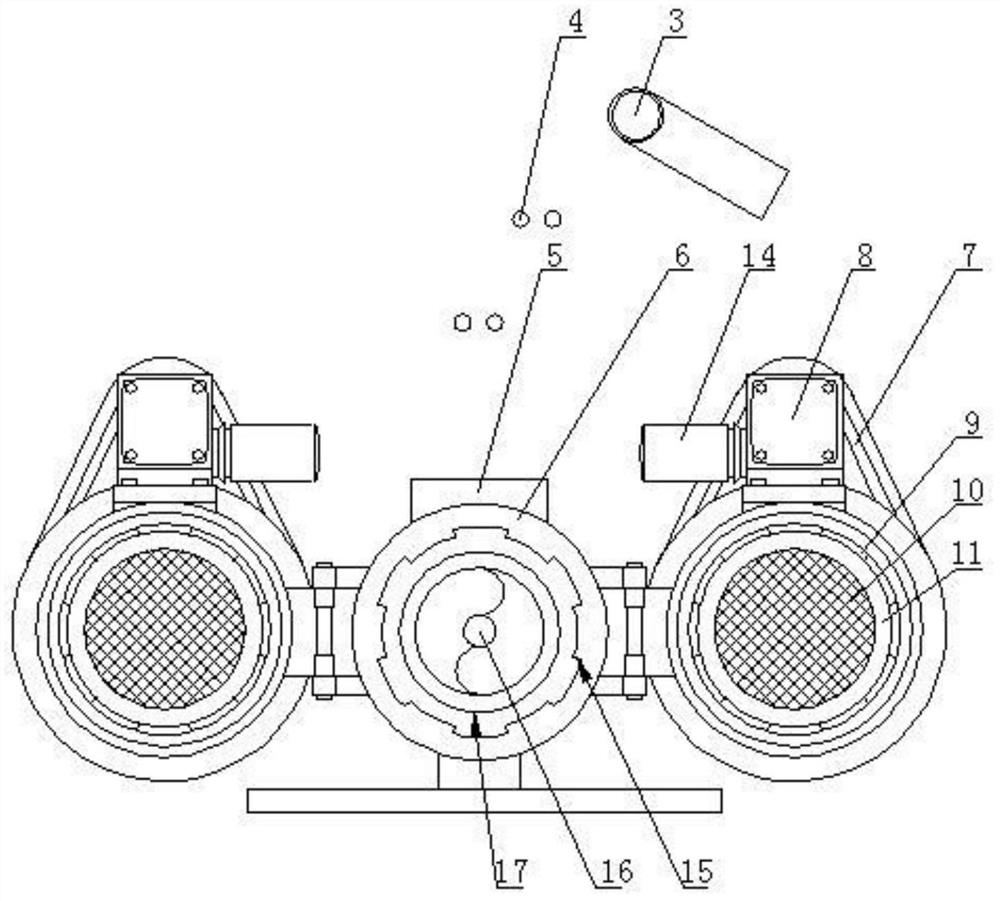

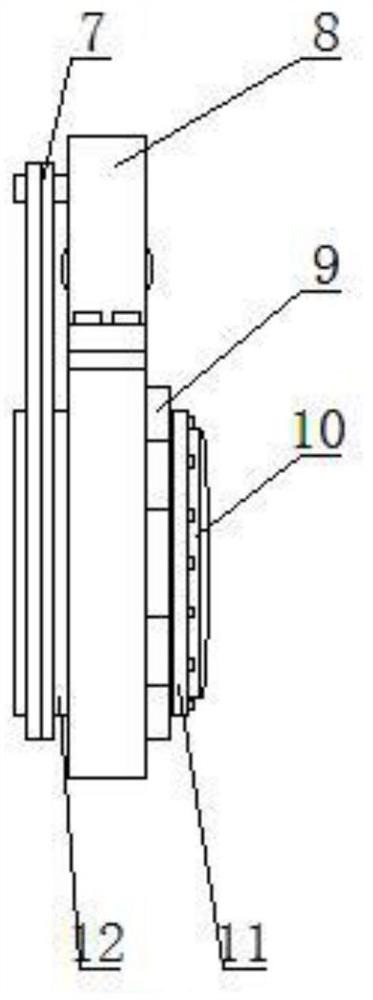

Rolling method and equipment for battery pole piece

ActiveCN108199005AImprove consistencyImprove defects such as poor snake shapeElectrode manufacturing processesElectrical batteryPole piece

The invention relates to the technical field of lithium-ion battery manufacturing, in particular to a rolling method for a battery pole piece. The method comprises the steps of making the coated and dried battery pole piece pass through a foil heating device, an electrode preheating device, an electrode rolling device and a thickness curing device in sequence; when the battery pole piece passes through the foil heating device, heating a foil area of the battery pole piece by using the foil heating device; when the battery pole piece passes through the electrode preheating device, heating a coating area of the battery pole piece by using the electrode preheating device; when the battery pole piece passes through the electrode rolling device, applying rolling force of different sizes to theedge part and the middle part of the battery pole piece by using the electrode rolling device to roll the battery pole piece; and when the battery pole piece passes through the thickness curing device, sequentially baking and cooling the battery pole piece by using the thickness curing device. The invention further provides rolling equipment for the battery pole piece. According to the rolling method and the rolling equipment, the thickness consistency of the rolled battery pole piece is effectively improved.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

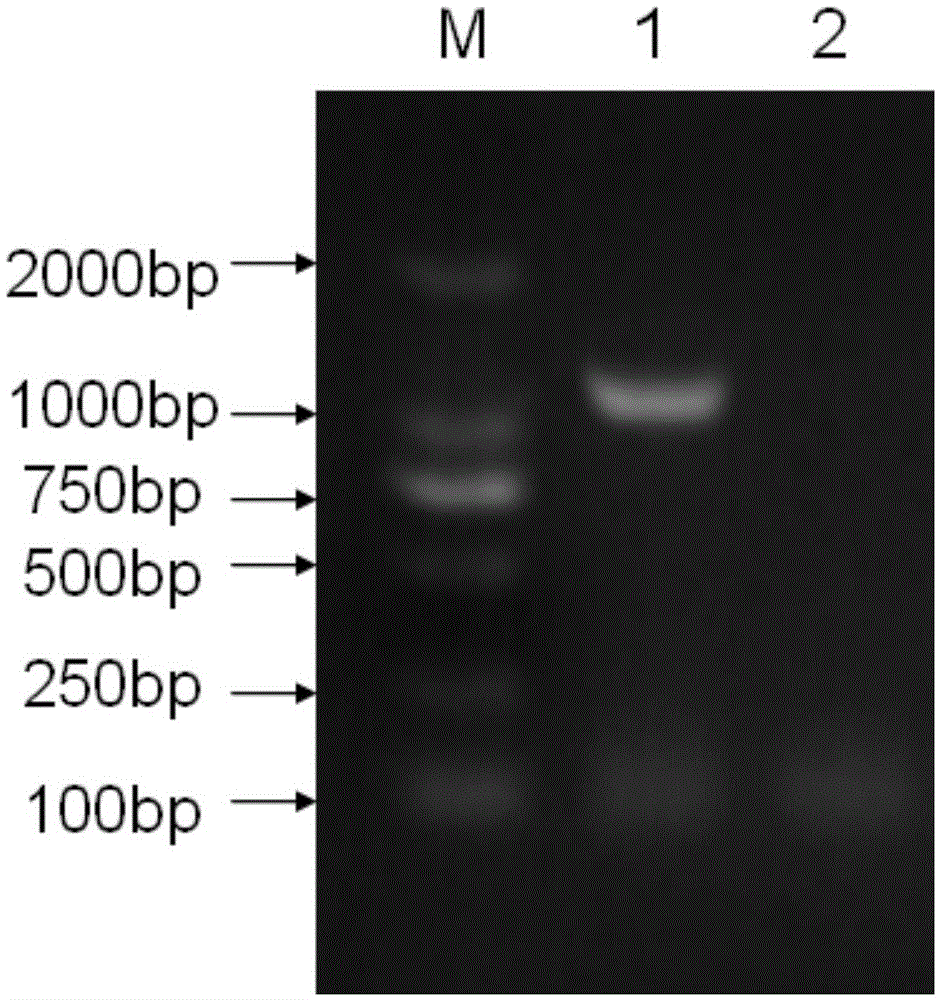

Construction and application of recombinant human interleukin 12 eukaryotic expression vector

InactiveCN101638657AFully extendedFully foldedGenetic material ingredientsAntibody medical ingredientsLaboratory mouseClinical trial

The invention provides a construction and an application of recombinant human interleukin 12 eukaryotic expression vector and relates to the development of recombinant human interleukin 12 (rhIL-12) eukaryotic expression vector, the screening of stable expression cell lines and the adjuvant function of nucleic acid vaccine gene and the therapeutical effect of tumor gene. Ten hydrophobic flexible amino acid joints are used to connect P40 and P35 to obtain fusion gene to construct rhIL-12 eukaryotic expression plasmid (pCDNA6-IL-12), then the expression plasmid is transferred to CHO cell and finally stable expression cell lines are screened. The expression product has good biological activity. Nucleic acid vaccine and pCDNA6-IL-12 are used for coimmune so as to significantly increase the immune effect. Strong antitumor effect can be exerted when the expression vector of the invention is directly injected inside the tumor of laboratory mouse tumor model or is first used to perform gene modification to tumor cells and then implanted in tumor. The expression vector of the invention can be used in the search of clinical trial stage after further perfecting.

Owner:张文卿

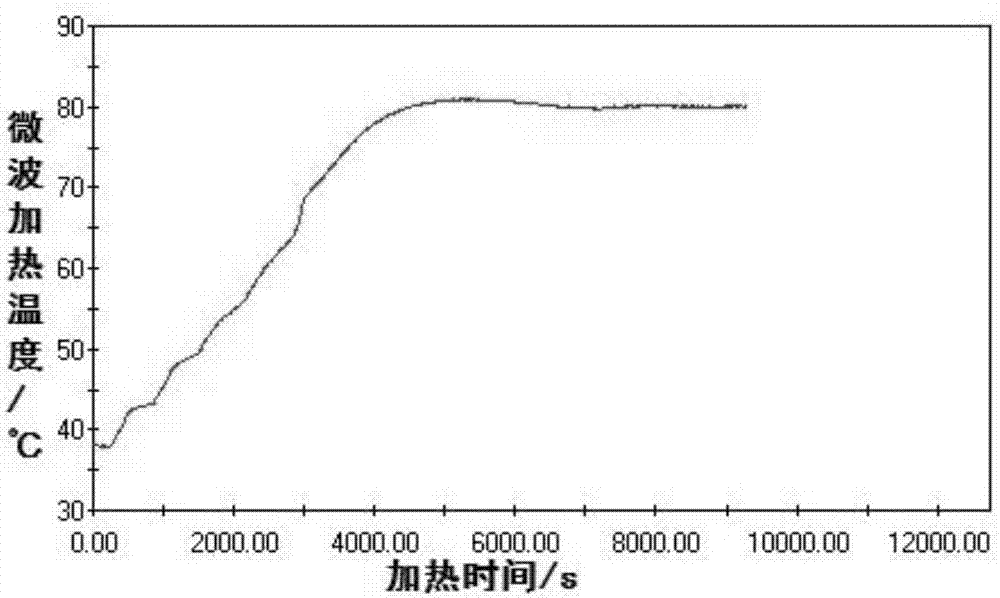

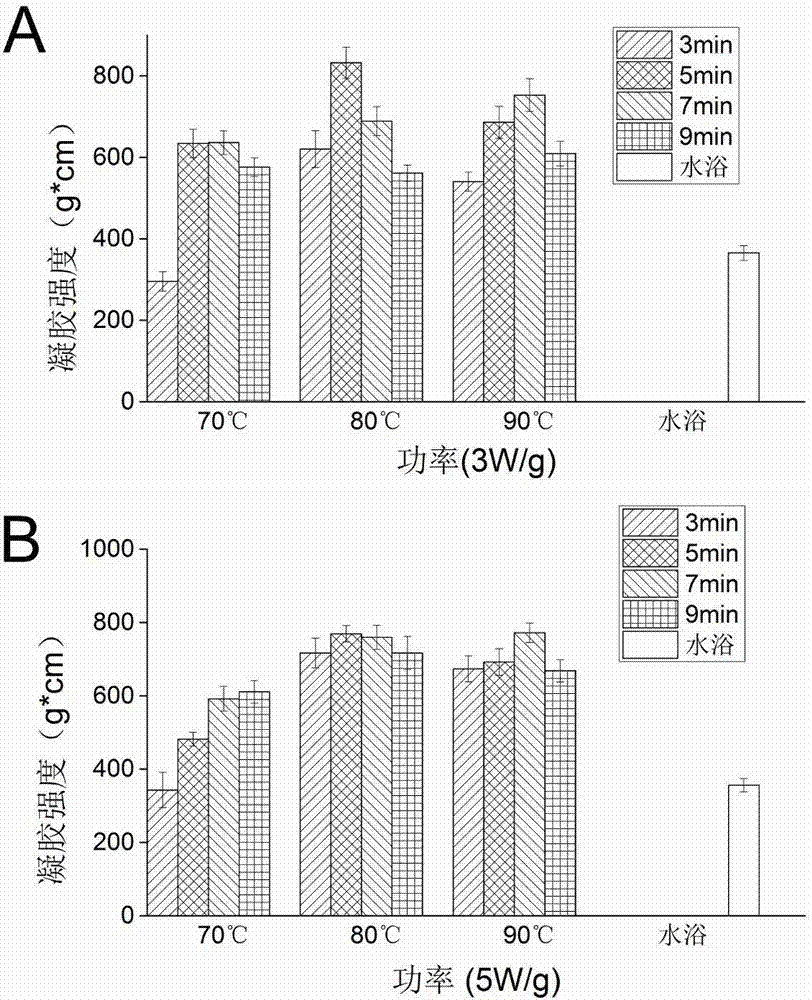

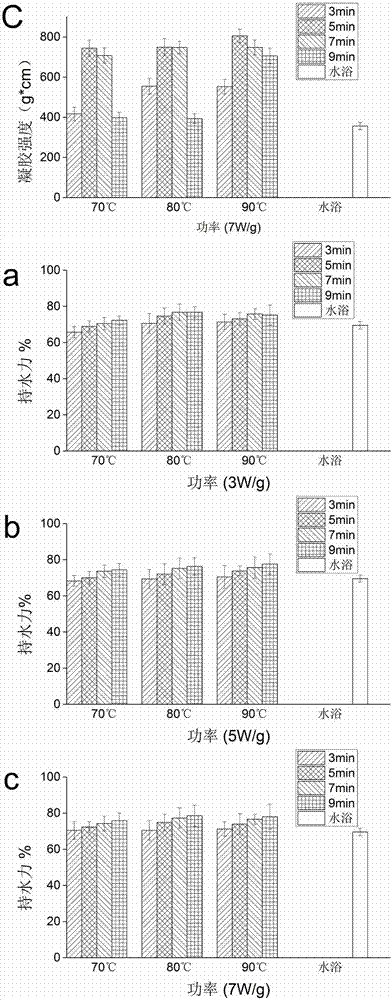

Microwave combined heating method for improving surimi product gel strength

ActiveCN107242471AHigh gel strengthIncrease productivityFood thermal treatmentFood preservationEngineeringMicrowave power

Belonging to the technical field of food processing, the invention discloses a microwave combined heating method for improving surimi product gel strength. According to the invention, firstly conduction is employed for full gelatinization of surimi, then microwave heating is carried out to make surimi gel pass a gel cracking area quickly, the microwave combined heating way not only can improve the surimi gel strength and endow the required elasticity, but also can save a lot of time and improve production efficiency. Compared with ordinary microwave heating, the microwave combined heating method using conduction and microwave heat preservation, i.e. adjustment of the microwave power in a specified temperature interval to maintain the surimi product temperature for a period of time, can effectively improve the surimi gel strength, and follows the current new tendency of application of microwave heating in surimi products.

Owner:FUJIAN ANJOY FOODS CO LTD +4

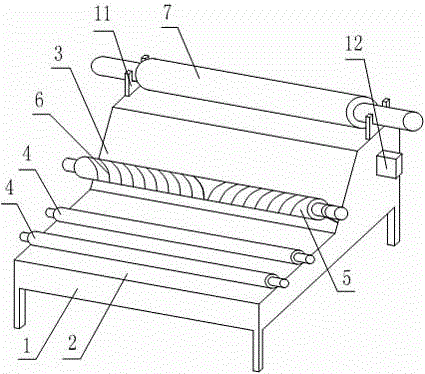

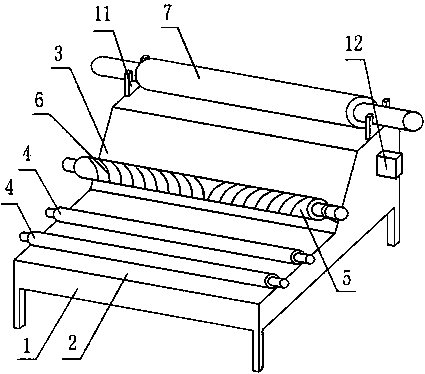

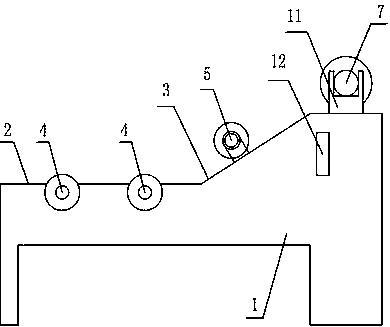

Cloth rolling machine bringing convenience to reading of length of rolled cloth

InactiveCN105800364AIncrease motivationFully extendedArticle deliveryWebs handlingPulp and paper industry

The invention discloses a cloth rolling machine bringing convenience to reading of the length of rolled cloth. The cloth rolling machine comprises a rack, a plane and a slope are arranged on the rack, at least two first cloth guide rollers are arranged on the plane of the rack, and a second cloth guide roller is arranged on the slope of the rack; the surface of the second cloth guide roller is wound with spiral silk-shaped protrusions spreading from the axial central line to the two ends; and the top or the back portion of the slope is provided with a cloth rolling roller, the first cloth guide rollers rotate in the direction of the top end close to the slope, the second cloth guide roller and the first cloth guide rollers rotate in the same direction, and the cloth rolling roller and the cloth guide rollers rotate in the reversed direction. The cloth rolling roller is further provided with a circle number counting device which is connected to a processing module, the processing module is connected to a display screen, and the processing module and the display screen are both arranged on the rack. The cloth rolling machine is used for solving the problems that in the prior art, a cloth rolling machine is complex in structure and cumbersome in operation, and the aims that the cloth rolling machine is simple in structure and convenient to operate, the length of the rolled cloth is conveniently obtained, and meanwhile it is guaranteed that the cloth is sufficiently and smoothly unfolded are achieved.

