Horizontal well fracturing method for promoting fracture height extension through two times of acid injection and inter-cluster temporary plugging

A horizontal well and acid injection technology, applied in the field of horizontal well fracturing, can solve the problem of limited fracture height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

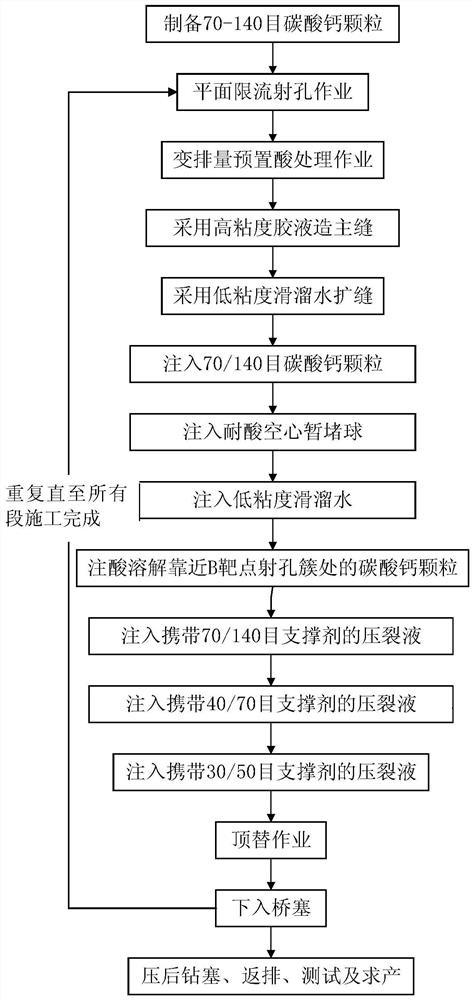

Method used

Image

Examples

Embodiment 1

[0073] A shale gas well in southwestern Sichuan has a vertical depth of 2200m, a sounding depth of 4385m, and a horizontal section length of 1585m. Follow the steps below to retrofit:

[0074] (1) Coiled tubing is used to carry a perforating gun to complete the first stage of perforating operation. Among them, perforating guns are arranged according to 3 perforations in each plane, the number of perforation clusters is 6 clusters, and there are 18 perforation holes in total.

[0075] (2) After the first section of perforation operation, 1m 3 A total of 30m of pretreatment acid is injected per minute 3 . then at 4m 3 / min displacement into low-viscosity slippery water 16m 3 For acid. Subsequent increase in displacement to 6m 3 / min inject low viscosity slippery water 16m 3 Replace the acid, and finally increase the displacement to 8m 3 / min inject low viscosity slippery water 18m 3 replace the acid to ensure that the acid can enter all perforation clusters.

[0076] ...

Embodiment 2

[0097] A shale gas well in southwestern Sichuan has a vertical depth of 2600m, a sounding depth of 4886m, and a horizontal section length of 1585m. Follow the steps below to retrofit:

[0098] (1) Coiled tubing is used to carry a perforating gun to complete the first stage of perforating operation. Among them, perforating guns are arranged according to 3 perforations in each plane, the number of perforation clusters is 6 clusters, and there are 18 perforation holes in total.

[0099] (2) After the first section of perforation operation, with 1.5m 3 A total of 30m of pretreatment acid is injected per minute 3 . then at 4m 3 / min displacement into low-viscosity slippery water 16m 3 For acid. Subsequent increase in displacement to 6m 3 / min inject low viscosity slippery water 16m 3 Replace the acid, and finally increase the displacement to 8m 3 / min inject low viscosity slippery water 18m 3 replace the acid to ensure that the acid can enter all perforation clusters.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com