Rolling method and equipment for battery pole piece

A battery pole piece and electrode technology, which is applied in battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as bad electrodes, difficult process, and difficult control of foreign matter in the process, so as to improve consistency, prevent short circuit of battery cells, and improve serpentine shape bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

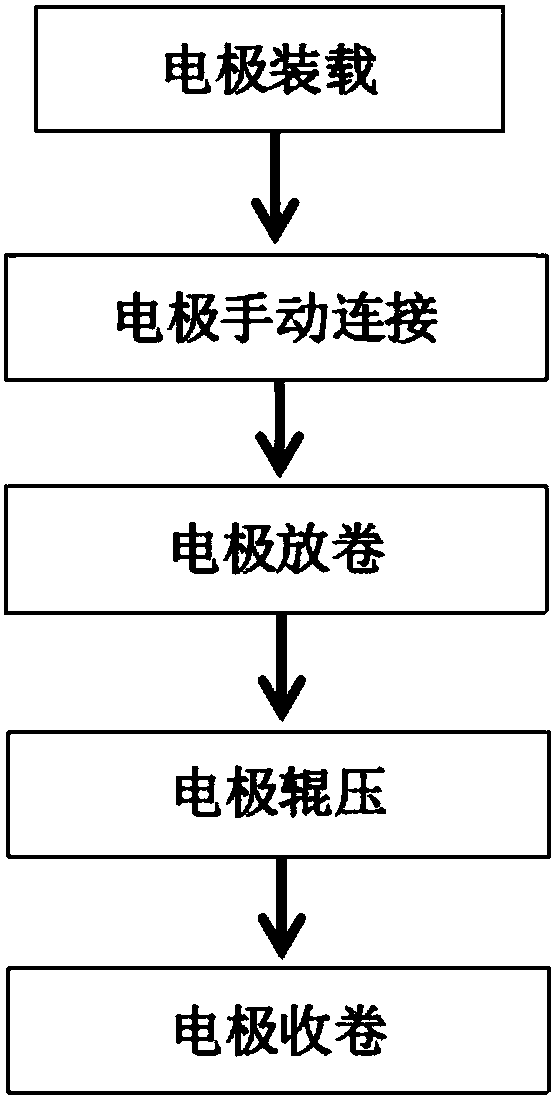

[0059] Requirements in the production process of battery pole pieces of lithium-ion batteries: (1) In the running direction, the rolling thickness of the battery pole piece must be controlled within the specified range, and it should be continuously stable, and the thickness fluctuation should be as small as possible; The thickness of the battery pole piece is in the transverse direction, and there is no obvious difference in thickness between the central position and the edge position; (2) The moisture content of the battery pole piece is required to be within the specified range. However, when the battery pole piece is rolled by the traditional rolling process, due to the insufficient precision of the unwinding, rolling, and winding actions during the rolling process, it is easy to cause tearing, wrinkling, and thickness changes of the battery pole piece. Larger; when an abnormality occurs, only temporary and simple remedial measures can be taken. In this way, when the batter...

