Patents

Literature

49results about How to "Improve construction capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

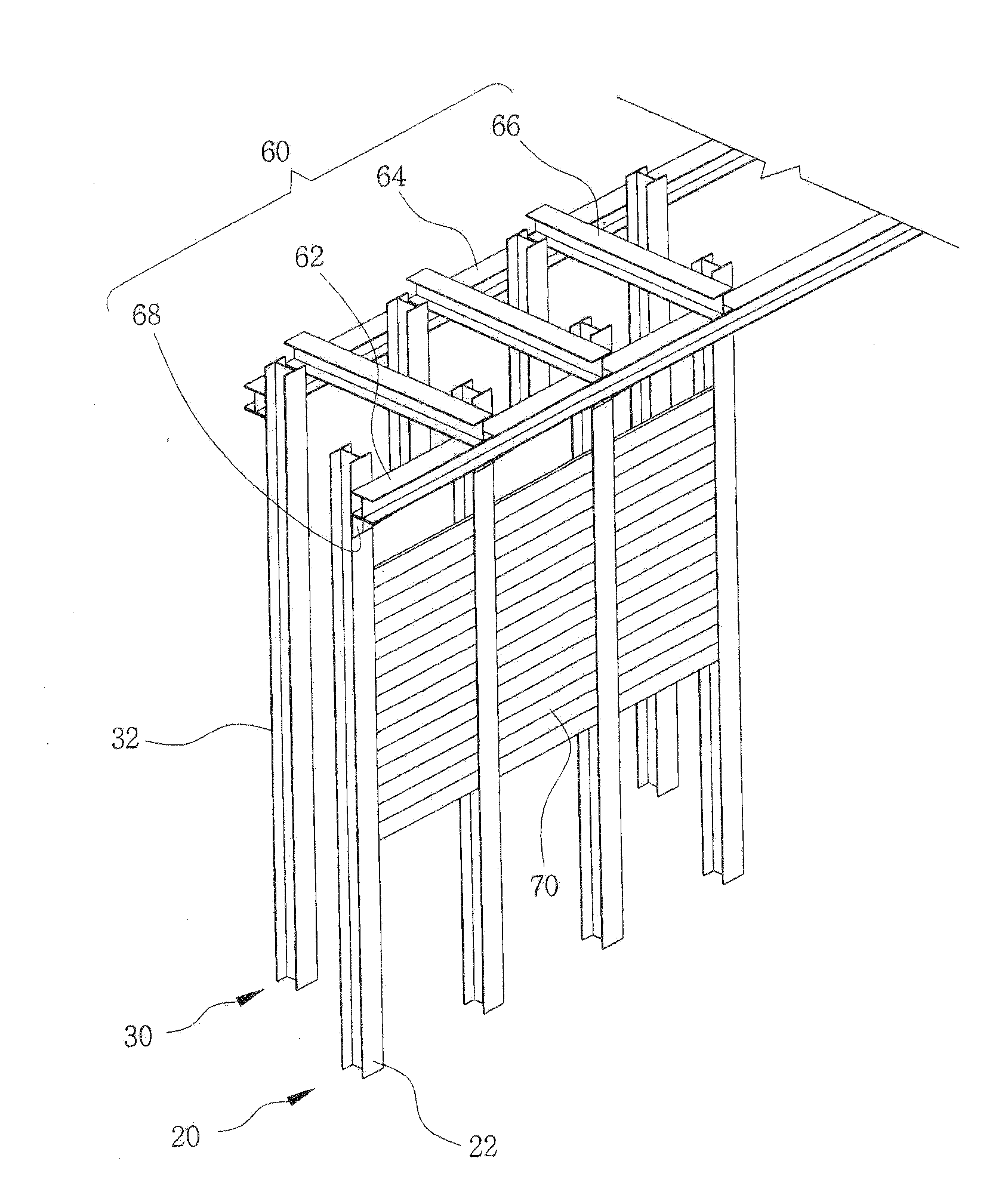

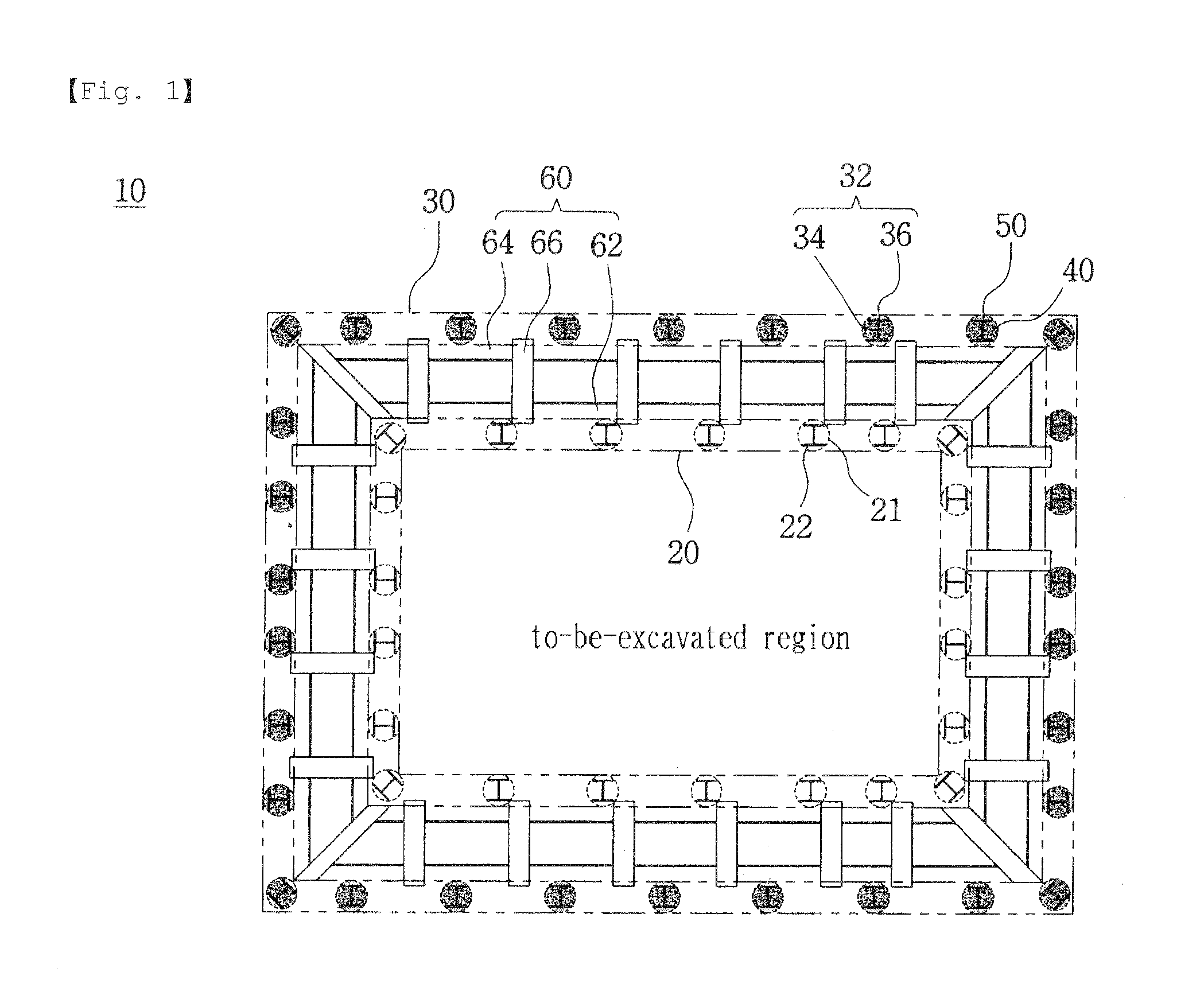

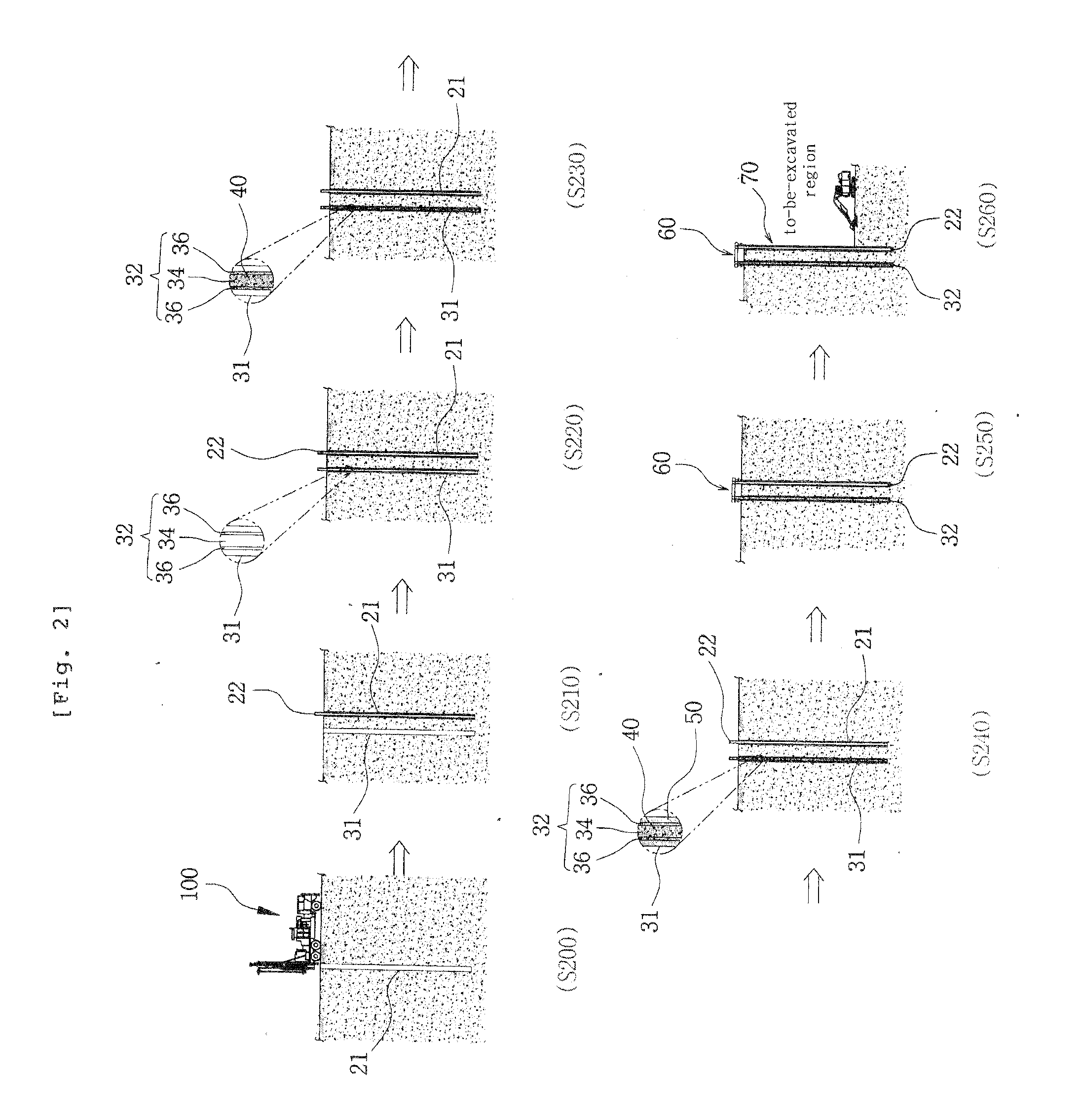

Method for constructing a chair-type, self-supported earth retaining wall

InactiveUS20110142550A1Low construction costShorten the construction periodArtificial islandsExcavationsRetaining wallOuter space

The present invention provides a method for constructing a chair-type, self-supported earth retaining wall used for retaining external forces such as earth pressure prior to an excavation. The method of the present invention forms a first column of piles having a plurality of piles arranged along the circumference of the region to be excavated. Subsequently, the method comprises forming a second column of piles having a plurality of piles by consecutively perforating a plurality of holes by a predetermined spacing at predetermined positions outwardly from the first column of piles, along the circumference of the region to be excavated, inserting H-beams into the respective holes, filling left and right spaces of the webs of the H-beams with soil, and filling the outer spaces of the flanges of the H-beams with a flowable stiffening material. The method subsequently comprises interconnecting the first column of piles and the second column of piles by a connection member. The first column of piles and the second column of piles are formed along the circumference of the region to be excavated, with an outward spacing, and connected to each other by the connection member.The present invention provides a method for constructing a chair-type, self-supported earth retaining wall used for supporting external forces such as earth pressure prior to an excavation. The method of the present invention comprises forming a first pile array 20 having a plurality of piles 22 arranged along a circumference of an region to be excavated. Subsequently, the method comprises forming a second pile array 30 having a plurality of piles arranged along a circumference of the to-be-excavated region by consecutively drilling a plurality of boreholes 31 at predetermined intervals at predetermined positions outwardly spaced apart from the first pile array, inserting H-beams into the respective boreholes, filling left and right spaces of webs 34 of the H-beams 32 with soil 40, and filling the outer spaces of flanges 36 of the H-beams with a flowable hardening material 50. The method subsequently comprises fixedly interconnecting the first pile array and the second pile array using a connection member. The first pile array and the second pile array are formed in such a fashion as to be outwardly spaced apart from each other along the circumferences of the to-be-excavated region, and are connected to each other by the connection member to construct an underground earth retaining wall.