Owner:CHENGDU LINSHI SHAGUA TECH CO LTD

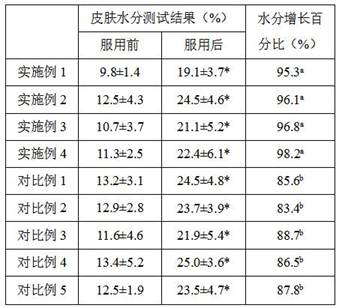

Composition for resisting wrinkles, preserving moisture and improving skin elasticity and preparation process of composition

ActiveCN113875993AIncrease elasticityAvoid churnNatural extract food ingredientsFood ingredient functionsBiotechnologyGrape seed

The invention relates to the technical field of health-care products, in particular to a composition capable of resisting wrinkles, preserving moisture and improving skin elasticity and a preparation technology of the composition. The composition comprises collagen peptide, elastin peptide, hyaluronic acid, salmon nasal cartilage composite powder, a pomegranate extract, an olive fruit extract, a grape seed extract and a German chamomile extract. The composition has the advantages of resisting wrinkles, preserving moisture, improving skin elasticity and being remarkable in antioxidant effect.

Owner:广东浠芮生物科技有限责任公司

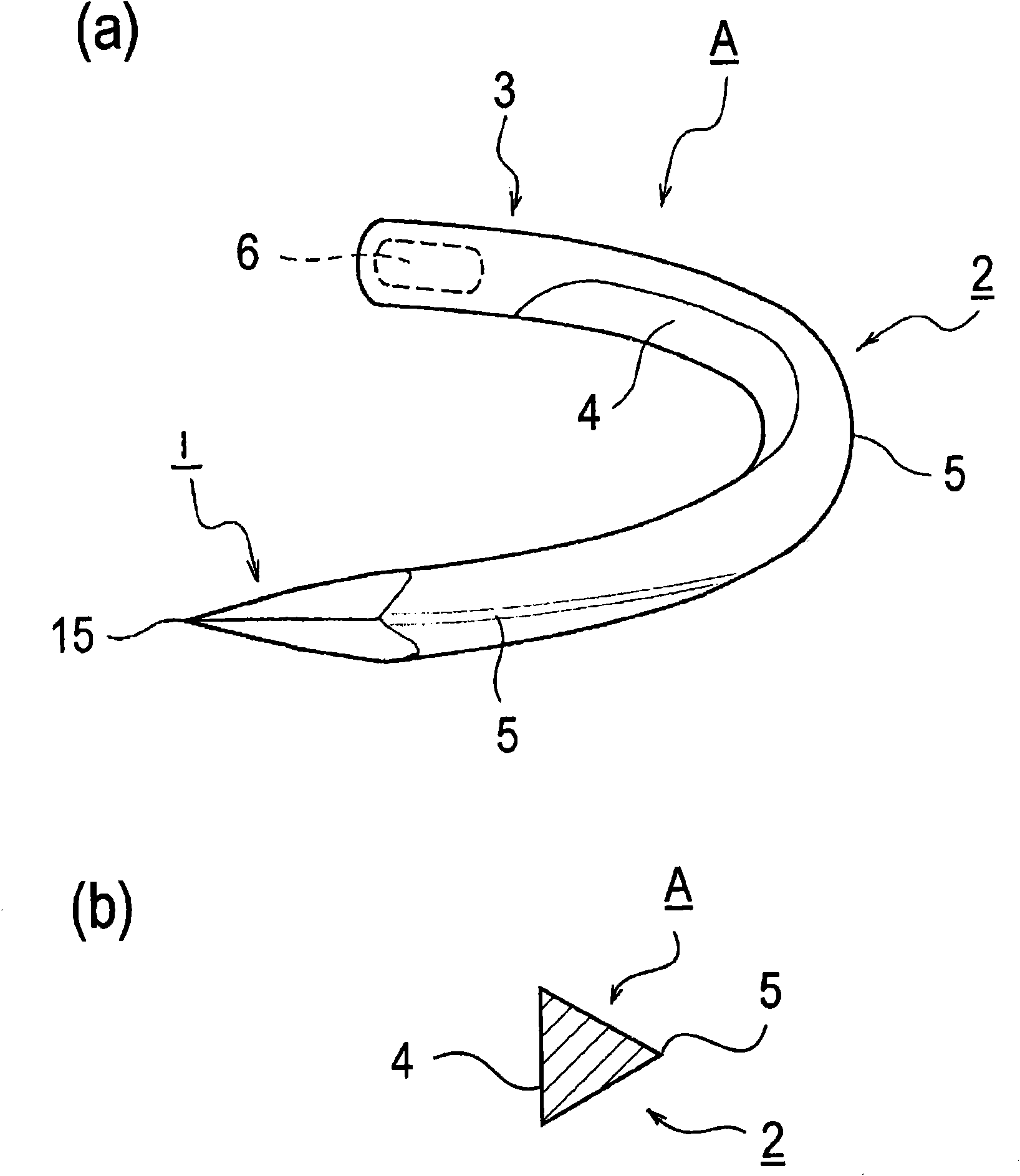

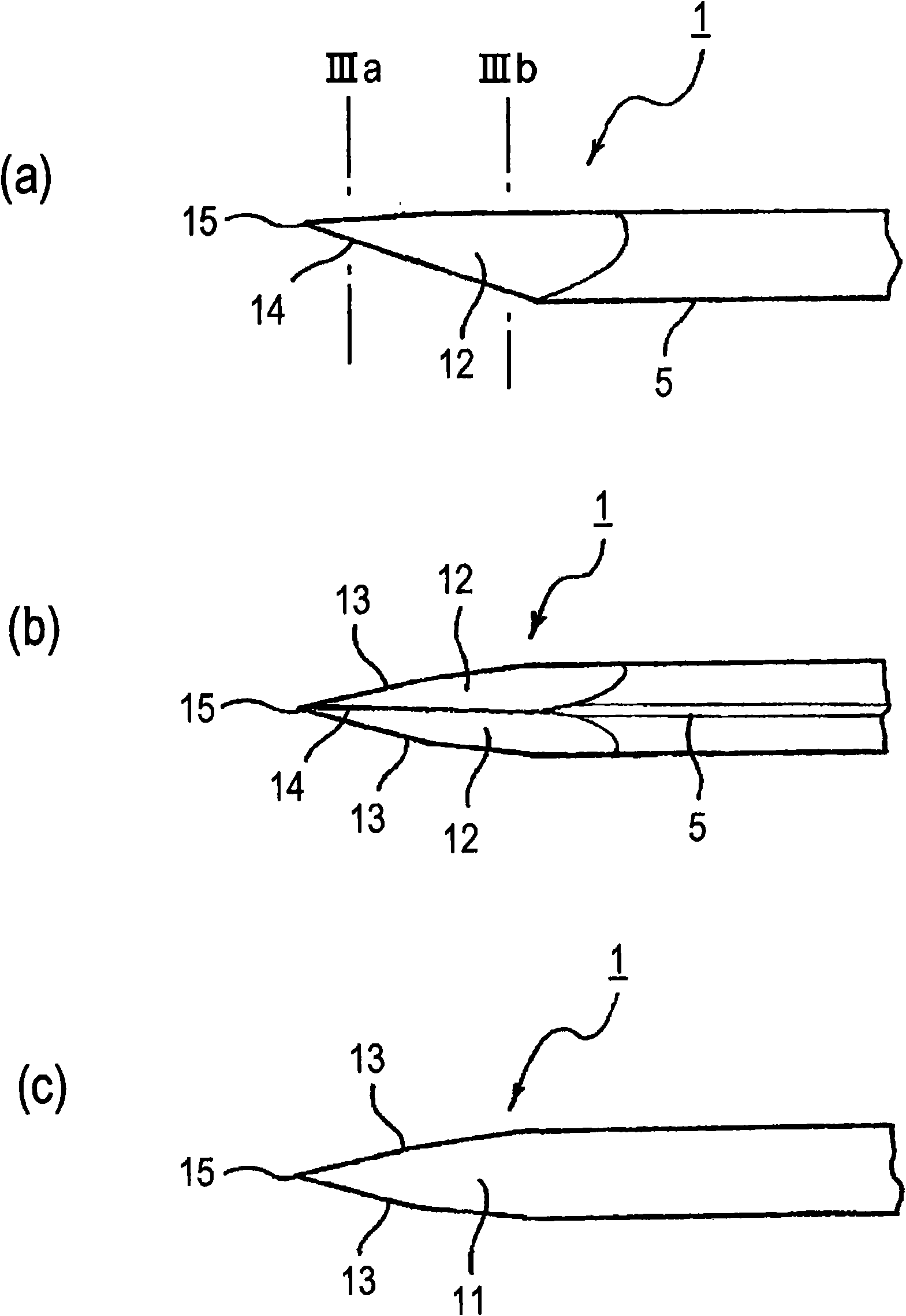

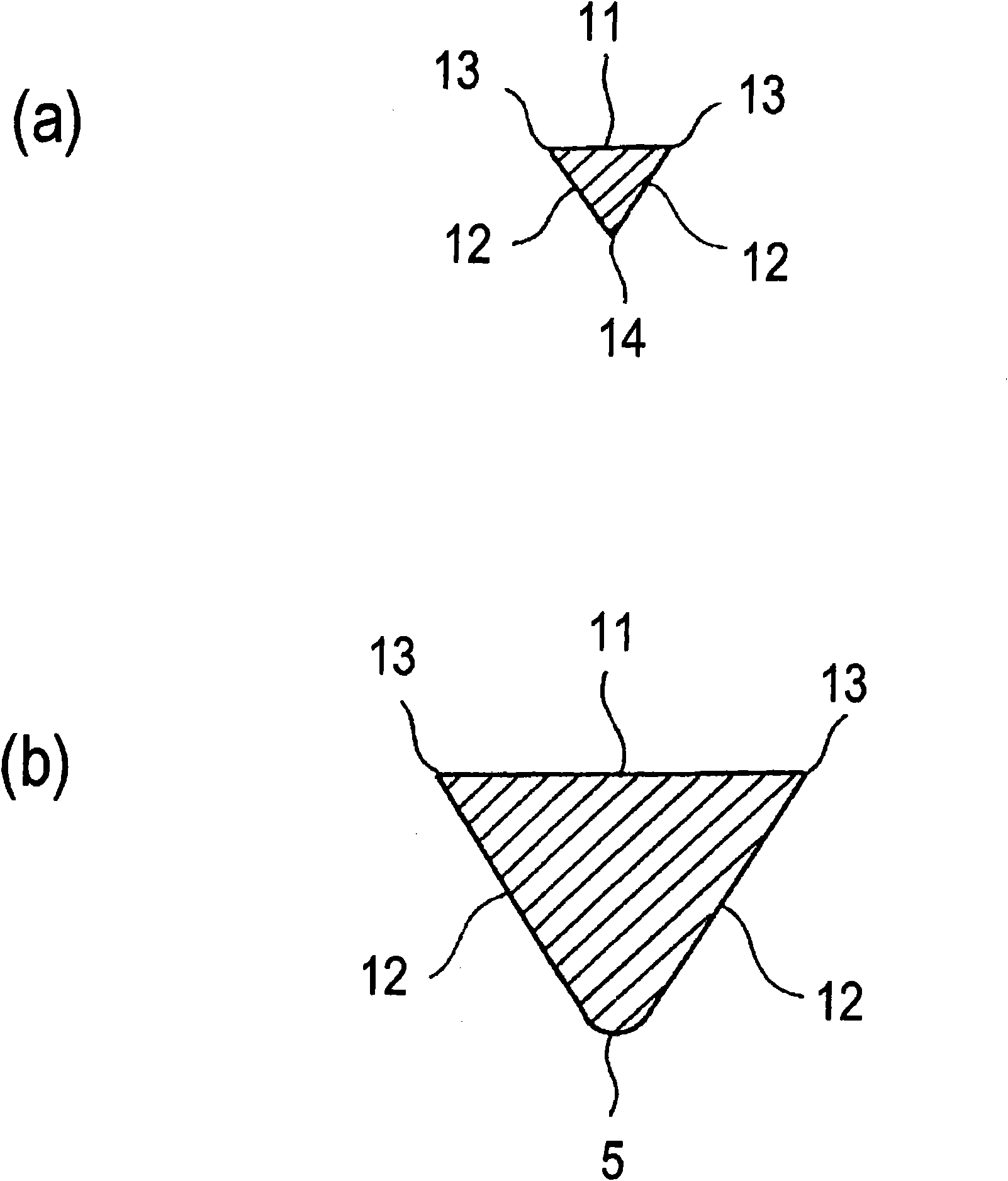

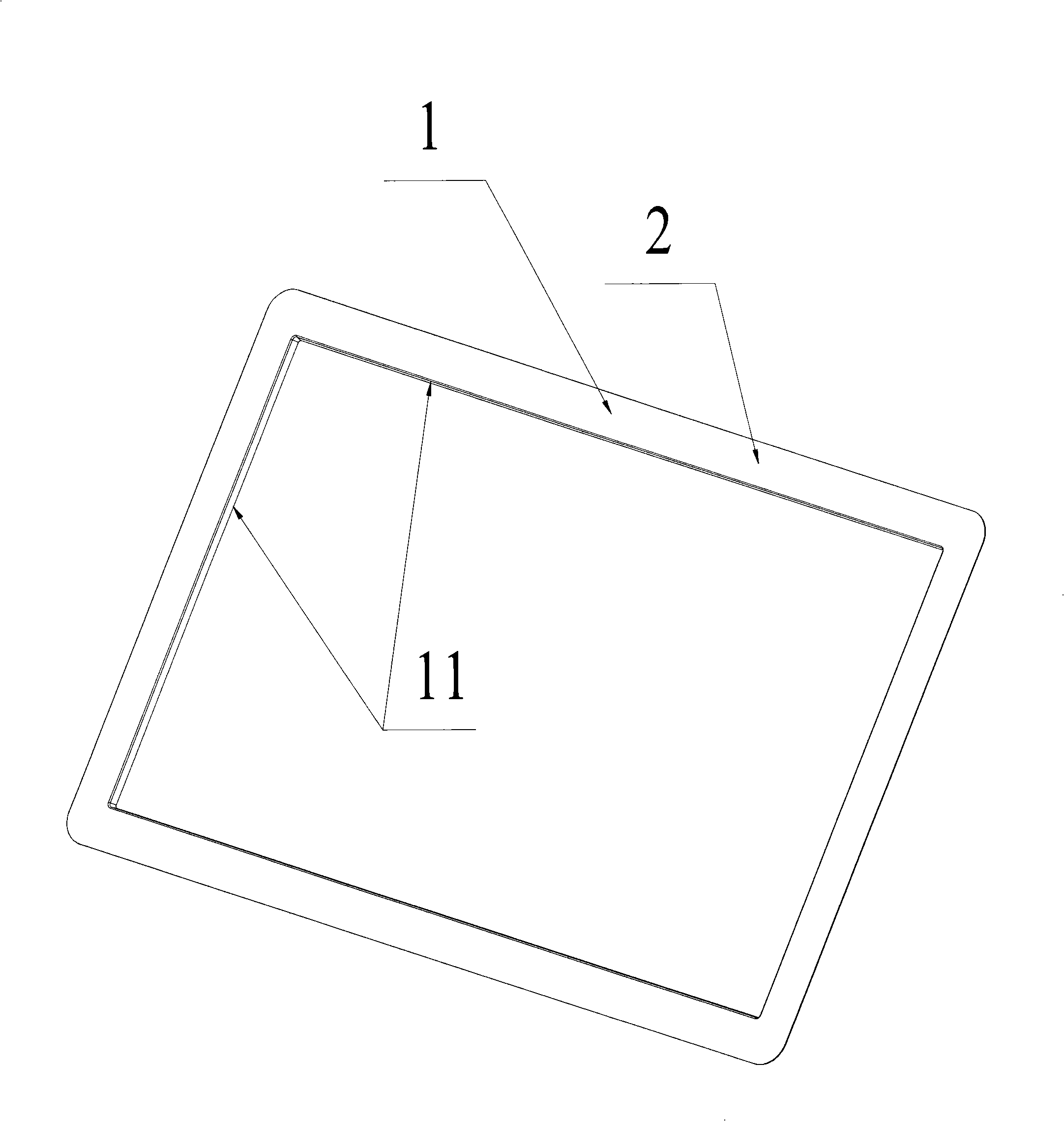

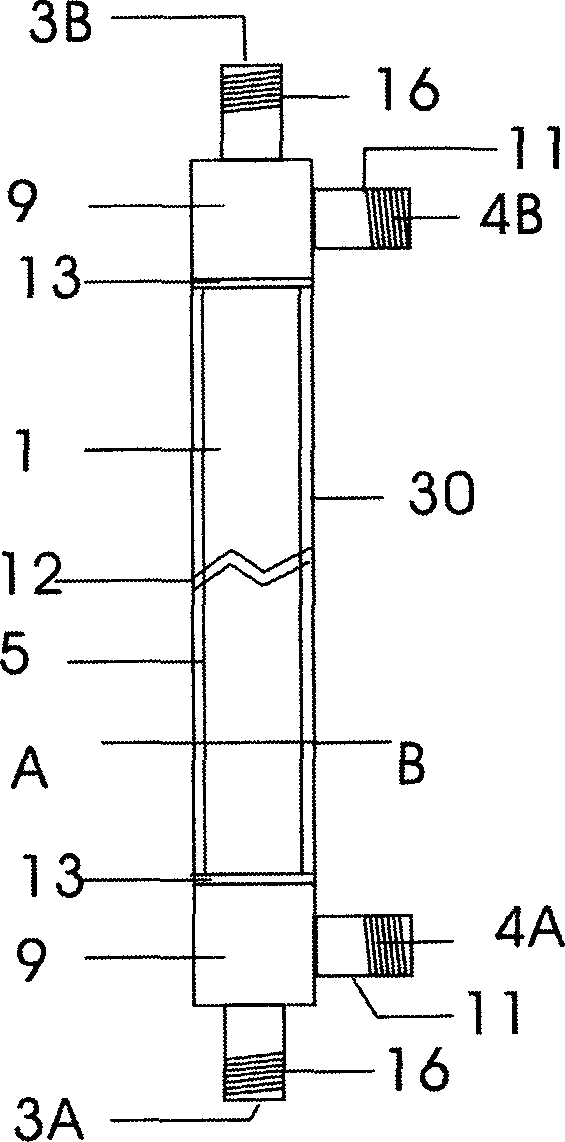

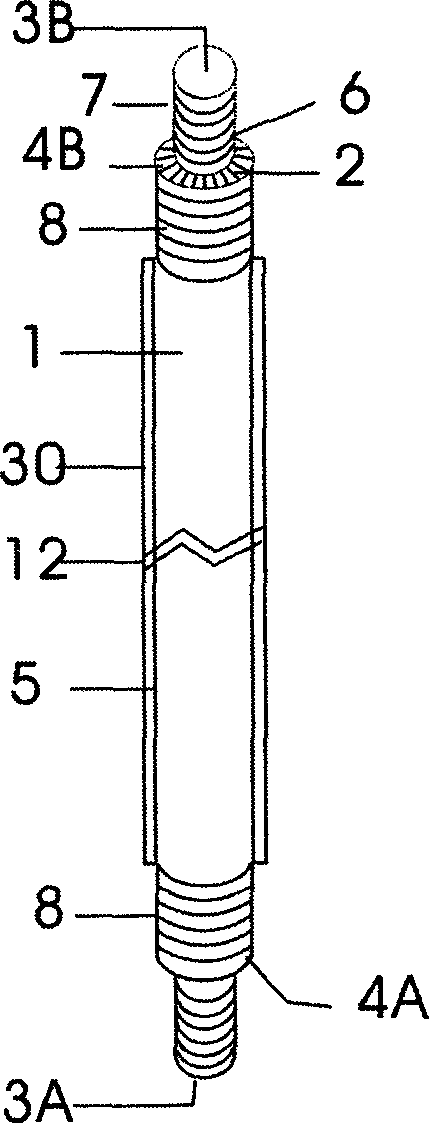

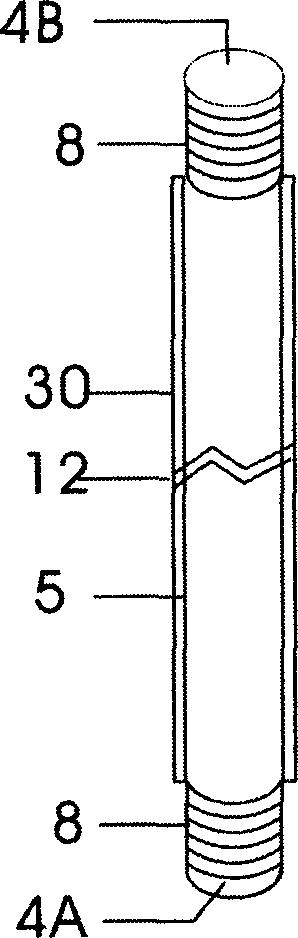

Medical suture needle

ActiveCN102014765AReduce hardnessHigh hardnessSurgical needlesGrinding machinesFlexural strengthSuture needles

The goal is to provide a medical suture needle having, as the material, austenite stainless steel with a structure that is elongated in a fiber form while improving the hardness and flexural strength of the blade. A medical suture needle (A) is made of austenite stainless steel having a structure that is elongated in fiber form, and has a blade (1) and a shaft (2) with a triangular cross-sectional shape that is continuous with said blade (1). The blade (1) has cutting edges (13), at least one surface of which is formed by a pressed surface (11), and which are formed by the intersection of said pressed surface (11) with two sharpened surfaces (12), and a cutting edge (14) that is formed by the intersection of the two sharpened surfaces (12). The tip (15) where the various cutting edges (13) and (14) converge is positioned in the center of the pressed surface (11). Moreover, the cutting edges (13) formed by the intersection of the above pressed surface (11) with the two sharpened surfaces (12) are longer than the cutting edge (14) that is formed by the intersection of the two sharpened surfaces (12).

Owner:MATSUTANI SEISAKUSHO CO LTD

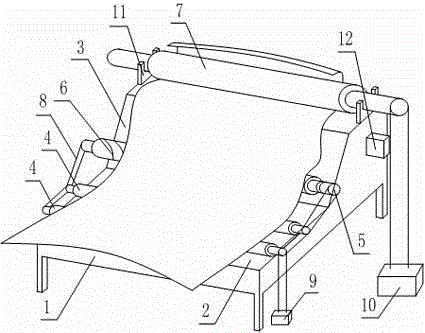

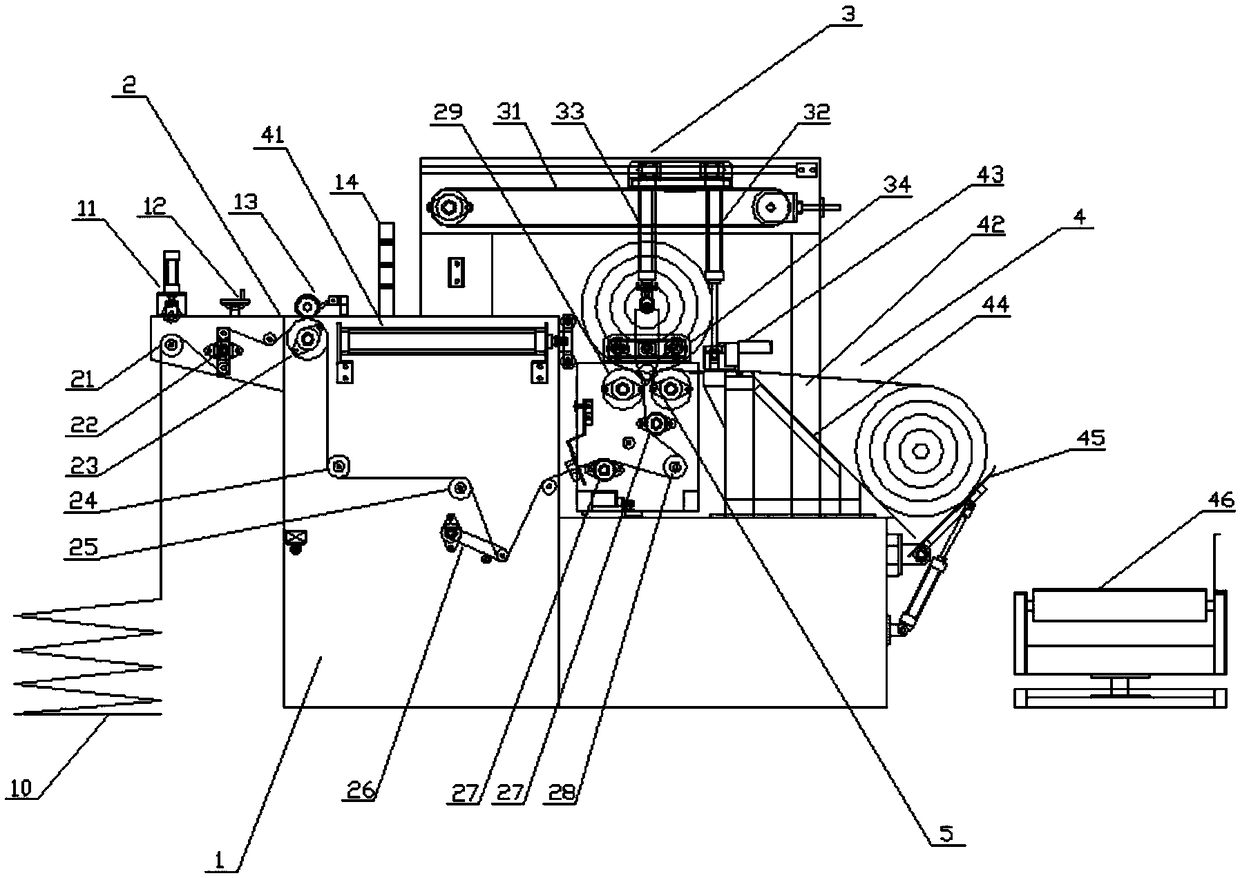

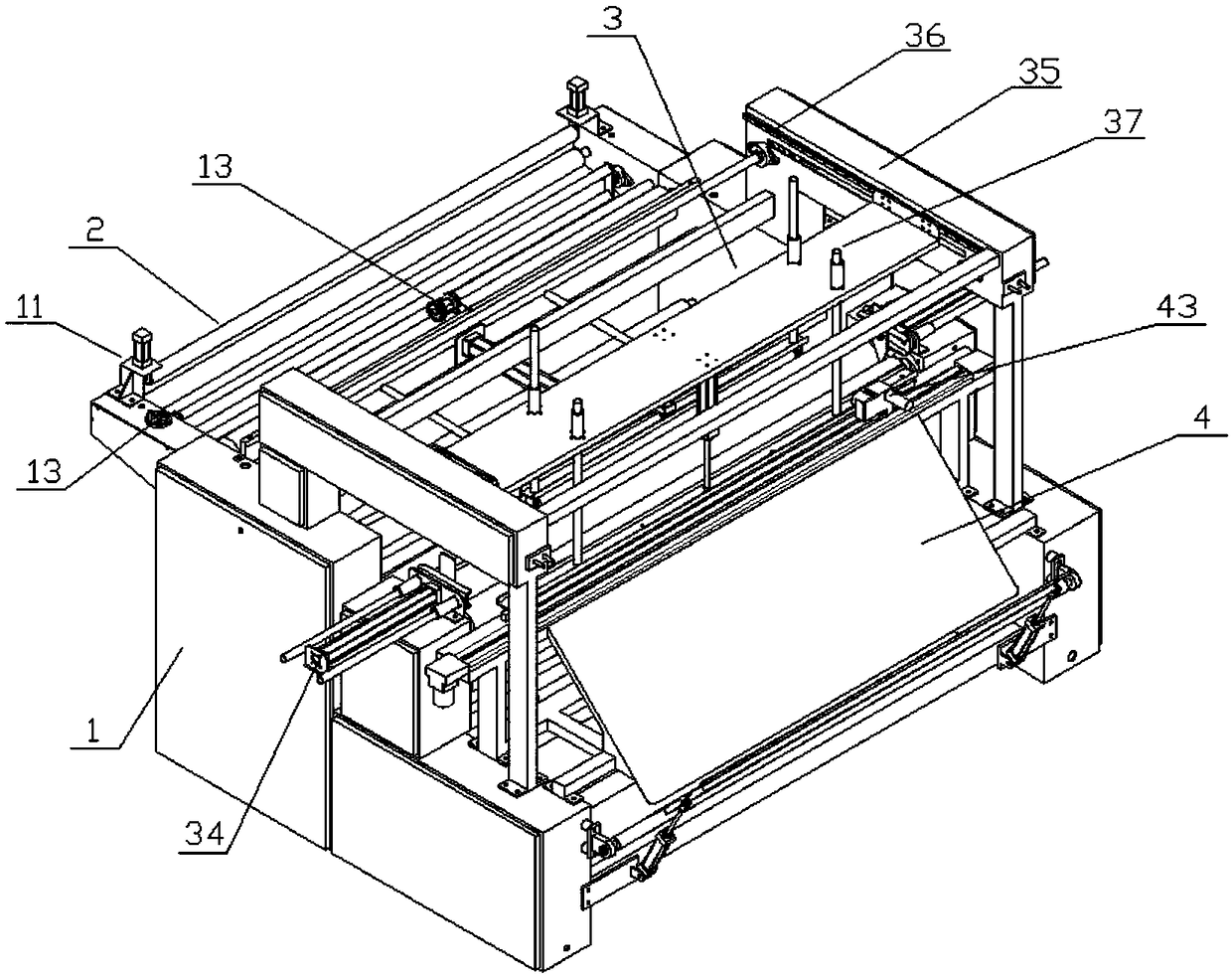

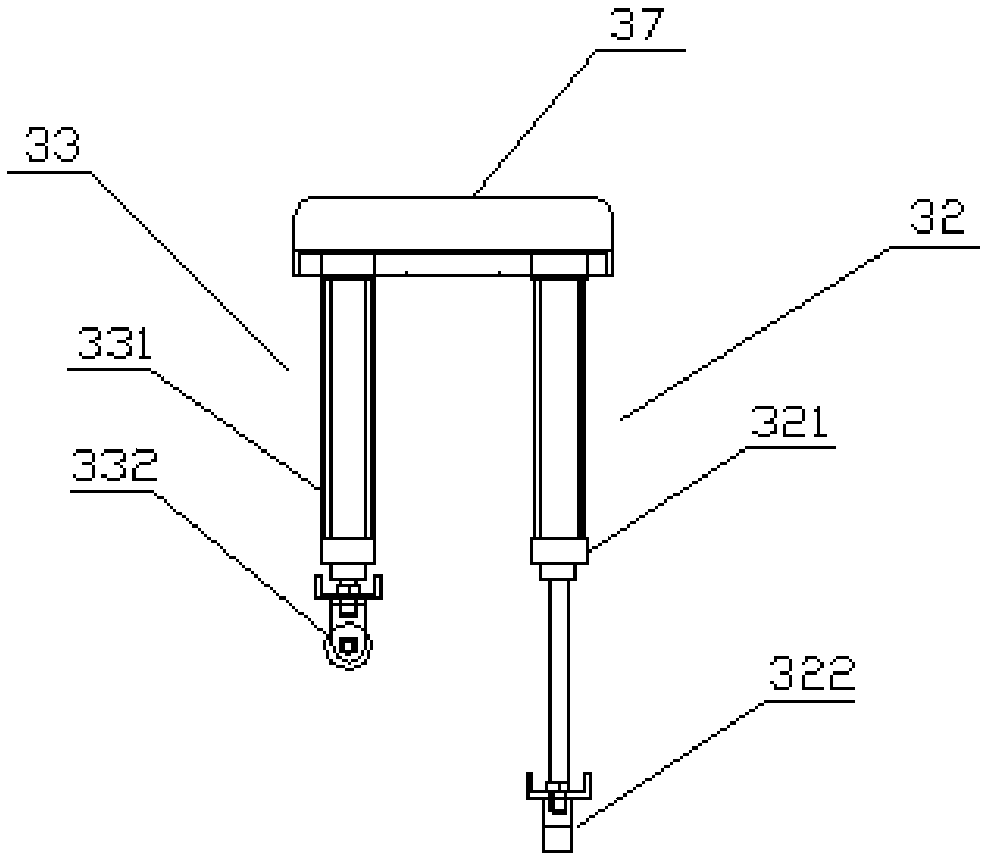

Automatic cloth rolling machine

