Medical suture needle

A suture needle and medical technology, applied in the field of medical suture needles, can solve problems such as the limit of hardness and bending strength, the weakening of the bending strength of the blade, and the inability to shorten the time, etc., to achieve high bending strength, easy penetration, and two-dimensional The effect of large second moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

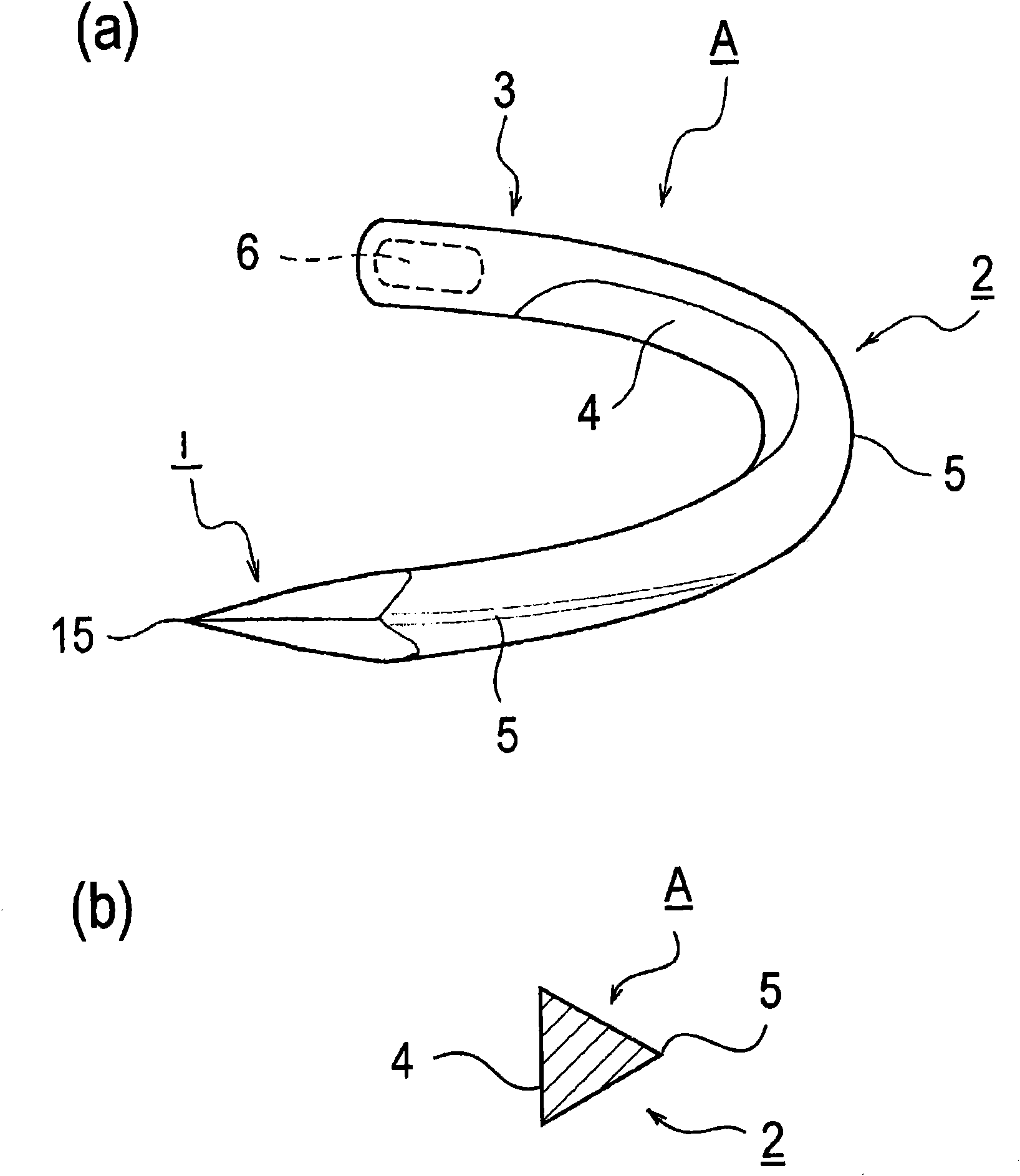

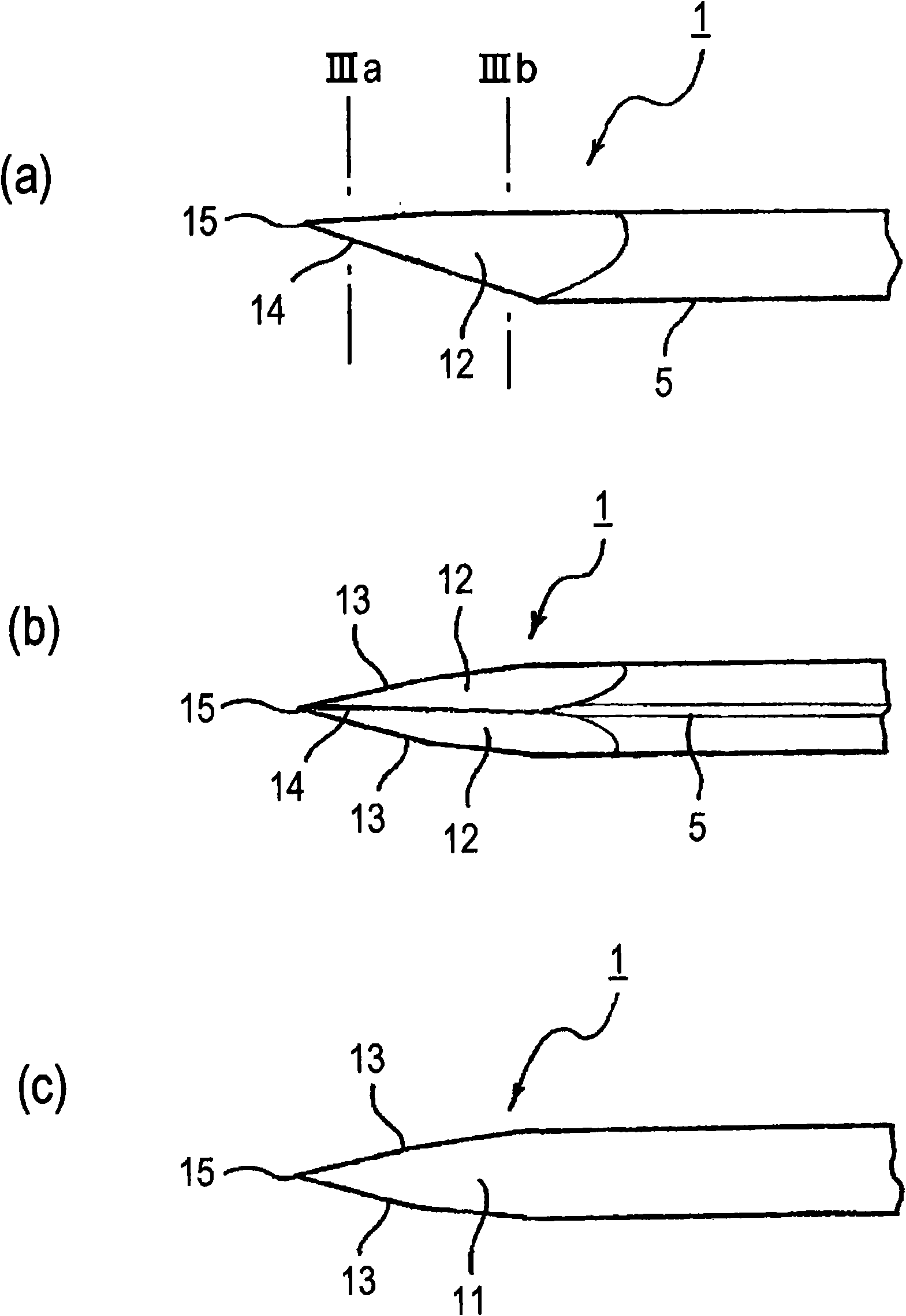