Owner:KOLON CONSTR CO LTD

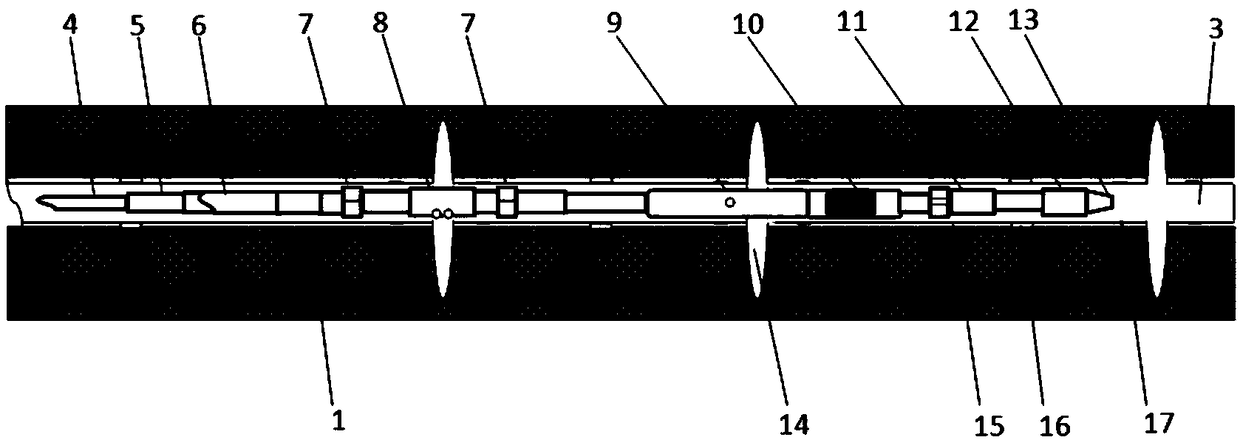

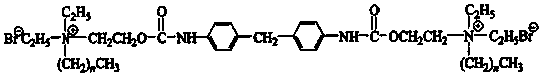

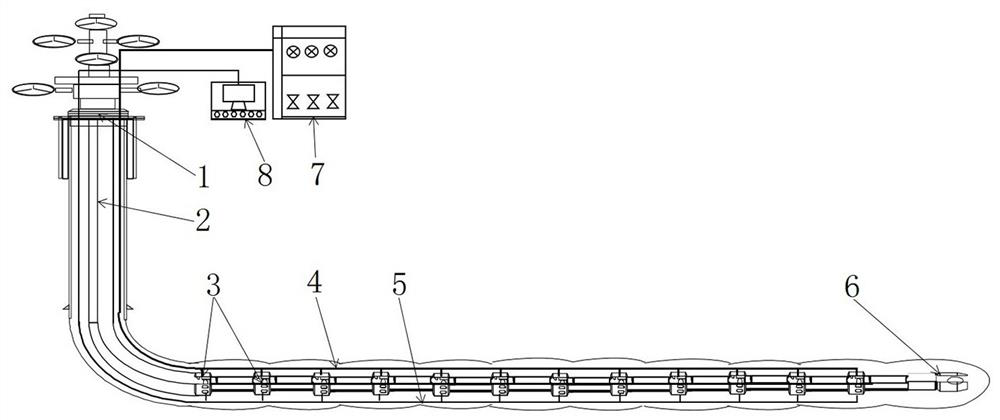

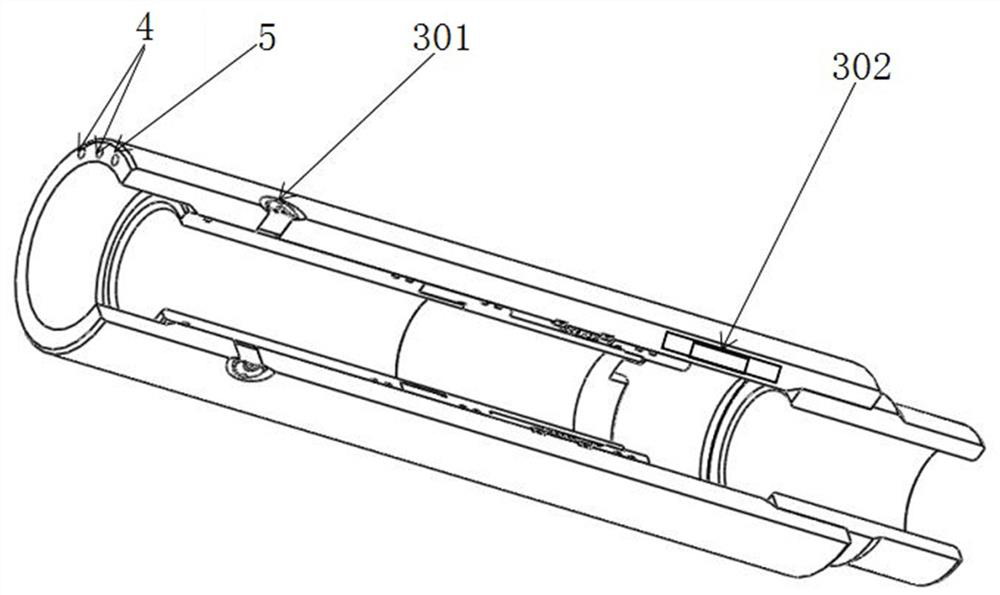

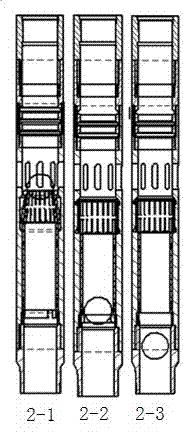

Directional hydraulic injection tool string and construction method for coal-bed gas horizontal well

InactiveCN108086964AImprove reliabilityImprove stabilityDrilling rodsFluid removalHorizontal wellsMaterial Perforation

Provided are a directional hydraulic injection tool string and a construction method for a coal-bed gas horizontal well. The directional hydraulic injection tool string is characterized by comprisinga guide cone, a screen pipe, a centering device one-way valve, a hydraulic anchor, a packer, an ejector, a hydraulic eccentric orientator, an upper centering device, a hydraulic releasing and an oil pipe which are sequentially connected, the hydraulic eccentric orientator is connected with the ejector through a fixed manner, the upper end of the hydraulic eccentric orientator and the lower end ofthe ejector are respectively through the upper centering device and the packer connected with an upper movable bearing and a lower movable bearing, and under the action of hydraulic, the eccentric orientator drives the ejector to achieve the function of directional ejection; the directional hydraulic injection tool string has reasonable design and complete functions, and higher reliability, stability and safety of the combined system, can achieve the function of outer pipe anti-channeling and fixed point fracturing, also achieve hydraulic sand blast perforation of large displacement, large hole, and orientation and subsection fracturing operation of large displacement and a large scale, is applied to the construction of coal-bed gas horizontal wells with complex conditions, such as cementing wells, uncementing wells and the like, and the directional hydraulic injection tool string has the advantages of high construction efficiency, low construction cost, a large scale of production increasing and improvement, high success rate of the construction and a good reconstruction effect and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

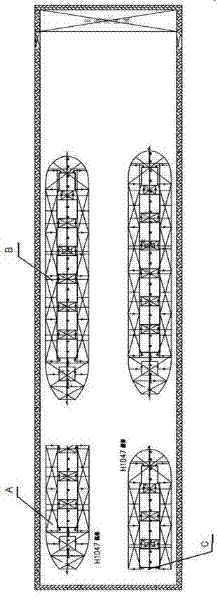

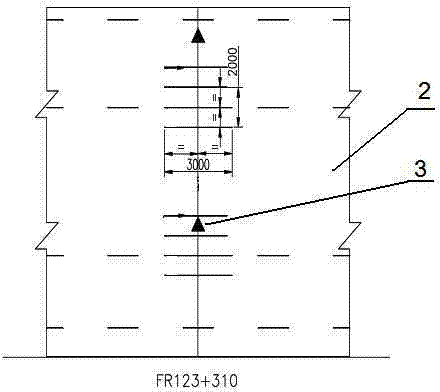

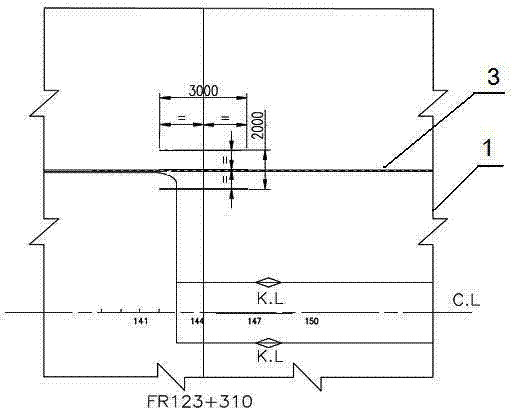

Process of afloat ship twin-islet jointing

The invention discloses a process of afloat ship twin-islet jointing. The process is characterized by comprising the flowing steps of: a, dividing a whole ship into two islets, building the two islets at the same time in a dock; b, performing ballast trimming on adjacent butt joint sections so that the afloat condition and draught of the two butt joint sections are consistent; c, centering, gathering and positioning the two sections; d, draining the dock so that the two islets fall down at specified docking blocks; e, draining a jointing partition; and f, performing assembling and jointing operation so as to complete the overall jointing work of a built object. The process has the advantages that the traditional concept that the construction contract is based on underwater facilities is broken through, and the construction capacity is improved on the basis of the advance of the process technology. The process is adapted to product market, and a large number of investment risks can be avoided, therefore the process is a positive construction method.

Owner:JIANGSU RONGSHENG SHIPBUILDING +2

Coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method

ActiveCN109339855AAvoid prone to collapse holesAvoid problems such as drill stickingFluid removalGas removalSand blastingCoiled tubing

The invention relates to a coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method. The method includes the steps that first, a gas extraction long drilled hole is constructed in a mudstone or sandstone roof with a certain distance to the top boundary of a broken soft coal seam or a hard layer of the broken soft coal seam or a hard coal seam with a good coal body structure; second, a guiding shoe and a rigid casing are lowered; third, cement paste blocking is carried out on annular space between the gas extraction long drilled hole and the rigid casing so as to solidify the hole; fourth, packing staging is carried out through a mode of dragging a packer by coiled tubing, an ejector carries out sand blasting perforation, and fracturing is carried out on the annulus between the coiled tubing and the casing; fifth, a fracturing tool is lifted out, and uniform blowout of fracturing fluid is carried out. The method can solve the problems that in existing gas extraction hole-drilling, hole forming is difficult, the crack initiation position of fracturing cracks is not determined, the fracturing cracks extend short, the fracturing modification effect is poor, the extraction affecting range is small and nonuniform, and extraction duration is short, and realizes gas extraction long drilled hole forming and multi-level precise staged fracturing.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