The invention discloses an automatic cloth rolling machine, which comprises a rack, a controlling cabinet, a cloth feeding device, a cloth rolling device and a discharging device. The cloth feeding device comprises a guide assembly, a transmission assembly, a cloth stretching assembly and a cloth swinging roller. The transmission assembly comprises a first transmission roller and a second transmission roller. The cloth stretching assembly comprises a front area cloth stretching roller and a pair of rear area silk separating rollers. The cloth swinging roller is arranged between the first transmission roller and the rear area silk separating rollers. The cloth rolling device is arranged on the upper portion of the second transmission roller and comprises a driving mechanism, a cloth drivingmechanism, a cloth fixing mechanism and a correcting mechanism. The discharging device comprises a boosting mechanism and a discharging table. The discharging table is provided with an automatic cutting knife. The practical cloth feeding device can stretch cloth adequately and eliminate creases. The cloth rolling device automatically places to-be-rolled cloth onto a cloth rolling paper barrel, cloth rolling is carried out and meanwhile cloth edge tidying operation can be realized, and the quality of rolling production is guaranteed. The discharging device can realize the functions of automatic cloth cutting, automatic conveying and automatic weighing, and manual operation is not required.

Owner:江苏澳得玛机械科技有限公司

Processing technique of liquid crystal television metal frame

The invention discloses a processing technology of a metal face frame of a liquid crystal television, and the processing technology comprises a processing procedure of folding edges and a processing procedure of ambient round angles. The processing technology is characterized in that an aluminum sheet with a cut in the middle is fixed between a concave pattern plate and a fixing plate in the processing procedure of folding edges, wherein the edge of a concave pattern cavity of the concave pattern plate is added with a ring of pressed rib pressed into the aluminum sheet, and the inner edge of the aluminum sheet is pressed by a convex pattern plate to form the folding edge; in the processing procedure of ambient round angles, three pairs of concave-convex pattern insert block components are adopted to bend, punch and shape the four round angles at the connecting places of the four straight edges on the folding edges in three steps, and the radiuses of the arc surfaces on the three convex pattern insert blocks of the concave-convex pattern insert block components are decreased sequentially. The processing technology of the invention can press the folding edges with smaller round angle radius and the four round angles at the connecting places of the four straight edges on the folding edges, and effectively prevent rupture at the four round angles in the processing course, which improves the product quality greatly.

