Patents

Literature

49results about How to "Improve production timeliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

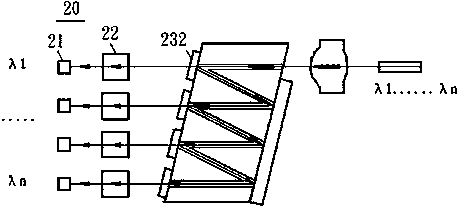

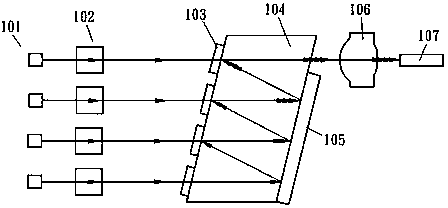

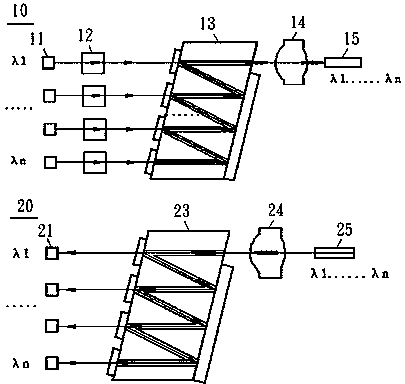

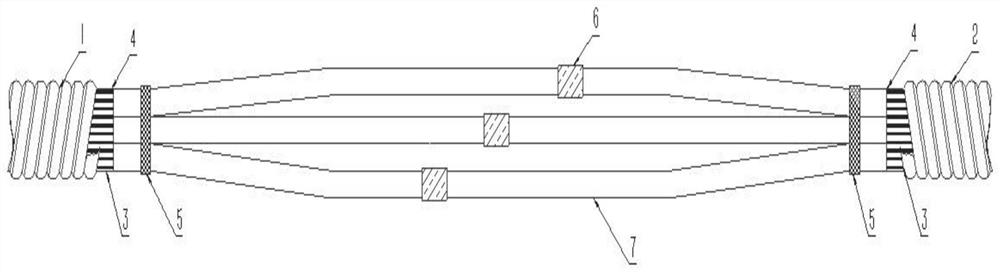

Multichannel integrated optical wavelength division multiplexing/demultiplexing component structure

InactiveCN104020527AImprove production timelinessLow costWavelength-division multiplex systemsCoupling light guidesBandpass filteringMultiplexing

Owner:WUHAN TELECOMM DEVICES

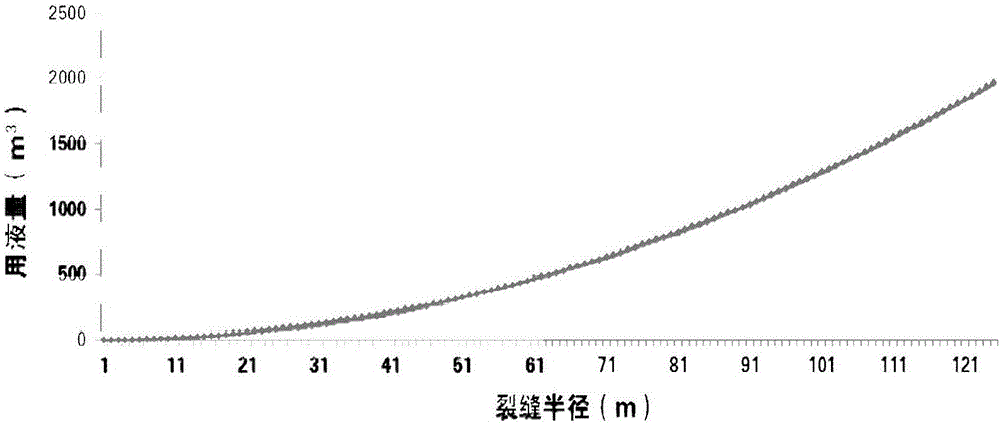

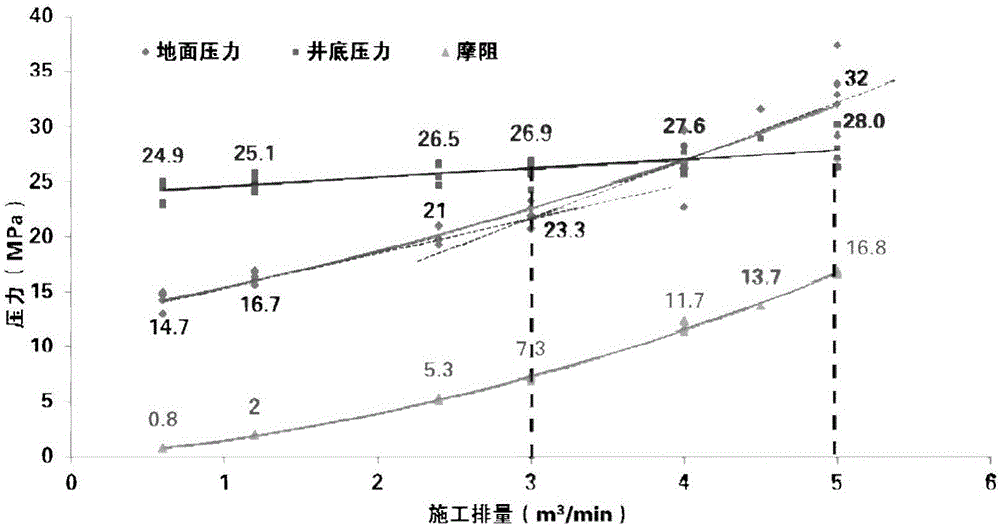

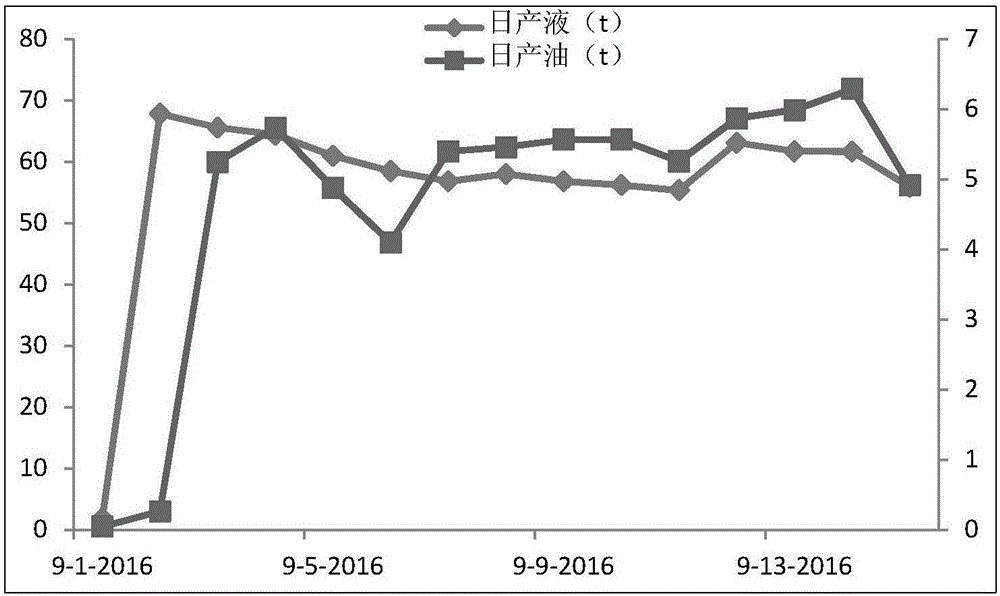

Method for injecting oil displacing agent into oil reservoir to improving oil recovery by using fracturing

ActiveCN106837274AReduce penetrationLess corrosiveFluid removalDrilling compositionViscosityPetroleum engineering

The invention relates to a method for injecting oil displacing agent into an oil reservoir to improve oil recovery by using fracturing. The method for injecting the oil displacing agent into the oil reservoir to improving oil recovery by using fracturing mainly solves the problems of large viscosity loss and low injection efficiency during the injection process of the existing three kinds of oil reservoir oil displacement agents. The method for injecting the oil displacing agent into oil reservoir to improving oil recovery by using fracturing is characterized in that (1) dividing a target stratum to the well fracturing section; (2) determining a half fracture length for the well fracturing section of the target stratum; (3) determining the oil displacement agent dosage for the well fracturing section of the target stratum; (4) determining a construction displacement the well fracturing section; (5) determining construction procedure of a pumping injection; and (6) mixing and injecting the oil displacement agent. The method for injecting the oil displacing agent into oil reservoir to improving oil recovery by using fracturing can greatly improve the injection efficiency and reduce the displacement efficiency loss, thus greatly improve the recovery efficiency and single well production.

Owner:PETROCHINA CO LTD +1

Modified Leituoshi stone for drilling liquor and its production mehtod

The present invention uses calcium base leituoshi stone ore as raw material, and adopts semi-dry artificial modification process including the steps: breaking clay mineral, adding 1%-5% sodium salt, uniformly mixing them, water-spraying, shearing, pressing, piling and ageing for 7-10 days, drying so as to obtain modified leituoshi stone. Said invention is simple in production method, convenient for operation, less in dosage of modifying agent and low in energy consumption and cost. The phi-600 reading value of drilling fluid prepared with modified leituoshi stone is greater than or equal to 60, mud-making rate is greater than or equal to 18 cu.m / t, filter loss is less than or equal to 13.5 ml and dynamic shear force is less than or equal to 1.2XPVPa. It is superior to sodium base bentonite in all the properties, and is applicable for drilling in the fields of petroleum industry, natural gas engineering, geologic drilling engineering and building engineering, etc.

Owner:湖北名流累托石科技股份有限公司

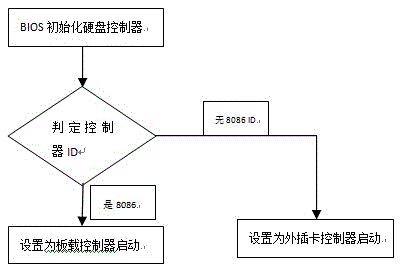

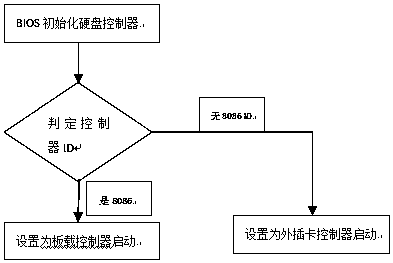

Method for automatically adjusting hard disk starting device according to different pieces of configuration information

ActiveCN105607911ARealize automatic adjustmentImprove usabilitySpecific program execution arrangementsDisk controllerUsability

The invention discloses a method for automatically adjusting a hard disk starting device according to different pieces of configuration information and relates to a hard disk starting technology. According to the difference of different hard disk configurations of a server, a hard disk controller is automatically recognized, and a hard disk starting priority is set, so that the server adjusts the hard disk starting device automatically. Firstly, the linking position of a hard disk in a system is automatically recognized by adopting the scheme of reading hard disk controller Vendor IDs; then, a BIOS selects and appoints different Boot hard disk options according to the different hard disk controller Vendor IDs. By means of the method, the server adjusts the hard disk starting device automatically, and the BIOS version consistency and customer usability are improved. Upgrading can be conducted in the server in a BIOS upgrading mode; when an upgraded server product supports different configurations on line, production manpower is emancipated, and production timeliness is improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