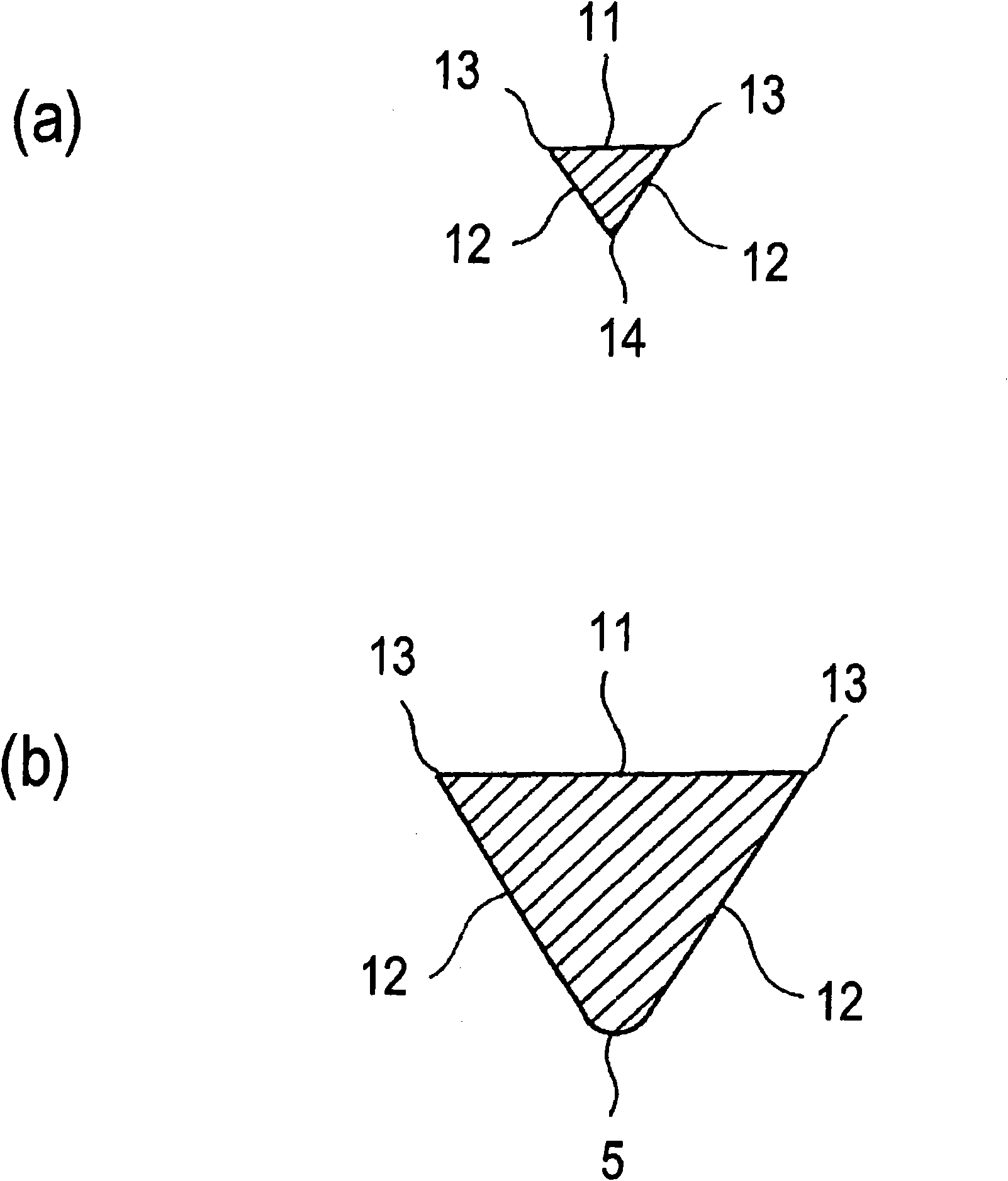

[0056] Next, the structure of the medical suture needle according to the first embodiment will be described with reference to the drawings. figure 1 It is a figure explaining the whole structure of the medical suture needle which concerns on this Example. figure 2 It is a figure explaining the structure of the front-end|tip part of the suture needle which includes a blade part. image 3 It is a figure explaining the cross-sectional shape of the tip part of a suture needle, and it is figure 2 The cross-sections of a and b.

[0057] First, through figure 1 The overall structure of the medical suture needle A will be described. The suture needle A is configured as a curved needle bent at a predetermined radius of curvature and bending angle. As mentioned above, the medical suture needle of the present invention is not limited to the curved needle of this embodiment, but may be a straight needle formed in a linear shape, and the overall shape is not limited.

[0058] In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com