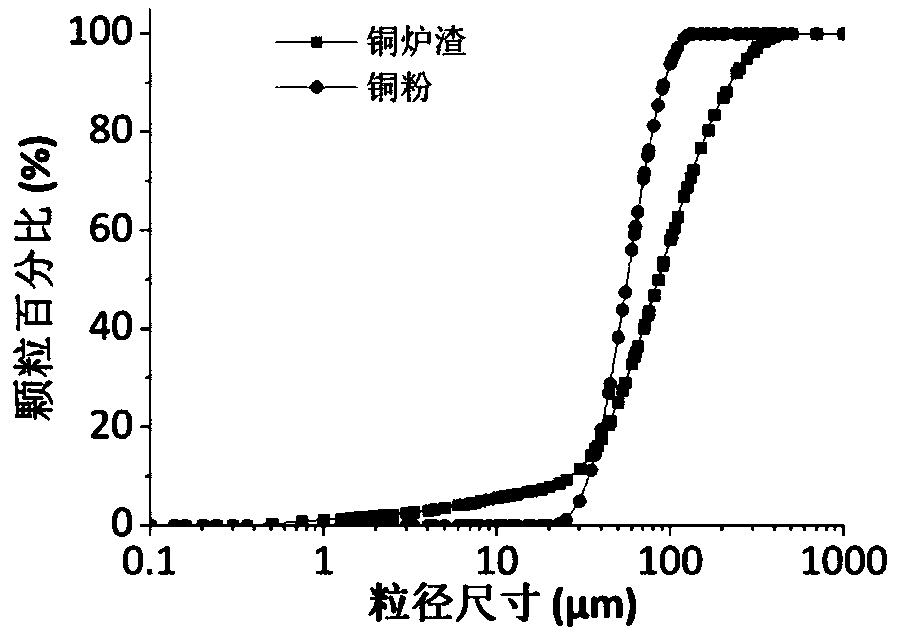

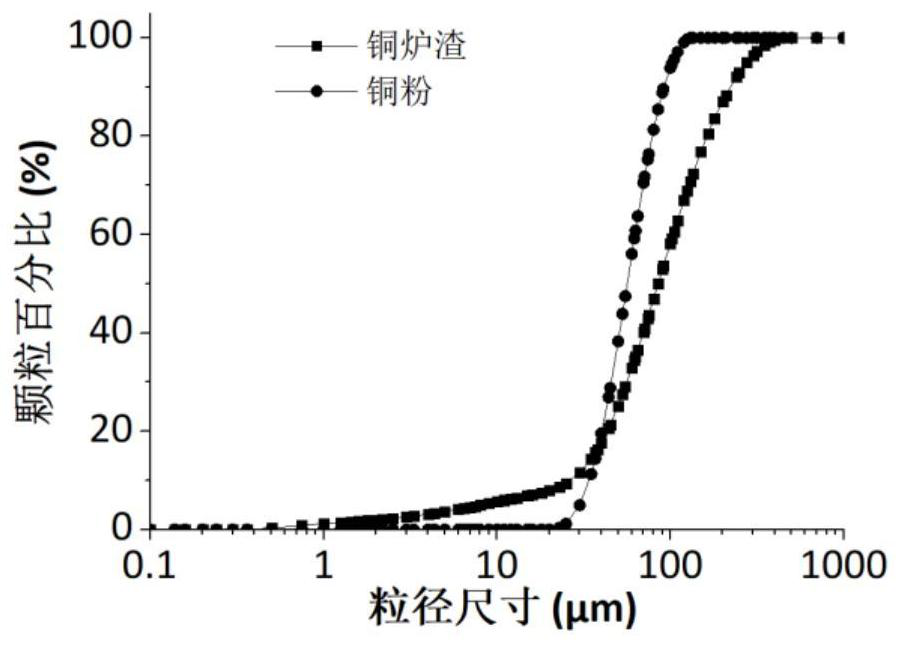

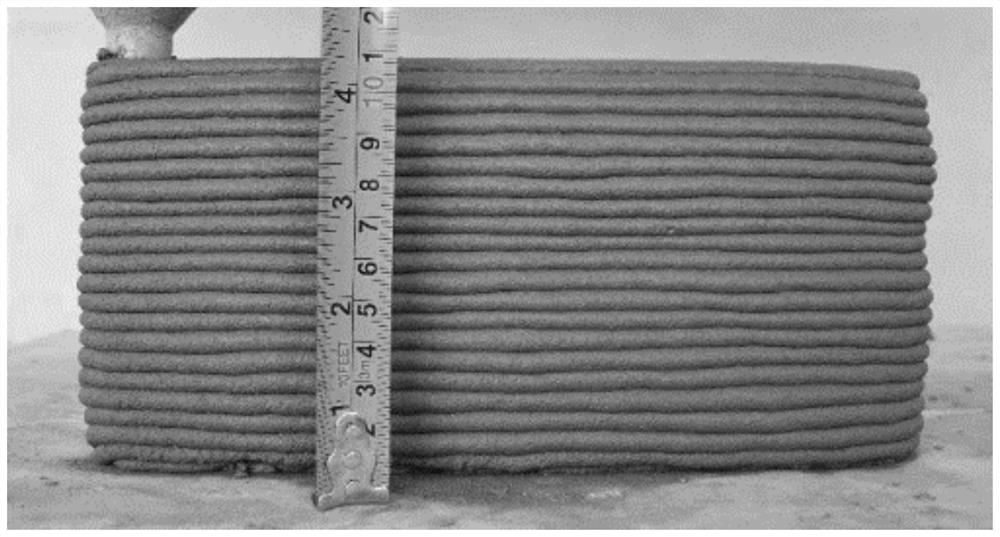

3D-printable copper slag electromagnetic wave-absorbing concrete and use method thereof

ActiveCN108609947ALow costImprove liquidityAdditive manufacturing apparatusBasalt fiberWater reducer

The invention relates to 3D-printable copper slag electromagnetic wave-absorbing concrete and a use method thereof. The concrete includes, by weight, 6.8-7.2 parts of quick-hardening ordinary Portlandcement, 6.9-7.1 parts of quartz sand, 1.65-1.75 parts of copper slag, and 0.28-0.71 parts of copper powder composed of brass powder and red copper powder according to the weight ratio of 7:2.5-3.5, 0.75-0.85 parts of silica fume, 0.09-0.15 parts of a water reducer, 0.04-0.07 parts of basalt fiber being 11-14 mm in length, 0.003-0.005 parts of hydroxypropyl methyl cellulose being 20,000-70,000 inviscosity, and 1.70-1.74 parts of water. With the copper slag and copper powder as raw materials, the concrete has both the printability and electromagnetic wave-absorbing effect of the copper slag and copper powder, so that the concrete allows 3D printing and can achieve more than 90% in electromagnetic wave absorption in the bandwidth of 3.4 GHz.

Owner:HEBEI UNIV OF TECH

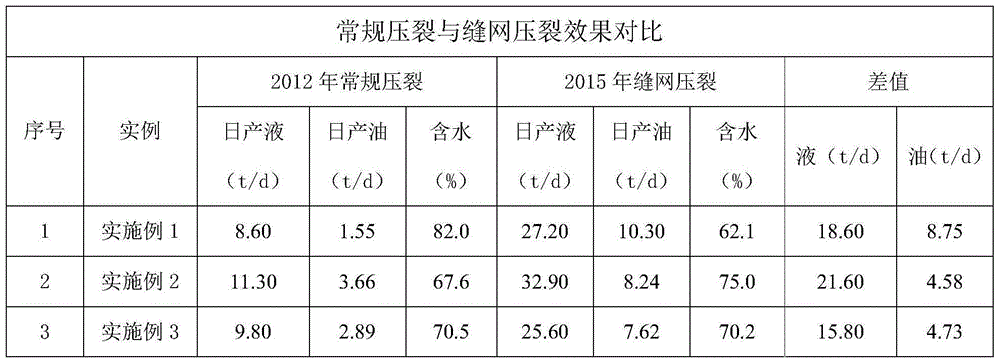

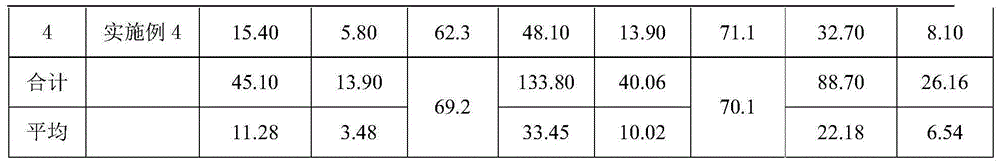

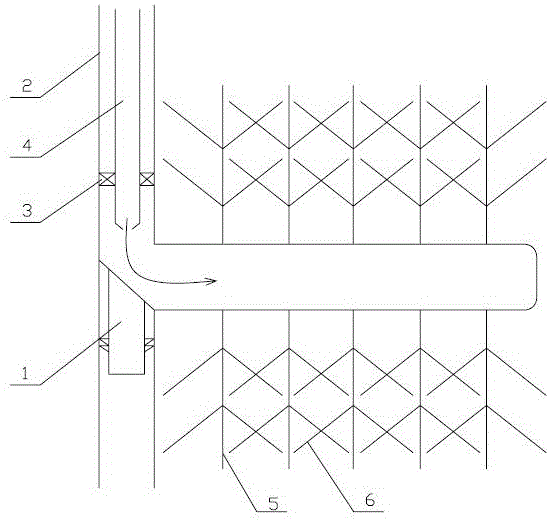

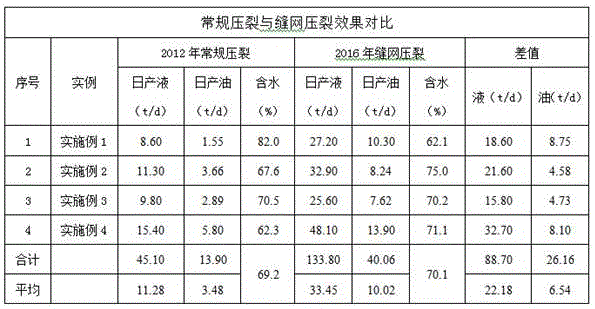

Oil and gas well fracture network system fracturing technology

InactiveCN105201478AStable supportIncrease net pressureFluid removalFracturing fluidMaterial Perforation

The invention relates to an oil and gas well fracture network system fracturing technology. The method comprises the following steps that perforation is carried out on an oil pipe; packers are utilized for blocking the upper end and the lower end of a perforated hole; fracturing liquid is injected through the perforated hole to enable a stratum to form a main fracture; a temporary plugging agent is used for plugging the main fracture; pressure of the fracturing liquid is increased to 5-10 MPa, the fracturing liquid is injected again by means of the perforated hole to enable the stratum to form a larger number of secondary fractures around the main fracture. The fracture network system fracturing technology is provided for increasing the yield of an oil and gas field, natural fractures around a shaft and the artificial fractures can be distributed in a staggered mode to form an artificial fracture three-dimensional network, the swept volume of the fractured fractures in a reservoir can be maximized, and the well seepage size after fracturing is increased by folds, so that the purpose of increasing the yield and the injection amount is achieved.

Owner:DAQING JINGTAI PETROLEUM ENG TECH

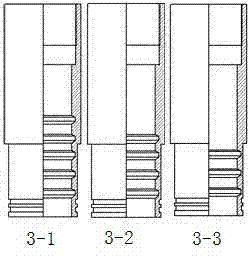

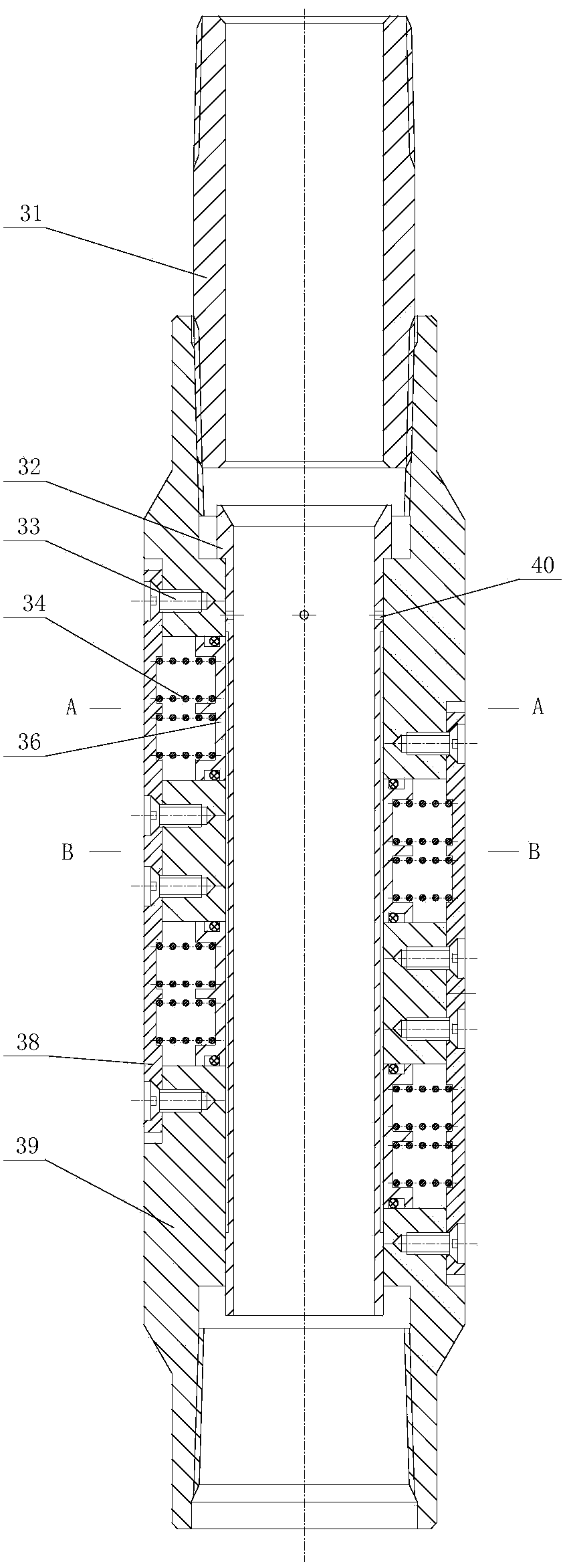

Well cementation casing or tubing sliding sleeve without limit on number of segments or clusters

ActiveCN105134131AImprove the effect of fracturingImprove single well productionFluid removalWell/borehole valve arrangementsWell cementingMultiple fracture

The invention relates to a well cementation casing or tubing sliding sleeve without limit on the number of segments or clusters, comprising an upper joint, a variable-diameter cylinder, a sliding sleeve body, and a lower joint. The upper joint is connected with the variable-diameter cylinder, the variable-diameter cylinder is connected with the sliding sleeve body, and the sliding sleeve body is connected with the lower joint. Grooves are arranged on the inner wall of the variable-diameter cylinder to make a variable-diameter area formed on the inner wall of the variable-diameter cylinder, and an elastic cylinder is installed in the variable-diameter area. Multiple fracturing ports are uniformly distributed in the middle of the sliding sleeve body along the circumference. The inner wall of the sliding sleeve body has a diameter expanding area which is disposed below the fracturing ports. An inner sliding sleeve is arranged inside the sliding sleeve body. The lower end inside the sliding sleeve body is equipped with a C ring. With the sliding sleeve, vertical and horizontal wells in oil and gas fields can be fractured in a layered manner under the conditions of an unlimited number of segments and an unlimited number of clusters between segments. Before fracturing, a wellbore is full-pass, and the sliding sleeve and a ball seat are non-throttled. The construction capacity is larger, the fracturing effect can be significantly improved, and the production capacity of a single well can be increased. After fracturing, a ball made of soluble material and the C ring are dissolved or drilled and ground, and the well bore is full-pass again, thus facilitating later production and operation.