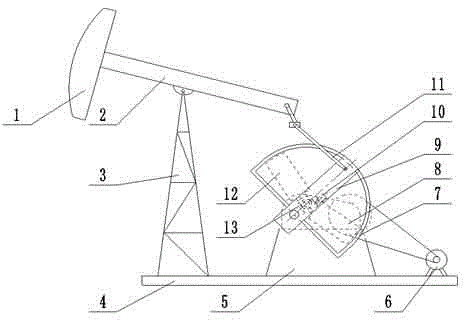

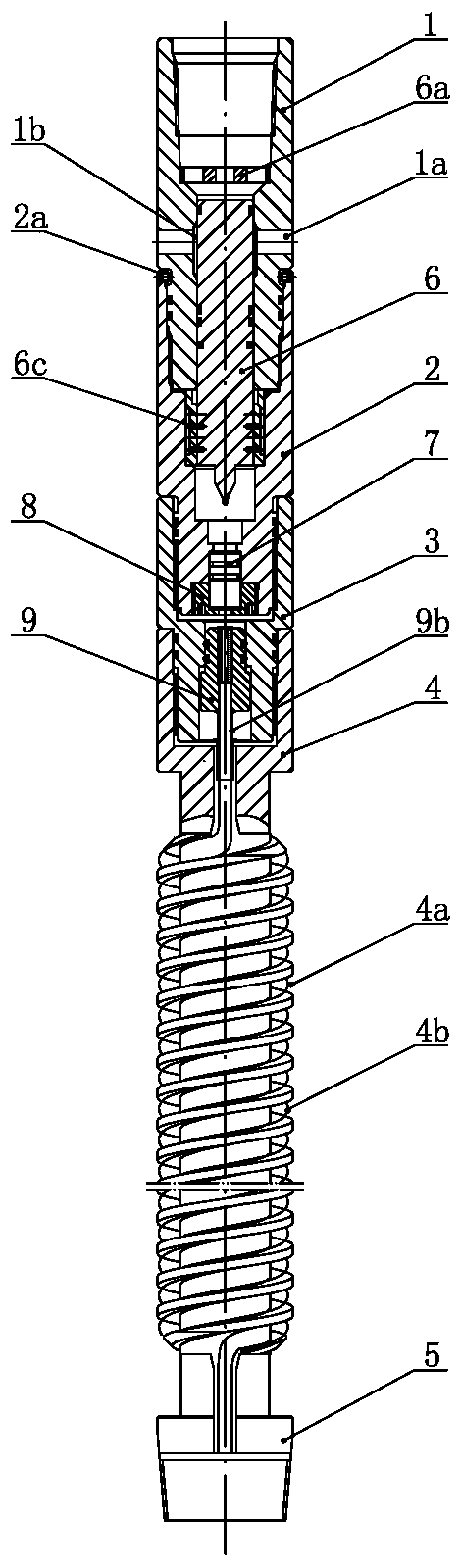

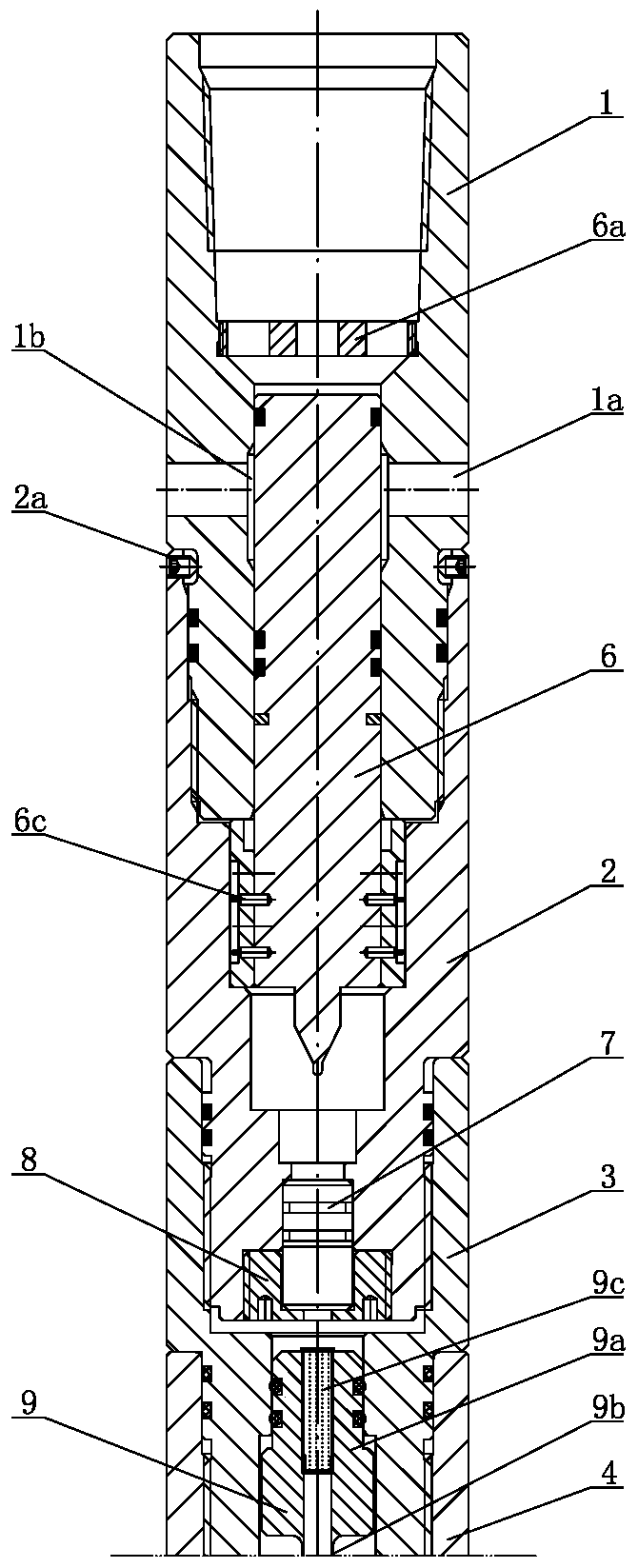

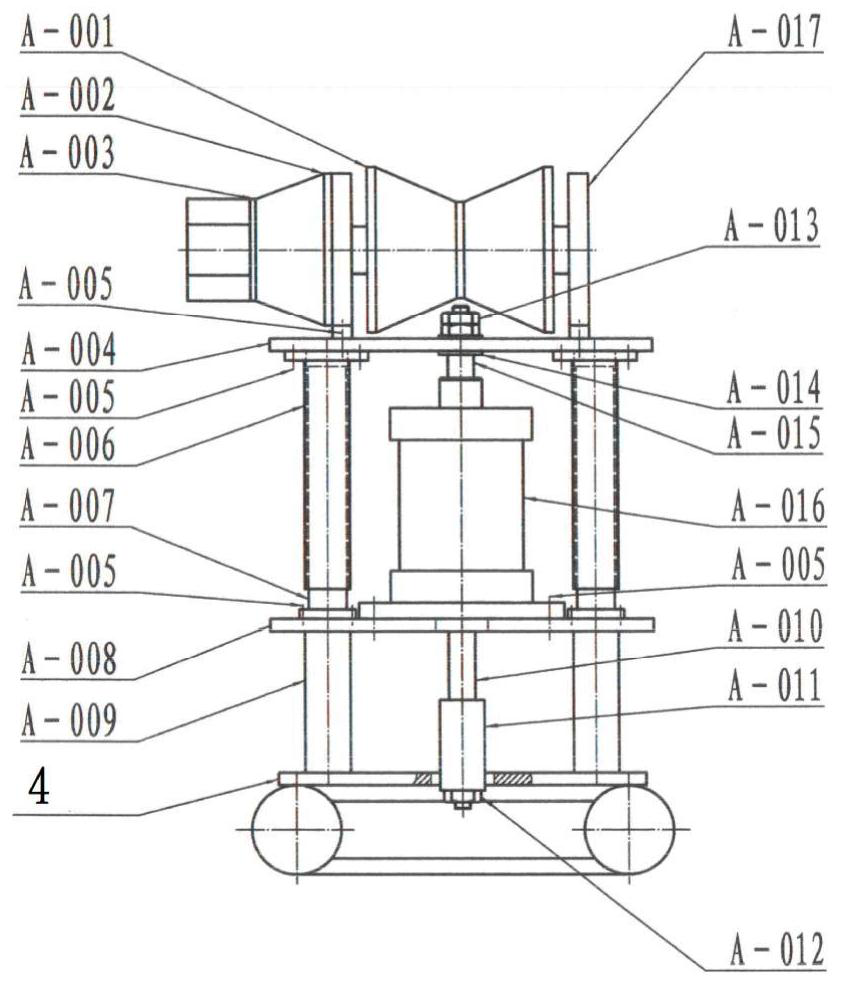

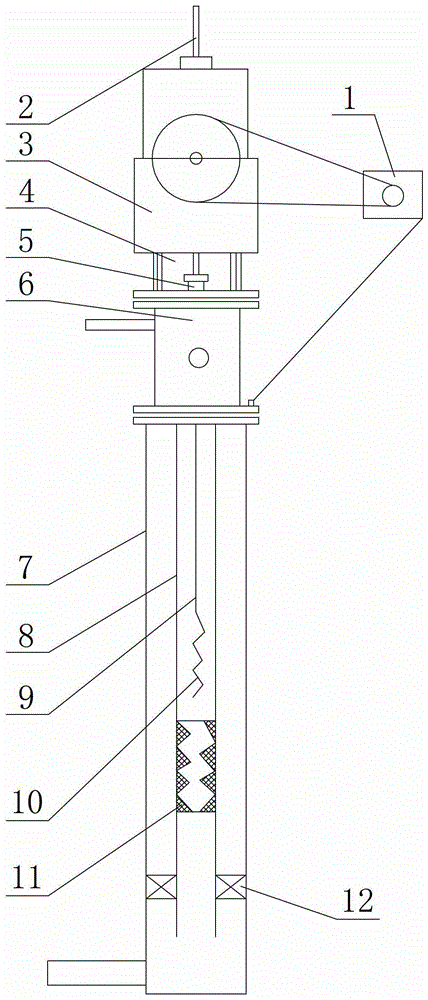

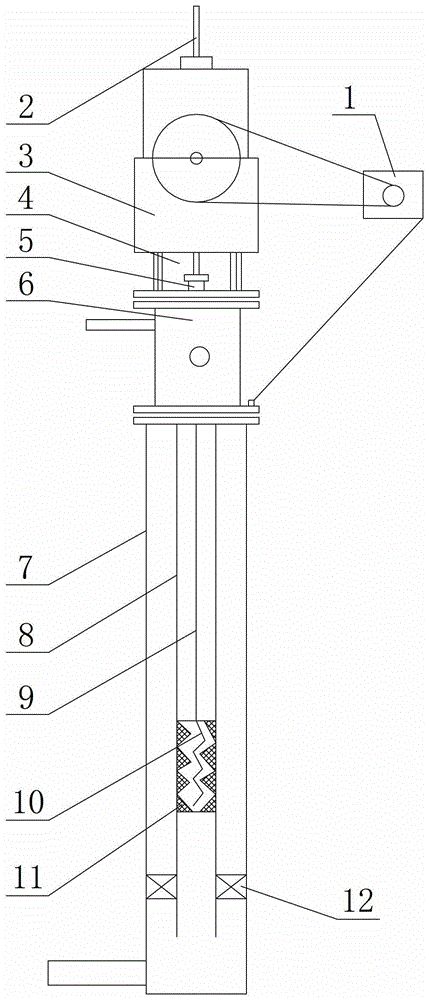

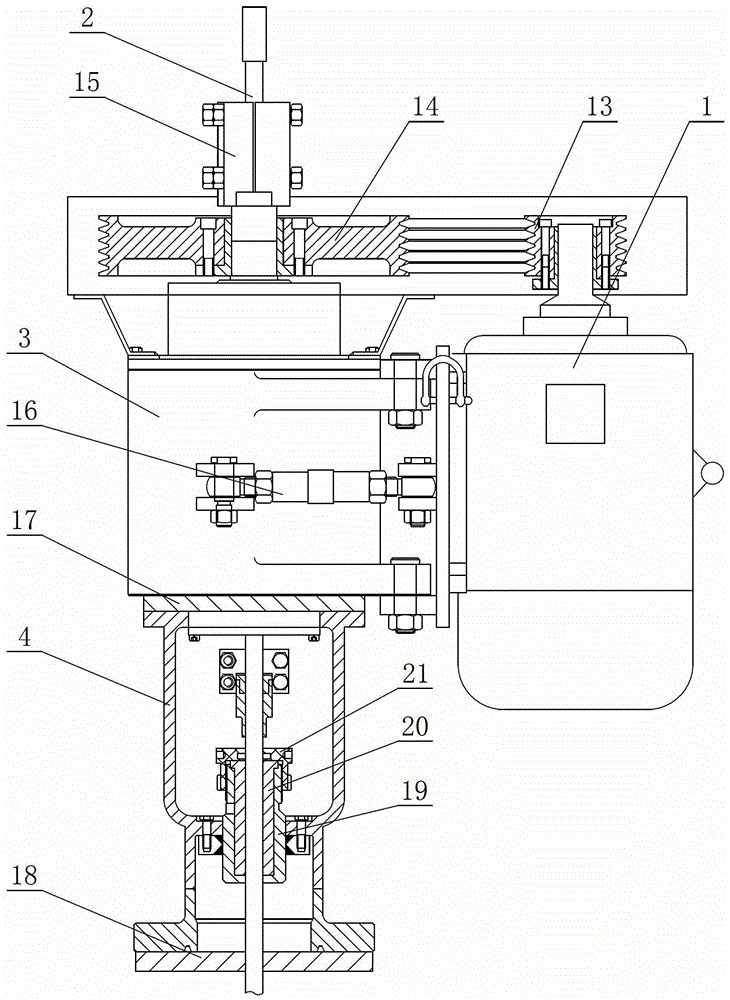

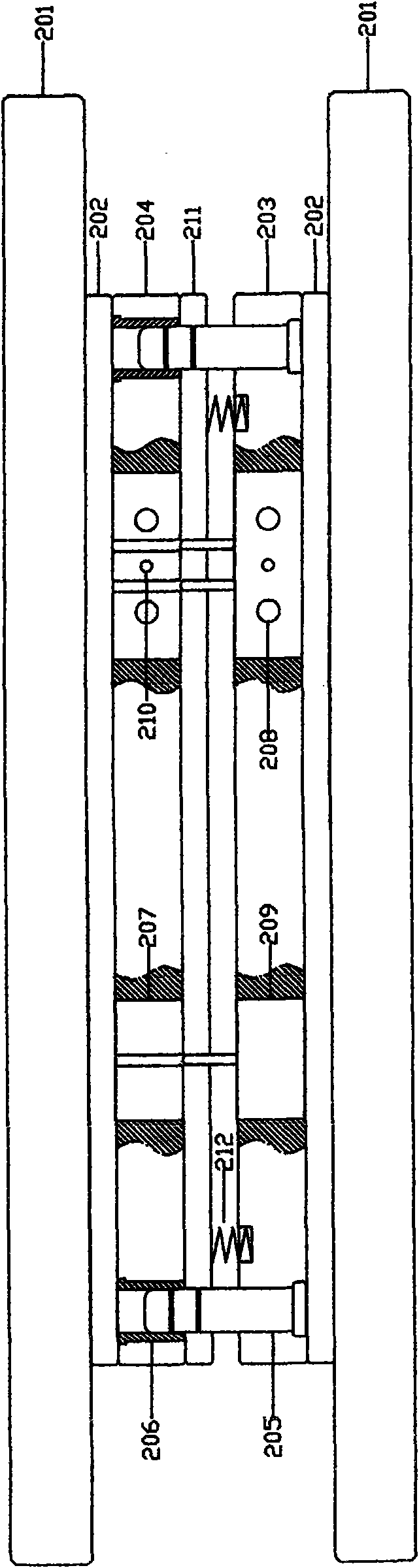

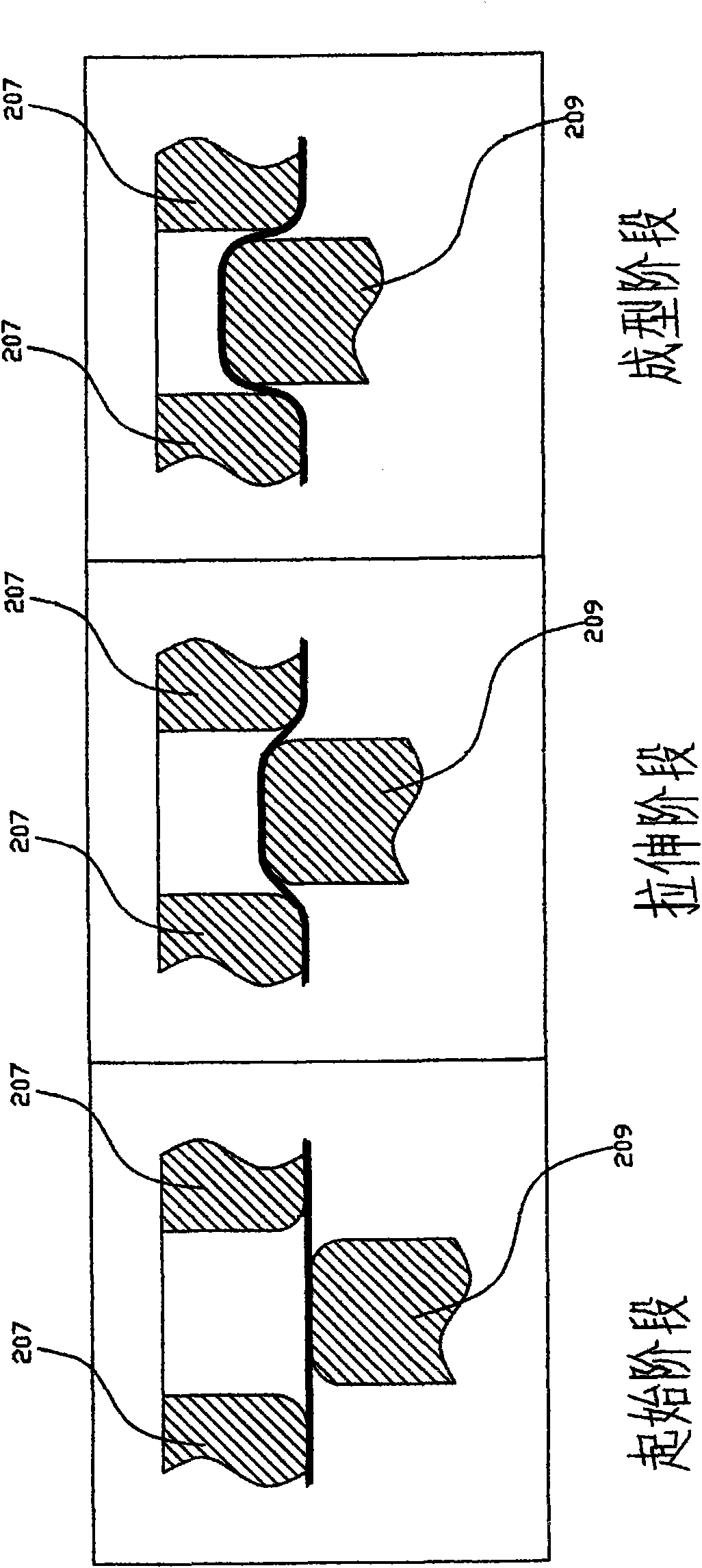

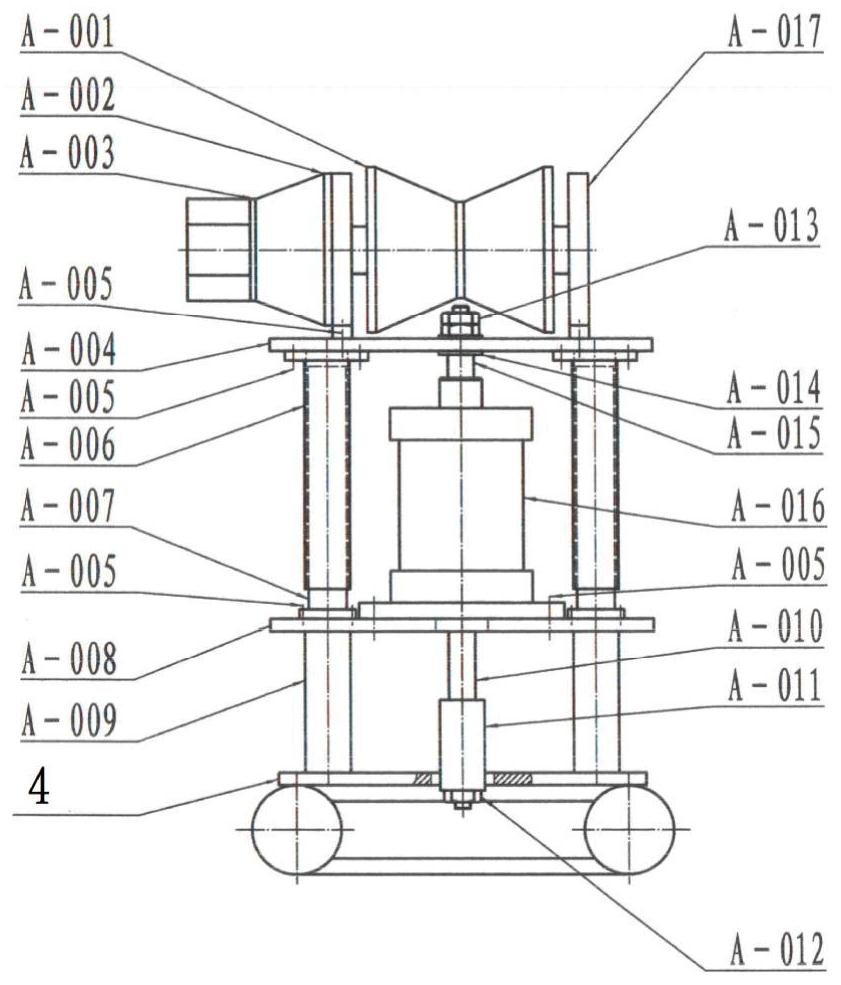

Automatic balance-adjusting beam-pumping unit and method

ActiveCN106150441AImprove production timelinessReduce manual labor intensityFluid removalEngineeringStart up

The invention discloses an automatic balance-adjusting beam-pumping unit and an automatic balance-adjusting method. An automatic balance-adjusting device is arranged on a crank of a pumping unit; the automatic balance-adjusting device comprises a fixed balance block, a left movable balance block, a right movable balance block, a balance motor and a right-angle speed reducer, wherein the fixed balance block is connected with the crank through a bolt, and the fixed balance block can slide on the crank in the length direction of the crank; the right-angle speed reducer is connected with the balance motor, and the right-angle speed reducer is mounted on the fixed balance block; output shafts are arranged on the two side surfaces of the right-angle speed reducer, and have opposite rotating directions; the left movable balance block and the right movable balance block are mounted on the output shafts on the two side surfaces of the right-angle speed reducer respectively. The balance motor is started up, the balance motor transmits power to the right-angle speed reducer, the right-angle speed reducer drives the left movable balance block and the right movable balance block to rotate, and the balance of the beam-pumping unit is adjusted by changing the gravity center positions of the left movable balance block and the right movable balance block.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pollution-free well workover process for oil field

InactiveCN102312659ANo pollution in the processReduce pollutionFlexible member pumpsFlushingParticulatesOil field

The invention relates to a pollution-free well workover process for an oil field, which is suitable for negative-pressure well workover operation in an oil-water gas well of the oil field. At present, in the well workover operation process of the oil field, a ground pump is usually used for pumping fluids, such as clear water, and the like into the well from the mouth of the well, solid particulate matters, such as scales, sands, scrap iron and the like are taken out from the bottom of the well by adopting positive cycle or reverse cycle flushing to achieve the purposes of washing the shaft, removing sand burying and refloating downhole junks; however, in the mid-later period of waterflooding extraction of the oil field, the interlayer conflict is increased, and stratum absorption wells are increased to cause the pollution to the stratum. The invention aims at providing a well workover process which has the advantages that ground pump cycle is not needed in the operation field, no stratum pollution exists in the well workover process, the construction cost is saved, the production ageing is improved, and the pollution to the environment during working is reduced.