Owner:SUZHOU VICTORY PRECISION MFG

Zinc liquid storage tank for hot galvanizing production line and method for storing zinc liquid by using same

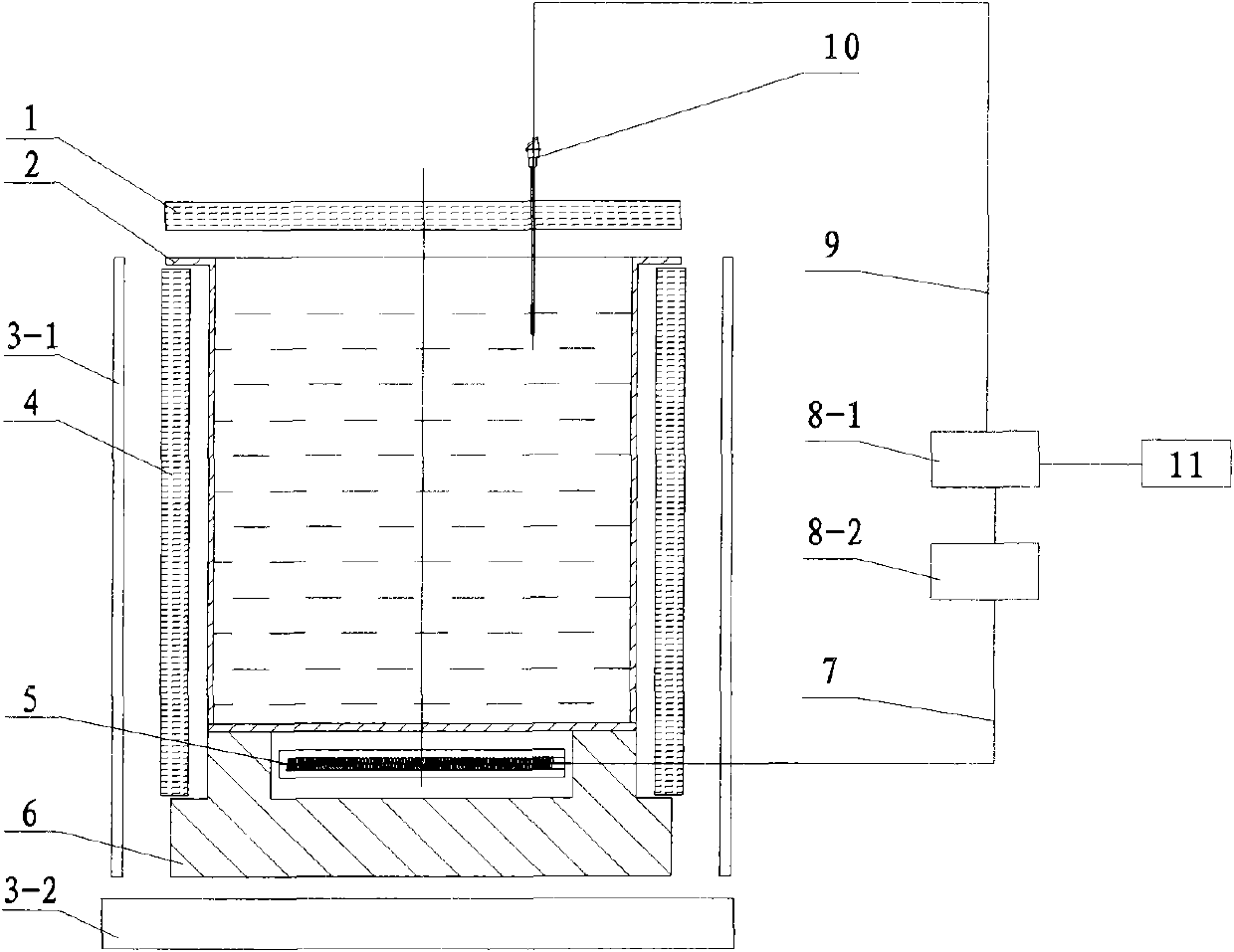

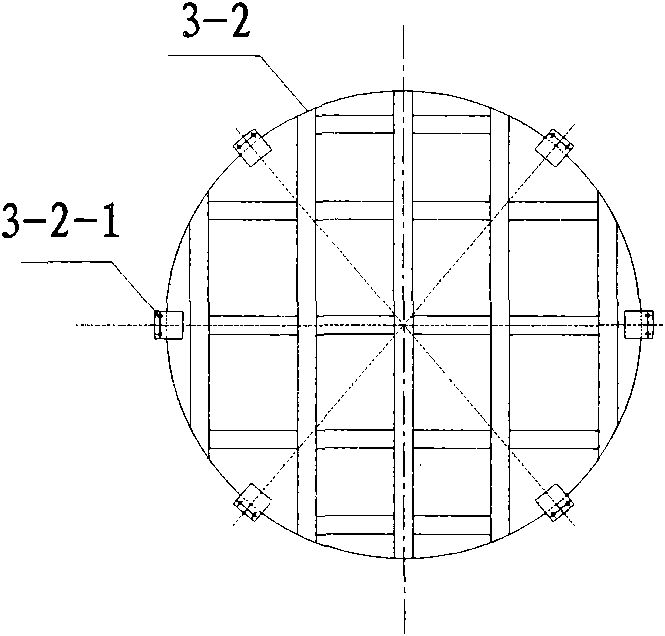

ActiveCN102002660AShorten the timeReduce oxidationHot-dipping/immersion processesTemperatue controlLiquid temperatureBrick

The invention discloses a zinc liquid storage tank for hot galvanizing production line and a method for storing zinc liquid by using the same. The zinc liquid storage tank comprises a zinc storage tank and a PLC (Programmable Logic Controller) temperature collecting and controlling system, wherein the lower part of a tank body inner container of the zinc liquid storage tank is provided with a brick set body; the periphery of the sides is provided with a tank wall insulation cushion; the upper part is provided with a tank body insulation cover; the tank body inner container is made from a steel plate which is specially used for hot galvanizing zinc pot and has the thickness of 20-50mm, and the steel plate specially used for hot galvanizing zinc pot is XG08 type steel plate, wherein C in the chemical component of the steel plate is less than 0.08 percent by weight, and Si is less than or equal to 0.03 percent by weight. The method for storing zinc liquid comprises the following steps of: measuring zinc liquid temperature through thermocouple inserted in the zinc liquid in the tank; and simultaneously controlling a plurality of zinc storage tank body heating elements by a PLC temperature collecting module and a relay assembly to heat and insulate the zinc liquid in the tank. The zinc liquid is stored by using the zinc liquid storage tank, the oxidation loss of the zinc is reduced and the stop production time is shortened.

Owner:SHANGHAI YONGFENG HOT DIP GALVANIZING

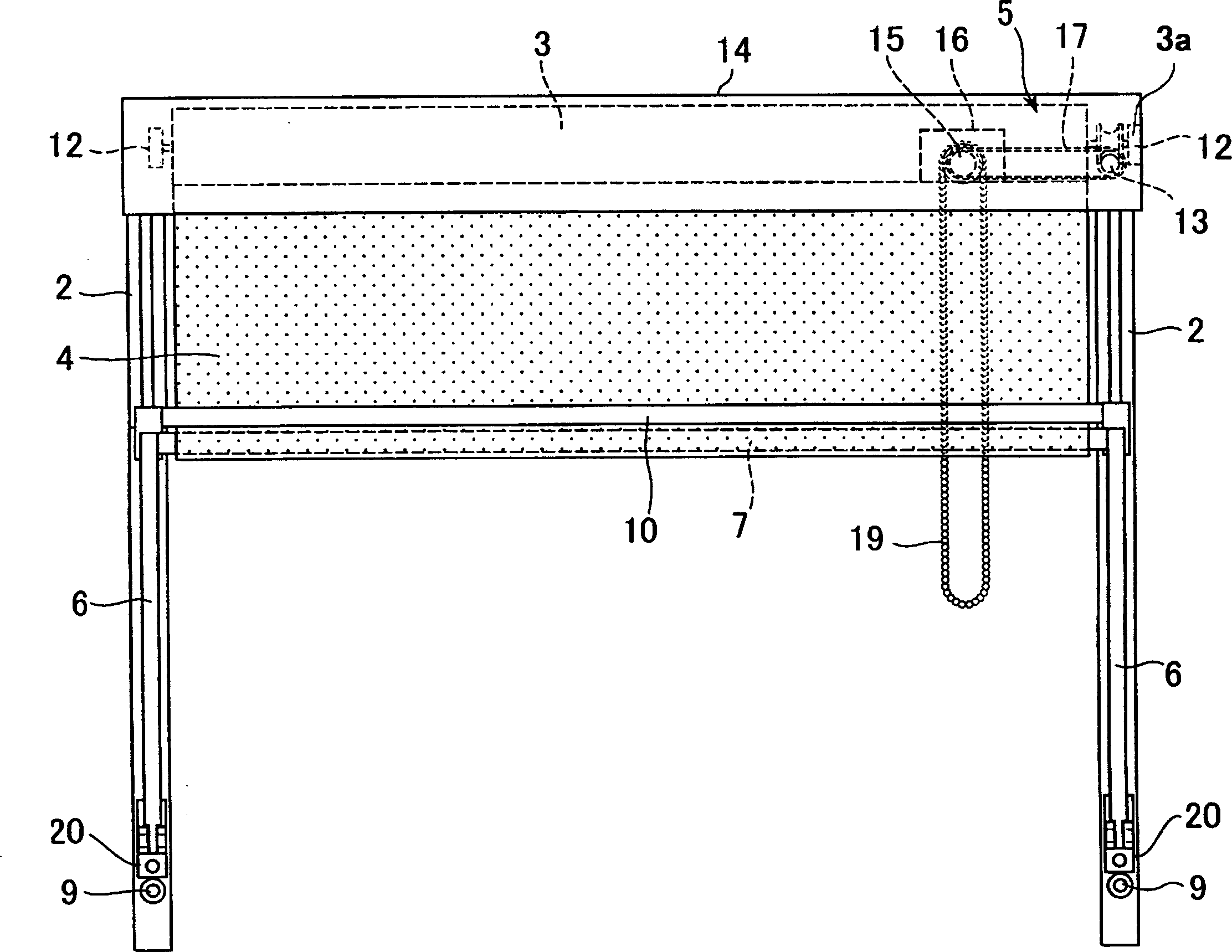

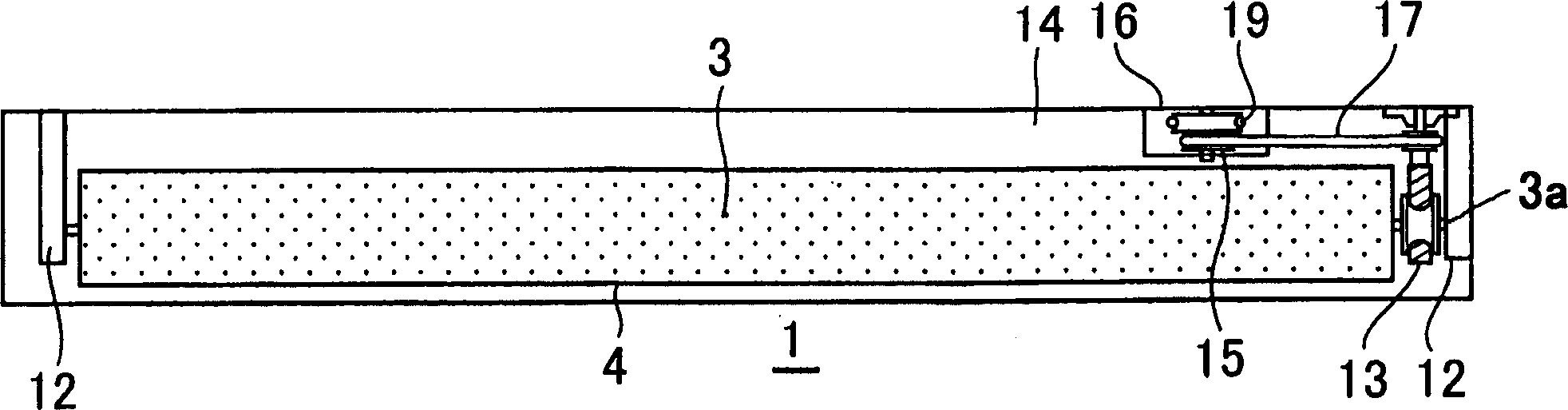

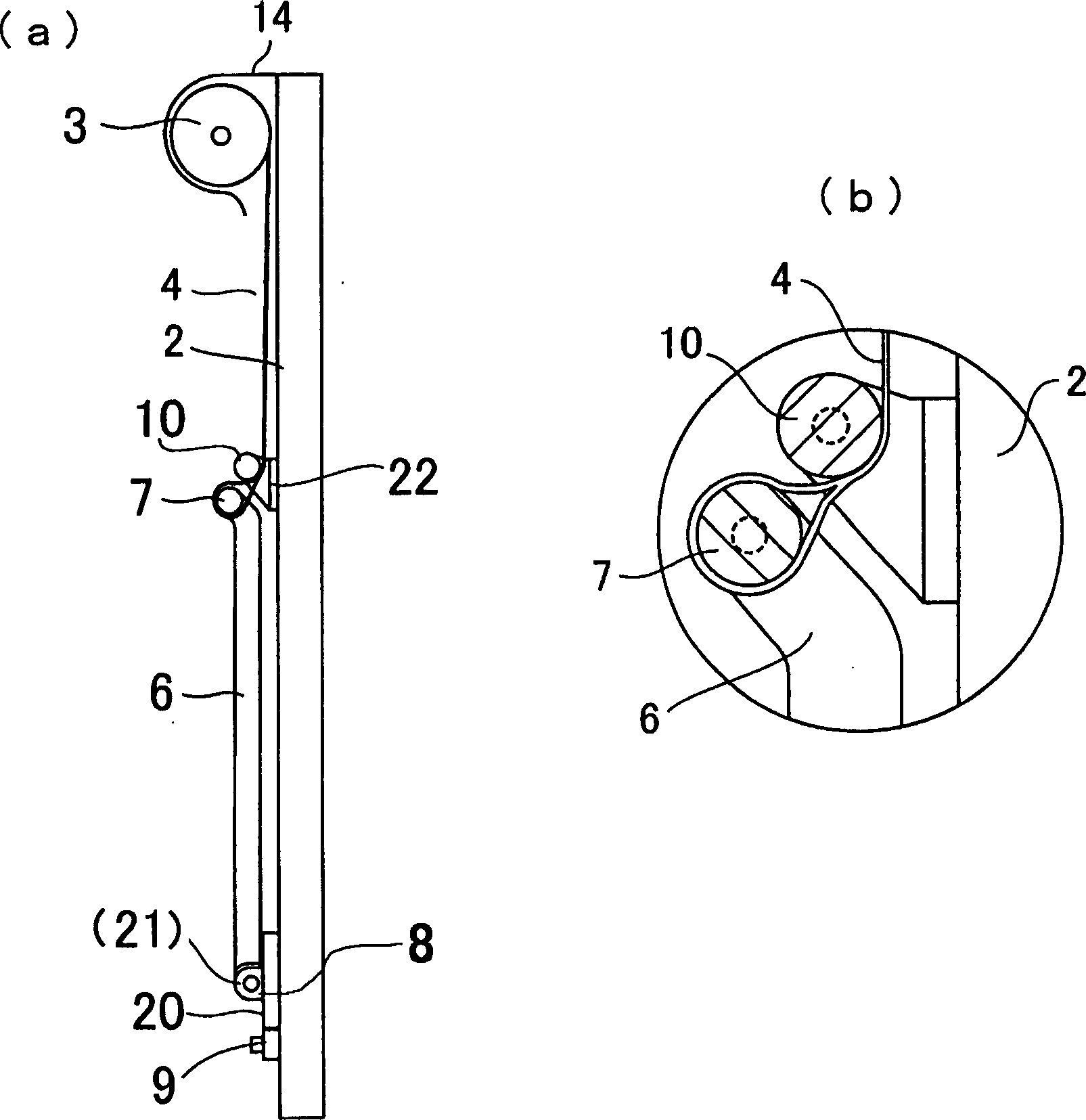

Sunshade device

Provided is a sunshade device for sending out and extending an awning covering an opening of a building, which can be easily operated from indoors and has a large amount of extension. By operating the chain (19) for operation from the indoor side, the roller (3) is rotated by the rotating mechanism (5), and the awning (4) is sent out. Along with the descending of the arm (6), the awning is also sent out until the arm (6) touches the stopper (9), once the arm (6) touches the stopper (9), the self-weight of the arm (6) disappears, through The elastic force of the spring in the arm (6), the arm (6) rotates, carries out the stretching out of awning (4).