Owner:PETROCHINA CO LTD

Method for plugging multiple sections of cracks in horizontal well by combining particles and gel

ActiveCN108204218ARealize the purpose of reengineeringRealize fixed-point segmental transformationSealing/packingHorizontal wellsWorking pressure

The invention discloses a method for plugging multiple sections of cracks in a horizontal well by combining particles and gel. The method comprises the steps that a horizontal well shaft is processed,the shaft is ensured to be unblocked, a plugging agent slug mixed by the chemical particles and gel liquid is subjected to pump injection through wellhead displacement, multiple times of pump injecting of the plugging agent slug is conducted, the working pressure is gradually increased to the casing limit pressure or the highest breaking pressure value of primary fracturing formation, and the well is closed to wait for solidification; and after the gel liquid is solidified, the particle plugging form is maintained, whole reverse pressure bearing of the plugging agent is achieved, the horizontal well shaft is subjected to secondary processing, the residual particles and the solidified gel in the horizontal well shaft are removed, and the shaft is ensured to be unblocked. The method for plugging the multiple sections of cracks in the horizontal well by combining the particles and the gel greatly improves the construction efficiency of repeated fracturing and the construction scale, andhas wide application prospects in the aspect of repeated fracturing of the low-yield horizontal wells with tight reservoirs.

Owner:PETROCHINA CO LTD

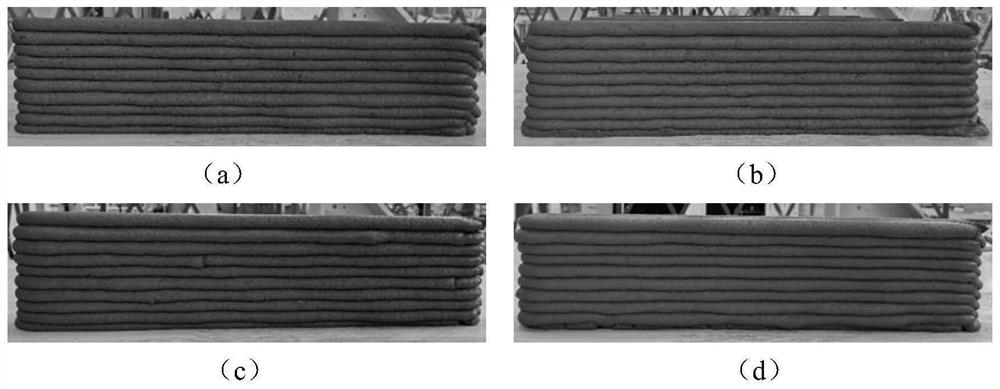

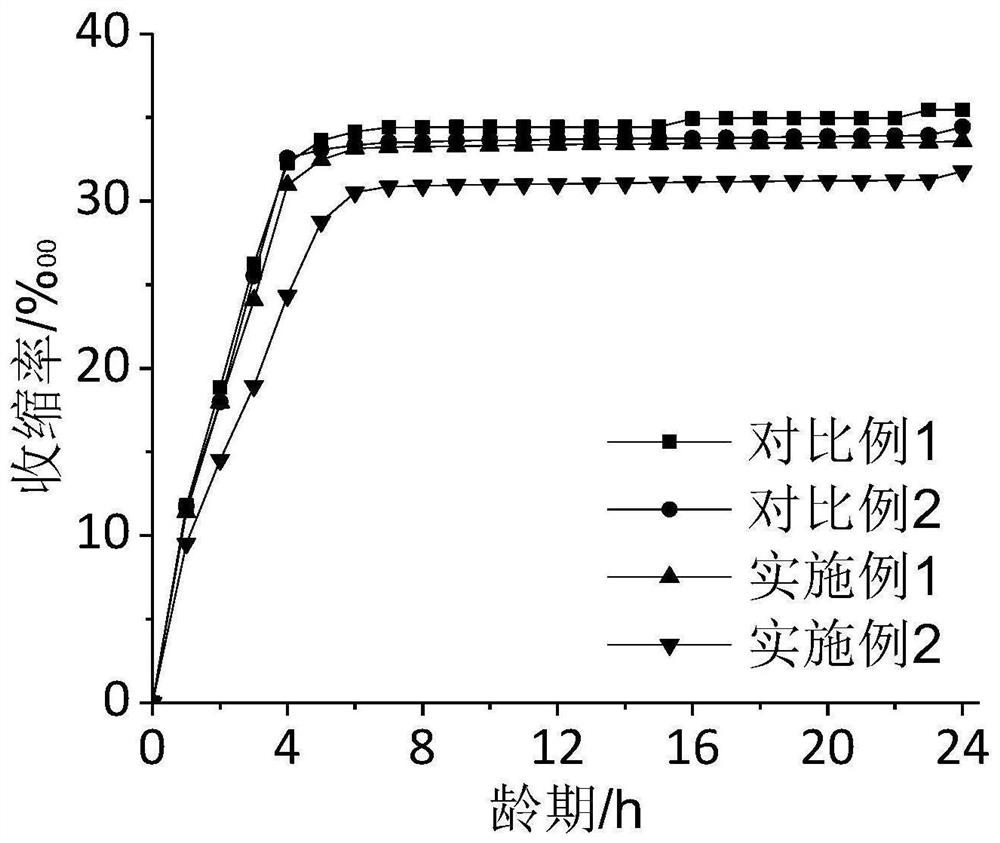

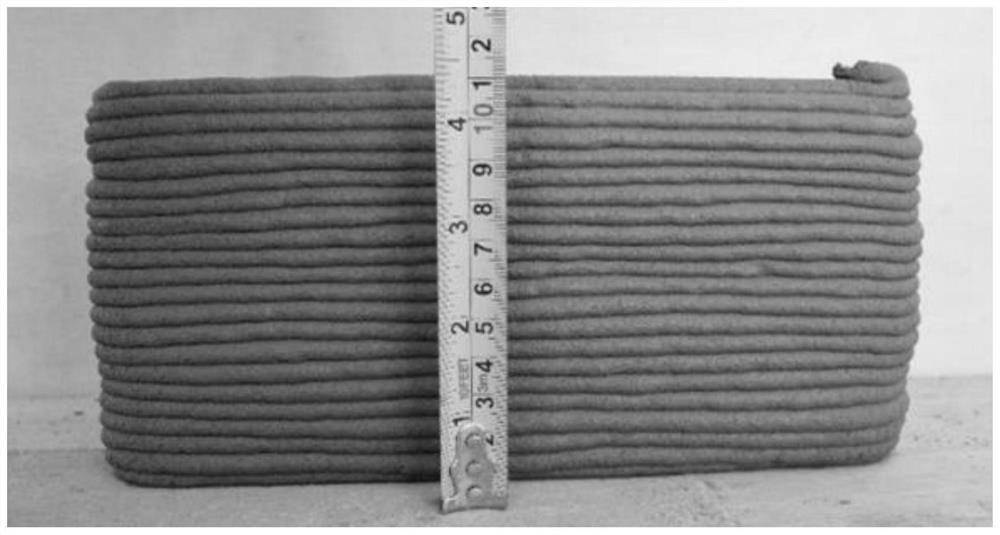

Low-shrinkage 3D printing concrete co-doped with lignin fibers and preparation method of low-shrinkage 3D printing concrete

ActiveCN113372074ASmall shrinkage deformationImprove early crack resistanceAdditive manufacturing apparatusSolid waste managementFiberAluminate

The invention discloses low-shrinkage 3D printing concrete co-doped with lignin fibers and a preparation method of the low-shrinkage 3D printing concrete. The concrete comprises the following components: high belite sulphoaluminate cement, ordinary Portland cement, lignin fibers, a UEA expanding agent, silica fume, quartz sand, water and an additive. The lignin fibers are applied to the 3D printing concrete for the first time, the effects of internal curing and fiber toughening are achieved, shrinkage deformation of the 3D printing concrete in all ages can be effectively reduced, the early-stage cracking resistance is improved, the interlayer bonding performance of the 3D printing concrete is effectively improved, and meanwhile the humidity balance of a concrete material can be adjusted. The high belite sulphoaluminate cement and the ordinary Portland cement are mixed according to a proper proportion to serve as a cementing material of the 3D printing concrete. The printability of the concrete can be optimized and the early strength of the concrete can be improved due to the characteristics of quick setting and early strength of the high belite sulphoaluminate cement, and the shrinkage deformation of the 3D printing concrete in the later period can be reduced due to the characteristic of low shrinkage.

Owner:HEBEI UNIV OF TECH +1

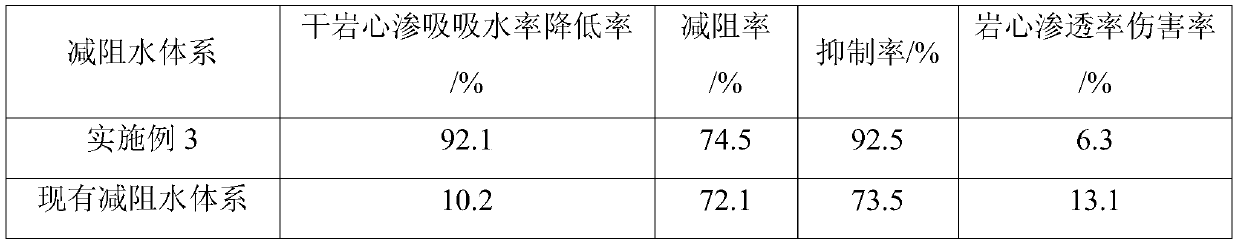

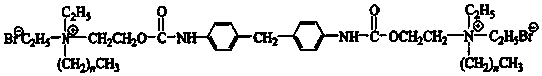

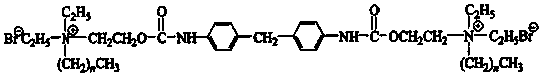

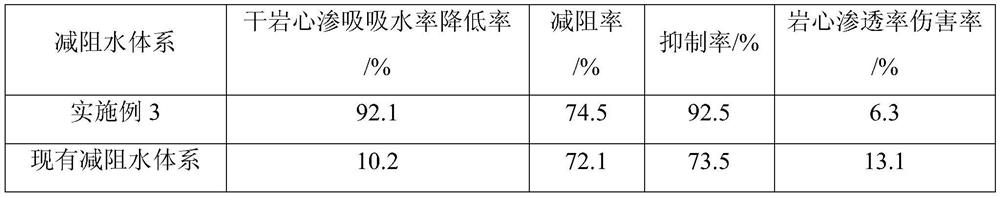

Multifunctional drag reduction water system for continental shale gas fracturing and preparation method thereof

ActiveCN110760299AReduce harmConducive to promoting green developmentDrilling compositionClay mineralsChemical reaction

The invention relates to a multifunctional drag reduction water system for continental shale gas fracturing and a preparation method thereof. The multifunctional drag reduction water system for continental shale gas fracturing comprises the following components in percentages by mass: 0.02% to 0.05% of a resistance reducing agent, 0.5% to 1% of an inhibitor, 0.1% to 0.3% of an antiscaling agent, 0.001% to 0.003% of a synergist, 0.2% to 0.5% of a regulator and the balance of water. The multifunctional drag reduction water system provided by the invention has the characteristics of high drag reduction rate, high inhibition, permeability reduction, adsorption reduction and the like, clay mineral expansion and clay particle migration can be inhibited, a seepage channel is kept smooth, water-rock physical and chemical reactions are effectively inhibited, a fracturing fluid is promoted to flow back quickly, the adsorption damage of the fracturing fluid is reduced, the requirement of continental shale gas fracturing construction is met, the damage of the drag reduction water fracturing fluid to a reservoir is reduced, and efficient development of terrestrial shale gas is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

High efficiency fracturing method using coiled tubing water-jet and soluble rubber plugs

InactiveCN106321050ARelieve pressureSolve the real problemFluid removalDrilling compositionTubing hangerCoiled tubing

The invention provides a high efficiency fracturing method using coiled tubing water-jet and soluble rubber plugs. The high efficiency fracturing method includes a sandblast and perforation stage, an annulus sand fracturing stage, a soluble rubber plug injection stage, a replacement stage, a curing and pressure test stage, and a blowout stage. The soluble rubber plugs are used as sealing members, the number of fracturing segments is not limited, the situation that sand blocks pipes can be avoided, gel-breaking of the rubber plugs can be controlled during construction, gel-breaking and rapid flow-back can be achieved at the same, and the construction efficiency and the successful rate can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient imbibition and drag-reducing water system applicable to atmospheric pressure shale gas reservoir and preparation method and application thereof

