Drilling, grinding and pigging method and device for coiled tubing with screw drill and application

A kind of oil pipe and screw technology, which is applied to the drilling driving device, drilling equipment, drilling tools and other directions in the wellbore, can solve the problems of long mud completion time, easy blockage of drilling and grinding tools, mud cementation and sedimentation, etc., to enhance the carrying capacity , Eliminate the risk of damage to the casing, reduce the effect of liquid wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A coiled tubing belt screw drilling method for drilling and grinding wells, the method comprising:

[0027] Circulate the guar base fluid in the well when drilling and grinding the well.

[0028] In the above-mentioned embodiments, the guar gum base fluid is generally used in the oilfield fracturing technology, and the guar gum base fluid is used to increase the viscosity. The friction resistance of the liquid improves the construction displacement and enhances the carrying capacity, and finally the mud in the well is effectively washed out, which can be successfully passed to the bottom of the artificial well, providing a qualified wellbore environment for later construction, and also eliminating the risk of damage to the casing. At the same time of normal construction operation, it can quickly and satisfactorily relieve the wellbore complexity caused by the cementation and sedimentation of drilling mud, improve the production timeliness, and create a new mode for the ...

Embodiment 2

[0030] Further, another embodiment of the drilling and milling method of a kind of coiled tubing band screw drilling method of the present invention, before the guar gum base fluid is circulated in the well when drilling and milling the well, it also includes:

[0031] Prepare guar gum base solution according to the concentration of 0.2%-0.25%.

[0032] In the above-mentioned embodiment, in the use of guar gum base fluid, the concentration is controlled between 0.2%-0.25%, which is compatible with the purpose of increasing the construction displacement, enhancing the carrying capacity and effectively washing out the mud in the well, while considering To the force of liquid viscosity, this concentration has the least influence on various operations in normal construction.

Embodiment 3

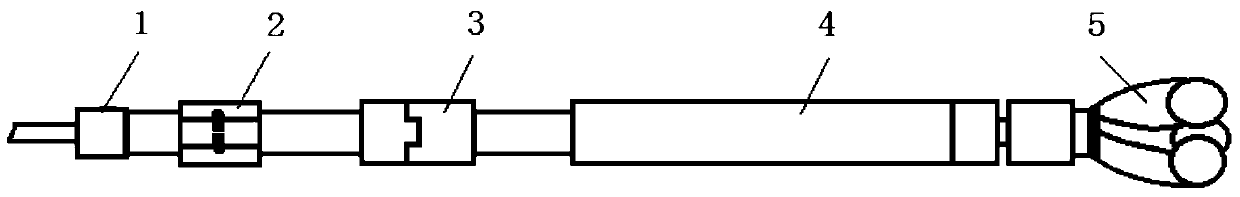

[0034] Further, another embodiment of the drilling and milling method of coiled tubing with screw drilling in the present invention uses a coiled tubing with screw drilling and milling string whose end is a tricone bit to conduct well drilling in the well;

[0035] Through the well to the bottom of the artificial well.

[0036] In the above-mentioned embodiment, the end of the coiled tubing with screw drilling and milling string in the existing construction adopts the flat-bottomed grinding shoe drill tool, because the mud completion time is long, the mud is cemented and precipitated, and the flat-bottomed grinding shoe is easy to block in the mud , resulting in extremely low drilling and grinding efficiency. The end of the coiled tubing with screw drill drilling and grinding string is used with a three-cone bit, which can not only ensure that the bit has very good adaptability in the cemented and sedimented mud, but also It can effectively guarantee the smooth flow of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com