Owner:YOKOTA RYOHAN

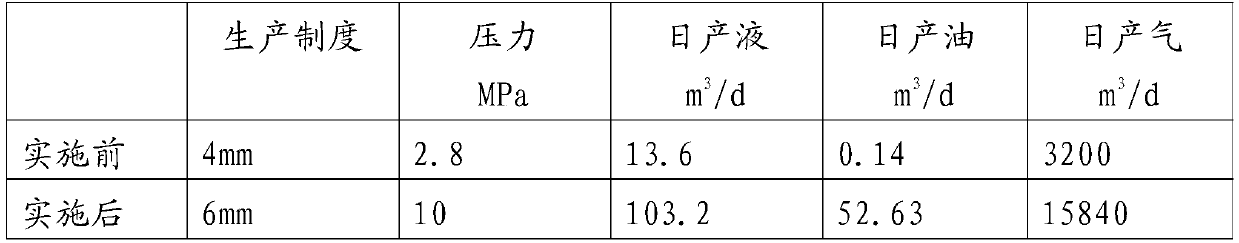

Fracturing process for development and application of low permeability heterogeneous sandstone oil and gas reservoir

ActiveCN110792421AExpand the affected volumeSolve the problems of poor connectivity and poor seepage capacityFluid removalFracturing fluidExpanded clay aggregate

The invention belongs to the field of oil field development, and particularly relates to a fracturing process for the development and application of a low permeability heterogeneous sandstone oil andgas reservoir. The fracturing process for the development and application of the low permeability heterogeneous sandstone oil and gas reservoir includes the following steps that (1), a slickwater leak-off and energization stage is carried out, specifically, slickwater and quartz sand or ceramsite are pumped into a reservoir to form micro-cracks to improve the seepage ability of a stratum; and (2),a main fracture stage of long cracks formed by fracturing fluid is carried out, specifically, the low viscosity fracturing fluid and the ceramsite are pumped into the stratum to form the long crackswith high conductivity, and the long cracks communicate the micro-cracks in the step (1) to establish a near-wellbore high seepage zone and reduce the seepage pressure. According to the fracturing process for the development and application of the low permeability heterogeneous sandstone oil and gas reservoir, a process method of slickwater leak-off energization+high conductivity main cracks formed by the fracturing fluid+large displacement is adopted. Compared with the prior art of using frozen-gel fracturing, the swept volume of the cracks is greatly increased, and the problems of poor connectivity of the heterogeneous sandstone reservoir and poor seepage capacity are solved; the stratum energy is replenished; and the long cracks with high flow conductivity are established, the stratum seepage field is improved, and the fracturing modification effect is improved.

Owner:DAGANG OIL FIELD GRP +1

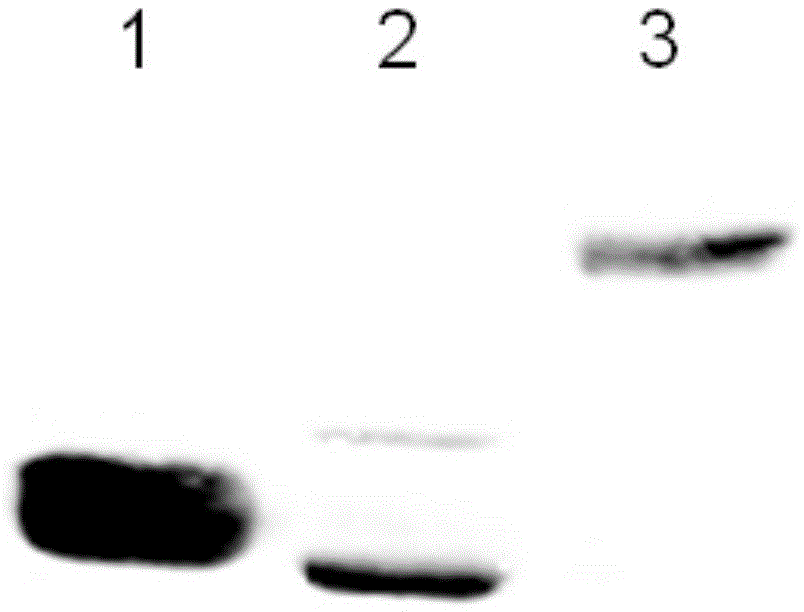

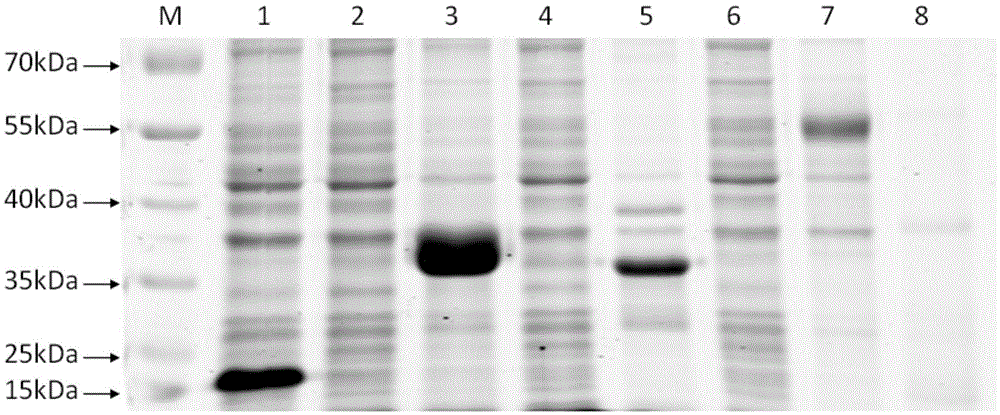

Tandem duck Alpha and Nu interferon genes and preparation method and application thereof

InactiveCN105647945AAchieve serial expressionHigh biological activityPeptide/protein ingredientsAntibody mimetics/scaffoldsEscherichia coliAntiviral drug

The invention discloses tandem duck Alpha and Nu interferon genes and a preparation method and application thereof and belongs to gene fusion expression in the biotechnical field. A nucleotide sequence of the tandem duck Alpha and Nu interferon genes is shown as in SEQ ID No. 1. The invention also provides the preparation method of the tandem duck Alpha and Nu interferon gene, a prokaryotic expression plasmid Alpha and Nu interferon prokaryotic expression plasmid pET32a-IFNAlpha-linker-IFNNuexpressing the tandem duck Alpha and Nu interferon gene and its preparation method, and application of a fusion protein expressed by the tandem duck Alpha and Nu interferon gene in the preparation of duck antiviral drugs. Recombinant duck Alpha and Nu interferon prokaryotic expression plasmid pET32a-IFNAlpha-linker-IFNNu is established successfully herein, the duck IFN-Alpha and IFN-Nu genes are tandemly expressed on an Escherichia coli prokaryotic expression system, and it is also possible to ensure that the two interferon genes are expressed in a ratio of 1:1.

Owner:SOUTH CHINA AGRI UNIV

Low-energy-consumption and environment-friendly polypropylene spunbond non-woven fabric and preparation process thereof

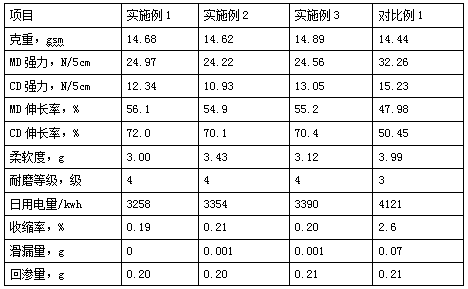

The invention provides a preparation process of low-energy-consumption and environment-friendly polypropylene spunbond non-woven fabric. The preparation process comprises the steps of material mixing,drafting treatment, hot rolling humidification treatment and drying winding treatment, wherein, in the drafting treatment, a spinneret is introduced into a drafting machine for drafting treatment, the pressure of an air bellow of a drafting fan of the drafting machine is 2800 to 3800 Pa, the monomer suction air volume is 1200 to 1600 m<3> / h, and the temperature of upper cold air is 19 to 21 DEG C; the speed of a hot rolling mesh belt is 587 m / min, and the hot rolling pressure is 85 daN / cm; spinning obtained through the preparation process is smooth in hand feeling, complete in extension and uniform and consistent in hardness; and the obtained non-woven fabric product has the softness of 3.00 to 3.43 g and the shrinkage rate of 0.19% to 0.21%, and is not prone to deformation.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

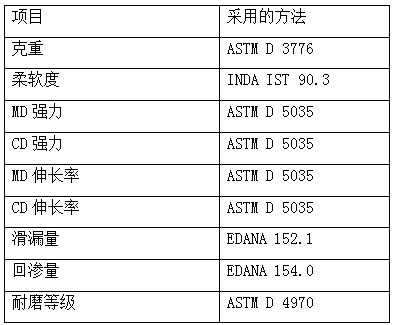

Effective volume fracturing method for shale with high clay content

ActiveCN112065349AIncreased stress disturbance effectIncreased complexityFluid removalSealing/packingThermodynamicsMechanics

The invention discloses an effective volume fracturing method for shale with high clay content. The effective volume fracturing method comprises the following steps that (1) compressibility, mechanical properties and fracturing quality of the shale are analyzed; (2) fracture morphological parameters and fracturing construction parameters are optimally designed; (3) perforation operation is carriedout on a first section; (4) acid treatment is carried out; (5) a main crack is formed by adopting a high-viscosity glue solution; (6) low-viscosity slickwater carrying 70-140 meshes of a propping agent is injected; (7) inter-crack temporary plugging construction is carried out by adopting the high-viscosity glue solution in cooperation with a temporary plugging agent; (8) a medium-viscosity gluesolution carrying 40-70 meshes of the propping agent is injected; (9) the high-viscosity glue solution carrying 30-50 meshes of the propping agent of is injected; (10) inter-cluster temporary pluggingconstruction is carried out by adopting the high-viscosity glue solution in cooperation with temporary plugging balls; and (11) displacement construction is carried out. According to the effective volume fracturing method for the shale with high clay content, the problems existing in an existing fracturing process can be solved, so that the effective transformation volume of the shale with high clay content is increased, and the crack complexity is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vehicle intake pipe silencer

ActiveCN105909435AFully extendedBreakout ElongationMachines/enginesIntake silencers for fuelDuctilityInternal cavity

The invention discloses a vehicle intake pipe silencer. The vehicle intake pipe silencer comprises a shell, and further comprises an intake port, an intake pipe exhaust port, an exhaust pipe, a silencing separation plate and a resonance inner cavity; the intake port is connected with the intake pipe; the intake pipe is connected with the resonance inner cavity; the resonance inner cavity is connected with the exhaust pipe; the exhaust pipe is connected with the exhaust port; the silencing separation plate is embedded in the inner wall of the intake pipe; an air guide port is formed in middle of the cylinder wall of the silencing separation plate for effectively absorbing noise generated in the intake pipe; and a space extends from the resonance inner cavity for absorbing the noise. A silencing cavity is directly machined by using an aluminum pipe, so that the ductility of the aluminum pipe is fully exerted, the production of the silencer is finished under the condition of no breakage, the machining ratio reaches 52%, the whole machining process is environment-friendly without pollution, the traditional die-casting can be replaced, the pollution is reduced, and the energy consumption is reduced.

Owner:WUJIANG KAILIANDA METAL PROD

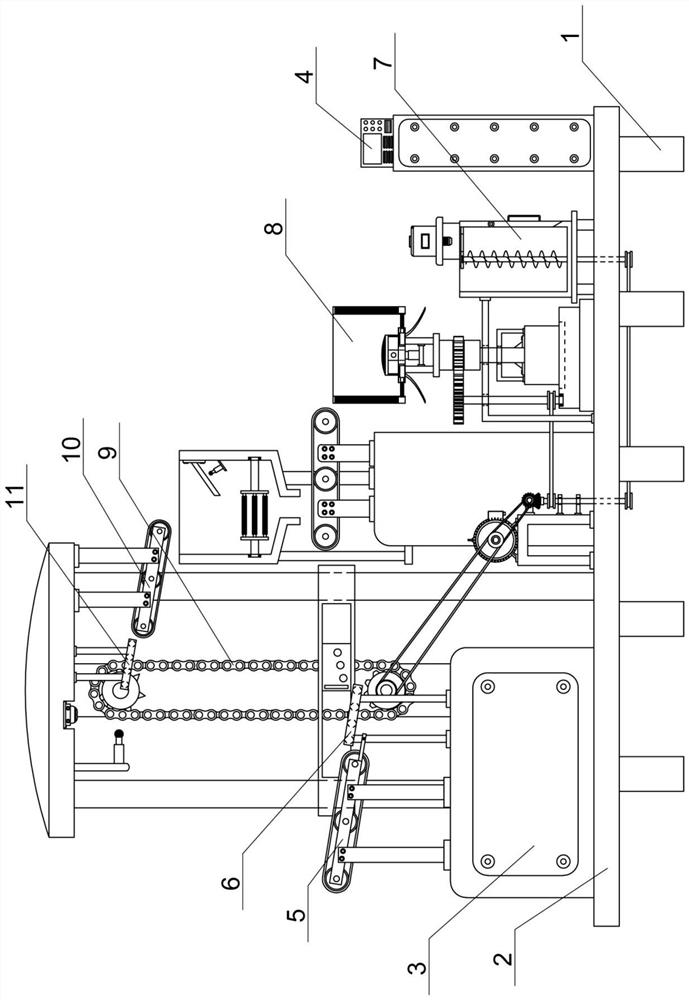

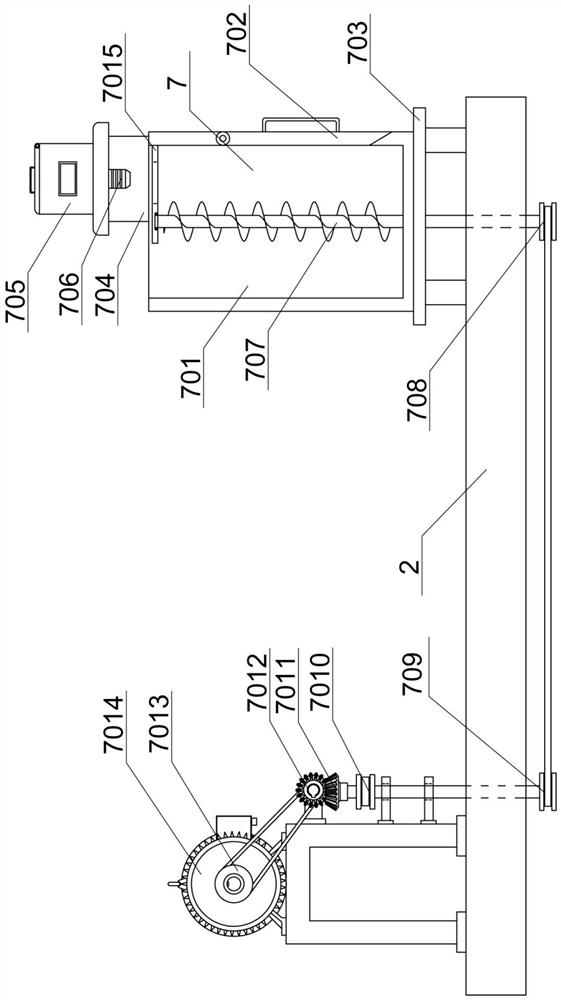

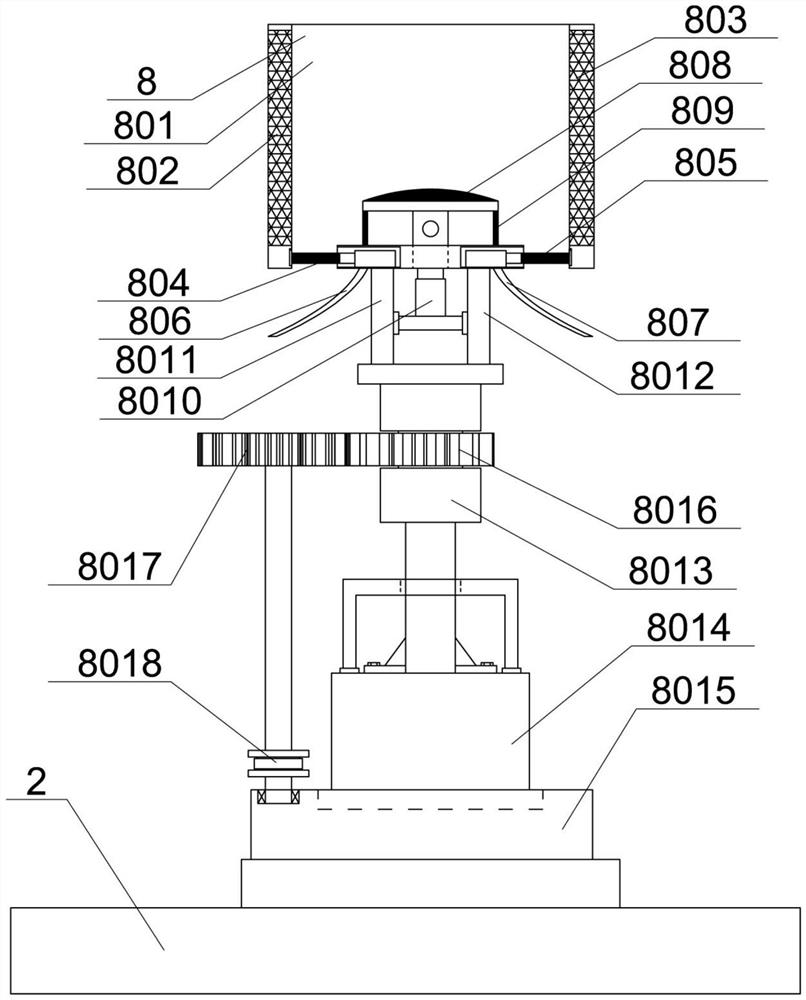

Filtering, extruding and cutting-off system for mixed compounds

ActiveCN111873217AIncrease elasticityImprove toughnessPlastic recyclingMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of mixed compound processing, in particular to a filtering, extruding and cutting-off system for mixed compounds. The filtering, extruding and cutting-offsystem comprises a lifting device, a sheet-compressing device, an extruding conveying device and a filtering and cutting-off device, the lifting device comprises a lifting roller, the discharging sideof the lifting roller is located above the filtering device, the sheet-compressing device is mounted between the lifting roller and a feeding inlet of the extruding conveying device, the filtering and cutting-off device is mounted at a discharging outlet of the extruding conveying device, the lifting roller is used for lifting the to-be-filtered strip-shaped mixed compounds to the upper part of the extruding conveying device, the sheet-compressing device is used for bearing the strip-shaped mixed compounds guided out by the lifting roller, pre-compressing the strip-shaped mixed compounds andguiding the strip-shaped mixed compounds into the feeding inlet of the extruding conveying device, and after the strip-shaped mixed compounds are guided into the extruding conveying device, the multiple side-by-side strip-shaped mixed compounds are formed through the filtering and cutting-off device and cut off.