Owner:崔朝轩

Preprocessing technology for processing integral key shaft

InactiveCN1598003AImprove processing qualityImprove uniformityFurnace typesIncreasing energy efficiencyProcess qualityGranularity

The invention realtes to a preprocessing technology for processing integral key shaft, accomplished by the following steps: induction annealing area of integral key shaft using electromagnetic induction to be heated to above A[C3] over 50-80 degree for incubation of 1-2 hours, namely slowly cooling to 300 degree in asbestos drum and then air colling to narmal temperature. The surface hardness can be greatly decreased by surface induction annealing treatment, at the same time the uniformity of hardness is increased and the grain can be refined (grain size 8), and the uniformity of structure can be advanced, therefore the processability of integral key shaft can be greatly improved, the process quality thereof can be advanced, the tool life is increased by more than 5 times, the processing cost is saved, and the production effciency and economy benefit can also be obviously generated. Compared with modulator procedure, the said technology saves proscessing cost and greatly increases production timeefficiency.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT

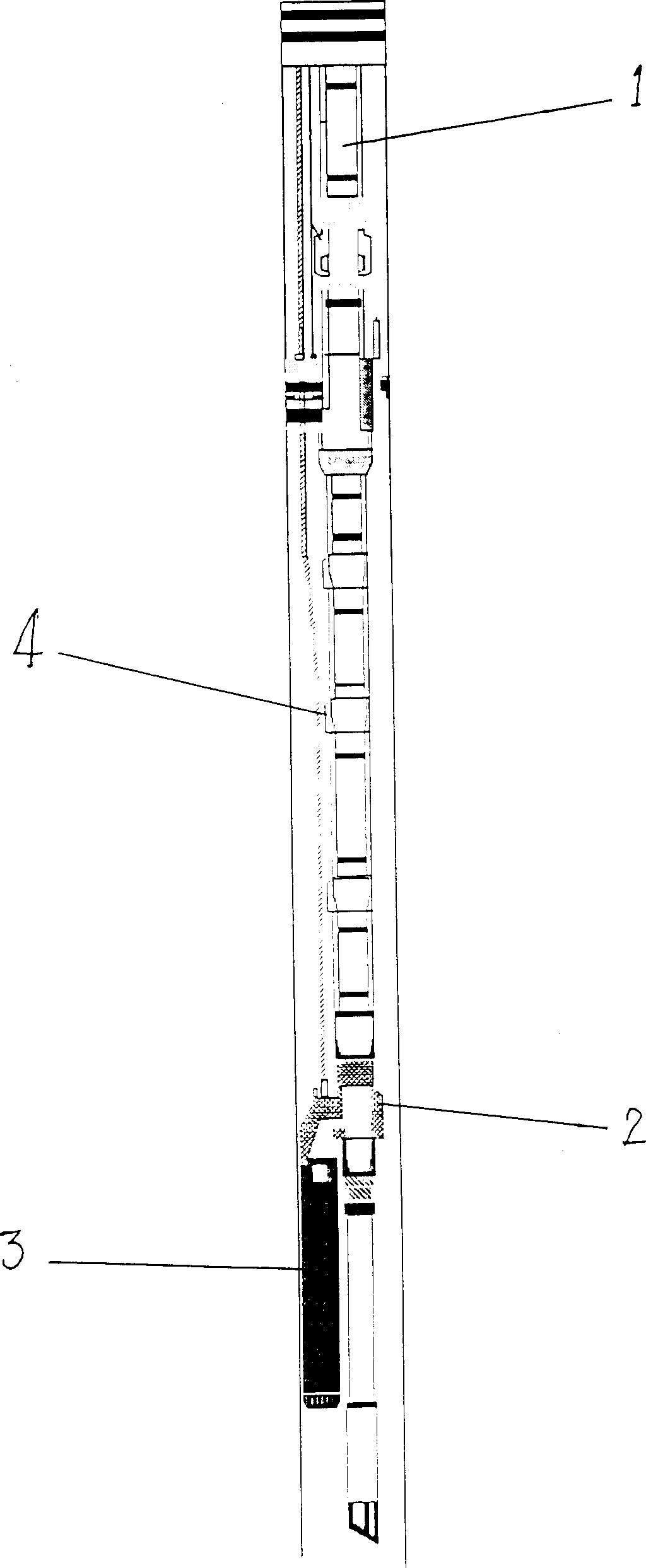

Oil-submersible electric pump-gas lift oil extraction method and its equipment

InactiveCN1538035AAvoid and overcome technical flawsImprove production timelinessFluid removalElectricityIt equipment

An electric submerged pump-gas lifting method for recovering oil by oil well features that a gas lifting valve is installed to the oil pipe above the electric submerged pump and the oil pipe for said electric submerged pump has the Y-shaped structure. As a result, the gas lifting method and the electric submerged pump method can be used simultaneously or individually for recovering petroleum.

Owner:上海石油天然气有限公司

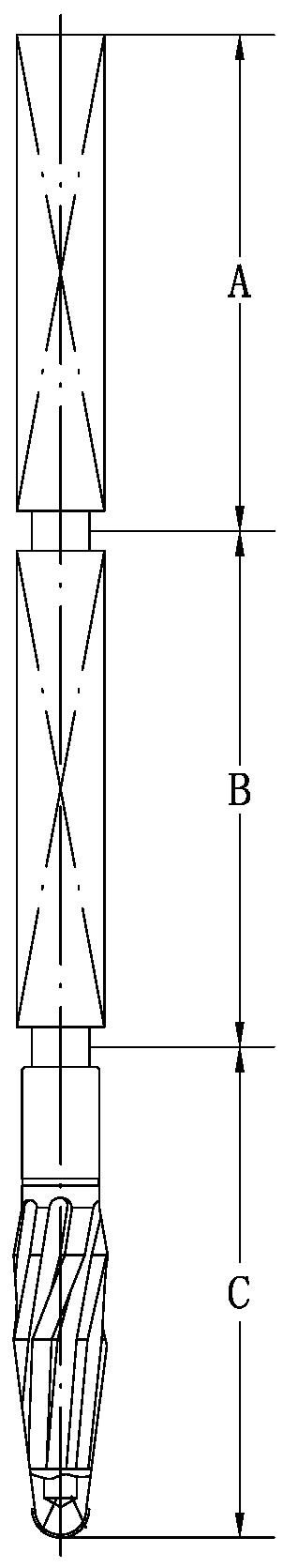

Method for reaming by explosion of detonating cord under well

ActiveCN108843244APlay a guiding roleLow costBlastingDrilling machines and methodsShock waveDetonation

The invention relates to a method for reaming by detonation of a detonating cord under a well. The method comprises the following steps: sequentially mounting a pilot reamer, an explosion reamer and avariable-diameter hole trimming device at the lowest end of a drill stem from bottom to top; enabling the drill stem to rotate and descend simultaneously, and when the drill stem descends until the explosion reamer is completely flush with the height of a predetermined reaming section, enabling the drill stem to stop descending and rotating; opening a mud pump and pressurizing same to the set detonation pressure to detonate the detonating cord of the explosion reamer, wherein shock waves generated by the explosion act on rocks of a well wall to cause stratum rocks on the entire periphery of this section to be crushed and fractured, thereby achieving reaming; opening the mud pump to the construction displacement and taking rock debris generated by the explosion reaming out of the well; enabling the drill stem to continuously descend, so that the variable-diameter hole trimming device reaches the reaming section to trim the well wall of the reaming section; and pulling the drill stem out of the well, putting a hole diameter logging unit into the well to detect the hole diameter and determining whether predetermined reaming requirements are met. By adopting the method, the reaming speed is high, risks under the well are low, the phenomena of repeatedly pulling a drill out of the well and putting the drill into the well is avoided and the well drilling efficiency is improved greatly.

Owner:中石化石油工程技术服务有限公司 +1

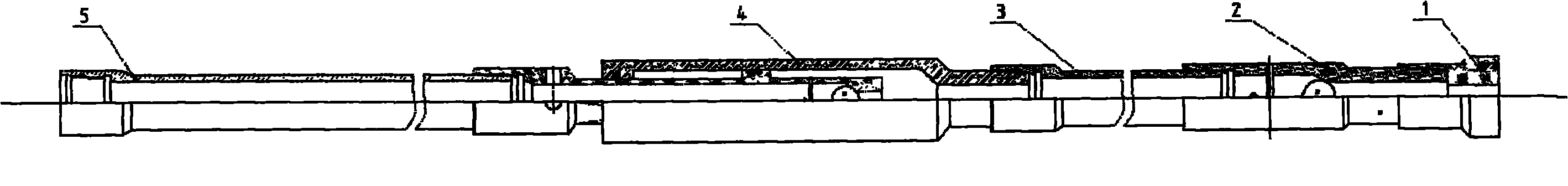

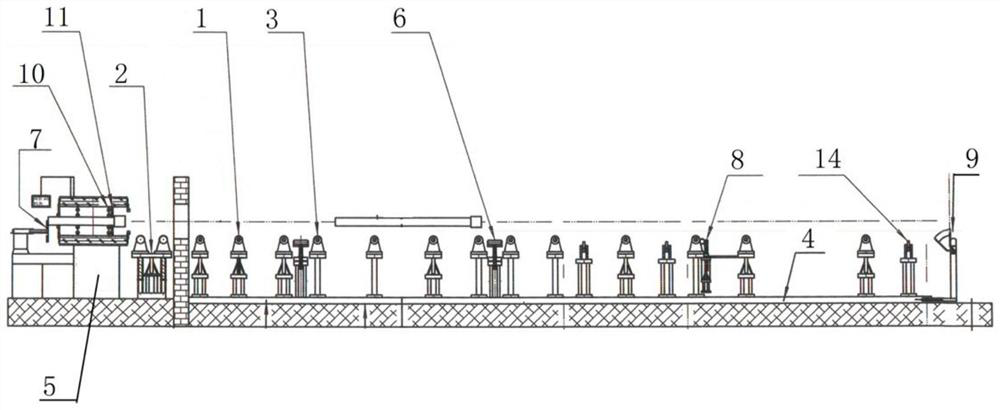

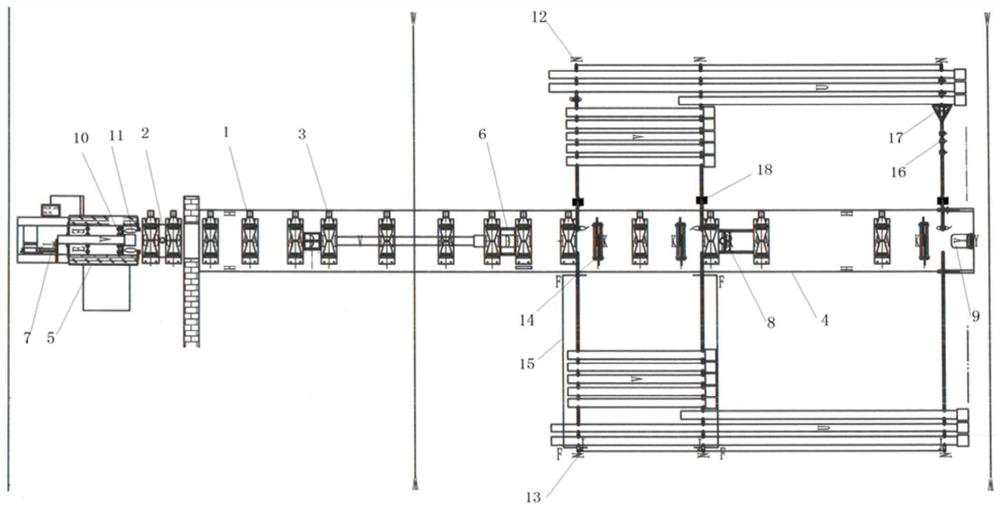

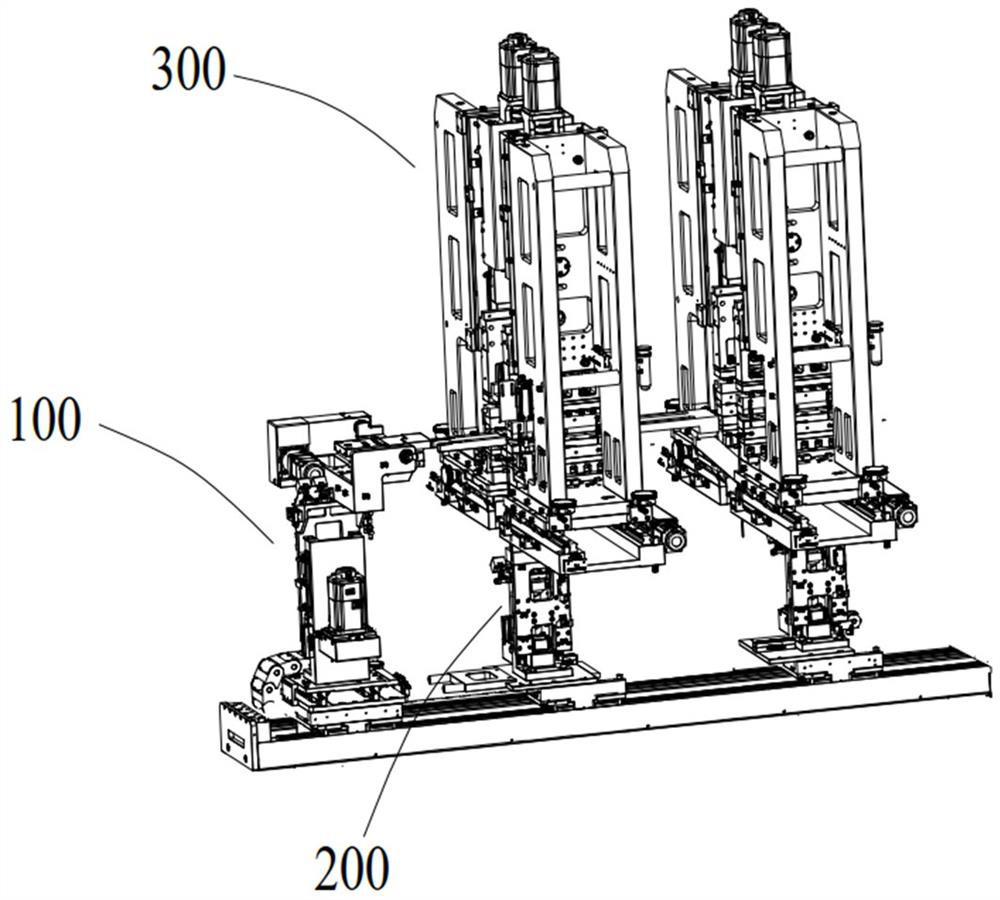

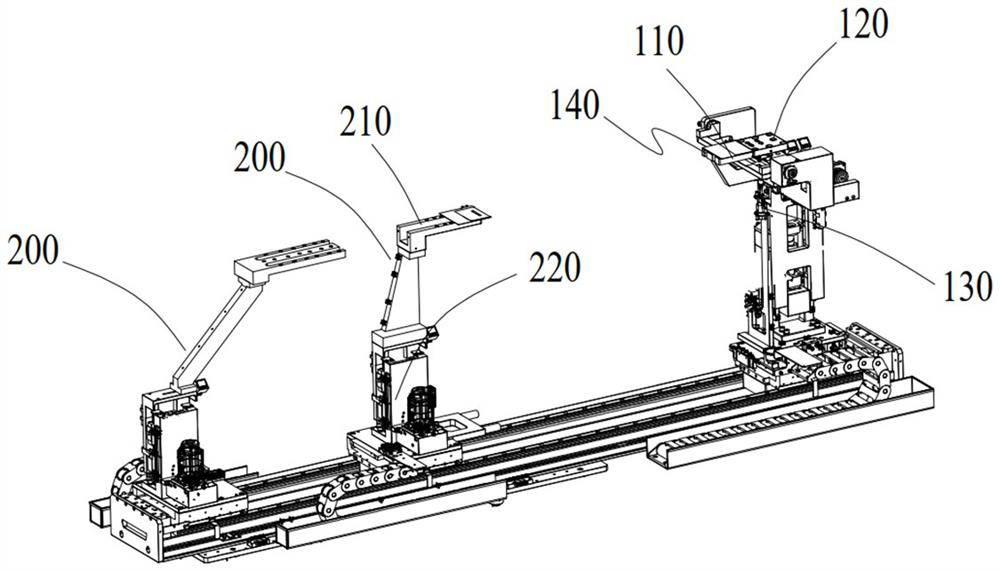

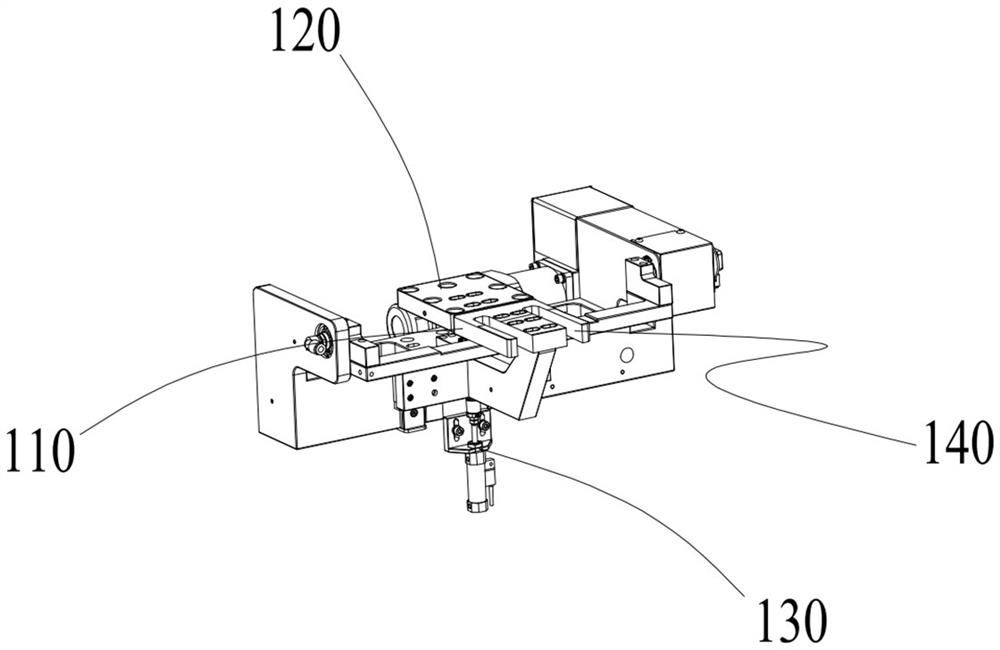

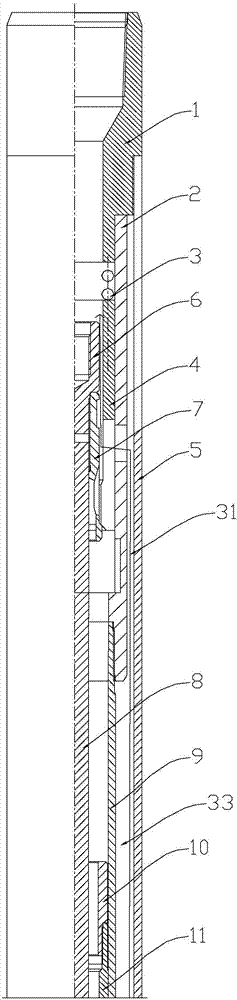

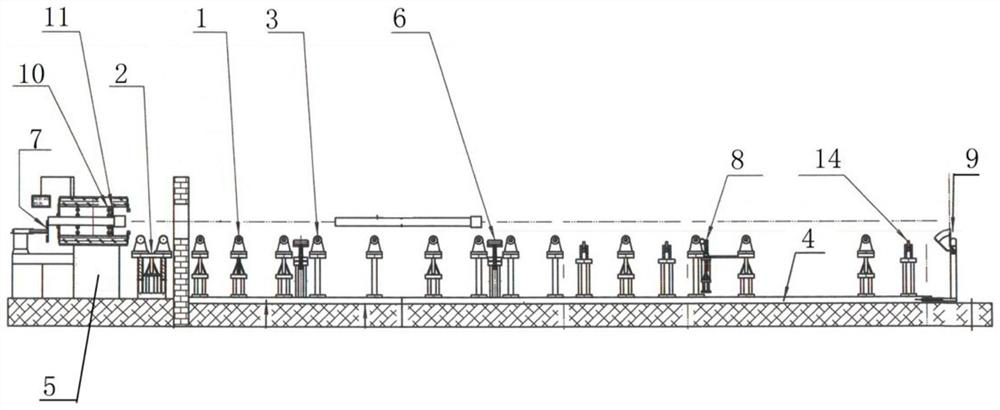

Workpiece conveying, positioning and clamping combined automatic line

ActiveCN112173657AScience of Design ConceptImprovement of design conceptConveyor partsEngineeringMechanical engineering

The invention discloses a workpiece conveying, positioning and clamping combined automatic line. The workpiece conveying, positioning and clamping combined automatic line comprises a lathe, a floatinglifting adjustment conveying roller wheel system, a workpiece rotary lifting righting wheel system, a workpiece conveying positioning clamping limiter, a workpiece duct righting clamping balancer anda workpiece storage rack; the floating lifting adjustment conveying roller wheel system is used for conveying workpieces with various diameters, the workpiece rotary lifting righting wheel system isused for adjusting the coaxiality of the conveyed workpieces, the workpiece conveying positioning clamping limiter is used for limiting the workpieces, the workpiece duct righting clamping balancer isused for guiding and clamping the workpieces, and the workpiece storage rack is used for storing the workpieces to be machined and the machined workpieces and transferring the workpieces. According to the workpiece conveying, positioning and clamping combined automatic line, mixed application and frequent alternate operation can be carried out on the various workpieces such as long and short bodies, an automatic line production environment is created, and the effects of efficient connection and conversion application are achieved.