ActiveCN108822825AConducive to fracturing constructionRapid hydration and dispersionDrilling compositionSoil scienceDesorption

The invention discloses an efficient imbibition and drag-reducing water system applicable to an atmospheric pressure shale gas reservoir. The efficient imbibition and drag-reducing water system applicable to the atmospheric pressure shale gas reservoir comprises the following components: 0.04-0.1 percent of a high-molecular polymer drag reducer, 0.05-0.2 percent of a moisture regulator, 0.1-0.3 percent of an efficient shale inhibitor, 0.01-0.03 percent of an environment-friendly fungicide, 0.05-0.1 percent of an imbibition conditioner and the balance of water. The efficient imbibition and drag-reducing water system applicable to the atmospheric pressure shale gas reservoir has the advantages that the efficient imbibition and drag-reducing water system is prepared by using a low molecular weight high-molecular polymer as a drag reducer and introducing the moisture regulator, the imbibition conditioner, the efficient shale inhibitor and the environment-friendly fungicide. Therefore, therock core spontaneous imbibition amount can be effectively increased, the imbibition of a fracturing fluid to a deep ground mass can be promoted; smoothness of a spontaneous imbibition passage can bekept; the desorption of adsorbed gas can be promoted; effects of water soluble replacement of the adsorbed gas, energy increasing and drainage are achieved; atmospheric pressure shale fracking construction requirements are satisfied; the drainage of atmospheric pressure shale gas drag-reducing water fracturing fluid flow-back fluid is reduced; and the development of economic benefits of an atmospheric pressure shale gas field is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-dimensional pipe fracturing method for low-yield well in low permeability oilfield

ActiveCN108643876AIncrease productionIncrease net pressureFluid removalDrilling compositionFiltrationMicro fracture

The invention relates to a multi-dimensional pipe fracturing method for a low-yield well in a low permeability oilfield. The multi-dimensional pipe fracturing method is characterized by comprising thefollowing steps that (1) fracturing liquid is injected through a low-displacement pump to displace oil and water or oil and water mixtures in initial fracturing artificial fractures; (2) the construction displacement is increased, and propping agents in the initial fracturing artificial fractures are suspended in the fracturing liquid; (3) through filtration of the fracturing liquid in a stratum,the propping agents are transported to the ends of the initial fracturing artificial fractures to be accumulated; (4) the construction displacement is increased to increase the net pressure in the fractures, and the micro fractures are opened; (5) after the fracturing liquid capable of carrying acid liquor corrodes the wall faces of the main fractures and the micro fractures, sand fracturing is conducted; (6) after fracturing operation is completed, blowout is controlled; and (7) construction is completed. According to the multi-dimensional pipe fracturing method, repeated fracturing of the low-yield well in the oilfield is achieved through optimization of the process method to open the micro fractures to form a multi-dimensional pipe fracturing system, and the target of increasing the single well yield of the low-yield well in the oilfield is achieved.

Owner:SHAANXI YOUBANG PETROLEUM ENG TECH CO LTD

Drilling, grinding and pigging method and device for coiled tubing with screw drill and application

PendingCN111101897AReduce frictionEffective wash outEarth drilling toolsCleaning apparatusThermodynamicsHorizontal wells

The invention relates to a drilling, grinding and pigging method and device for a coiled tubing with a screw drill and application, belongs to the technical field of oil and gas field well repair andcompletion. The drilling, grinding and pigging method for the coiled tubing with the screw drill comprises the step of circulating guanidine gum base liquid in a well during drilling, grinding and pigging. The adopted guanidine gum base liquid reduces liquid friction resistance, improves construction displacement, strengthens carrying capacity, finally effectively washes out mud in a well, can besuccessfully led to an artificial well bottom, provides a qualified wellbore environment for later construction, eliminates the risk of damage to a casing pipe, can quickly and perfectly relieve complex wellbores caused by cementation and precipitation of drilling mud while not influencing normal construction operation, improves the production efficiency and creates a new mode for horizontal wellcoiled tubing well pigging and flushing operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

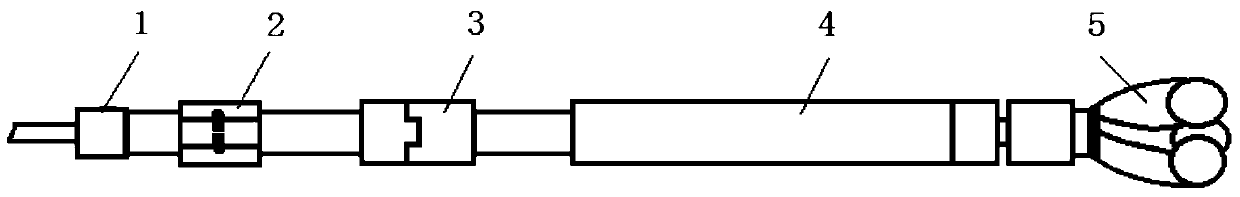

Resistance reducing acid used for transformation of ultra-deep well

InactiveCN101875841BIncrease productionIncrease the intensity of acidification transformationDrilling compositionHydroxylamine HydrochlorideSodium erythorbate

The invention relates to resistance reducing acid used for the transformation of an ultra-deep well, in particular to the resistance reducing acid used for the acidification transformation of ultra-deep and high-temperature oil and gas wells. The resistance reducing acid comprises the following components in percentage by weight: 2.0 to 4.0 percent of ethylene glycol 1,2-propanediol copolymer, 2.0 to 4.0 percent of beta-(N,N)-diethylamino phenyl ketone, 1.0 to 2.0 percent of dodecyl trimethyl ammonium halide, 1.0 to 2.0 percent of sodium erythorbate or hydroxylamine hydrochloride, 15 to 28 percent of hydrochloric acid or a mixed acid which contains 12 to 15 percent of the hydrochloric acid and 1 to 3 percent of hydrofluoric acid, and the balance of water. By utilizing the characteristics of high fluidity and low friction of a high-molecular-weight linear polymer, an auxiliary corrosion inhibitor, a ferric ion stabilizer, a cleanup additive and the like form a resistance reducing acid system which is adapted to the acidification of the ultra-deep well so as to reduce the friction in a pump injection process in construction, reduce additional energy dissipation, contribute to improving construction displacement, increase reservoir acidification transformation dynamics and improve the yield of the oil and gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

4-inch half-sleeve layered fracturing pipe column and fracturing method

PendingCN109915097AImprove construction capacitySolve the problem of effective mobilizationFluid removalEngineeringConstant pressure

The invention discloses a 4-inch half-sleeve layered fracturing pipe column and a fracturing method. The 4-inch half-sleeve layered fracturing pipe column comprises a constant-pressure sliding sleeve,packing assemblies, a hydraulic anchor, a releasing packer and a connecting pipe, wherein a plurality of the packing assemblies are arranged; the connecting pipe comprises a first connecting pipe, aplurality of second connecting pipe and a third connecting pipe; the upper end of the constant-pressure sliding sleeve is connected with the packing assemblies through the first connecting pipe; the plurality of packing assemblies are sequentially connected from bottom to top through the plurality of second connecting pipes; the packing assembly at the uppermost end is connected with the hydraulicanchor through the third connecting pipe, the upper end of the hydraulic anchor is connected with the releasing packer, the constant-pressure sliding sleeve, the packing assemblies, the hydraulic anchor and the releasing packer are all provided with inner through holes, and the diameters of the inner through holes of the packing assemblies, the hydraulic anchor and the releasing packer are all larger than the diameter of the inner through hole of the constant-pressure sliding sleeve.

Owner:PETROCHINA CO LTD

A kind of multifunctional drag reducing water system and preparation method for continental shale gas fracturing

ActiveCN110760299BReduce harmConducive to promoting green developmentDrilling compositionClay mineralsChemical reaction

The present invention relates to a multifunctional drag-reducing water system for continental shale gas fracturing and a preparation method thereof. The components and mass percentages of the multifunctional drag-reducing water system for continental shale gas fracturing are as follows: Drag reducer 0.02-0.05%, inhibitor 0.5-1%, anti-scaling agent 0.1-0.3%, synergist 0.001-0.003%, regulator 0.2-0.5%, and the balance is water. The multi-functional drag-reducing water system provided by the present invention has the characteristics of high drag-reducing rate, strong suppression, reduced imbibition, and reduced adsorption. , chemical reaction, promote the rapid flowback of fracturing fluid, reduce the adsorption damage of fracturing fluid, meet the requirements of continental shale gas fracturing construction, reduce the damage of drag-reducing water fracturing fluid to reservoirs, and realize continental shale Efficient development of gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