Owner:TIANJIN FEILONG RUBBER PROD CO LTD

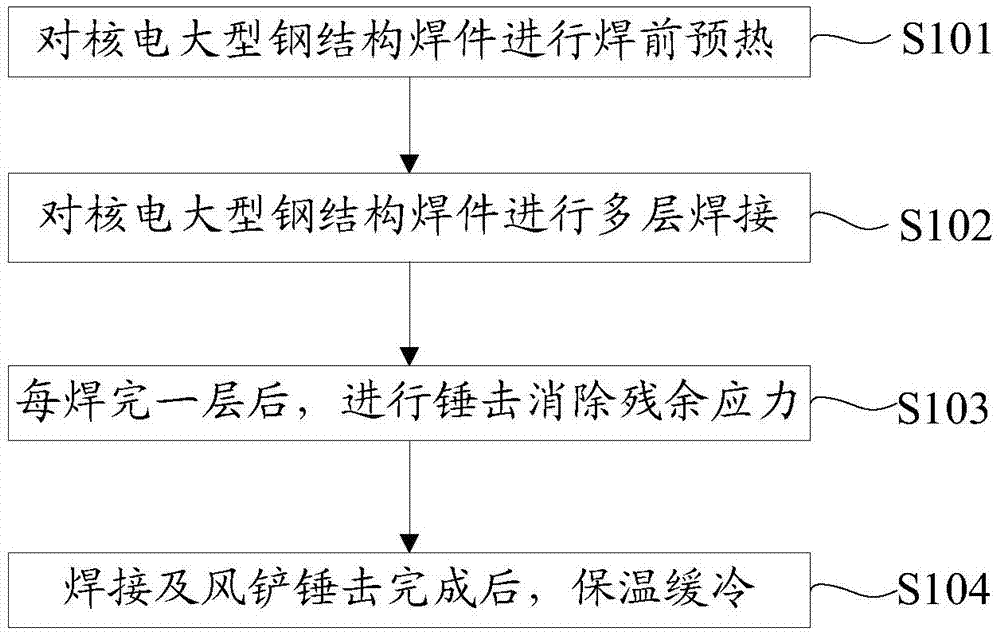

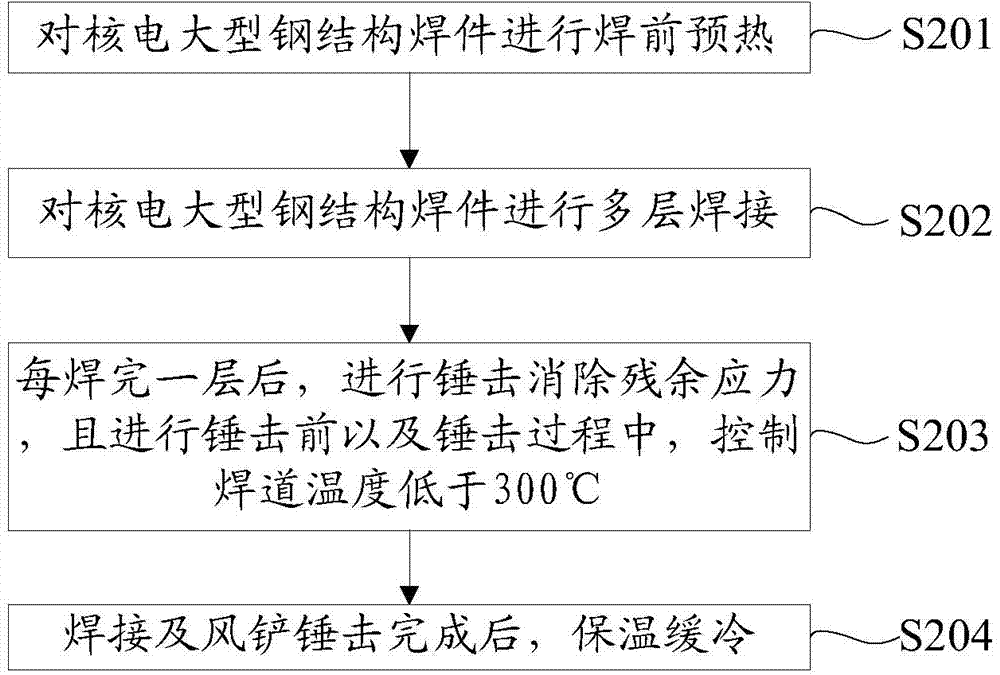

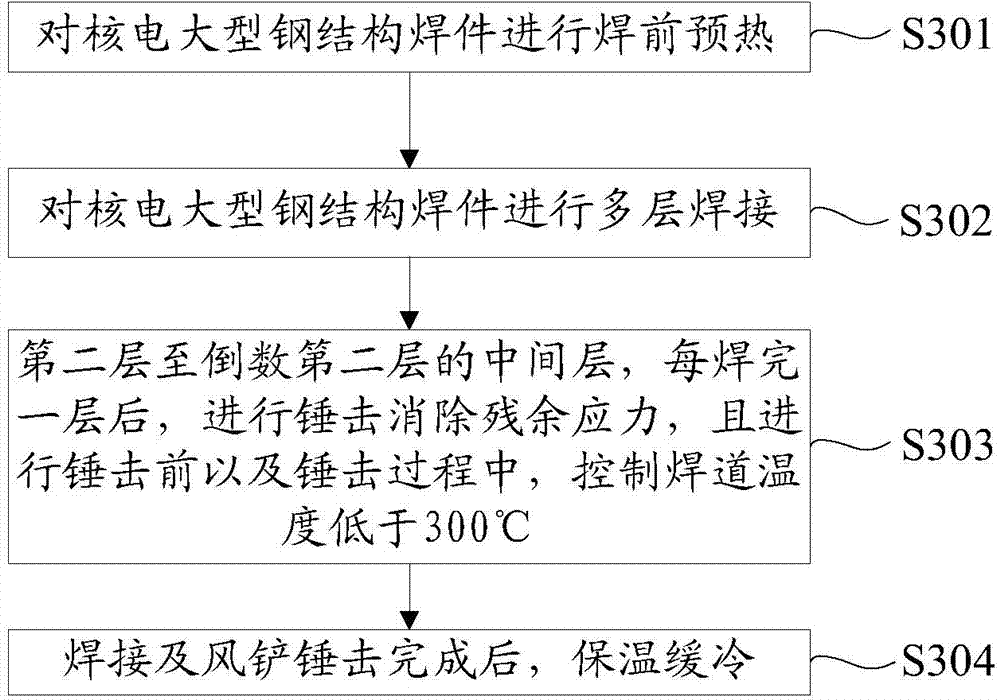

Welding with trailing peening stress eliminating method of large nuclear power steel structure

InactiveCN104289831AFully extendedImprove carrying capacityWelding/cutting auxillary devicesAuxillary welding devicesNuclear powerEngineering

The invention discloses a welding with trailing peening stress eliminating method of a large nuclear power steel structure. Multi-layer welding is carried out on the large nuclear power steel structure, when welding is conducted at least from the second layer to the penultimate layer, after one layer is welded, peening is carried out and can make welding seam filling metal completely expand in a hot state, and therefore the residual stress in the cooling shrinkage process is reduced, the bearing capacity of the steel structure is improved, and the welding quality is improved; a pneumatic digger is connected with an air compressor through an air pipe and can extend to each position of the upper air and corners, and the stress eliminating quality is guaranteed; the stress eliminating speed of the pneumatic digger is high, the work of eliminating stress can be finished when welding is finished, and the welding efficiency is improved.

Owner:TAISHAN NUCLEAR POWER JOINT VENTURE

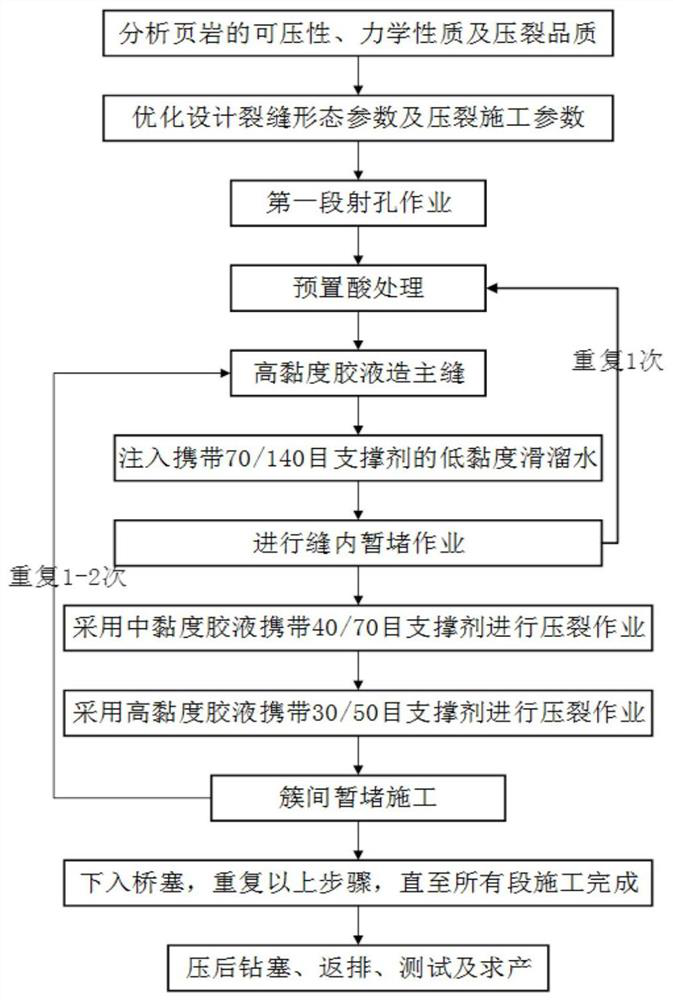

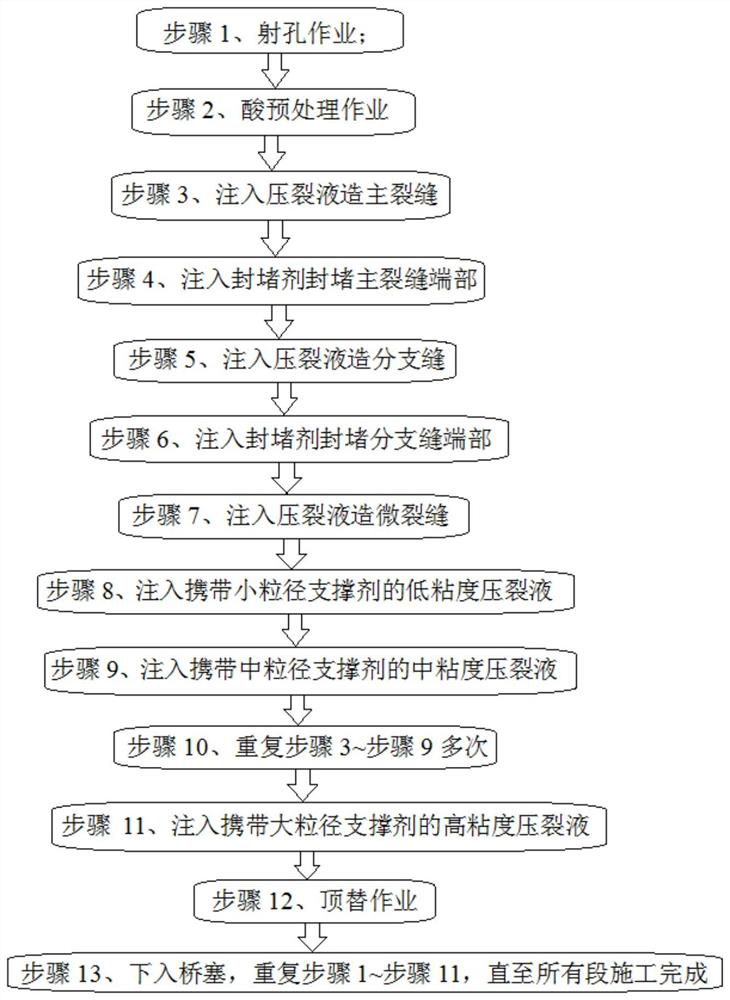

Fracturing method for staged supporting of proppants with different particle sizes in multi-scale cracks

ActiveCN113530513AFully extendedImprove utilizationFluid removalSealing/packingThermodynamicsFracturing fluid

The invention discloses a fracturing method for staged supporting of proppants with different particle sizes in multi-scale cracks. The fracturing method comprises the following steps: 1) perforation operation is performed; 2) acid pretreatment operation is performed; (3) fracturing fluid is injected to make a main crack; (4) a blocking agent is injected to block the end of the main crack; (5) fracturing fluid is injected to make branch cracks; (6) a blocking agent is injected to block the ends of the branch cracks; (7) fracturing fluid is injected to make micro cracks; (8) low-viscosity fracturing fluid carrying a small-particle-size proppant is injected; (9) medium-viscosity fracturing fluid carrying a medium-particle-size proppant is injected;10) steps 3-9 are repeated for multiple times; (11) high-viscosity fracturing fluid carrying a large-particle-size proppant is injected; (12) displacement operation is carried out; and (13) a bridge plug is put down, and steps 1-11 are repeated until all sections are constructed. According to the method, the strategy that the large-scale main crack and the medium-scale branch cracks are temporarily blocked in sequence, and the main crack, the steering branch cracks and the micro cracks are temporarily plugged in sequence is adopted, and full extension of the main crack, the steering branch cracks and the micro cracks is promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

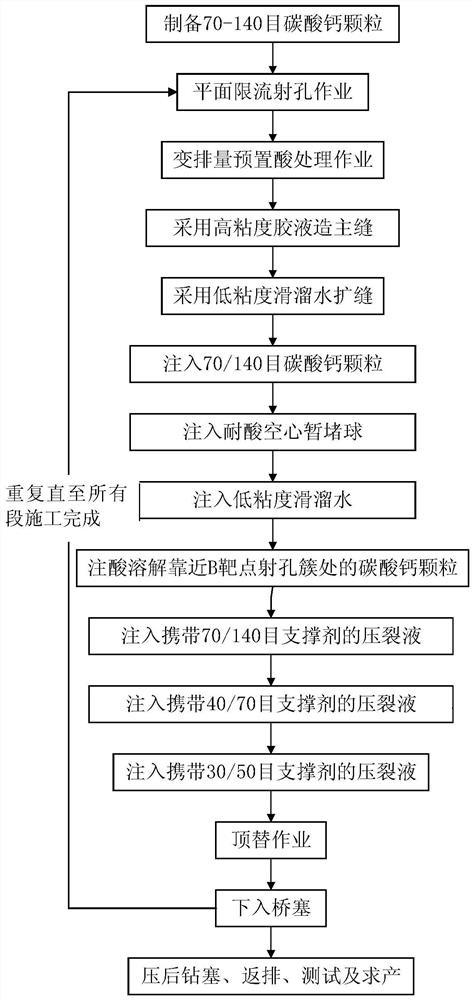

Horizontal well fracturing method for promoting fracture height extension through two times of acid injection and inter-cluster temporary plugging

ActiveCN112443305AUniform initiation and extensionExtend evenlyFluid removalDrilling compositionHorizontal wellsFracturing fluid

The invention discloses a horizontal well fracturing method for promoting fracture height extension through two times of acid injection and inter-cluster temporary plugging. The horizontal well fracturing method comprises the following steps that planar flow-limiting perforation operation is conducted; variable-displacement acid pretreatment operation is conducted; a main fracture is built by adopting a high-viscosity glue solution, and the fracture is expanded by adopting low-viscosity slickwater; fracturing fluid carrying calcium carbonate particles is injected; fracturing fluid carrying theacid-resistant hollow temporary plugging ball is injected; low-viscosity slickwater is injected; acid liquor is injected to dissolve the calcium carbonate particles; the fracturing fluid is continuously injected; displacement operation is conducted; a bridge plug is lowered; and the steps are repeated until all sections are constructed, and plug drilling, flowback, testing and production solvingafter fracturing are conducted. According to the horizontal well fracturing method, planar flow-limiting perforation, calcium carbonate particle temporary plugging and acid-resistant hollow temporaryplugging ball temporary plugging processes are adopted, the single-cluster displacement is increased, the extension length of fractures in the height direction is effectively increased, uniform fracture initiation and extension of multiple clusters of fractures are promoted, finally, the longitudinal use degree of a shale gas reservoir is finally increased, the reservoir transformation size is increased, and finally, the efficient development of the shale gas reservoir is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