Owner:CNPC BOHAI DRILLING ENG +1

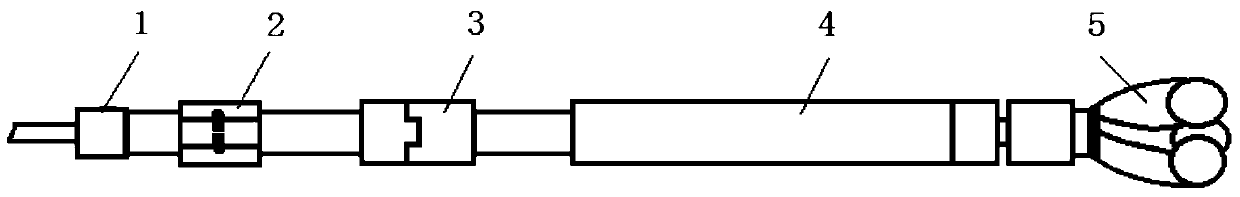

Drilling, grinding and pigging method and device for coiled tubing with screw drill and application

PendingCN111101897AReduce frictionEffective wash outEarth drilling toolsCleaning apparatusThermodynamicsHorizontal wells

The invention relates to a drilling, grinding and pigging method and device for a coiled tubing with a screw drill and application, belongs to the technical field of oil and gas field well repair andcompletion. The drilling, grinding and pigging method for the coiled tubing with the screw drill comprises the step of circulating guanidine gum base liquid in a well during drilling, grinding and pigging. The adopted guanidine gum base liquid reduces liquid friction resistance, improves construction displacement, strengthens carrying capacity, finally effectively washes out mud in a well, can besuccessfully led to an artificial well bottom, provides a qualified wellbore environment for later construction, eliminates the risk of damage to a casing pipe, can quickly and perfectly relieve complex wellbores caused by cementation and precipitation of drilling mud while not influencing normal construction operation, improves the production efficiency and creates a new mode for horizontal wellcoiled tubing well pigging and flushing operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preprocessing technology for processing integral key shaft

InactiveCN1313629CImprove processing qualityImprove uniformityIncreasing energy efficiencyFurnace typesProcess qualityGranularity

The invention realtes to a preprocessing technology for processing integral key shaft, accomplished by the following steps: induction annealing area of integral key shaft using electromagnetic induction to be heated to above A[C3] over 50-80 degree for incubation of 1-2 hours, namely slowly cooling to 300 degree in asbestos drum and then air colling to narmal temperature. The surface hardness can be greatly decreased by surface induction annealing treatment, at the same time the uniformity of hardness is increased and the grain can be refined (grain size 8), and the uniformity of structure can be advanced, therefore the processability of integral key shaft can be greatly improved, the process quality thereof can be advanced, the tool life is increased by more than 5 times, the processing cost is saved, and the production effciency and economy benefit can also be obviously generated. Compared with modulator procedure, the said technology saves proscessing cost and greatly increases production timeefficiency.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT

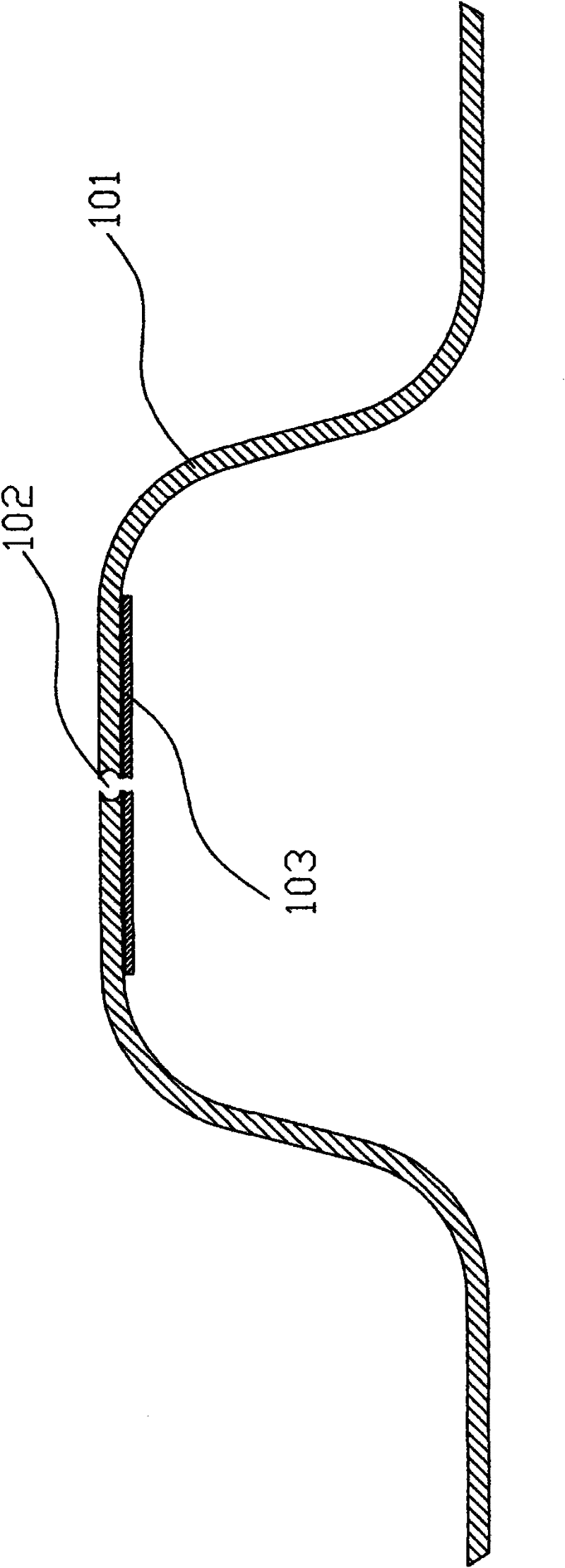

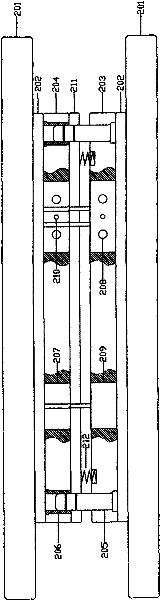

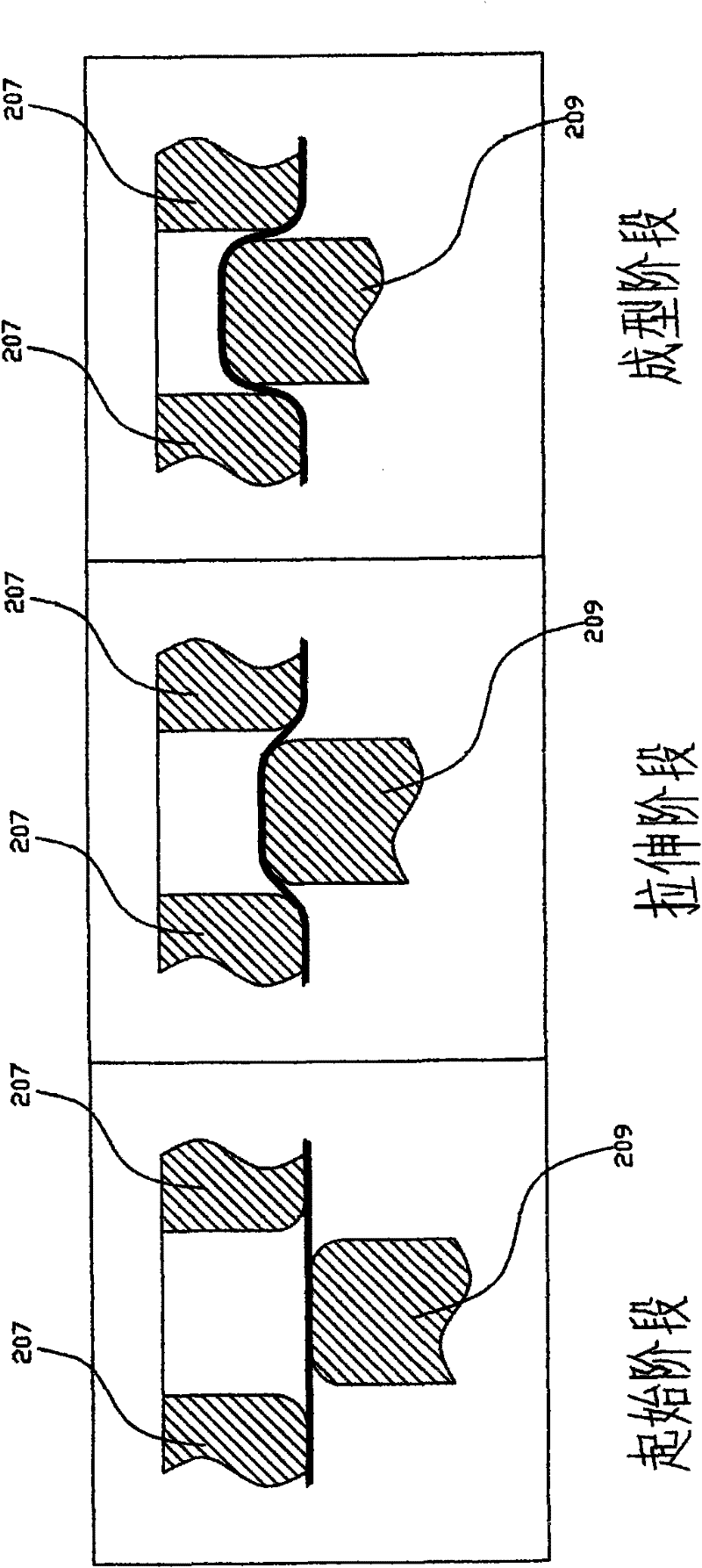

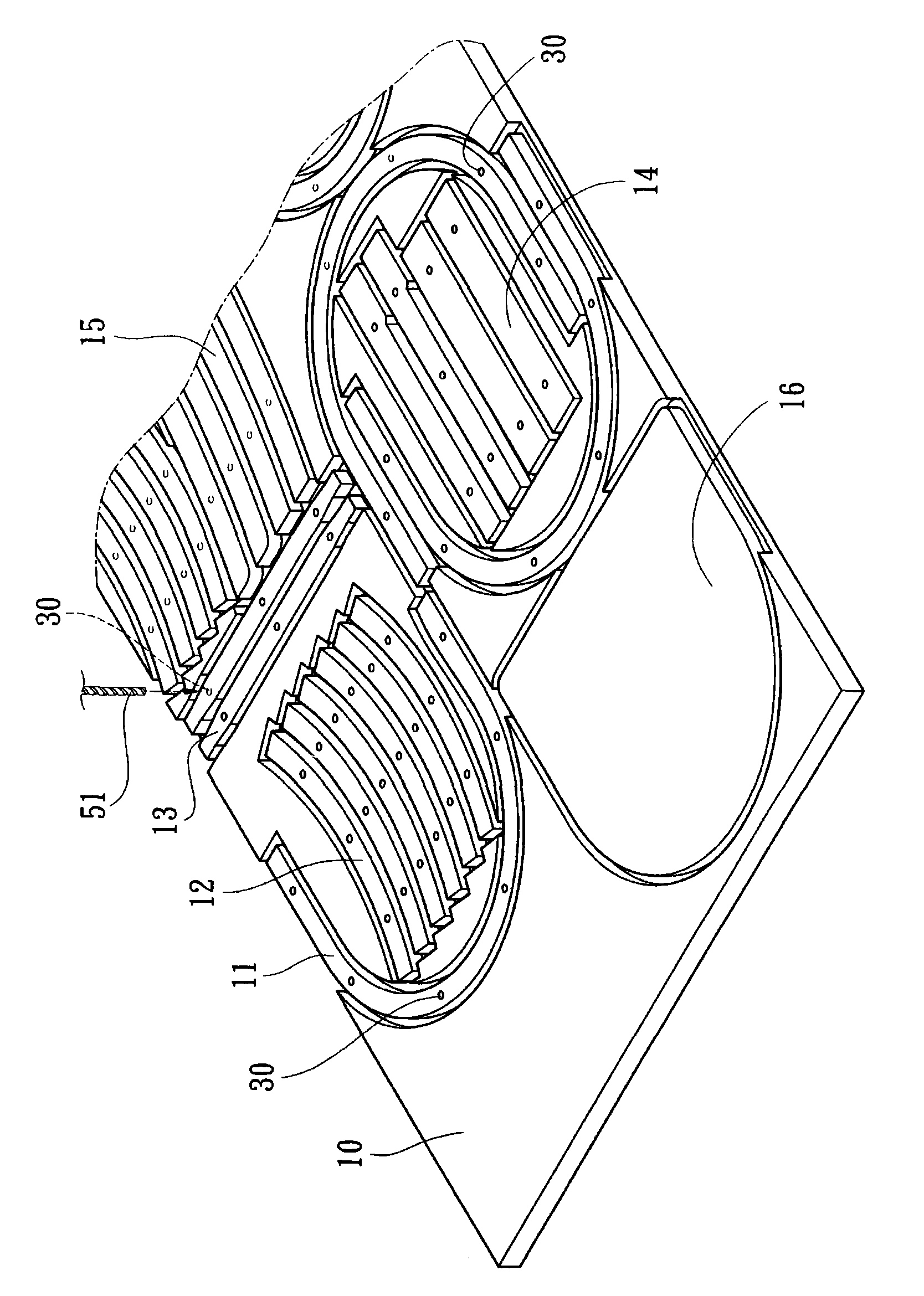

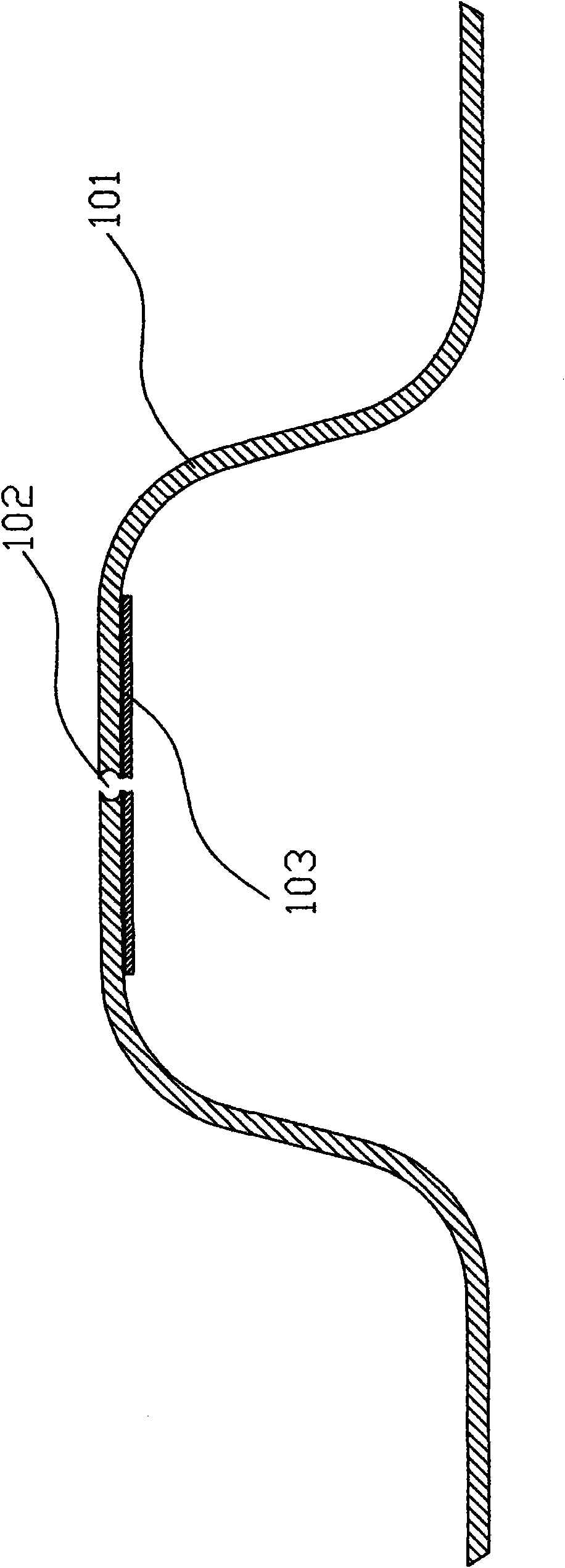

Film with bulge for computer keyboard or flexible printed circuit and bulge forming process thereof

InactiveCN102412080ABeautify the lighting effectSave the sticking processElectric switchesKey pressingPunching

The invention relates to the technical field of production of input equipment, in particular to a film with a bulge for a computer keyboard or a flexible printed circuit and a bulge forming process thereof. A light transmission hole is arranged at the top part of the bulge; and light shading film materials are attached on the upper surface or the lower surface of the bulge per se. The bulge forming process comprises the following steps of: firstly, designing a bulge forming mould according to the materials required to be formed, the bulge shape and the dimension and determining the parameters of a key part of the forming mould; secondly, carrying out bulge forming to the materials required to be formed by using the bulge forming mould; and finally, after the completion of bulge forming, punching the light transmission hole at the top part of the bulge by adopting a special punching mould, wherein the position of the light transmission hole is corresponding to the key center of the keyboard. The invention has the beneficial effect that a traditional lampshade and foam are replaced by the shape of the bulge to shield an accumulated light ray so as to realize the attractive overall appearance of the keyboard, shorten the production process, improve the production efficiency and reduce the production reject ratio and the production cost.