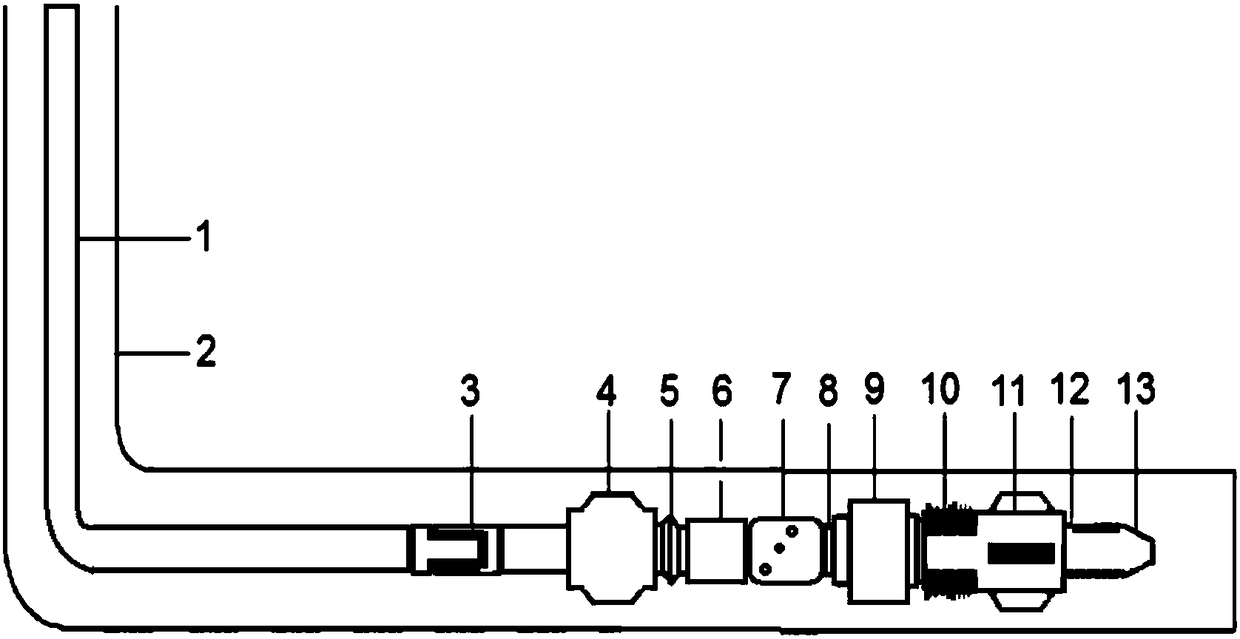

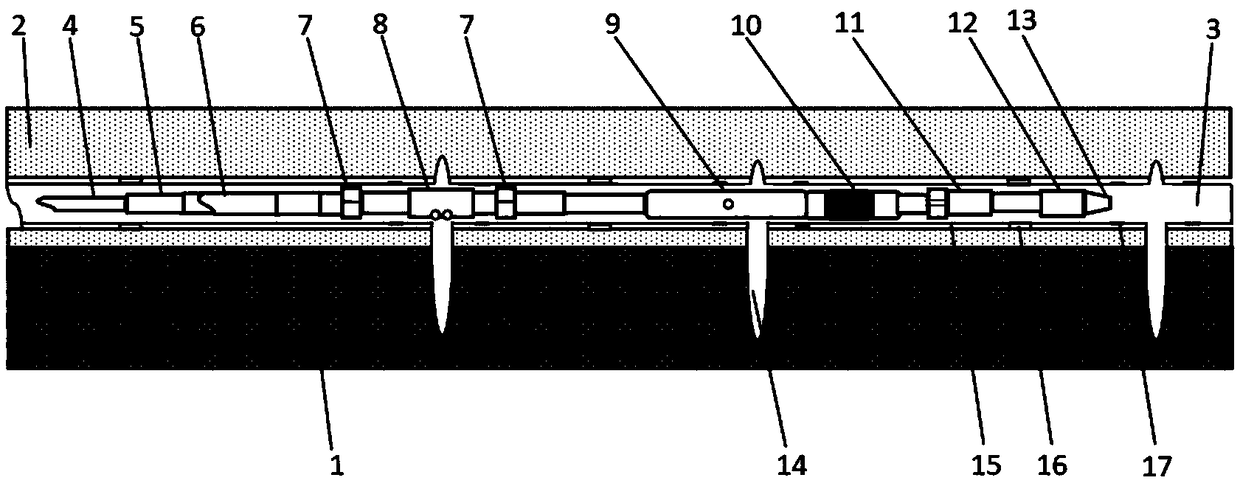

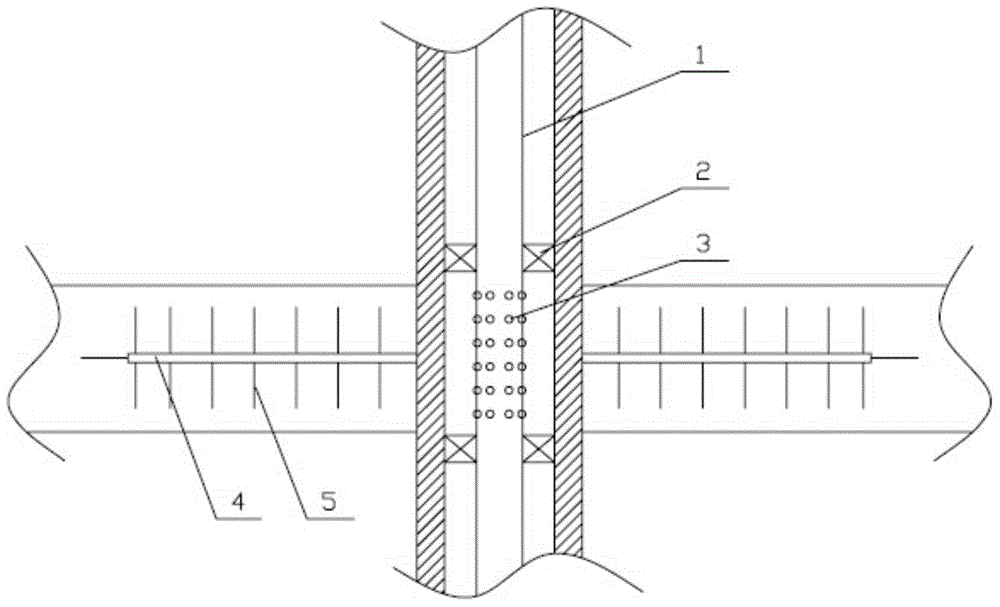

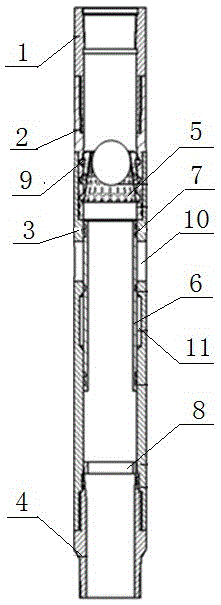

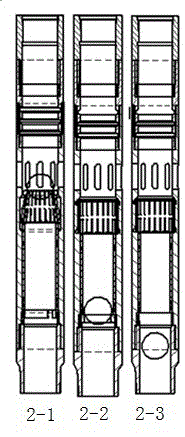

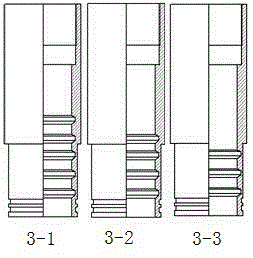

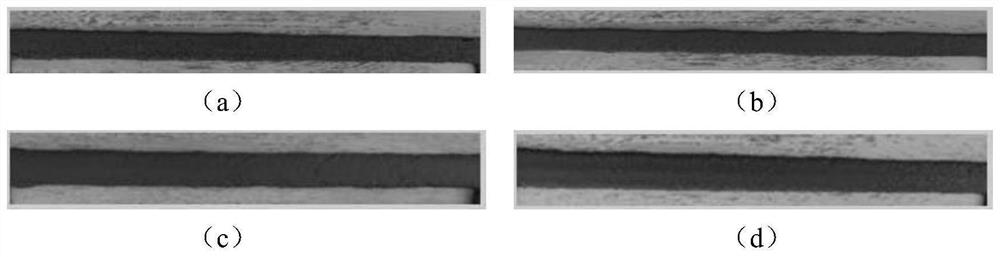

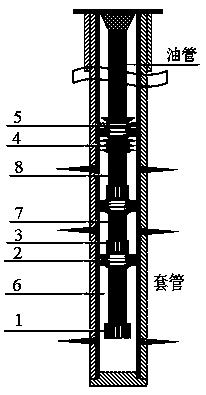

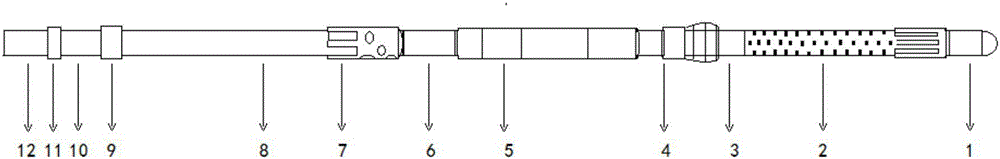

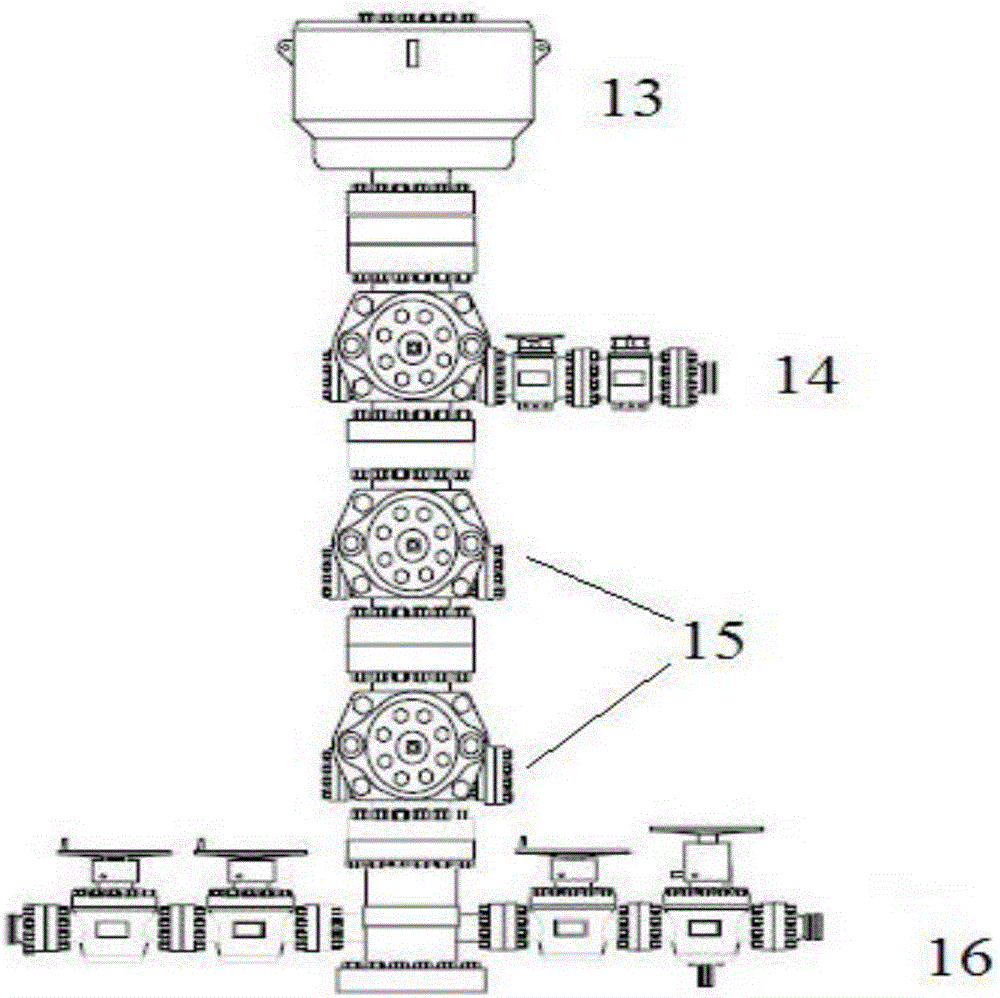

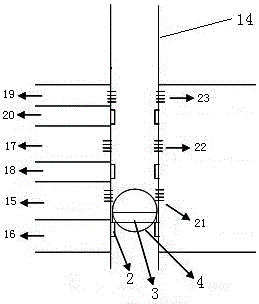

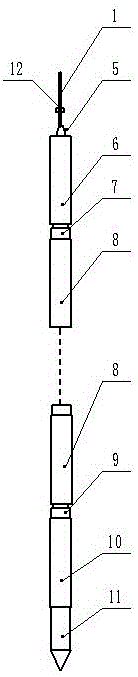

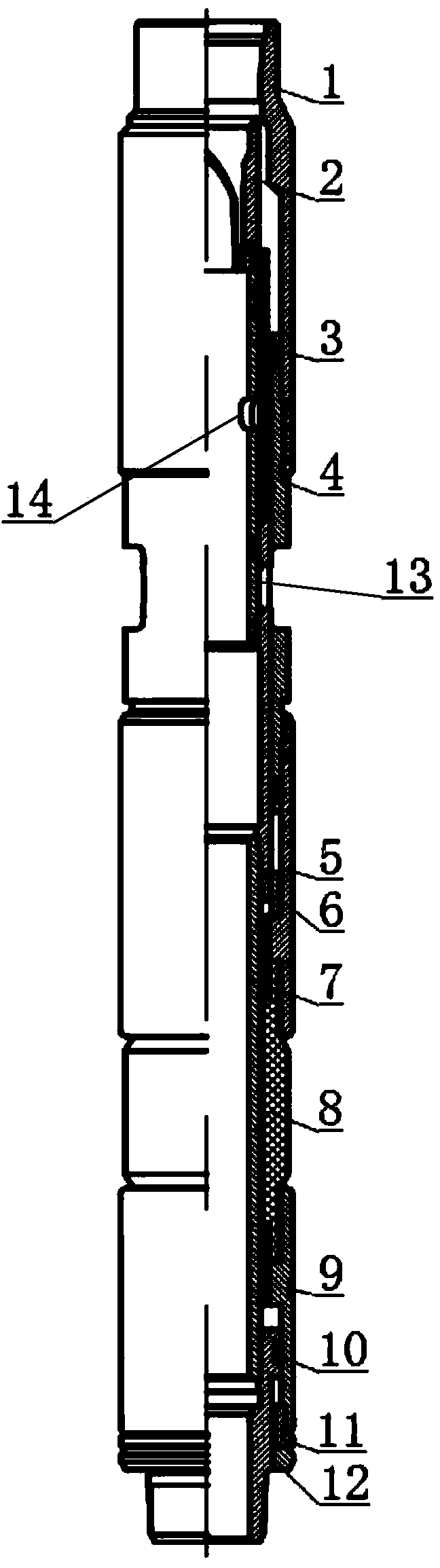

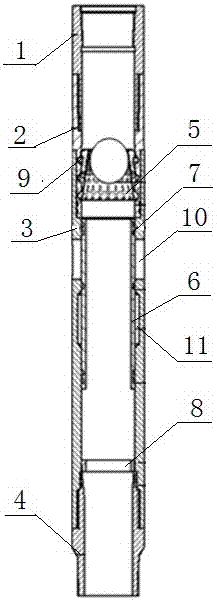

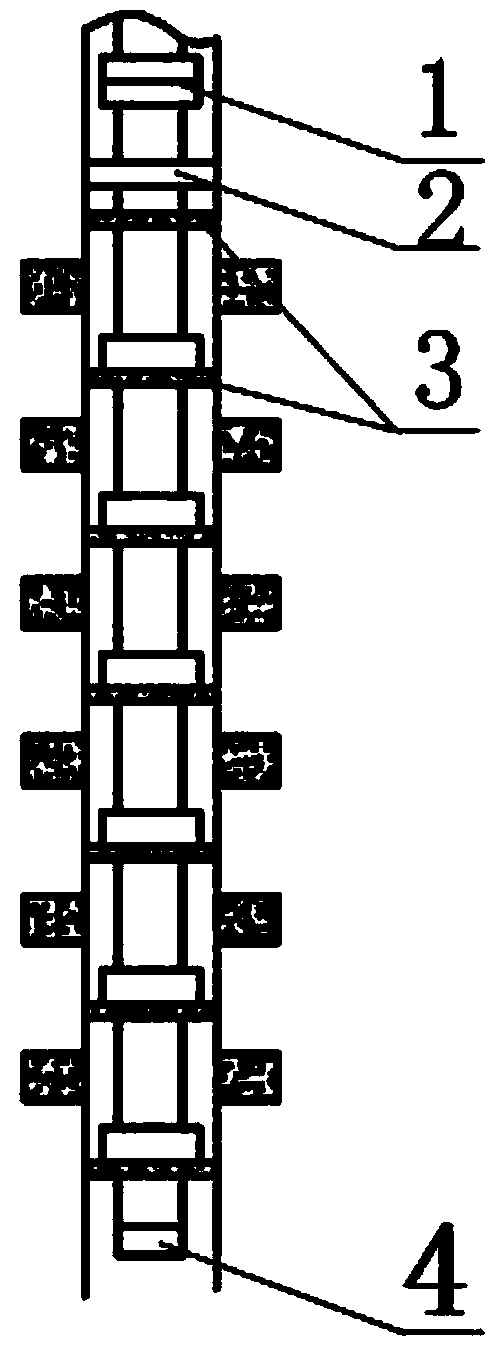

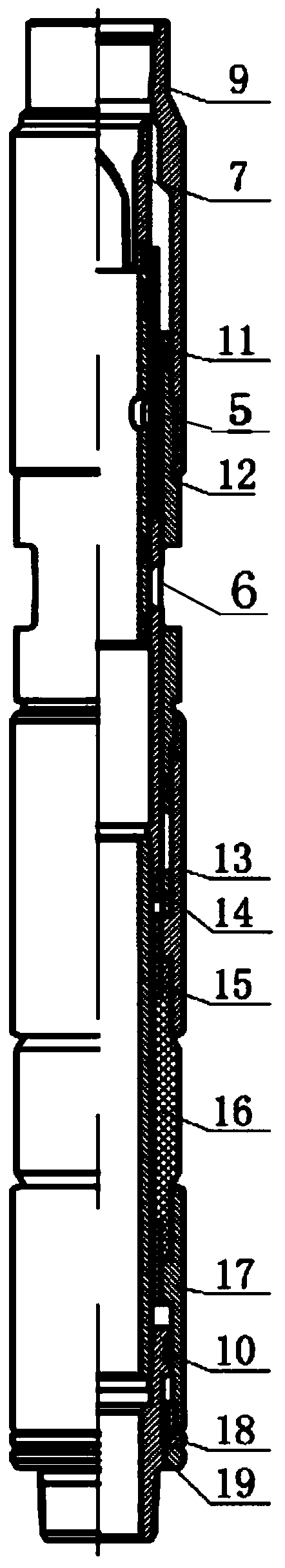

Oil-pipe under-pressure dragging fracturing device and technology

The invention discloses an oil-pipe under-pressure dragging fracturing device and technology. The oil-pipe under-pressure dragging fracturing device comprises a fracturing tool and a fracturing wellhead device, wherein the fracturing tool comprises a choke plug (1), a sieve tube (2), a coupling (3), a double-severing backpressure check valve (4), a packer (5), a nipple (6), an injector (7), a first oil pipe nipple (8), a sand passing check valve (9), a second oil pipe nipple (10) and a working barrel (11), which are sequentially connected with one another in order; and the fracturing wellhead device comprises an annular blowout control device (13), a slip blowout control device (14) and a safety blowout control device (15). The invention further relates to the fracturing technology using the oil-pipe under-pressure dragging fracturing device.

Owner:BEIJING YILONG HENGYE PETROLEUM ENG TECH

Vertical-well fixed-point multistage fracturing method and application

ActiveCN106761642ARealize vertical effective useIncrease productionFluid removalWell cementingEngineering

The invention provides a vertical-well fixed-point multistage fracturing method. The method includes the following steps: according to a plurality of fracturing segments divided from the reservoir stratum, when a casing is setting into a casing seat, performing well cementing and completion; putting a gauge cutter to the artificial well bottom; setting an elastic ring releasing tool and a perforation combined operation tool string to the position of the casing seat at the lowest end through a cable; energizing the cable to enable gunpowder in the elastic ring releasing tool to burn, and pushing an elastic ring out of the releasing tool to be seated on the casing seat; lifting the tool string through the cable to the perforation position for perforation, and pulling out the tool string; throwing in a soluble ball which is seated on an elastic ring to plug the lower layer, and performing fracturing through a polished casing to complete fracturing of this layer; repeating the above operation, and completing operation of multiple intervals from bottom to top in sequence till well completion. Polished casing injected fracturing is adopted, construction displacement is large, and technical requirements for volume fracturing are met; the bottom layer is plugged by the aid of the soluble ball, the soluble ball is dissolved after fracturing without drilling, the problem of drilling plug of the conventional bridge-plug separate-layer fracturing process is solved, construction is safe, and cost is low.

Owner:PETROCHINA CO LTD

Drive-by-wire sliding sleeve fracturing technology

InactiveCN113931609ALarge diameterImprove construction capacityConstructionsFluid removalHydraulic cylinderLine tubing

The invention relates to the field of oil and gas well exploitation, and provides a drive-by-wire sliding sleeve fracturing technology. After a pipe column is tripped in, a control system sends an instruction to the last stage of drive-by-wire sliding sleeve, a hydraulic oil way is communicated, a pipeline pressurizes the drive-by-wire sliding sleeve, a fracturing nozzle is opened, and fracturing construction is carried out; after fracturing construction is achieved, the pipeline pressurizes the drive-by-wire sliding sleeve again, the fracturing nozzle is closed, the control system sends the instruction to the last stage of drive-by-wire sliding sleeve, and the hydraulic oil way is closed; the steps are repeated, the other layer sections are fractured, and after all the steps are completed, the drive-by-wire sliding sleeves of all the layer sections are opened for production; and the structure is reliable, two pipeline hydraulic switches are adopted, and the switch thrust is large. According to the drive-by-wire sliding sleeve fracturing technology, mechanical metal sealing and hydraulic cylinder compensation sealing are adopted, and the sealing pressure is high; a double-hydraulic-cylinder structure is adopted, so that the tripping-in depth is not influenced; the flow area of the fracturing nozzle is large, and impurity accumulation is avoided; an anti-scouring inner pipe is designed, and the service life is long; and long-time well bottom monitoring is achieved.

Owner:DONGYING FLUID SCI & TECH

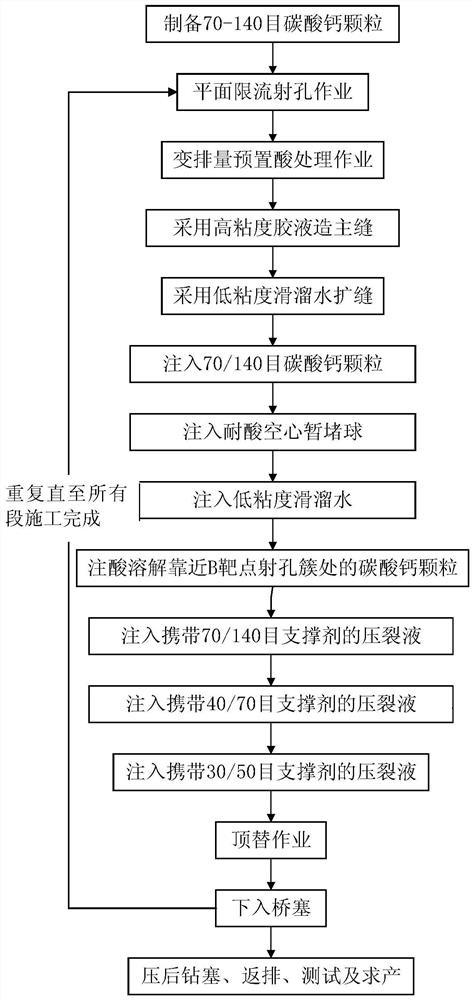

Horizontal well fracturing method for promoting fracture height extension through two times of acid injection and inter-cluster temporary plugging

ActiveCN112443305AUniform initiation and extensionExtend evenlyFluid removalDrilling compositionHorizontal wellsFracturing fluid