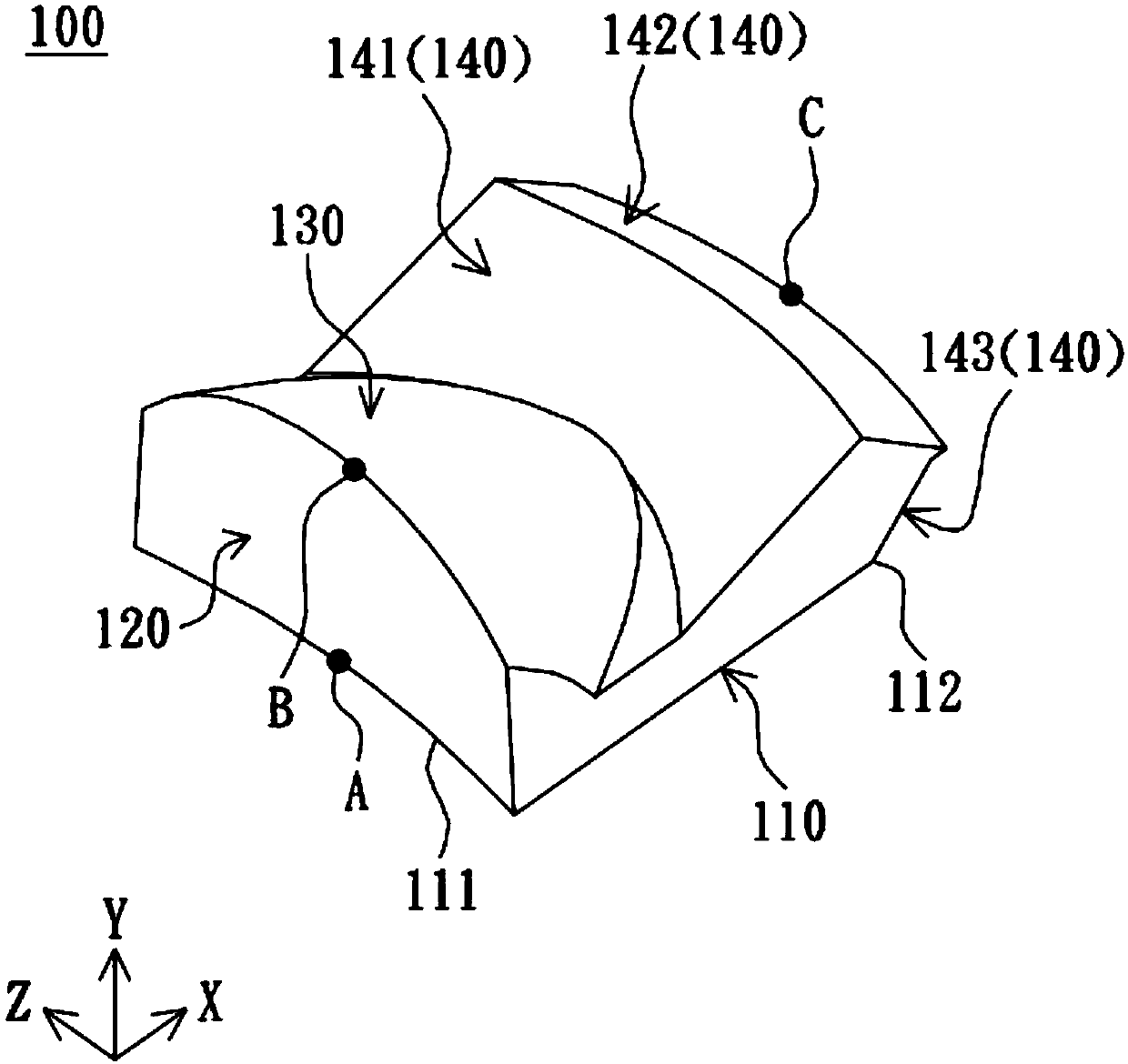

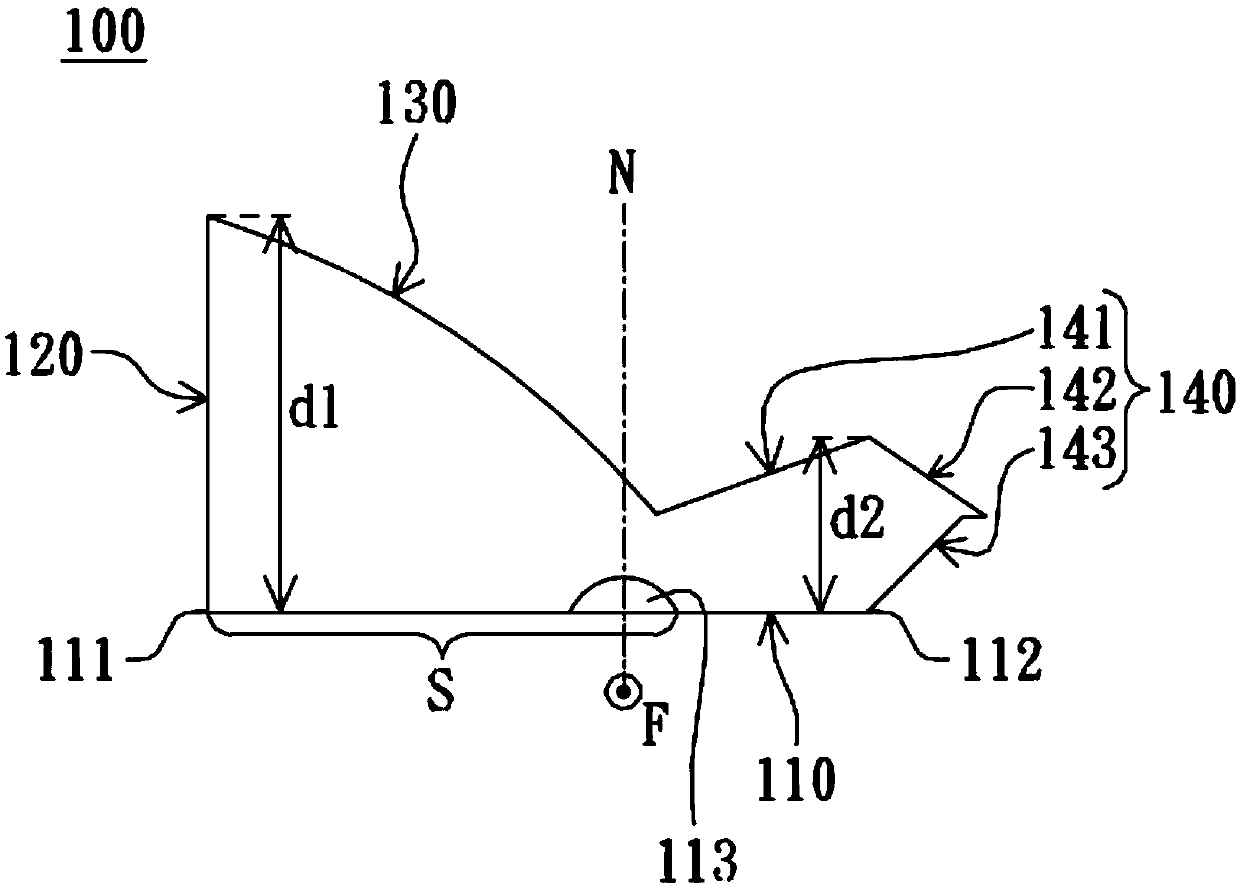

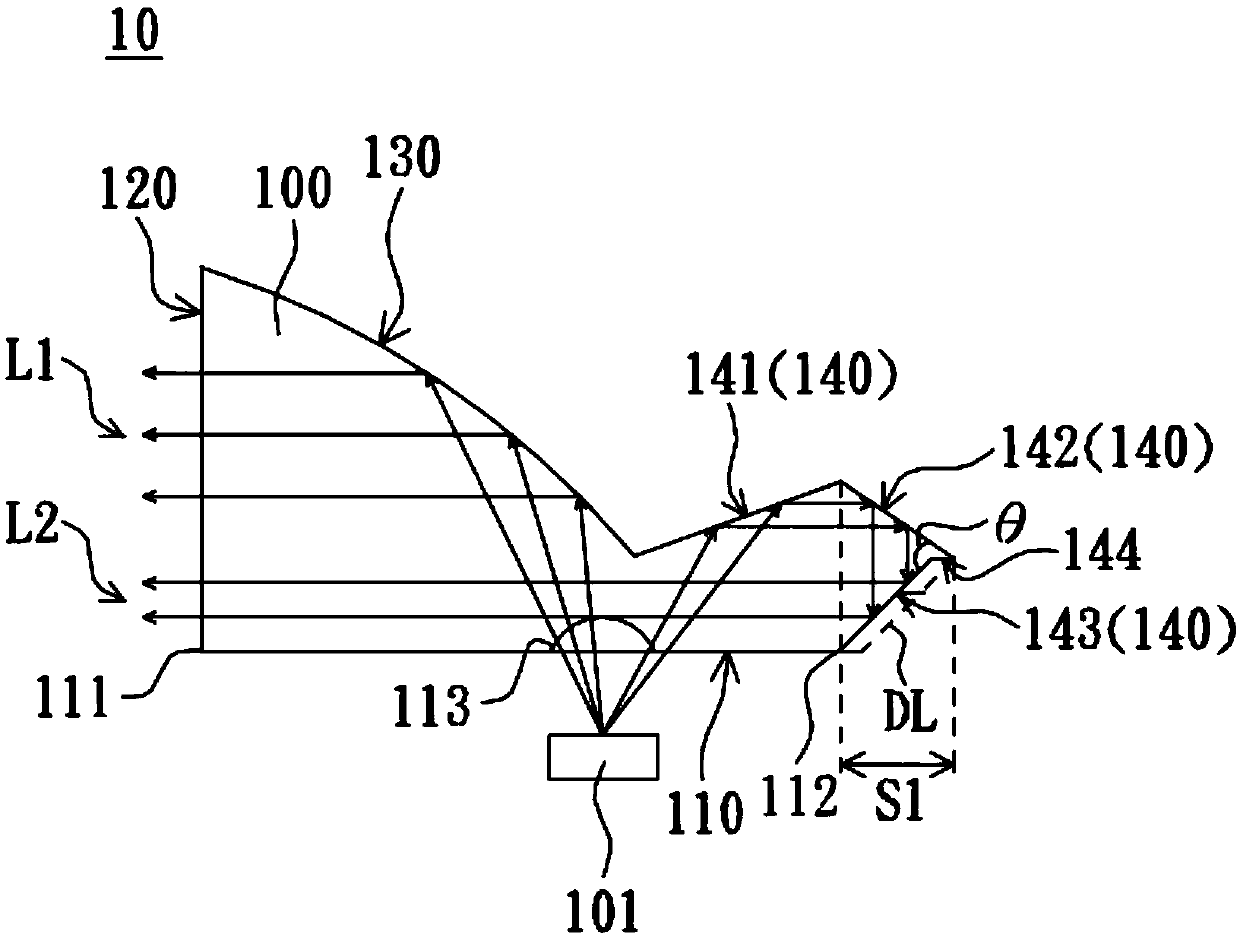

Light guide lens and vehicle head lamp

PendingCN111380027AThe production process is simpleReduce manufacturing costVehicle headlampsRoad vehiclesVertical projectionLight guide

The invention discloses a light guide lens, and the lens is provided with a bottom surface, a light emitting surface, a first reflecting surface and a reflecting structure. The bottom surface is provided with a first side edge and a second side edge which are opposite to each other, and a light incident part. The light emitting surface is connected to the first side edge. The first reflecting surface is opposite to a part of the bottom surface and is connected to the light emitting surface, and the light incident part is located in a projection area of vertical projection of the first reflecting surface to the bottom surface. The reflection structure comprises a plurality of reflection surfaces connected between the second side edge and the first reflection surface. The invention also provides a vehicle head lamp comprising the light guide lens.

Owner:YANGZHOU LEDLINK OPTICS +2

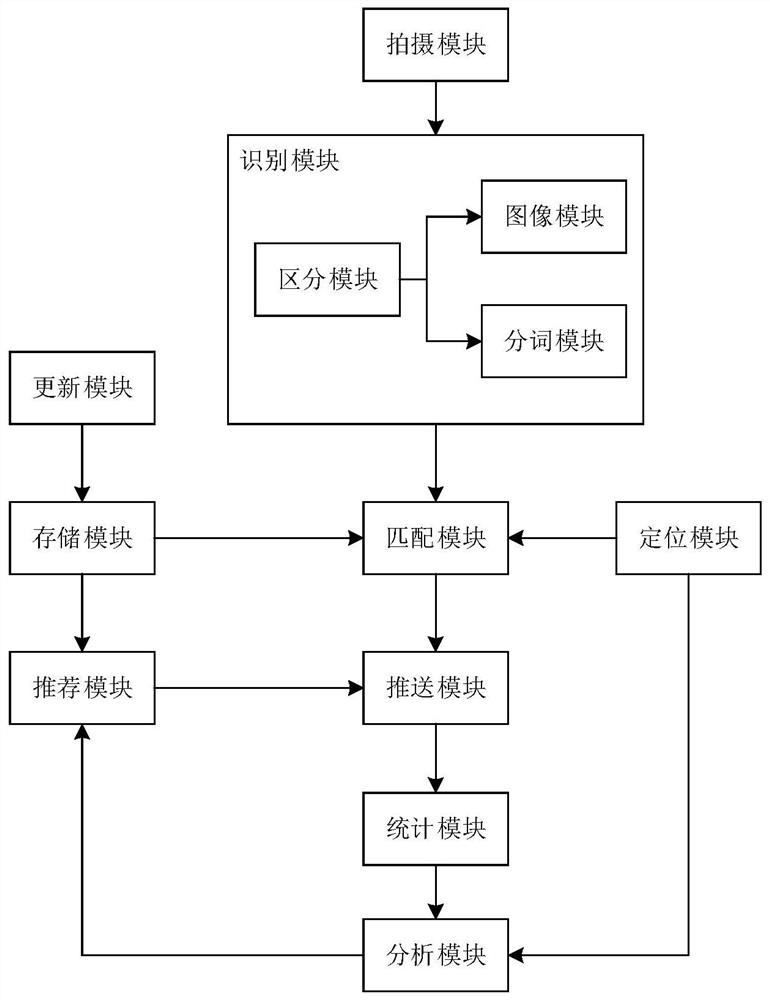

Marketing system and method based on image recognition

PendingCN113191813AIncrease conversion rateFully extendedAdvertisementsNatural language data processingComputer graphics (images)Engineering

The invention belongs to the field of marketing systems, and particularly relates to a marketing system and method based on image recognition, wherein the system comprises a storage module, an updating module, an image obtaining module, a recognition module, a matching module, and a pushing module; the storage module is used for storing advertisement associated information, and the advertisement associated information comprises coupon information; the updating module is used for updating the advertisement associated information in the storage module in real time; the image obtaining module is used for obtaining advertisement photos shot by a terminal; the identification module is used for extracting key elements on the advertisement photos; the matching module is used for matching the key elements with the advertisement associated information; and the pushing module is used for pushing the advertisement associated information to the terminal. According to the invention, the problem of low advertisement conversion rate in forms of paper media, buildings, outdoors and the like in the prior art is solved.

Owner:贵州海普科技有限公司

Composite tube alternatively using cold energy and heat energy

InactiveCN103398601AFully extendedGood plasticity materialStationary tubular conduit assembliesTubular elementsHeat conductingThermal insulation

The invention relates to an apparatus which can alternatively use cold energy and heat energy, wherein the apparatus is particularly suitable for devices for producing cooled boiled water or core apparatuses which are used for manufacturing devices for heating the cold water and cooling the hot water so that mutual utilization of the cold energy and the heat energy can be achieved. Two water flow channels are combined together to form a combined pipeline, one of the two channels is arranged in the middle of the inner portion of the pipeline, the other channel is arranged on the periphery of the inner portion of the pipeline, strip-shaped heat-conducting fins are fully distributed on the pipe wall of the channel which is arranged in the middle of the inner portion of the pipeline, and a thermal insulation layer is arranged outside the channel on the periphery of the inner portion of the pipeline. The hot water in the channel in the middle of the inner portion of the pipeline gradually becomes cold when influenced by the cold water flow in the channel on the periphery of the hot water, and the cold water in the channel outside the inner portion of the pipeline gradually becomes hot when influenced by the hot water flow in the channel in the middle of the inner portion of the pipeline. Temperatures of water in the two channels can be exchanged even though the water in the two channels is not compatible due to water qualities. When used for producing the cooled boiled water, the technology saves about 90% of energy compared with a traditional method for producing the cooled boiled water.