Owner:INJECTION PRECISION RUBBER SUZHOU CO LTD

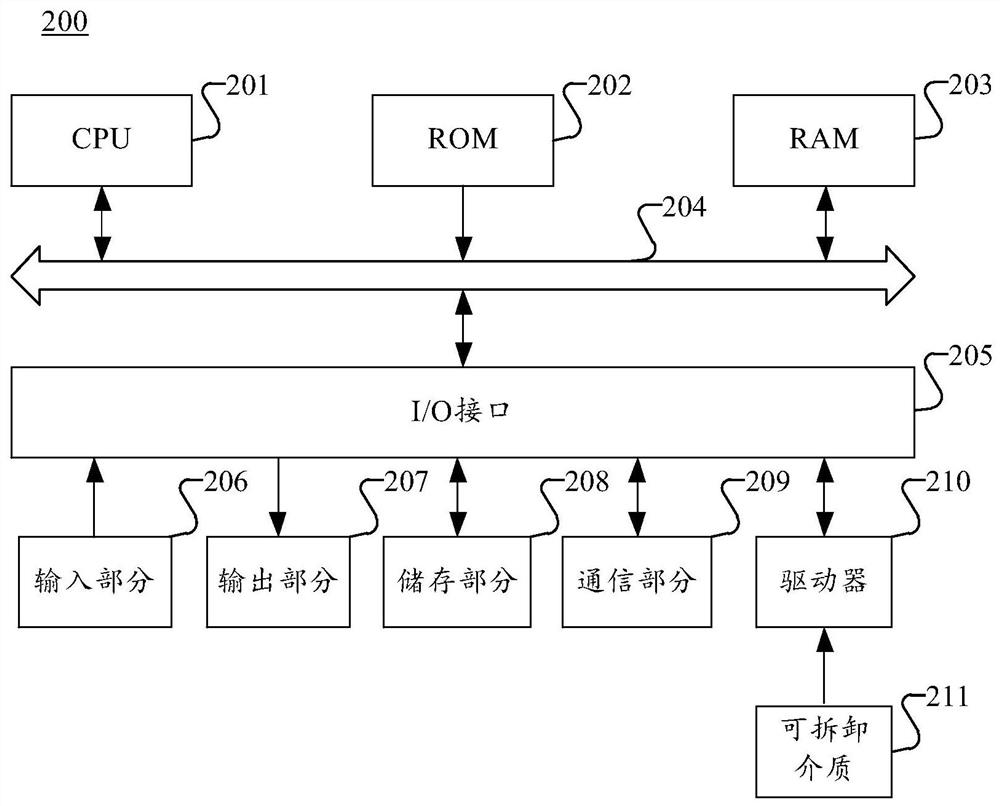

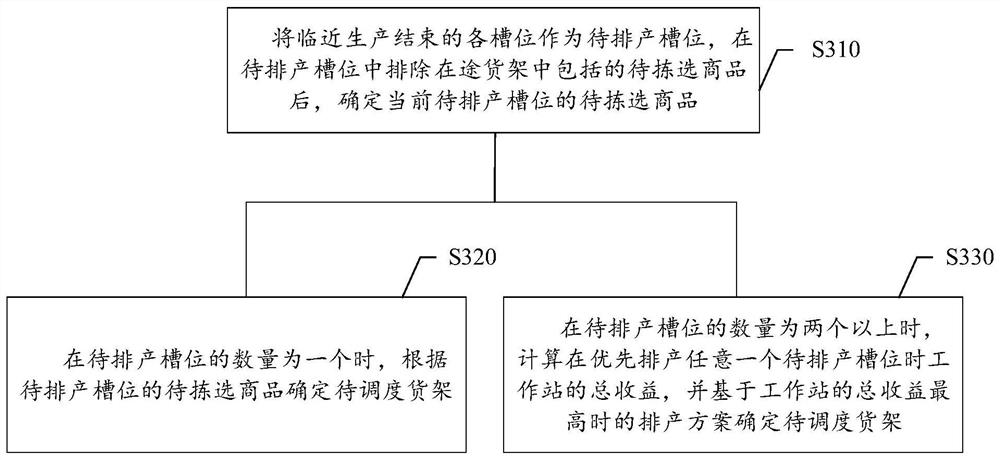

Goods shelf scheduling method and device for goods-to-person warehouse, electronic equipment and medium

PendingCN111754152AImprove overall revenueShorten production timeResourcesLogisticsLogistics managementWorkstation

The invention provides a goods shelf scheduling method and device for a goods-to-person warehouse, electronic equipment and a computer readable storage medium, and relates to the technical field of warehouse logistics. The method comprises the following steps: taking each slot position close to the end of production as a to-be-scheduled slot position; after the to-be-sorted commodities included inthe in-transit goods shelf are excluded from the to-be-scheduled production slots, determining the to-be-sorted commodities at the current to-be-scheduled production slots; when the number of the to-be-scheduled slots is one, determining a to-be-scheduled shelf according to the to-be-sorted commodities of the to-be-scheduled slots; and when the number of the to-be-scheduled slots is more than two, calculating the total income of the workstation when any to-be-scheduled slot is scheduled preferentially, and determining the to-be-scheduled shelf based on the scheduling scheme when the total income of the workstation is the highest. According to the method, the production time of the collection order can be shortened, and the production timeliness of the order and the overall sorting efficiency are improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

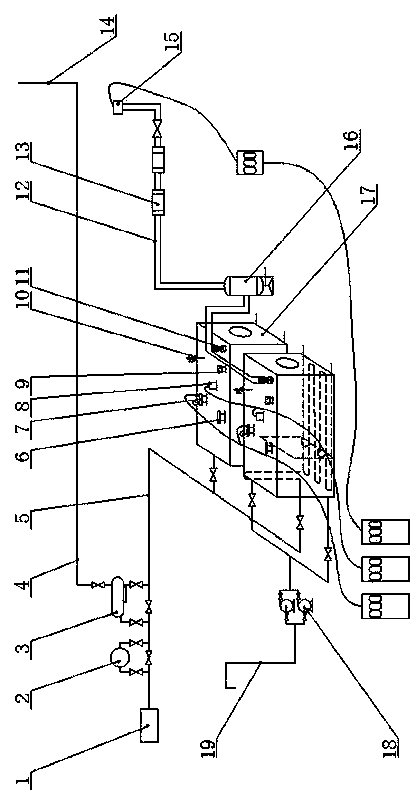

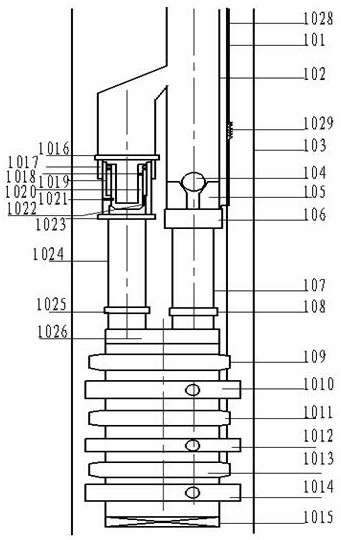

Sealed formation testing process of high hydrogen sulfide well

InactiveCN103835692AGuarantee the safety of lifeImprove production timelinessFluid removalRelief valveNatural gas

The invention relates to a sealed formation testing process of a high hydrogen sulfide well. The sealed formation testing process of the high hydrogen sulfide well comprises an on-site installation process and an on-site formation testing process. According to the on-site installation process, the high hydrogen sulfide well is sequentially connected with a fluid conveying pipeline, a water jacket furnace and an oil-gas separator, wherein a gas outlet of the oil-gas separator is divided into two paths, one path is connected with a hoop gate valve, a separator exhaust pipeline and an ignition torch, and the other path is connected with the fluid conveying pipeline, the hoop gate valve and an oil inlet of a sealed measurement tank. An oil outlet of the sealed measurement tank is connected with the hoop gate valve, an anti-explosion oil conveying pump and an oil charging platform, and an exhaust port of the sealed measurement tank is connected with a flange gate valve I, an oil catcher, a liquid separating bag, an exhaust pipeline, a back-fire relief valve, a flange gate valve II and an emission combustion torch. According to the on-site formation testing process, mixed fluid entering the sealed measurement tank is separated in a slippage mode, separated liquid passes through the hoop gate valve and the anti-explosion oil conveying pump to the oil charging platform to be loaded on a vehicle and transported outwards, separated sulfur-contained natural gas passes through the flange gate valve I, the oil catcher, the liquid separating bag, the exhaust pipeline, the back-fire relief valve and the flange gate valve II to the emission combustion torch.

Owner:CHINA PETROLEUM & CHEM CORP +1

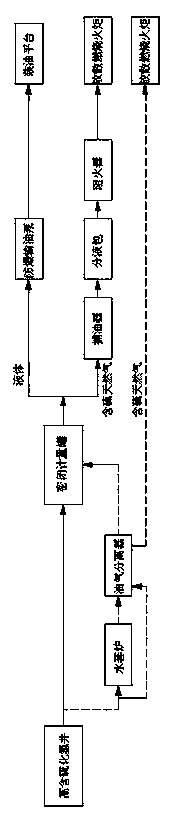

Battery cell packaging mechanism, battery cell packaging logistics line and battery cell turnover and transfer method

ActiveCN113130967ARealize straight-line transferImprove production timelinessPrimary cell manufactureAssembling battery machinesEngineeringMechanical engineering

The invention relates to a battery cell packaging mechanism, a battery cell packaging logistics line and a battery cell turnover and transfer method. The battery cell packaging mechanism comprises a turnover unit, a transfer unit and a packaging unit; the turnover unit and the transfer unit are arranged along the same straight line; the packaging unit is arranged on the moving path of the transfer unit; the turnover unit is used for turning over an aluminum film; the transfer unit is used for transferring a battery cell subjected to aluminum film turnover on the turnover unit to the packaging unit for packaging processing; the turnover unit and the transfer unit form a height difference to transfer the battery cell from the turnover unit to the transfer unit. According to the battery cell packaging mechanism, the battery cell is directly cut off and transferred to the transfer unit from the turnover unit through the height difference, the placement angle of the battery cell in the machining process is not changed through transfer of the battery cell by the transfer unit, and then the battery cell is packaged and machined through the packaging unit, so that the packaging efficiency of the battery cell is improved, and unification during the package processing of the battery cell can be maintained. Compared with a traditional mechanical arm for carrying battery cells, the battery cell packaging mechanism has the advantage of higher time efficiency.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

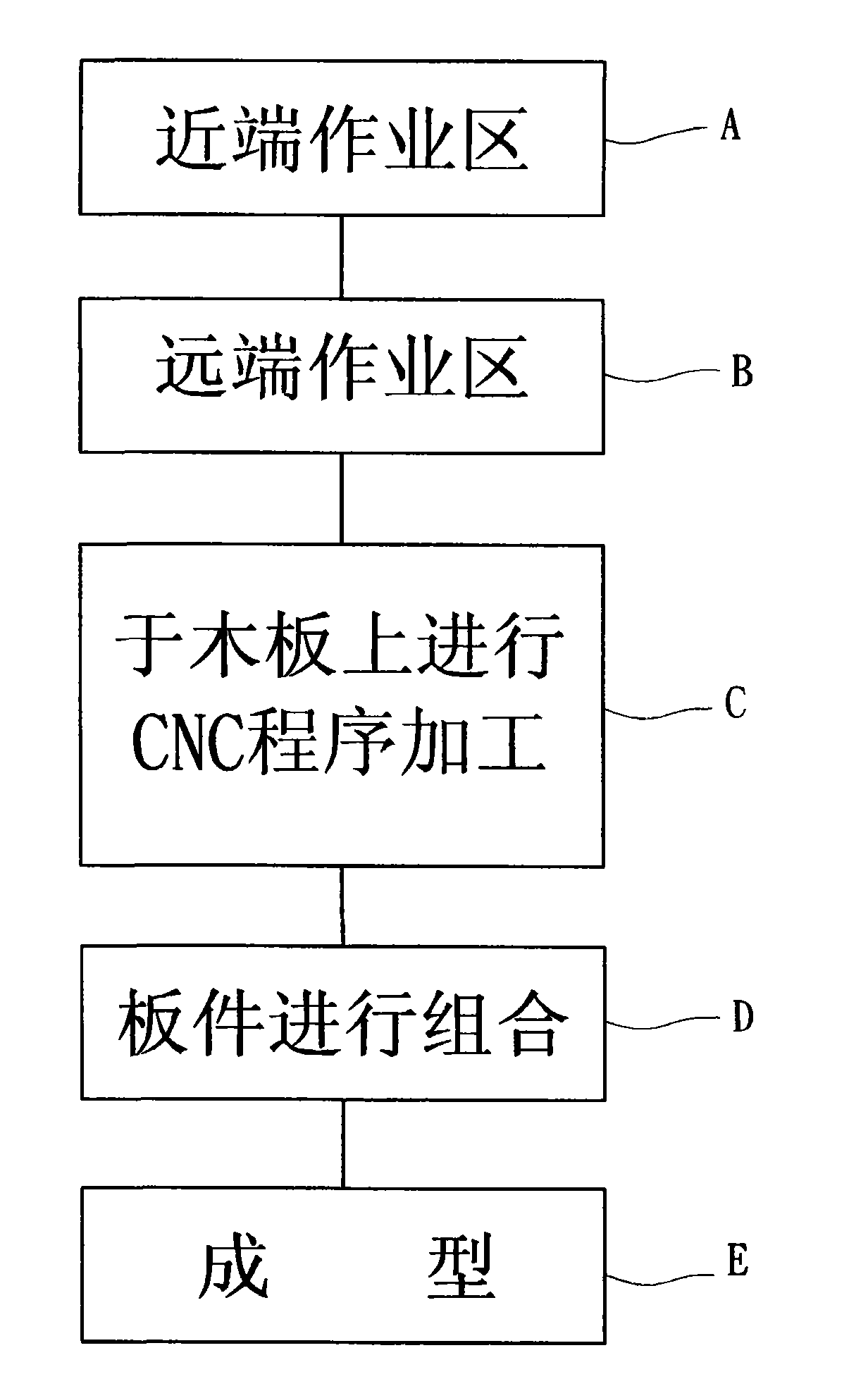

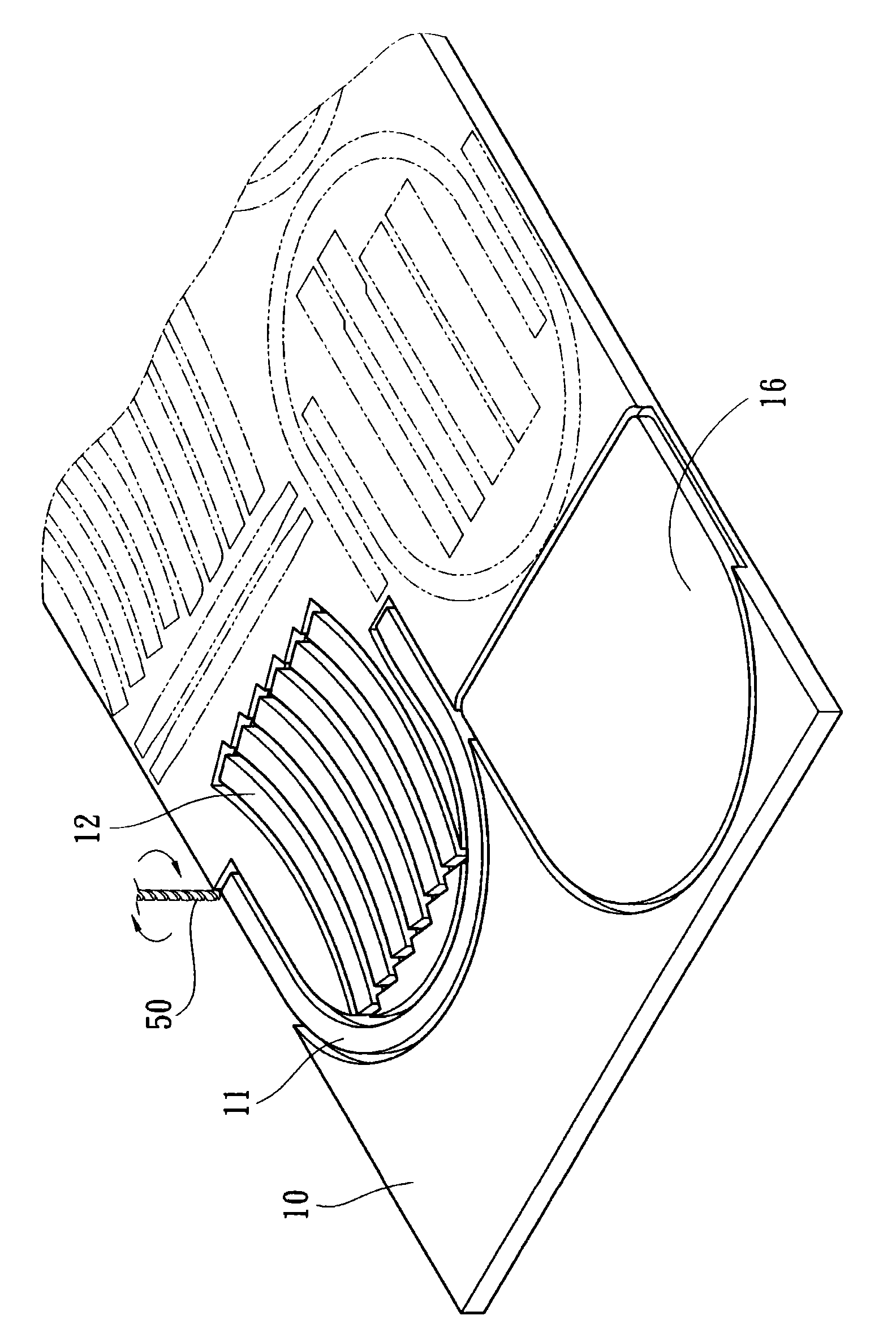

Rapid customized manufacturing method for chair

The invention discloses a rapid customized manufacturing method for a chair. A near-end operating region and a far-end operating region are arranged; the near-end operating region is a transaction platform for consumers to input; the transaction platform is provided with one near-end operating region; the near-end operating region is provided with menus for various different chair patterns, wood material qualities, sizes, colors and decorative patterns; the menu information can be transmitted to the far-end operating region through an internet and converted into a formal CNC processing program for wood plate material selection; and a chair is manufactured by joggling a single wood plate machined by a CNC machine by gluing.