The invention discloses a horizontal well fracturing method for promoting fracture height extension through two times of acid injection and inter-cluster temporary plugging. The horizontal well fracturing method comprises the following steps that planar flow-limiting perforation operation is conducted; variable-displacement acid pretreatment operation is conducted; a main fracture is built by adopting a high-viscosity glue solution, and the fracture is expanded by adopting low-viscosity slickwater; fracturing fluid carrying calcium carbonate particles is injected; fracturing fluid carrying theacid-resistant hollow temporary plugging ball is injected; low-viscosity slickwater is injected; acid liquor is injected to dissolve the calcium carbonate particles; the fracturing fluid is continuously injected; displacement operation is conducted; a bridge plug is lowered; and the steps are repeated until all sections are constructed, and plug drilling, flowback, testing and production solvingafter fracturing are conducted. According to the horizontal well fracturing method, planar flow-limiting perforation, calcium carbonate particle temporary plugging and acid-resistant hollow temporaryplugging ball temporary plugging processes are adopted, the single-cluster displacement is increased, the extension length of fractures in the height direction is effectively increased, uniform fracture initiation and extension of multiple clusters of fractures are promoted, finally, the longitudinal use degree of a shale gas reservoir is finally increased, the reservoir transformation size is increased, and finally, the efficient development of the shale gas reservoir is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

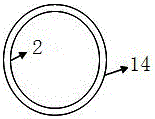

Packer applicable to environment of 120 DEG C and 70 MPa

The invention relates to a packer applicable to an environment of 120 DEG C and 70 MPa. The packer applicable to the environment of 120 DEG C and 70 MPa mainly solves the problem that existing packers are not applicable to high-temperature and high-pressure environments and is characterized in that the inner side of the lower portion of an upper joint (1) is connected with a pressure transmitting main body (4), and the inside of the pressure transmitting main body (4) is connected with a slide bushing (3); the inside of the slide bushing (3) is provided with a diameter-variable slide bushing (2), the side wall of the slide bushing (3) is provided with slide bushing sand outlet holes (14), and the side wall of the diameter-variable slide bushing (2) is provided with diameter-variable slide bushing sand outlet holes (14); the outside of the lower end of the pressure transmitting main body (4) is connected with an upper rubber barrel seat (5), the lower portion of the upper rubber barrel seat is connected with a rubber barrel (8), the lower portion of the rubber barrel (8) is connected with a lower rubber barrel seat (9), and the lower portion of the lower rubber barrel seat (9) is connected with a lower joint. The packer applicable to an environment of 120 DEG C and 70 MPa is applicable to underground high-temperature and high-pressure environments up to 120 DEG C and 70 MPa, high in sealing performance and reliable in packing.

Owner:DAQING FUWANTONG PETROLEUM SCI & TECH

Method for repeated acid fracturing of deep carbonate rock weighted foam acid

PendingCN113818858AImprove construction capacityIncrease the extension lengthFluid removalDrilling compositionCarbonate rockViscous fingering

The invention discloses a method for repeated acid fracturing of deep carbonate rock weighted foam acid and application. The method comprises the steps that an alternate injection mode of low-viscosity gel acid and weighted clean foam diverting acid is adopted, a viscous fingering effect is utilized, a non-uniform etching effect is generated in a main crack and a diverting crack, and the transformation size and flow conductivity of an acid etching crack are improved. According to the method, the filtration degree of an original crack can be effectively reduced, the extension length of the crack during repeated acid fracturing is increased, the crack is promoted to divert, and the transformation range of repeated acid fracturing is further expanded.

Owner:CHINA PETROLEUM & CHEM CORP +1

A 3D-printable copper slag electromagnetic wave-absorbing concrete and a method of using the same

The invention relates to 3D-printable copper slag electromagnetic wave-absorbing concrete and a use method thereof. The concrete includes, by weight, 6.8-7.2 parts of quick-hardening ordinary Portlandcement, 6.9-7.1 parts of quartz sand, 1.65-1.75 parts of copper slag, and 0.28-0.71 parts of copper powder composed of brass powder and red copper powder according to the weight ratio of 7:2.5-3.5, 0.75-0.85 parts of silica fume, 0.09-0.15 parts of a water reducer, 0.04-0.07 parts of basalt fiber being 11-14 mm in length, 0.003-0.005 parts of hydroxypropyl methyl cellulose being 20,000-70,000 inviscosity, and 1.70-1.74 parts of water. With the copper slag and copper powder as raw materials, the concrete has both the printability and electromagnetic wave-absorbing effect of the copper slag and copper powder, so that the concrete allows 3D printing and can achieve more than 90% in electromagnetic wave absorption in the bandwidth of 3.4 GHz.

Owner:HEBEI UNIV OF TECH

Horizontal drilling and coring of directional window cutting and matching methods

The invention relates to horizontal drilling and coring of directional window cutting and matching methods. The process comprises the steps: (1) drilling a horizontal hole using an ultra-short radius radial horizontal drilling tool guided by a whipstock; (2) plugging the position of a casing above the whipstock by using a packer; (3) injecting a fracturing fluid by using a fracturing string to form a major fracture in the stratum; (4) plugging the major fracture with a temporary plugging agent; and (5) improving the pressure of the fracturing liquid by 5-10 MPa, and injecting once more the fracturing liquid via the fracturing string to form a great quantity of secondary fractures around the major fracture in the stratum. According to the invention, ultra-short radius radial horizontal drilling and fracture network fracturing are combined so that the direction of a horizontal hole can be determined and a drilling diameter and a drilling length can be increased on the basis of the existing techniques; common fracturing is replaced by fracture network fracturing; thus, a new production-increasing and efficiency-raising technique is provided in the aspects of excavating potential remaining oil, improving low permeability reservoirs, etc., allowing tenfold increase or more in per-well production.