Owner:叶于安

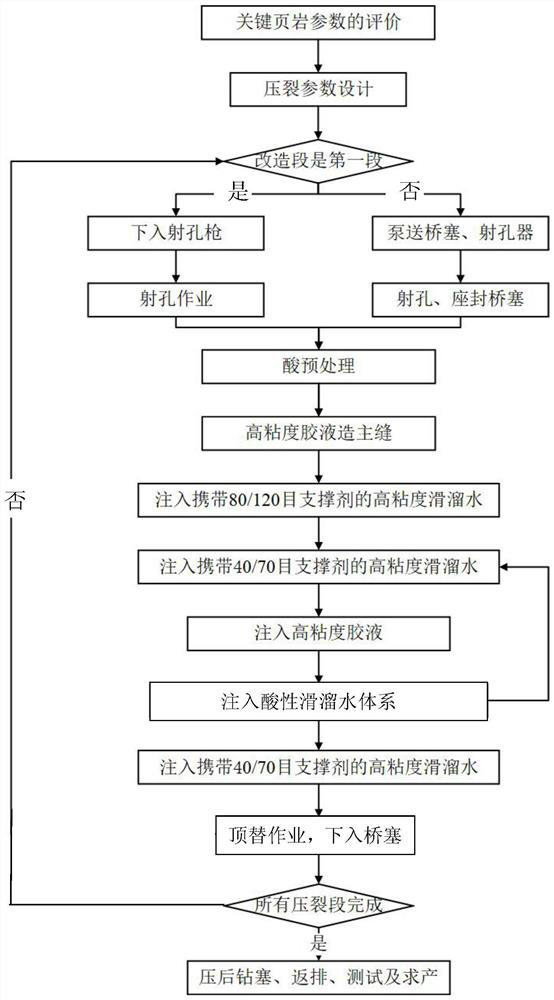

Pressure-control fracturing method for improving fracture complexity of deep shale gas well

ActiveCN112443306AReal-time control of net pressure riseControl construction pressureFluid removalShale gasViscosity

The invention discloses a pressure-control fracturing method for improving fracture complexity of a deep shale gas well. The pressure-control fracturing method comprises the following steps of (1) evaluating key shale parameters and optimizing fracturing construction parameters; (2) carrying out perforation operation; (3) carrying out acid treatment; (4) making a main fracture by adopting a high-viscosity glue solution; (5) injecting high-viscosity slickwater carrying a 80-120-mesh propping agent; (6) injecting high-viscosity slickwater carrying a 40-70-mesh propping agent; (7) injecting a high-viscosity glue solution; (8) injecting an acidic slickwater system; (9) repeating the steps (6)-(8) twice or more; (10) injecting a high-viscosity glue solution carrying a 40-70-mesh propping agent;(11) carrying out displacement operation by adopting displacement liquid, and then tripping in a bridge plug; and (12) repeating the steps (2)-(11) until construction completion of all sections, andfinally, carrying out plug drilling, flowback, testing and production solving after fracturing. According to the pressure-control fracturing method, the high-viscosity liquid is replaced by the acidicslickwater to be matched with a variable-displacement fracturing process, so that the efficient transformation of deep shale gas is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

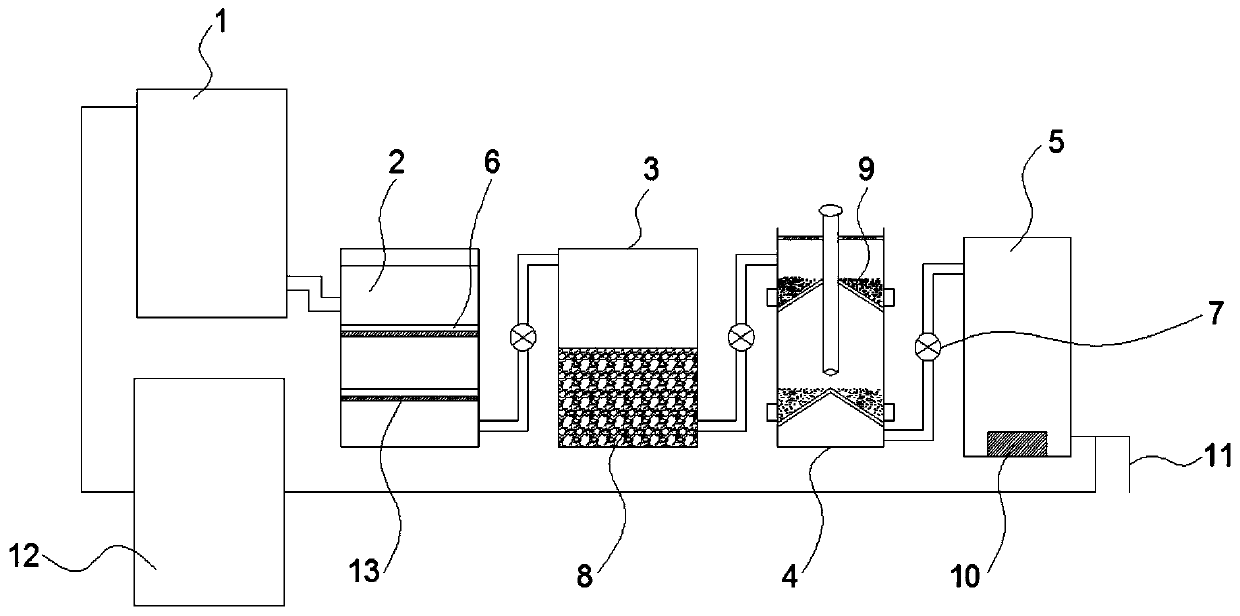

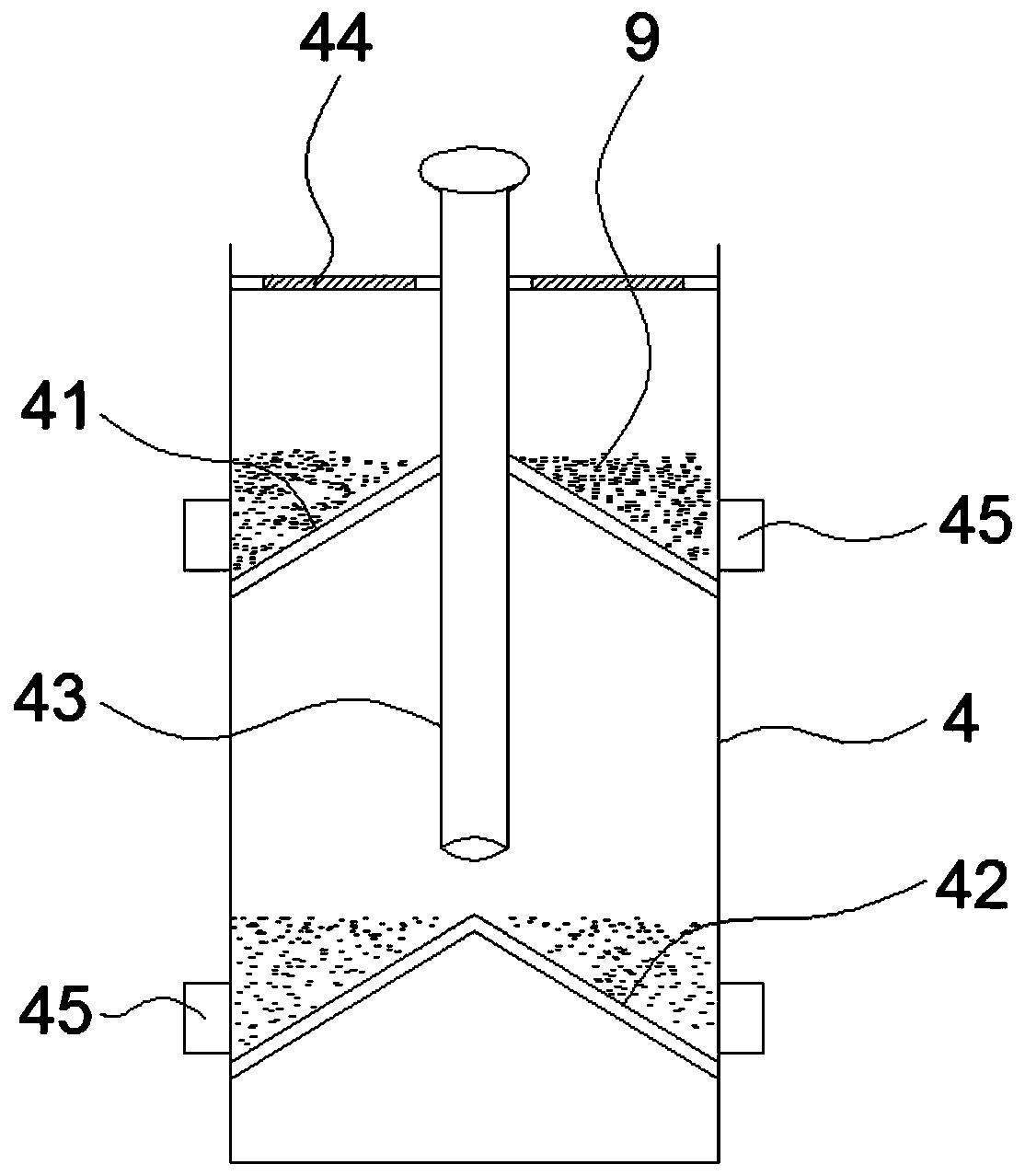

Wall-mounted collection and purification treatment device for wastewater from washing machine on balcony and treatment method of device

PendingCN110862175AEfficient degradationFully extendedWater/sewage treatment by irradiationSpecific water treatment objectivesActivated carbonSand filter

The invention discloses a wall-mounted collection and purification treatment device for wastewater from a washing machine on a balcony and a treatment method of the device. The device includes the washing machine installed on the balcony and a water collection tank, a multi-media quick-filter tank, a multi-media adsorption tank and an ultraviolet sterilization tank which are arranged in sequence;a water discharge pipe of the washing machine is connected to the water collection tank, and the water collection tank is provided with two layers of primary filter nets; and the water collection tankis connected to the multi-media quick-filter tank through a pressure pump, the interior of the multi-media quick-filter tank is provided with a quartz sand filter layer, the multi-media quick-filtertank is connected to the multi-media adsorption tank through a pressure pump, and the interior of the multi-media adsorption tank is provided with replaceable adsorption-type activated carbon. According to the device, the wastewater from the washing machine on the balcony is directly guided to the water collection tank, and the wastewater from the washing machine on the balcony can be purified andtreated under the combined action of the water collection tank, the multi-media quick-filter tank, the multi-media adsorption tank and the ultraviolet sterilization tank.

Owner:TAIZHOU UNIV

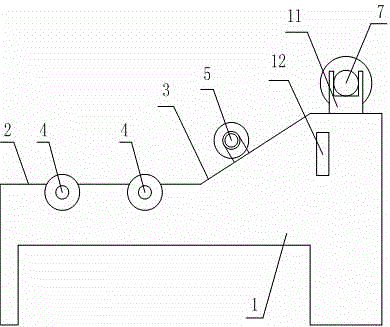

Cloth rolling machine facilitating rolled cloth length reading

InactiveCN107777418AEnsure roll qualitySimple structureMechanical length measurementsWebs handlingRing counterChassis

The invention discloses a cloth rolling machine which is convenient for reading the length of rolled cloth, comprising a frame, a plane and an inclined surface are arranged on the frame, at least two first cloth guide rollers are arranged on the plane of the frame, and the frame There is a second cloth guide roller on the inclined surface, and the surface of the second cloth guide roller is wound with spiral filament-shaped protrusions that propagate from the axial center line to both ends; a cloth rolling roller is arranged on the top or rear of the inclined surface, and the first cloth guide roller The roller rotates toward the direction that the top is close to the slope, the second cloth guide roller rotates in the same direction as the first cloth guide roller, and the cloth winding roller and the cloth guide roller rotate in opposite directions. The cloth winding roller is also equipped with a lap counter, and the lap counter is connected to the processing module, and the processing module is connected to the display screen, and the processing module and the display screen are both arranged on the frame. The invention is used to solve the problems of complex structure and cumbersome operation of the cloth rolling machine in the prior art, realize the purpose of simple structure of the cloth rolling machine, easy operation, easy acquisition of the length of the rolled cloth, and at the same time ensure that the cloth is fully and flatly unfolded.

Owner:史军

Rolling method and equipment for battery pole piece

ActiveCN108199005BImprove consistencyImprove defects such as poor snake shapeElectrode manufacturing processesElectrical batteryEngineering

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

A filter extrusion cutting system for rubber compound

ActiveCN111873217BIncrease elasticityImprove toughnessPlastic recyclingMetal working apparatusEngineeringTableting

The invention relates to the technical field of rubber mixing processing, in particular to a filtering extrusion cutting system for rubber mixing, comprising a lifting device, a tablet pressing device, an extrusion conveying device and a filtering cutting device, wherein the lifting device comprises a lifting roller, the The discharge side of the lifting roller is located above the filtering device, the tablet pressing device is installed between the lifting roller and the feeding port of the extrusion conveying device, and the filtering and cutting device is installed at the discharging port of the extrusion conveying device Position, the lifting roller is used to lift the belt-shaped rubber compound to be filtered to the top of the extrusion conveying device, and the tableting device is used to receive the belt-shaped rubber compound exported by the lifting roller, carry out pre-compression and guide it into the extrusion transmission device. At the feeding port of the device, the belt-shaped rubber compound is introduced into the extrusion conveying device, and then passes through the filter and cutting device to form a plurality of side-by-side strip-shaped rubber compounds, which are then cut.

Owner:TIANJIN FEILONG RUBBER PROD CO LTD

An ore fertilizer soil manufacturing device

ActiveCN111570045BChurn will notImprove breathabilityTransportation and packagingRotary stirring mixersSoil scienceAgricultural engineering

The invention relates to the ore field, in particular to an ore fertilizer soil manufacturing device. The technical problem to be solved by the present invention is to provide an ore fertilizer soil manufacturing device. An ore fertilizer soil manufacturing device, including the first four-roller grid, a fertilizer making device, a potash fertilizer introduction device, a splitting device, a second conveyor belt and a second four-roller grid; the fertilizer making device is arranged on the right side of the top middle of the bottom plate ; The middle right rear side of the top middle of the bottom plate is provided with a potash fertilizer external introduction device. The present invention achieves full mixing of ore and soil, which is beneficial to plant rooting and prevents soil compaction; ensures that the ore in the outer layer of the entire air-drying box can be heated evenly, disrupts the contact structure between the ores through the lifting of the mushroom board, and prevents the ores from being stuck to each other; The water mica blocks are automatically crushed by impact, which improves the crushing effect and speed, does not cause waste of raw materials, and does not cause the effect of projecting fragments to hurt people.

Owner:嘉兴鼎尚信息科技有限公司

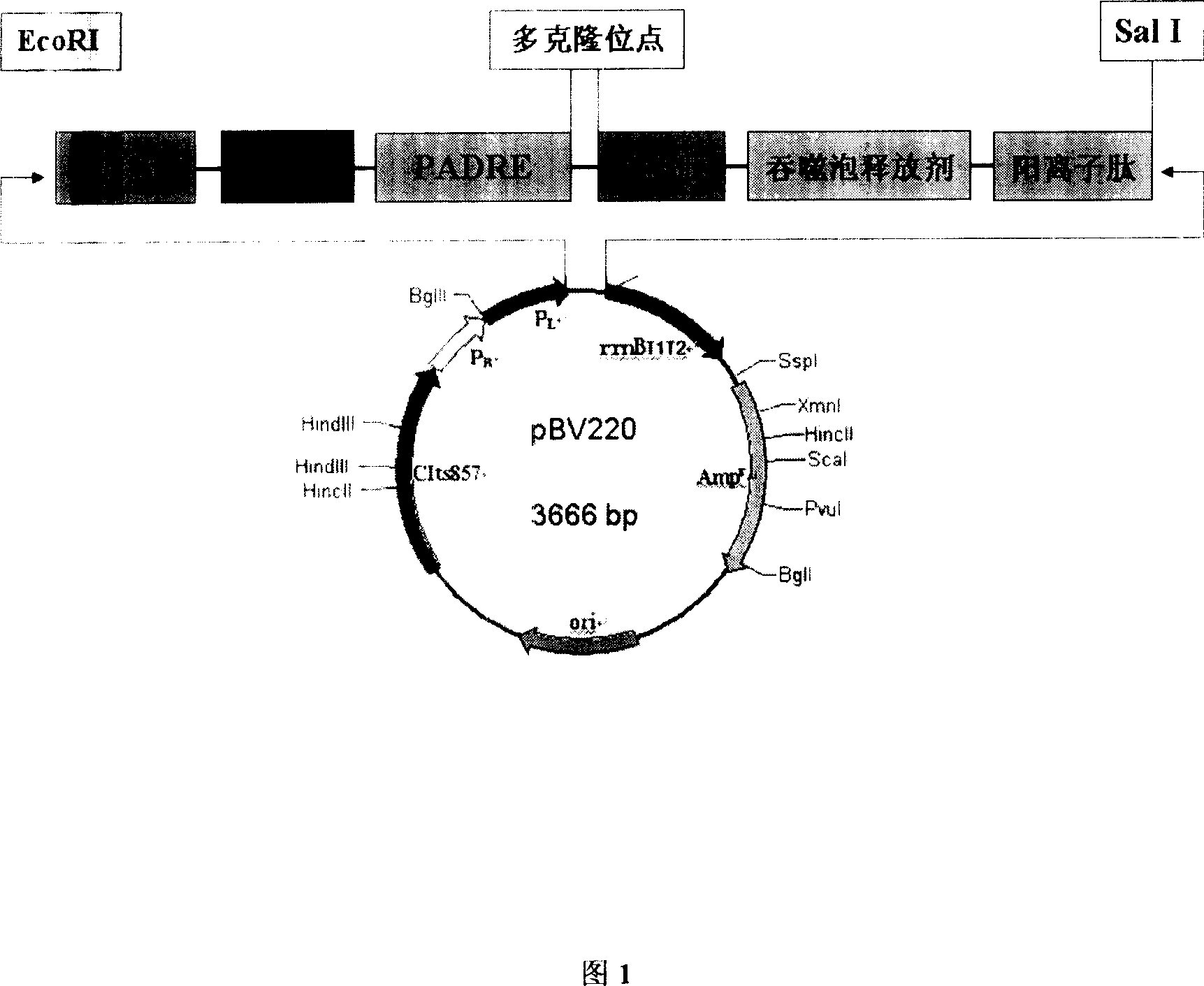

Construction and expression for tumor immunity synergistic carrier pBVIM

InactiveCN101053664AEffective immune warningEffectively immune to blowsGenetic material ingredientsAntineoplastic agentsActive cellTumor-specific antigen

Disclosed is a chimeric expression vector pBVIM with full length of 4338bp comprising most of the sequences of plasma pBV220 and some of small molecular immunologic adjvant gene, wherein SLC (secondary lymphoid chemokine) is the secondary lymph chemotactic factor, PADRC is the universal DR allclomorphic gene epitope, the cationic peptide can combine with the nucleic acid, membrane-penetrating peptide and phagosome releaser by electrostatic adsorption so as to increase the property of transfer of exogenous gene to the interior of tumor cell and resistance of degradation. Moreover, a tetrapeptide sequence for enhancing the expression of exogenous gene expression and a multi-clone enzyme cutting sites to facilitate the insertion of exogenous gene are also incorporated. The vector is used mainly in expression of tumor specific antigen, it can upgrade the immunogenicity of the antigen, promote the presentation and recognition of tumor antigen, and collect active cell in the local part of the tumor, create suitable immune micro-circumstances thereby promoting the immunity utilized bio-treatment on tumor.

Owner:INST OF BASIC MEDICAL SCI ACAD OF MILITARY MEDICAL SCI OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com