Owner:李尚民

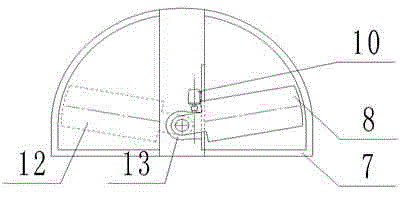

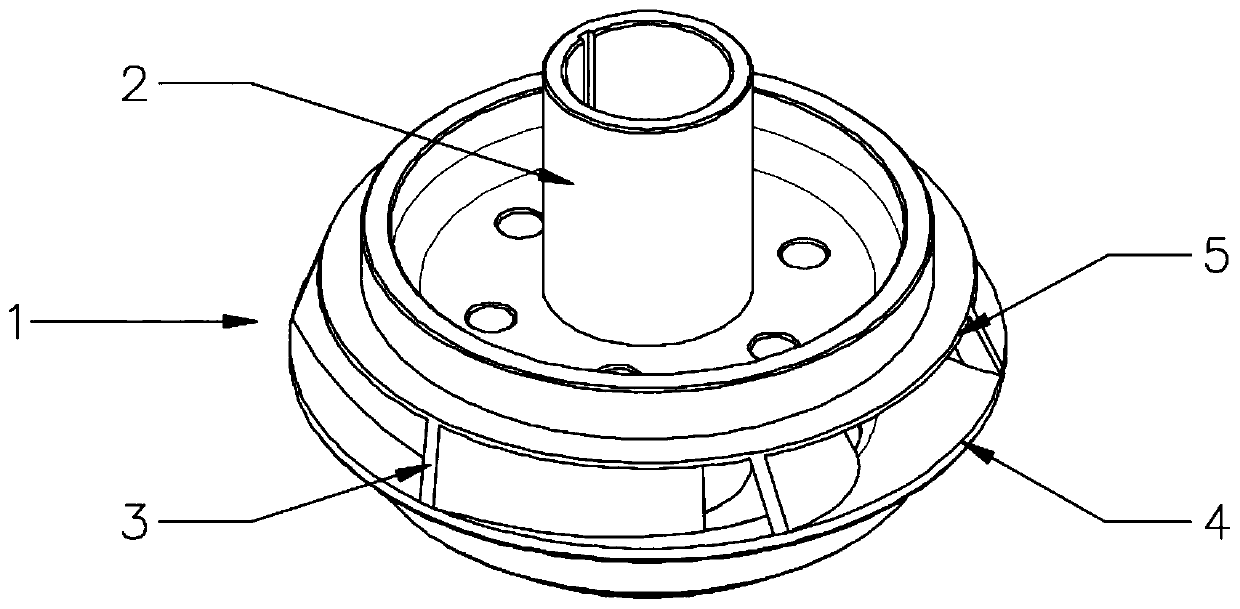

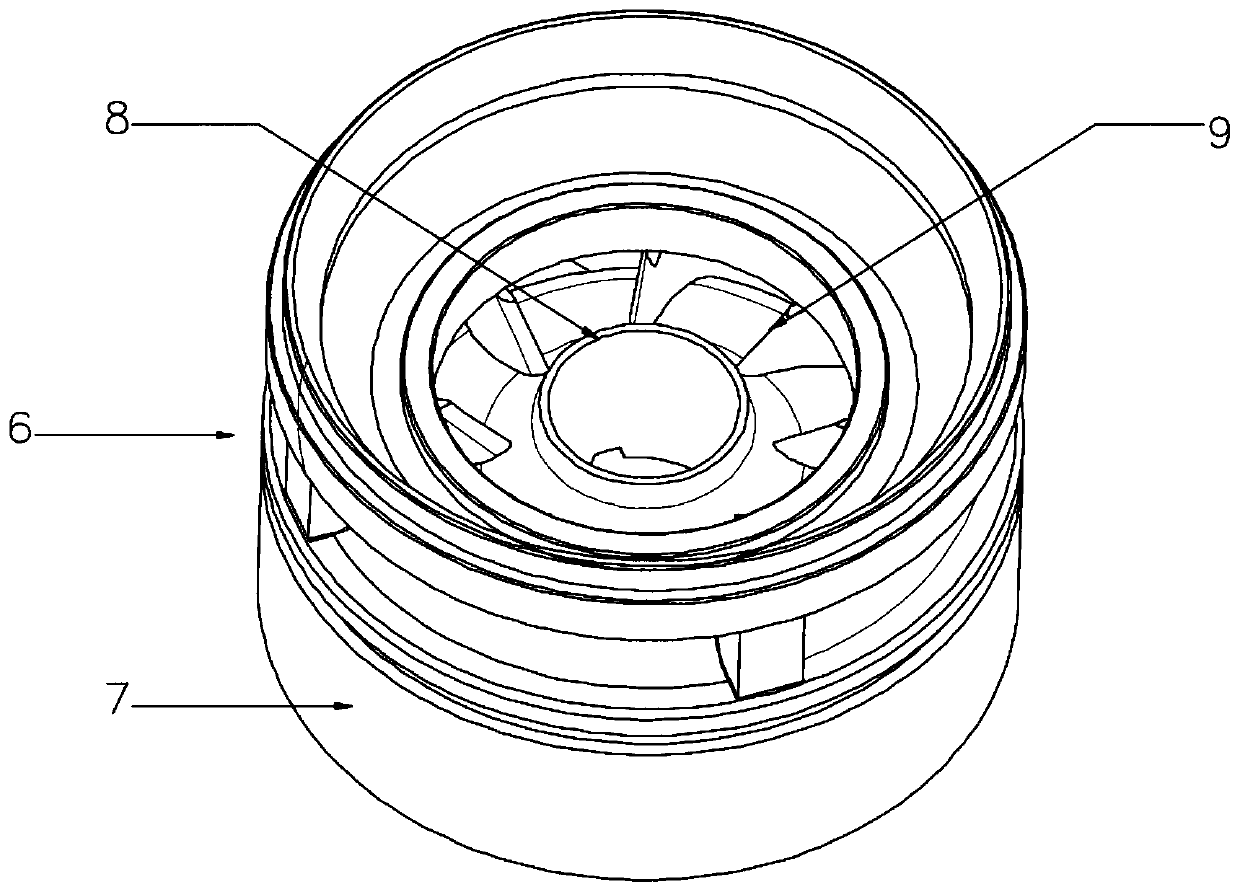

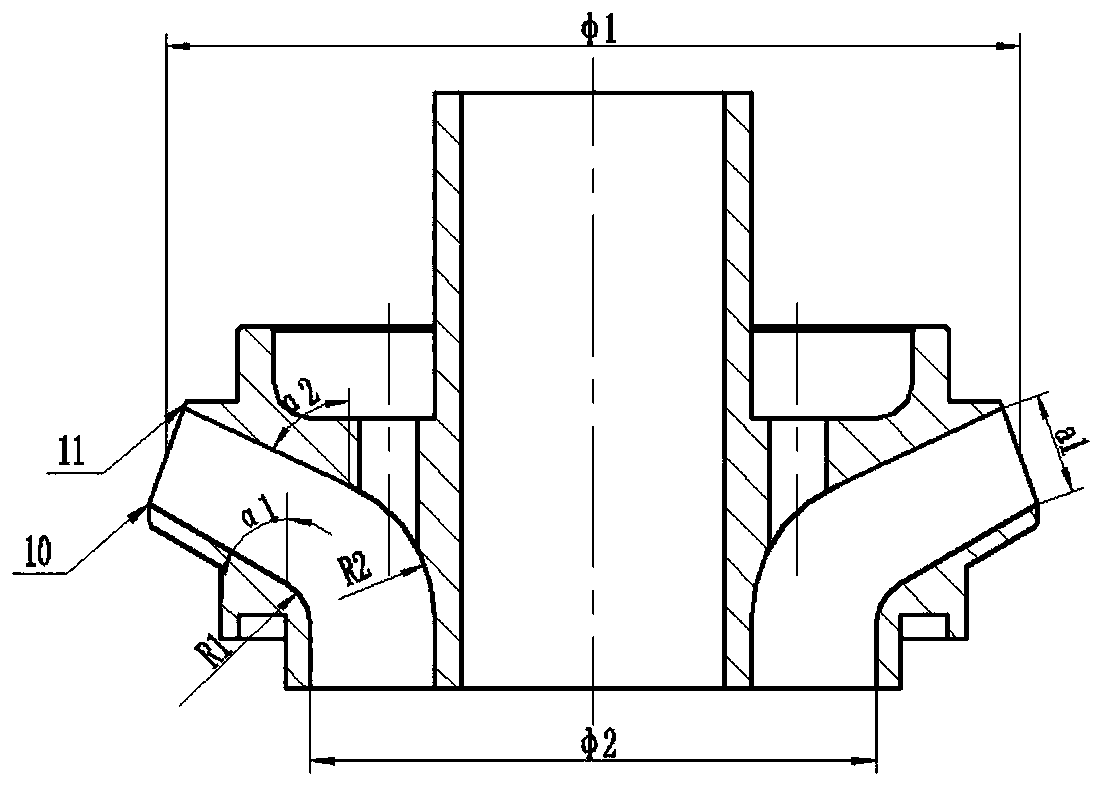

Wide-amplitude high-efficiency blade guide wheel suitable for 387 series submersible electric pump

ActiveCN110701098ASolve problems that affect the operating life of electric pumpsSolve the problem of operating lifePump componentsPumpsImpellerEngineering

The invention discloses a wide-amplitude high-efficiency blade guide wheel suitable for a 387 series submersible electric pump. The wide-amplitude high-efficiency blade guide wheel comprises an impeller and a guide shell; the impeller comprises an impeller hub, blades, a front cover plate and a rear cover plate which are arranged in an integrated structure, six blades are arranged, the blades areuniformly arranged on the outer wall of the impeller hub in an annular mode by taking the center point of the impeller hub as a base point; the front cover plate and the rear cover plate are positioned at the front end and the rear end of the blades respectively; and the guide shell comprises an outer shell, a guide wheel hub and guide vanes which are arranged in an integrated structure, wherein the guide wheel hub is arranged inside the shell, eight guide vanes are arranged, the guide vanes are uniformly distributed between the shell and the impeller hub in an annular mode by taking the center point of the impeller hub as a base point, and the guide wheel hub and the impeller hub are in clearance fit with each other and then are positioned above the front cover plate after being assembled. According to the wide-amplitude high-efficiency blade guide wheel, the range is wide and the efficiency is high in the efficient area, on the premise of widening the range of the efficient area, theefficiency is ensured to be high compared with a conventional blade guide wheel, the efficient area coverage under 50 Hz is 150-500 m<3> / d, and the rated point pump efficiency is 66%.

