Low-energy-consumption and environment-friendly polypropylene spunbond non-woven fabric and preparation process thereof

A spun-bonded non-woven fabric, a preparation technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., to achieve good softness, low shrinkage, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

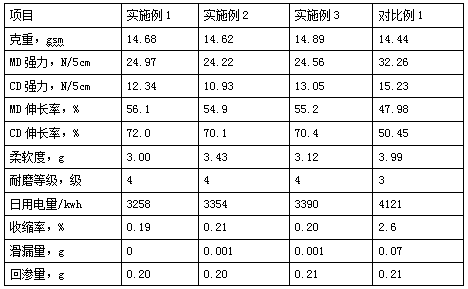

Examples

Embodiment 1

[0045] Embodiment 1 A kind of low energy consumption environment-friendly polypropylene spunbonded nonwoven fabric and its preparation process

[0046] The preparation process of the low energy consumption and environment-friendly polypropylene spun-bonded non-woven fabric of the present invention and its non-woven fabric product comprise the following steps:

[0047] (1) Mixture:

[0048] Weigh PP material, melt blown material, low melting point PP material, elastic masterbatch, soft masterbatch, white masterbatch, and the percentage of each raw material is: melt blown material 2-10%, low melting point PP material 2- 10%, elastic masterbatch 10-30%, soft masterbatch 0.3-1.1%, white masterbatch 0.5-1.0%, and the balance is PP material.

[0049] Add PP material, meltblown material, low melting point PP material, elastic masterbatch, soft masterbatch, white masterbatch to the mixing device, and the above raw materials are automatically loaded to complete the mixing.

[0050] I...

Embodiment 2

[0073] Embodiment 2 A kind of low energy consumption environment-friendly polypropylene spunbonded nonwoven fabric and its preparation process

[0074] The preparation process of a kind of low energy consumption and environment-friendly polypropylene spunbonded nonwoven fabric and its nonwoven fabric product of the present invention comprise the following steps:

[0075] (1) Mixture:

[0076] Weigh PP material, melt blown material, low melting point PP material, elastic masterbatch, soft masterbatch, white masterbatch, and the percentage of each raw material is: melt blown material 2-10%, low melting point PP material 2- 10%, elastic masterbatch 10-30%, soft masterbatch 0.3-1.1%, white masterbatch 0.5-1.0%, and the balance is PP material.

[0077] Add PP material, meltblown material, low melting point PP material, elastic masterbatch, soft masterbatch, white masterbatch to the mixing device, and the above raw materials are automatically loaded to complete the mixing.

[0078...

Embodiment 3

[0099] Embodiment 3 A kind of low energy consumption and environment-friendly polypropylene spunbonded nonwoven fabric and its preparation process

[0100] The preparation process of a kind of low energy consumption and environment-friendly polypropylene spunbonded nonwoven fabric and its nonwoven fabric product of the present invention comprise the following steps:

[0101] (1) Mixture:

[0102] Weigh PP material, melt blown material, low melting point PP material, elastic masterbatch, soft masterbatch, white masterbatch, and the percentage of each raw material is: melt blown material 2-10%, low melting point PP material 2- 10%, elastic masterbatch 10-30%, soft masterbatch 0.3-1.1%, white masterbatch 0.5-1.0%, and the balance is PP material.

[0103] Add PP material, meltblown material, low melting point PP material, elastic masterbatch, soft masterbatch, white masterbatch to the mixing device, and the above raw materials are automatically loaded to complete the mixing.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com