Embodiment 2

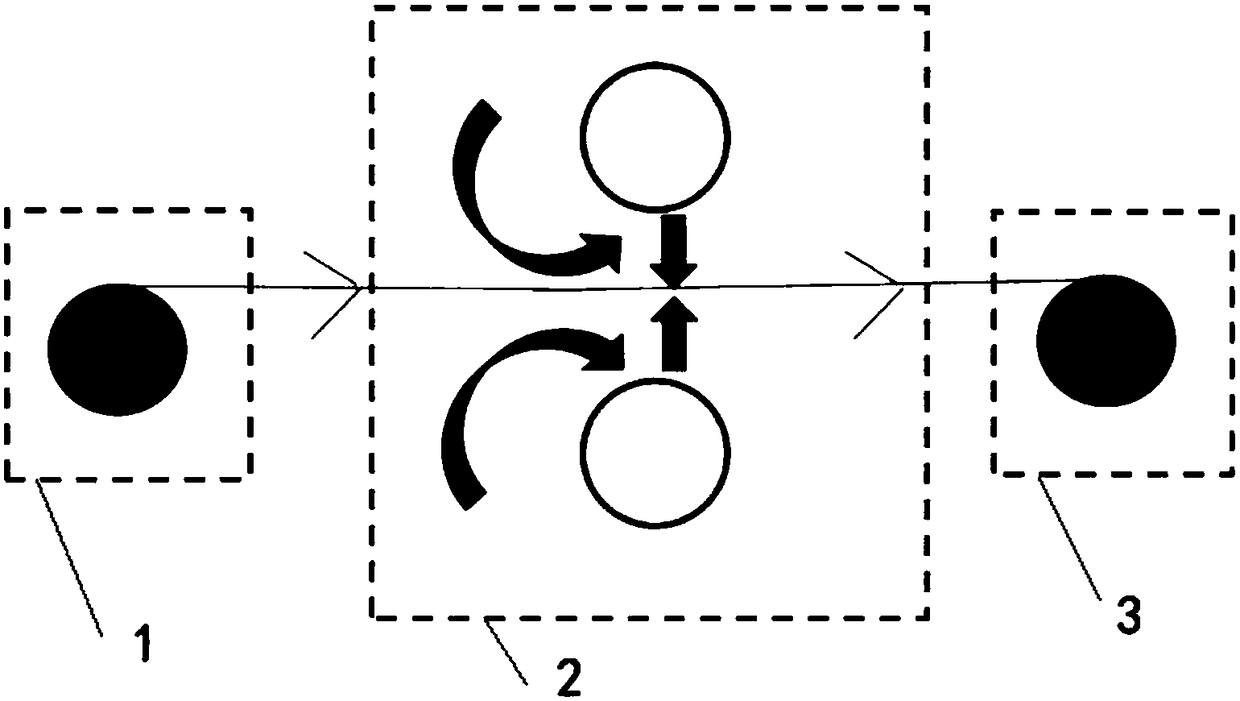

[0070] This embodiment provides a battery pole piece rolling equipment, which is used to run the battery pole piece 15 rolling method of the first embodiment. The rolling equipment for battery pole pieces includes a foil heating device 7 , an electrode preheating device 8 , an electrode rolling device 9 and a thickness curing device arranged in sequence.

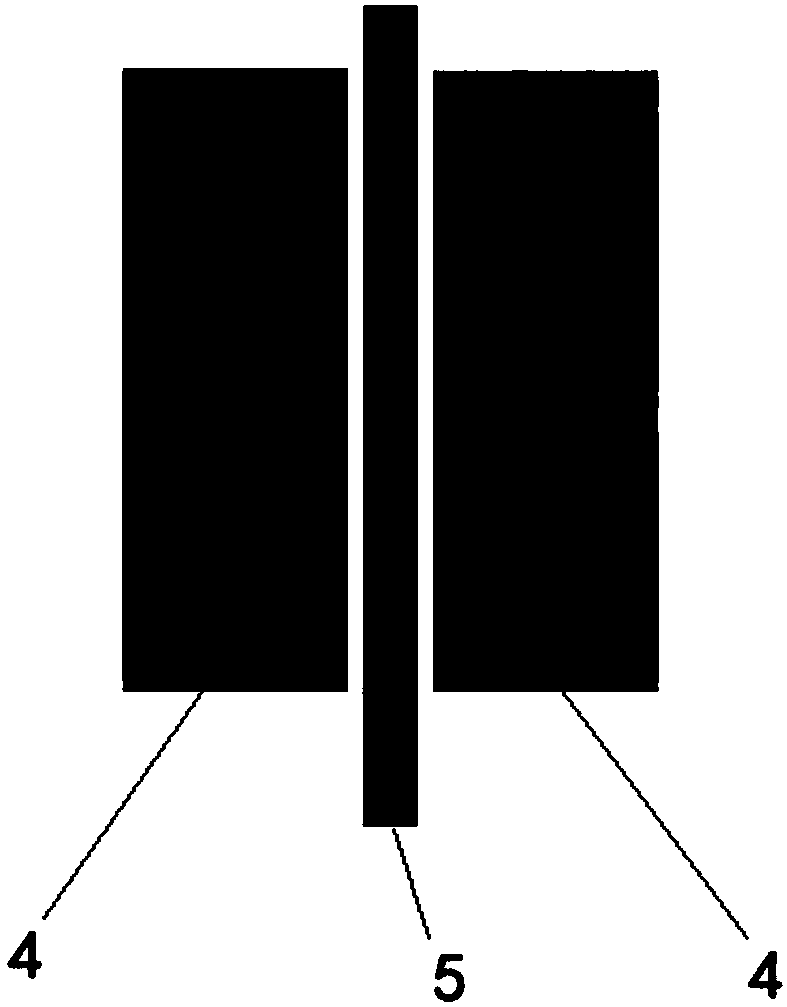

[0071] See Figure 11-Figure 13 , wherein, the foil heating device 7 is used to heat the foil area of the battery pole piece 15; the electrode preheating device 8 is used to heat the coating area of the battery pole piece 15; the electrode rolling The device 9 is used for rolling the battery pole piece 15; the thickness curing device is used for sequentially baking and cooling the battery pole piece 15, so that the thickness of the battery pole piece 15 is solidified; the electrode rolling device 9 includes The first lamination roller 91, the second lamination roller 92, the first lamination roller support 912, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com