Owner:CHINA NAT OFFSHORE OIL CORP +1

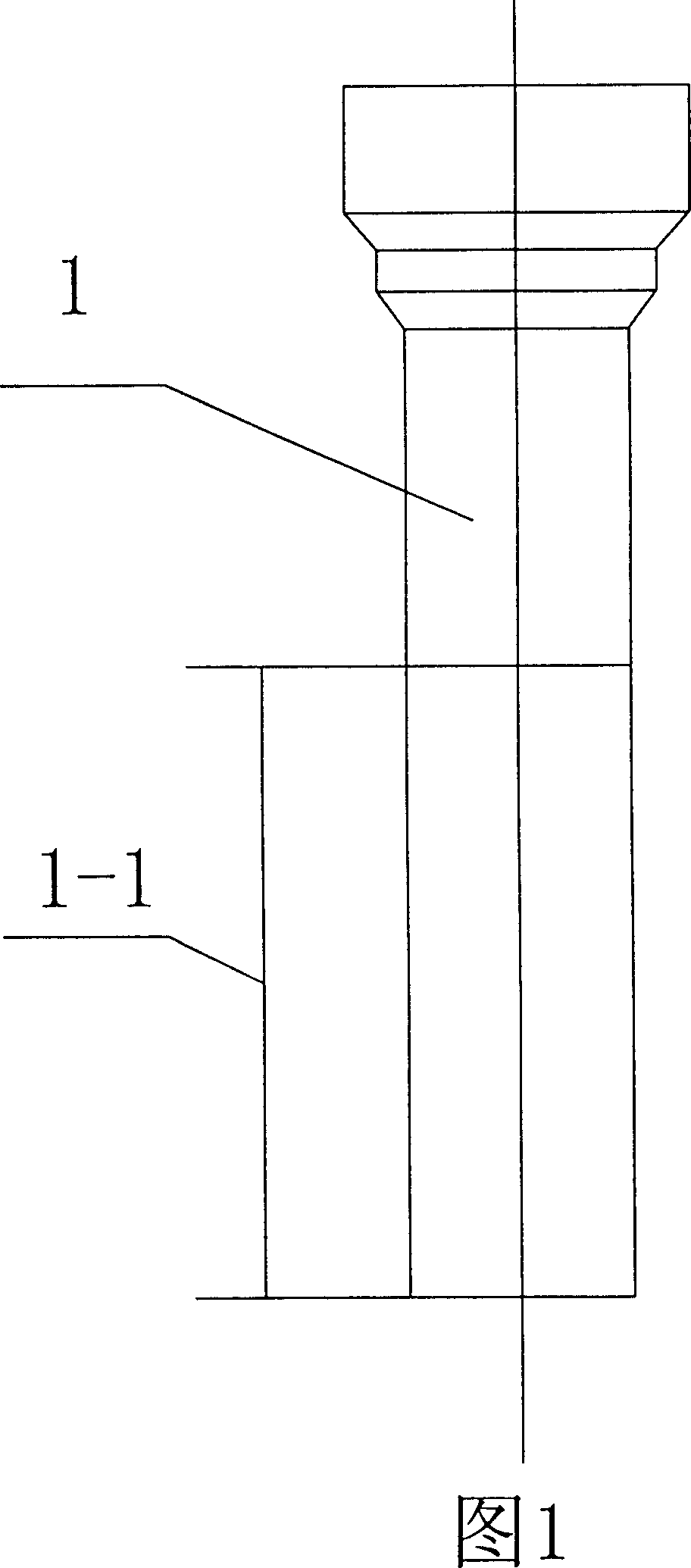

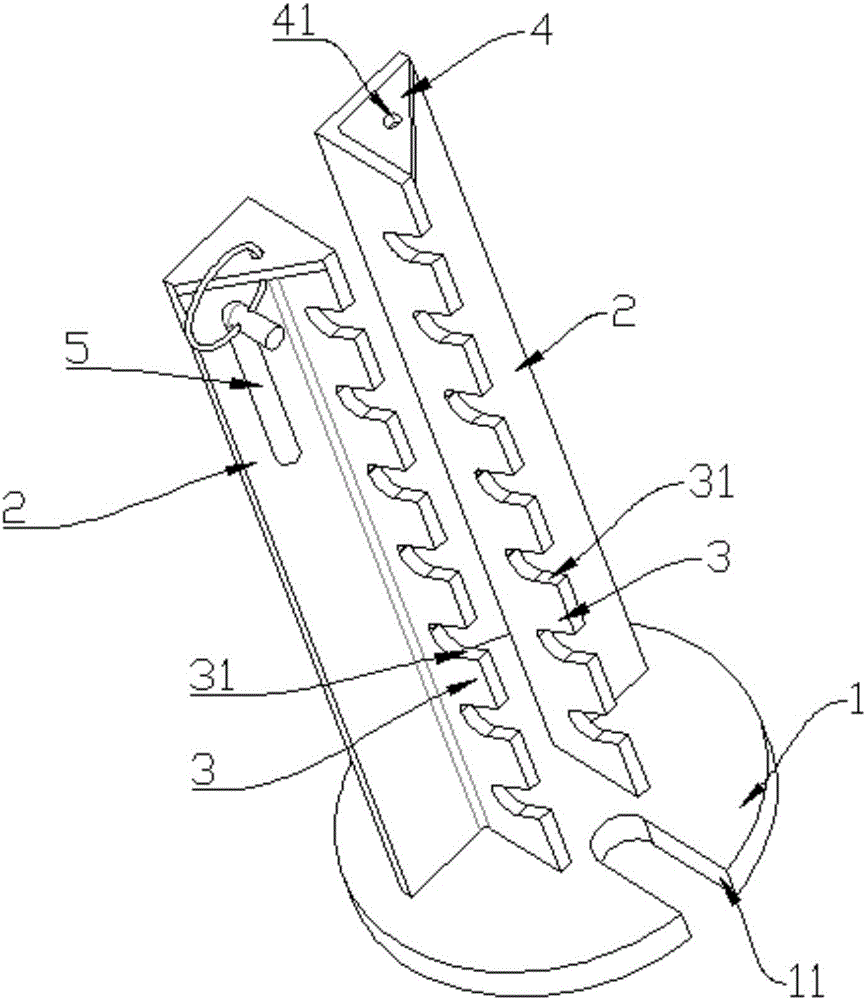

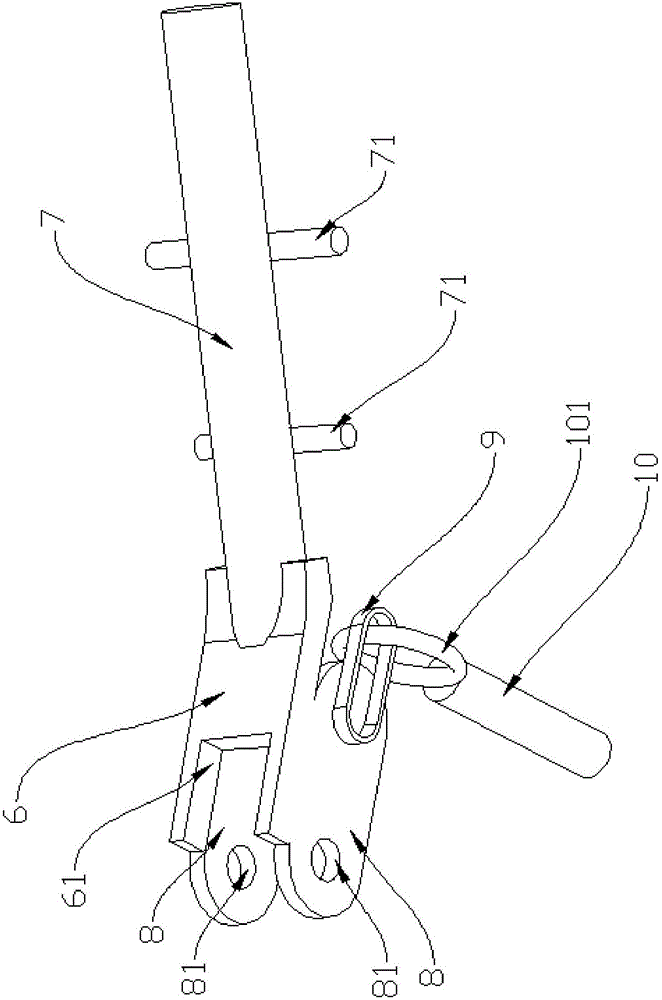

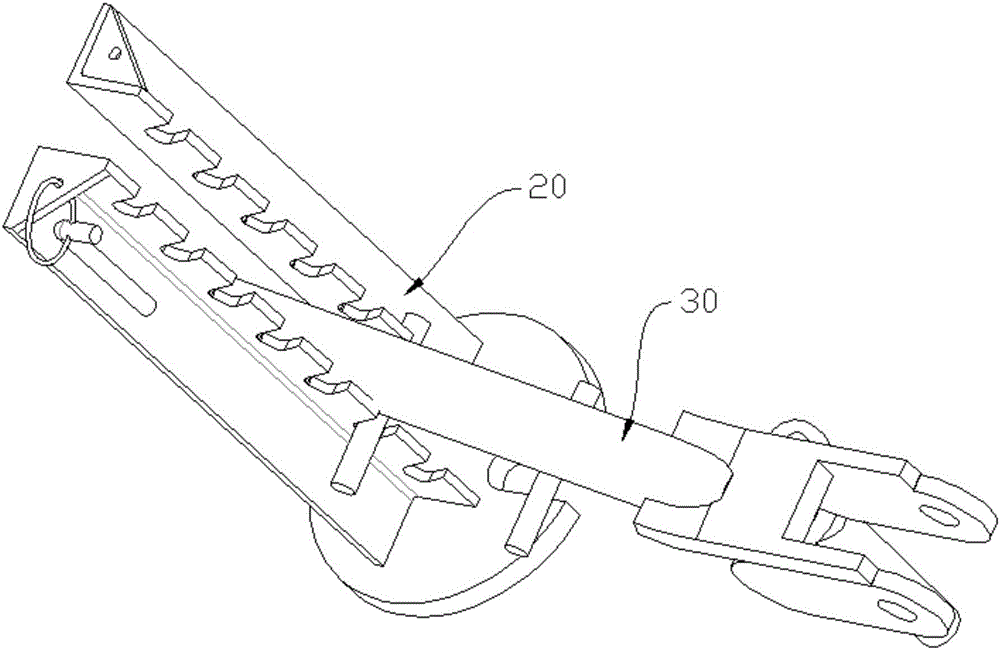

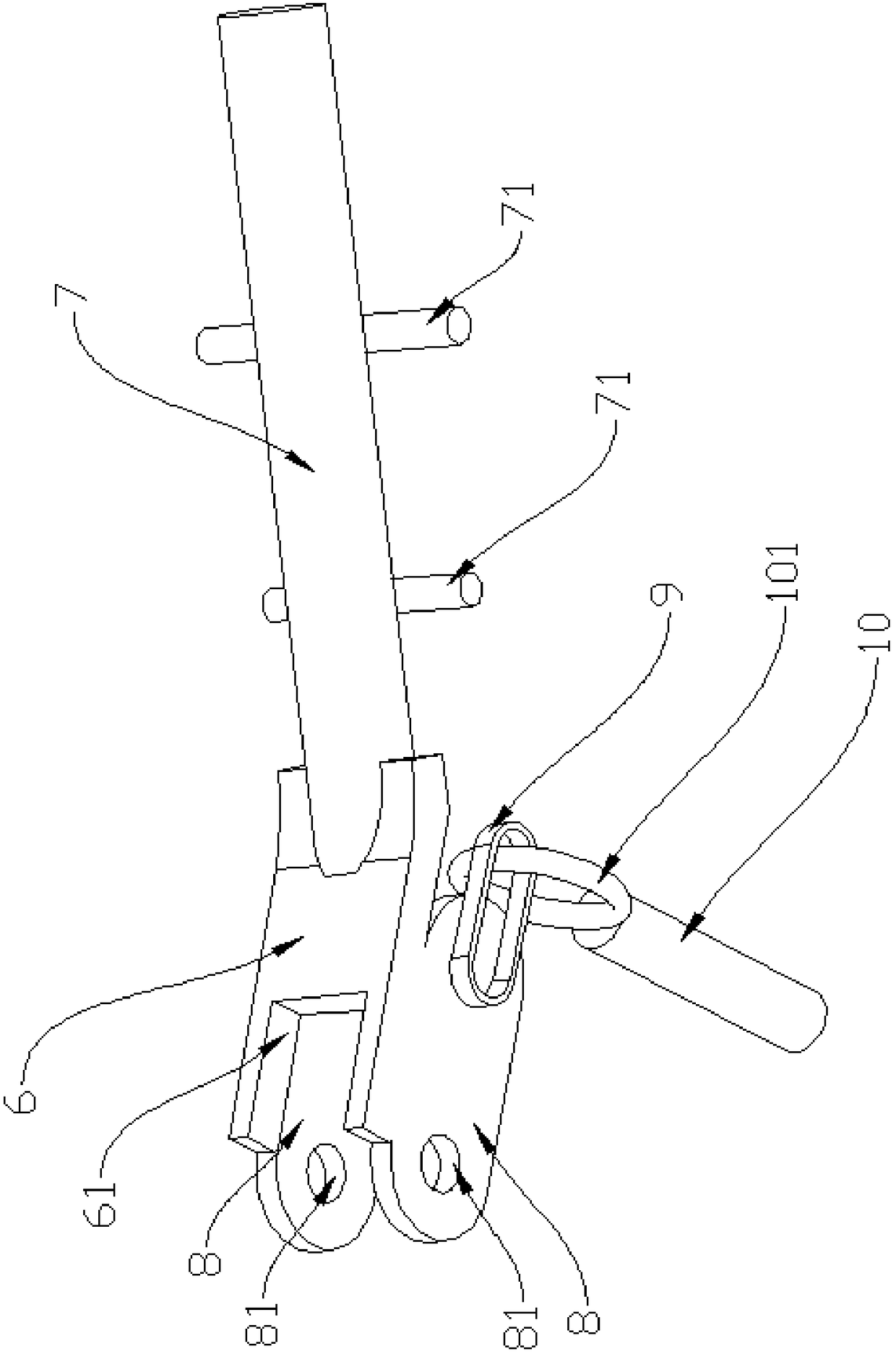

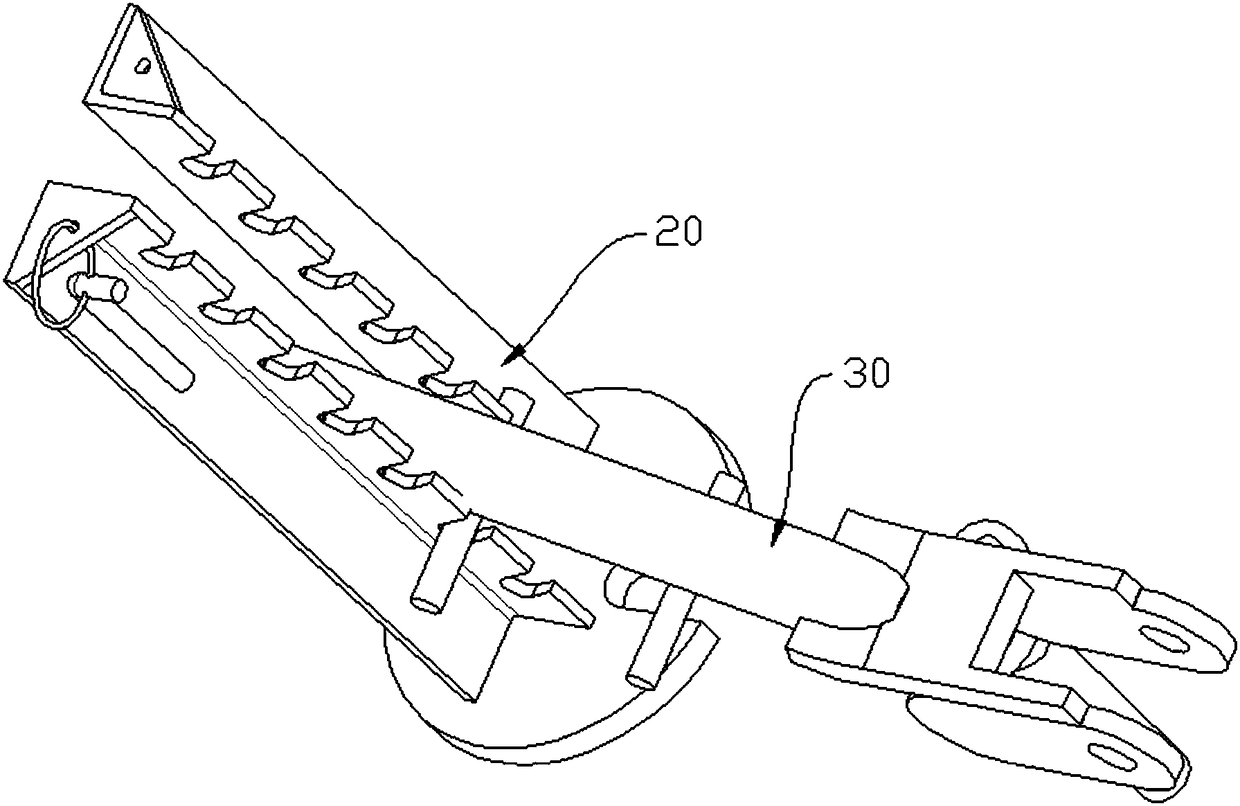

Ground wire pile pulling out device

The invention provides a ground wire pile pulling out device, which belongs to the field of well drilling auxiliary equipment. The ground wire pile pulling out device comprises a positioning component and a skid-mounted component, wherein the positioning component comprises a bottom plate and a support frame vertical to the upper side of the bottom plate, one side of the support frame is provided with two support plates disposed in parallel, the support plates are provided with a plurality of chutes disposed in parallel and open outwards, the skid-mounted component comprises a chuck and a pry bar, one end of the chuck is fixedly connected to one end of the pry bar, one end of the chuck away from the pry bar is provided with a neck, positioning plates are symmetrically disposed on both ends of the lower end surface of the chuck, the ends of the positioning plates away from the pry bar are provided with positioning holes, positioning pins are disposed by being matched with the positioning holes, positioning levers are disposed at the lower end surface of the pry bar, and the positioning lever is disposed by being matched with the chutes. The ground wire pile pulling out device is stable in operation, a ground wire pile can be loosened by pulling at first, then a fulcrum height or distance of the pry bar can be randomly adjusted till the ground wire pile is pulled out, and the aims of safety, easiness and quickness are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

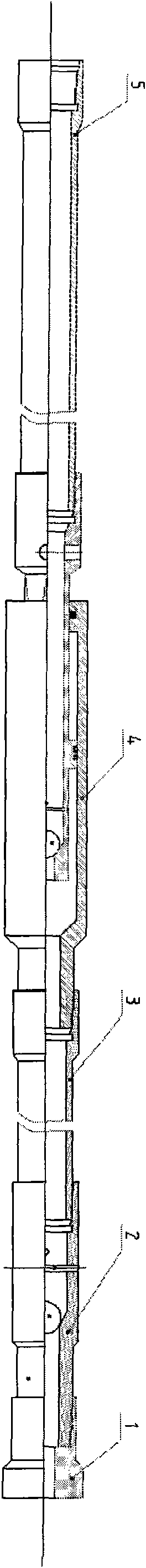

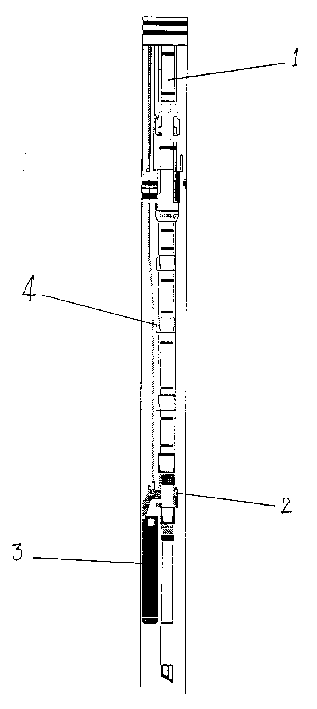

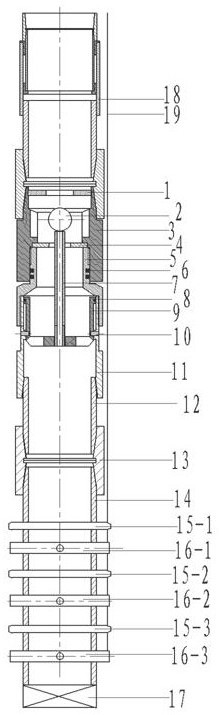

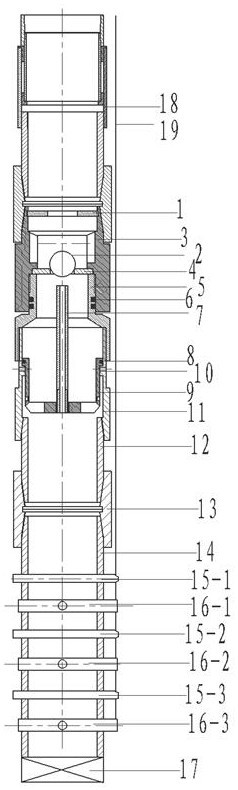

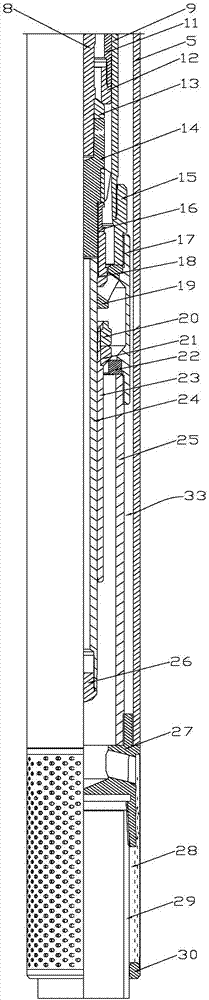

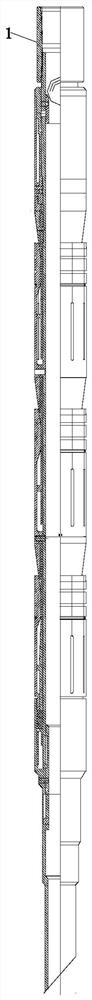

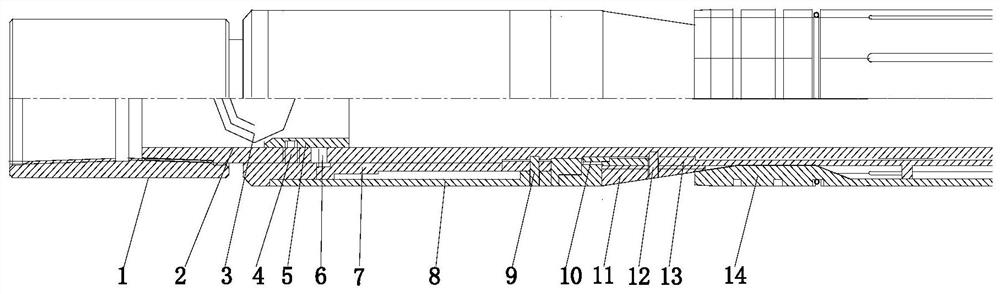

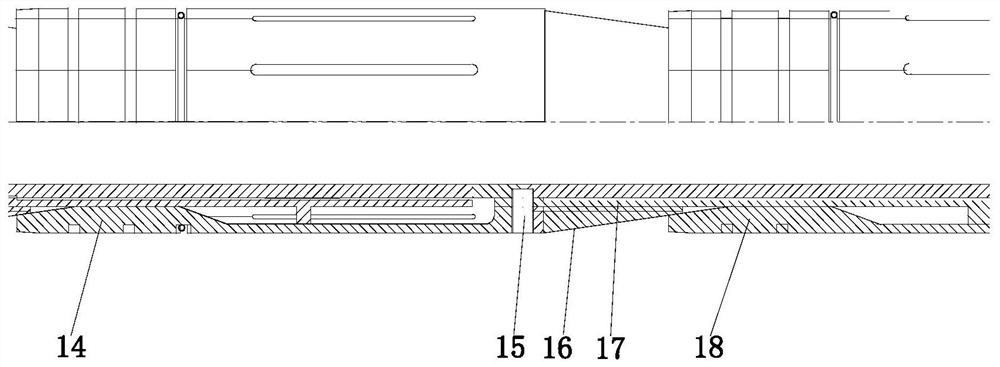

Intelligent separation production string

ActiveCN110952960BExtend working lifeAvoid premature failureDrilling rodsFluid removalControl engineeringProcess engineering

The invention discloses an intelligent separate mining production string, including a layered production string and a fixed valve, the fixed valve is connected above the layered production string, and the layered production string includes at least two layered control switches, at least Two packers, one packer is connected between two layer control switches, one packer is connected above the top layer control switch, and the bottom end of the layer production string is connected to a plug. Layer control switches correspond to their respective production oil layers. All packers are equipped with axial penetration fixing holes for the control cables to pass through. All layer control switches are electrically connected with the control cables in parallel to form an integrated structure. . The present invention utilizes the integral cable-split production tubing string, aiming at the tubular pump lifting system and the rodless pump lifting system such as the electric pump, while carrying out the pressure setting of the packer, and quickly realizes the large-displacement lifting, thereby Reduce the labor intensity of workers and shorten the construction period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ground stake extraction device

The invention provides a ground wire pile pulling out device, which belongs to the field of well drilling auxiliary equipment. The ground wire pile pulling out device comprises a positioning component and a skid-mounted component, wherein the positioning component comprises a bottom plate and a support frame vertical to the upper side of the bottom plate, one side of the support frame is provided with two support plates disposed in parallel, the support plates are provided with a plurality of chutes disposed in parallel and open outwards, the skid-mounted component comprises a chuck and a pry bar, one end of the chuck is fixedly connected to one end of the pry bar, one end of the chuck away from the pry bar is provided with a neck, positioning plates are symmetrically disposed on both ends of the lower end surface of the chuck, the ends of the positioning plates away from the pry bar are provided with positioning holes, positioning pins are disposed by being matched with the positioning holes, positioning levers are disposed at the lower end surface of the pry bar, and the positioning lever is disposed by being matched with the chutes. The ground wire pile pulling out device is stable in operation, a ground wire pile can be loosened by pulling at first, then a fulcrum height or distance of the pry bar can be randomly adjusted till the ground wire pile is pulled out, and the aims of safety, easiness and quickness are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Heavy oil steam huff and puff injection-production integrated device

ActiveCN102877821BSimple structureEasy to implementInsulationFluid removalThermal insulationOil production

The invention discloses a thickened oil steam huff and puff injection-production integrated device comprising a driving device, a gas injection-oil production integrated well, an oil pipe, a sucker rod, a double-metal screw rod pump and a cam anchor, wherein the driving device comprises a base, a box body, a motor and a motor base; an oil well jacket is arranged on the gas injection-oil production integrated well; the oil well jacket is sleeved outside the oil pipe; the stator of the double-metal screw rod pump is connected with the bottom of the oil pipe; the cam anchor is arranged at the lower end of the stator; the sucker rod is arranged inside the oil pipe; the lower end of the sucker rod is connected with the rotor of the double-metal screw rod pump, and the upper end of the sucker rod is connected with a polish rod; the polish rod and the motor are in transmission connection; a sealer is arranged inside the base; the lower end of the base is connected with the gas injection-oil production integrated well; a first thermal insulation cushion is arranged between the base and the gas injection-oil production integrated well; the upper end of the base is connected with the box body; a second thermal insulation cushion is arranged between the base and the chassis body; and the box body is hinged with the motor base. The thickened oil steam huff and puff injection-production integrated device provided by the invention integrates a gas injection device with an oil production device, so that the production aging of a thickened oil well can be improved.