Owner:DAQING JINGTAI PETROLEUM ENG TECH

A cementing casing or tubing sliding sleeve with unlimited segments and clusters

ActiveCN105134131BIncrease productionImprove construction capacityFluid removalWell/borehole valve arrangementsFracture zoneHorizontal wells

The invention relates to a cementing casing or tubing sliding sleeve with unlimited sections and clusters, comprising an upper joint, a reducing sleeve, a sliding sleeve body and a lower joint, the upper joint is connected with the reducing sleeve, and the reducing sleeve is connected with the sliding sleeve. The main body is connected, the sliding sleeve body is connected with the lower joint, and the inner wall of the reducing tube is provided with grooves to form a reducing area on the inner wall of the reducing tube, and an elastic tube is installed on the reducing area; the middle part of the sliding sleeve body is evenly distributed along the circumferential direction with multiple fracturing port, the inner wall of the sliding sleeve body is provided with an expanding area, the expanding area is located below the fracturing port, the sliding sleeve body is covered with an inner sliding sleeve, and a C ring is installed at the lower end of the sliding sleeve body. , gas field vertical wells, horizontal wells with unlimited sections and infinite clusters between sections, and the full diameter of the wellbore before fracturing, no throttling of sliding sleeves and ball seats, large construction displacement, can greatly improve the fracturing effect, increase the unit Well production: after fracturing, the ball and C ring made of soluble materials are dissolved or drilled off, and the wellbore becomes full diameter again, which is convenient for later production and operation.

Owner:PETROCHINA CO LTD

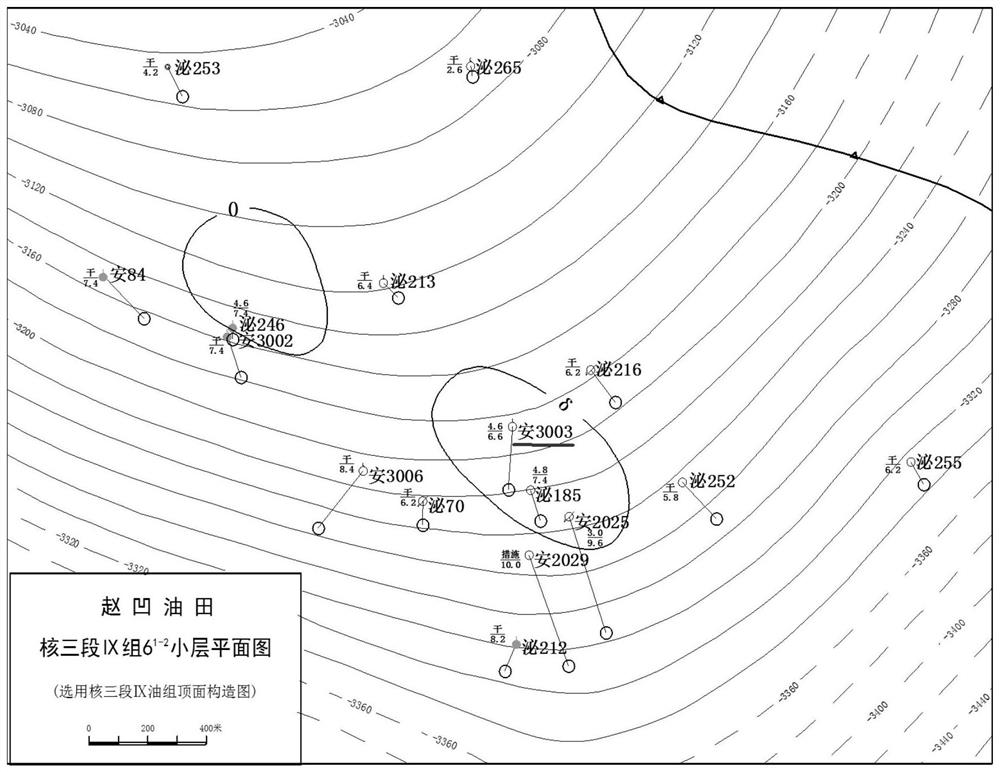

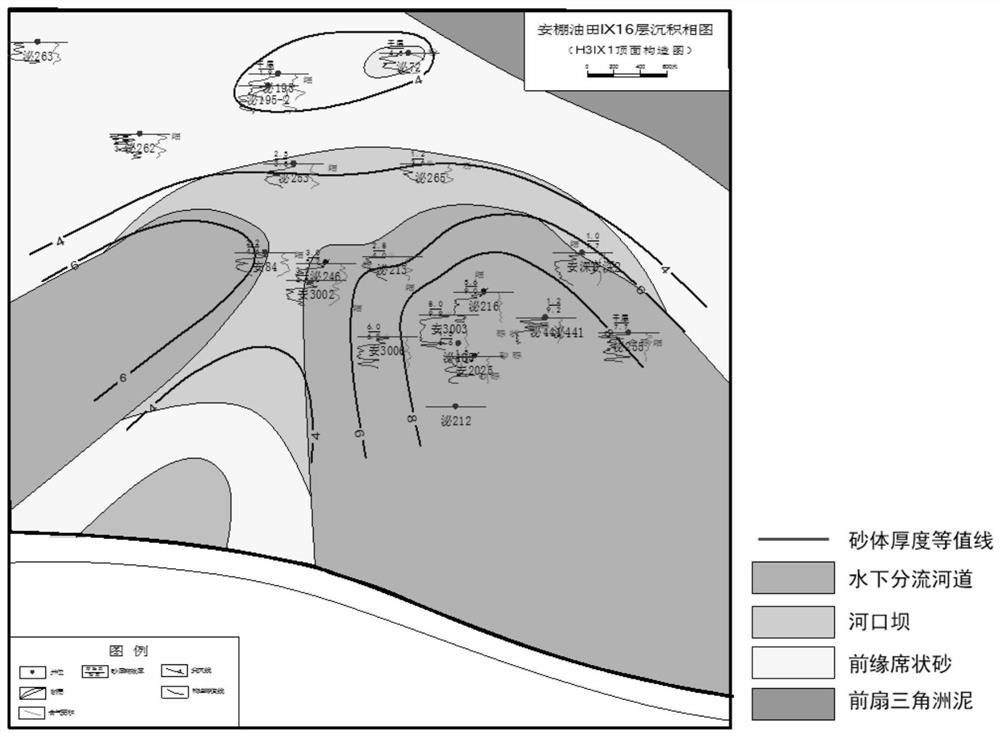

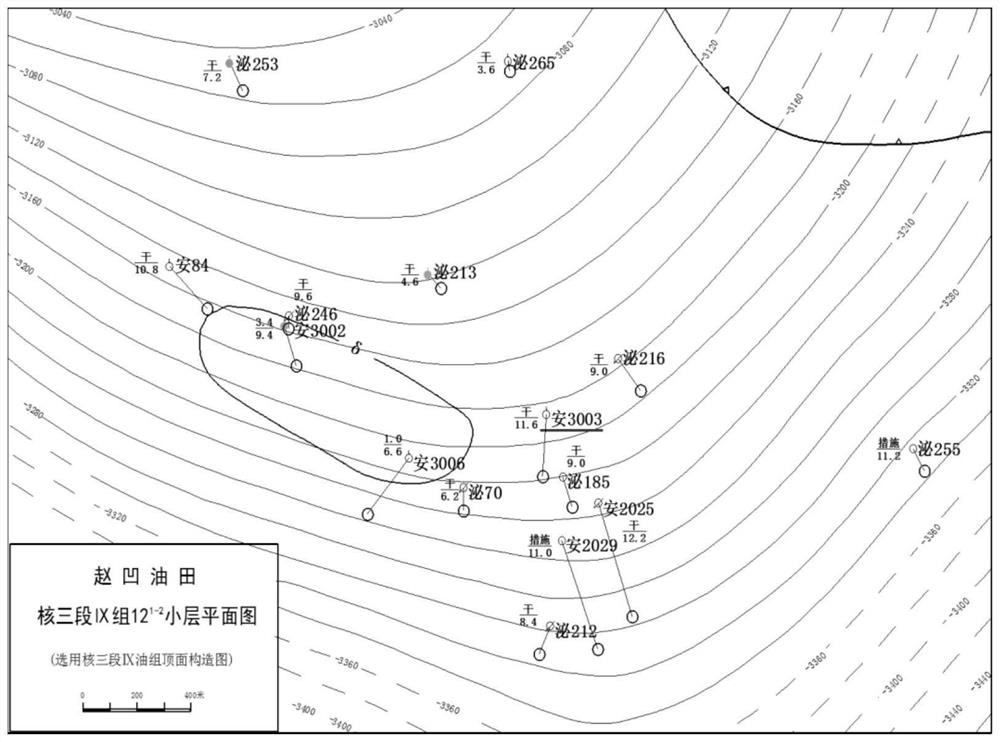

Multi-layer small sand body comprehensive fracturing method for sedimentary microfacies of underwater shunt channel

The invention belongs to the field of oil and gas reservoir exploitation, and particularly relates to a multi-layer small sand body comprehensive fracturing method for sedimentary microfacies of an underwater shunt channel. The method comprises the following steps: aiming at a small sand body tight gas reservoir of which the sedimentary microfacies is an underwater shunting river channel and the longitudinal target layers are more than two layers, according to the sand body positions of the target layers, performing first fracturing construction, changing the heterogeneous difference between the target layers, then performing fracturing construction for at least one time, and performing fracturing transformation on the target layers. The small sand body tight gas reservoir of the sedimentary microfacies of the underwater shunt channel has the characteristics of multiple layers, compact lithology and poor physical property, and the conventional fracturing is easy to cause that fracturing fluid only enters a loose stratum, so that a small sand body layer is under-transformed. According to the method, the heterogeneous difference between the target layers is changed through at least two times of fracturing transformation according to the positions of the sand bodies where the target layers are located, then the fracturing effect on all the target layers is improved, and the gas production degree of the oil reservoirs can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for plugging multi-stage fractures in horizontal wells combined with particles and gel

ActiveCN108204218BRealize the purpose of reengineeringRealize fixed-point segmental transformationSealing/packingHorizontal wellsPetroleum engineering

The invention discloses a method for plugging multiple sections of cracks in a horizontal well by combining particles and gel. The method comprises the steps that a horizontal well shaft is processed,the shaft is ensured to be unblocked, a plugging agent slug mixed by the chemical particles and gel liquid is subjected to pump injection through wellhead displacement, multiple times of pump injecting of the plugging agent slug is conducted, the working pressure is gradually increased to the casing limit pressure or the highest breaking pressure value of primary fracturing formation, and the well is closed to wait for solidification; and after the gel liquid is solidified, the particle plugging form is maintained, whole reverse pressure bearing of the plugging agent is achieved, the horizontal well shaft is subjected to secondary processing, the residual particles and the solidified gel in the horizontal well shaft are removed, and the shaft is ensured to be unblocked. The method for plugging the multiple sections of cracks in the horizontal well by combining the particles and the gel greatly improves the construction efficiency of repeated fracturing and the construction scale, andhas wide application prospects in the aspect of repeated fracturing of the low-yield horizontal wells with tight reservoirs.

Owner:PETROCHINA CO LTD

Composite acid fracturing method for improving flow conductivity of ultra-deep carbonate reservoir and application

The invention discloses a composite acid fracturing method for improving flow conductivity of an ultra-deep carbonate reservoir and application. The method comprises the steps that firstly, low-viscosity low-friction neutral slickwater is injected to form cracks, then low-viscosity low-friction strong-acid slickwater is injected to etch the formed cracks, the displacement is gradually increased, the neutral slickwater and the acid slickwater are injected in a circulating mode, after the corrosion range and the crack width of acid liquor are gradually enlarged, self-suspension propping agents with different particle sizes are added from small to large to support formed main crack and branch crack micro-crack systems, and finally displacement operation is conducted. According to the method, the construction displacement and the net pressure in the cracks can be effectively increased, the transformation range and the corrosion width of the acid liquor are enlarged, adding of the self-suspension propping agents is facilitated, the flow conductivity of the multiple types of acid etching cracks under the ultra-deep condition is improved, and the production stability and the long-term performance are kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

Large-diameter multi-layer fracturing string applicable to environment of 120 DEG C and 70 MPa

ActiveCN103742117AReduce throttling lossImprove construction capacityFluid removalAgricultural engineeringThrottle

The invention relates to a large-diameter multi-layer fracturing string applicable to an environment of 120 DEG C and 70 MPa. The large-diameter multi-layer fracturing string applicable to the environment of 120 DEG C and 70 MPa mainly solves the problems of obvious throttle effects and high friction resistance of existing multi-layer fracturing strings and is characterized in that the bottom of a safe joint (1) is connected with a hydraulic anchor (2), the bottom of the hydraulic anchor (2) is connected with a plurality of packers (3), the upper portions of the packers (3) are connected with a sand blaster. The large-diameter multi-layer fracturing string applicable to the environment of 120 DEG C and 70 MPa achieves a large channel and has the advantages of reducing throttle losses and friction resistance.

Owner:DAQING FUWANTONG PETROLEUM SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com