Owner:BEIJING GASOLINEEUM MACHINERY FACTORY

Insulation enhancement protection technology method special for cable root of electric submersible pump

InactiveCN111934250AImprove insulation performanceStrong mechanical propertiesCable junctionsApparatus for joining/termination cablesStress concentrationInsulation layer

The invention discloses an insulation enhancement protection technology method special for a cable root of an electric submersible pump. The method can be used to protect an insulation layer at the root of a cable from damage caused by stress concentration, meanwhile, the root of the cable is coated with a special insulation sealant to prevent gas channeling through a sheath layer, a high-temperature-resistant and high-pressure-resistant heat shrinkable tube is used for conducting heat shrinkage on a cable connecting part, and after heat shrinkage, the two ends of the heat shrinkable tube arewound with a pressure-sensitive adhesive tape to prevent gas channeling through the two ends. The connecting part of the submersible cable has relatively strong insulation and mechanical properties. The service life of an oil-submerged pump is prolonged, pump inspection operation times caused by cable connection faults are reduced, and oil field production timeliness is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

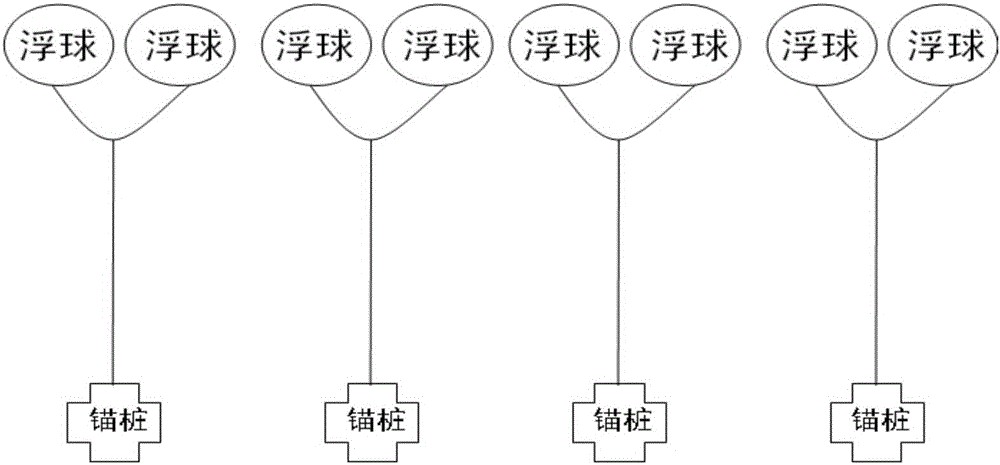

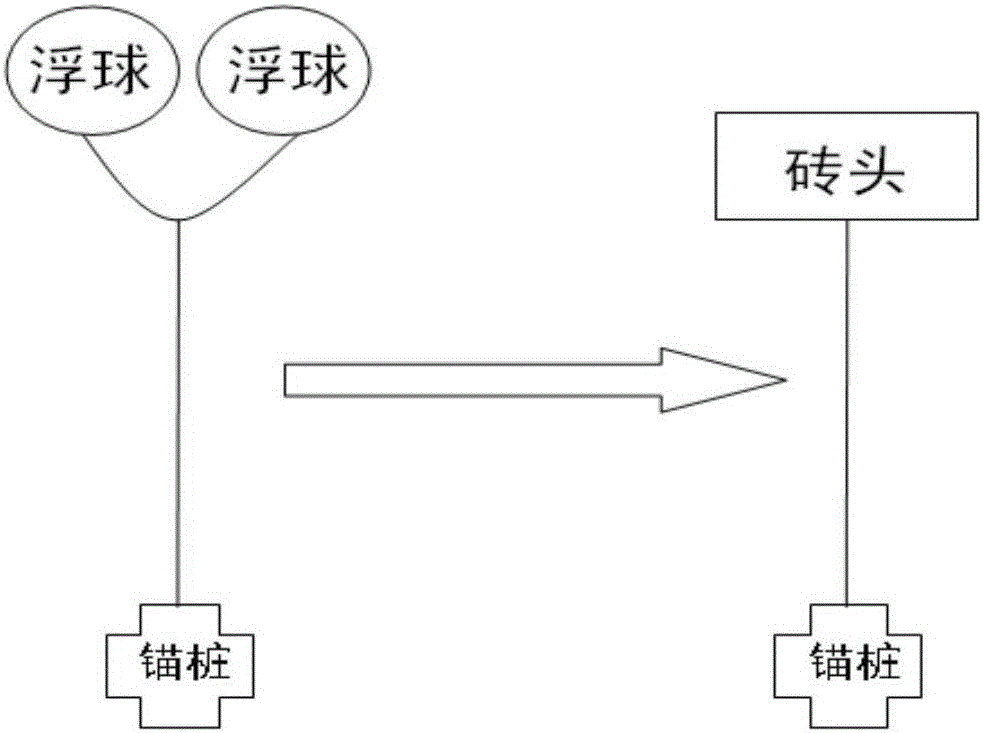

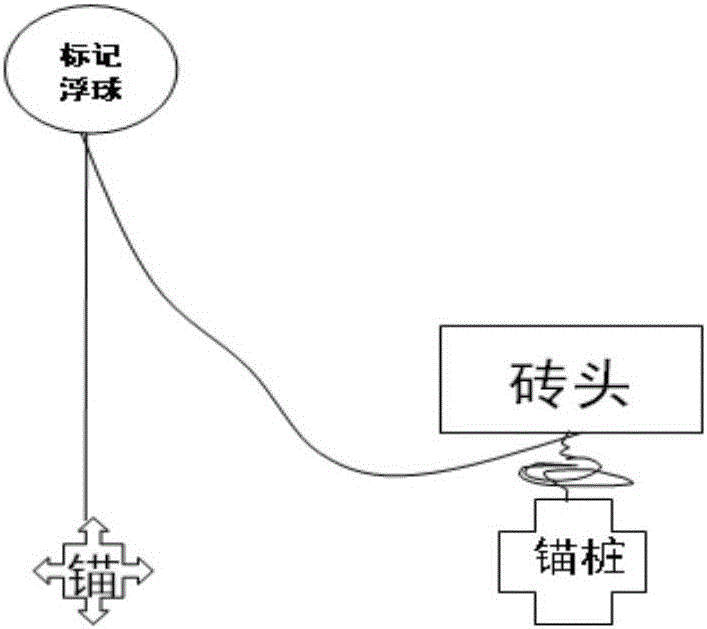

Construction method for submarine cable seismic acquisition in scallop culture area

ActiveCN104076399BLower Exploration CostsImprove production timelinessSeismology for water-covered areasOcean bottomBrick

The invention discloses an earthquake collecting construction method for submarine cables in a scallop breeding area, and belongs to the technical field of earthquake exploration collecting and marine geologic survey in the breeding area of scallops and other marine products. The method comprises the following steps that a long line is tied on an anchor rope of a starting floating ball, a marking floating ball is tied at one end of the long line, the marking floating ball is tied on an anchor, the marking floating ball and the anchor are thrown into the sea, and construction coordinates are recorded; weights, namely bricks, replace the floating balls in sequence and are connected with the long line, and when a centrum ship carries out the excitation operation, a plurality of rubber boats carry out corresponding alerting or marking floating ball dragging operation; the weights, namely the bricks, are fished up along the long line, the floating balls replace the weights, namely the bricks, in sequence, and the scallop floating ball site can be recovered by removing the connected long line; the rubber boats or wooden boats are used for packing up the cables, the floating ball replacing operation is carried out after cable laying, and the floating balls are recovered after centrum implementing and before cable packing up.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

A method for automatically adjusting hard disk boot devices according to different configuration information

ActiveCN105607911BRealize automatic adjustmentImprove usabilitySpecific program execution arrangementsDisk controllerUsability

The invention discloses a method for automatically adjusting a hard disk startup device according to different configuration information, which relates to hard disk startup technology. According to the difference in the configuration of different hard disks of a server, the hard disk controller is automatically identified and the priority of the hard disk startup is set to realize the automatic adjustment of the hard disk by the server. Start the device; first read the scheme of the hard disk controller Vendor ID, and automatically identify the connection position of the hard disk in the system; then the BIOS selects and specifies different Boot hard disk options according to different hard disk controller Vendor IDs. The invention realizes the automatic adjustment of the hard disk boot device by the server, improves the consistency of the BIOS version and the ease of use of the customer; the method can be upgraded in the server by adopting the BIOS upgrade method, and when the upgraded server product supports multiple different configurations online, it is liberated. Production manpower improves the timeliness of production.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Film with bulge for computer keyboard or flexible printed circuit and bulge forming process thereof

InactiveCN102412080BBeautify the lighting effectSave the sticking processElectric switchesKey pressingPunching

The invention relates to the technical field of production of input equipment, in particular to a bulge forming process of a film with a bulge for a computer keyboard or a flexible printed circuit. A light transmission hole is arranged at the top part of the bulge; and light shading film materials are attached on the upper surface or the lower surface of the bulge per se. The bulge forming process comprises the following steps of: firstly, designing a bulge forming mould according to the materials required to be formed, the bulge shape and the dimension and determining the parameters of a key part of the forming mould; secondly, carrying out bulge forming to the materials required to be formed by using the bulge forming mould; and finally, after the completion of bulge forming, punching the light transmission hole at the top part of the bulge by adopting a punching mould, wherein the position of the light transmission hole is corresponding to the key center of the keyboard. The invention has the beneficial effect that a traditional lampshade and foam are replaced by the shape of the bulge to shield an accumulated light ray so as to realize the attractive overall appearance of the keyboard, shorten the production process, improve the production efficiency and reduce the production reject ratio and the production cost.

Owner:INJECTION PRECISION RUBBER SUZHOU CO LTD

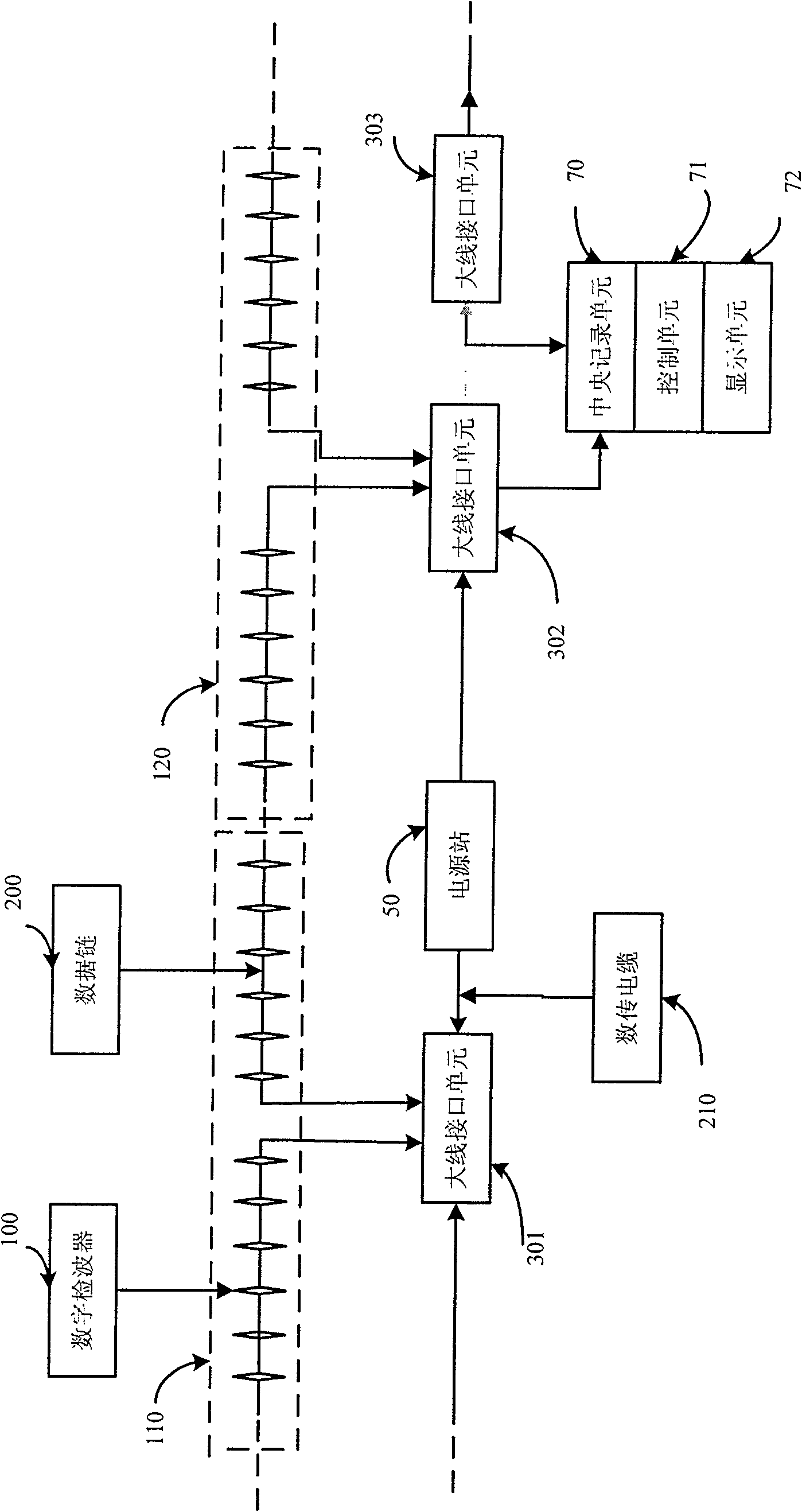

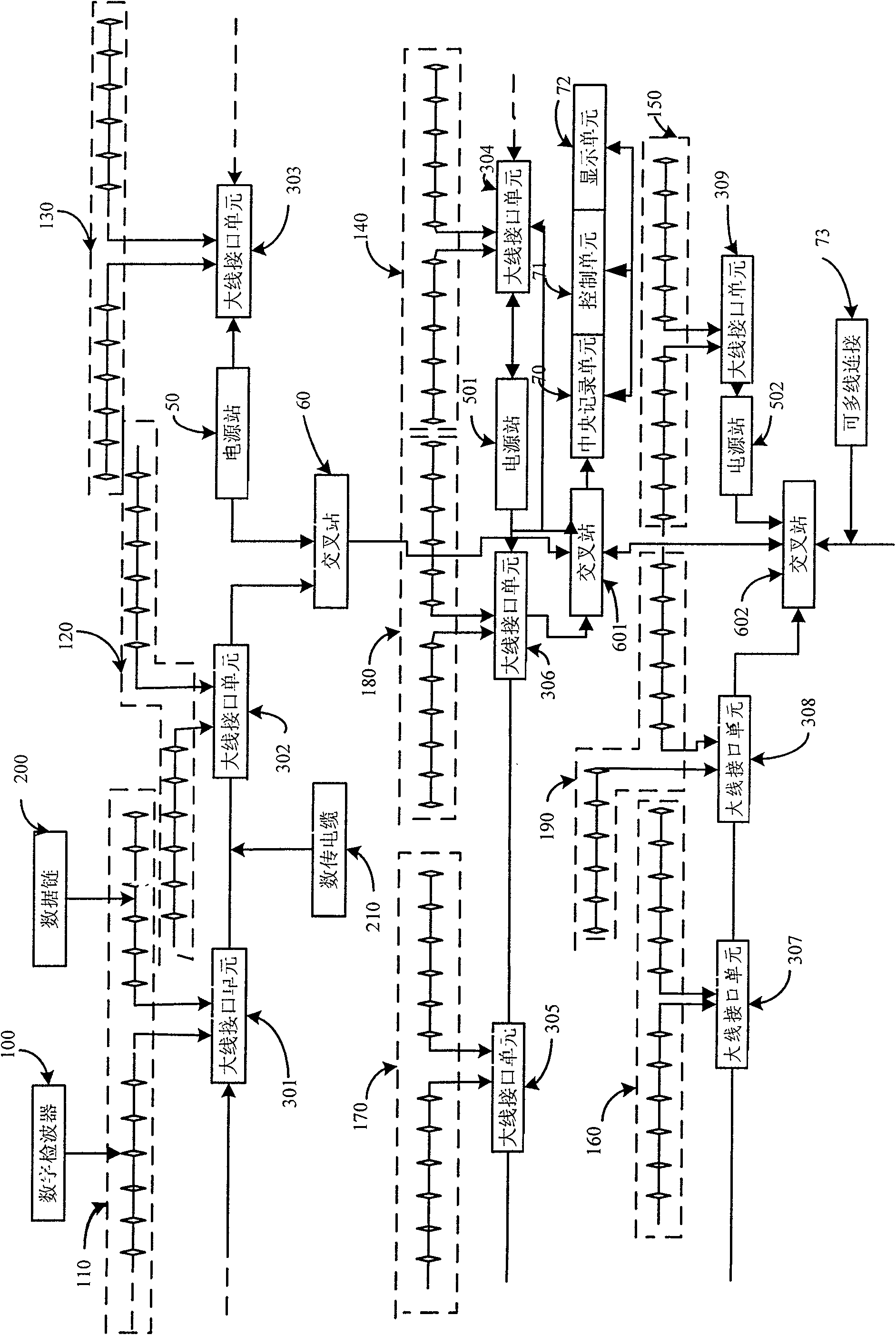

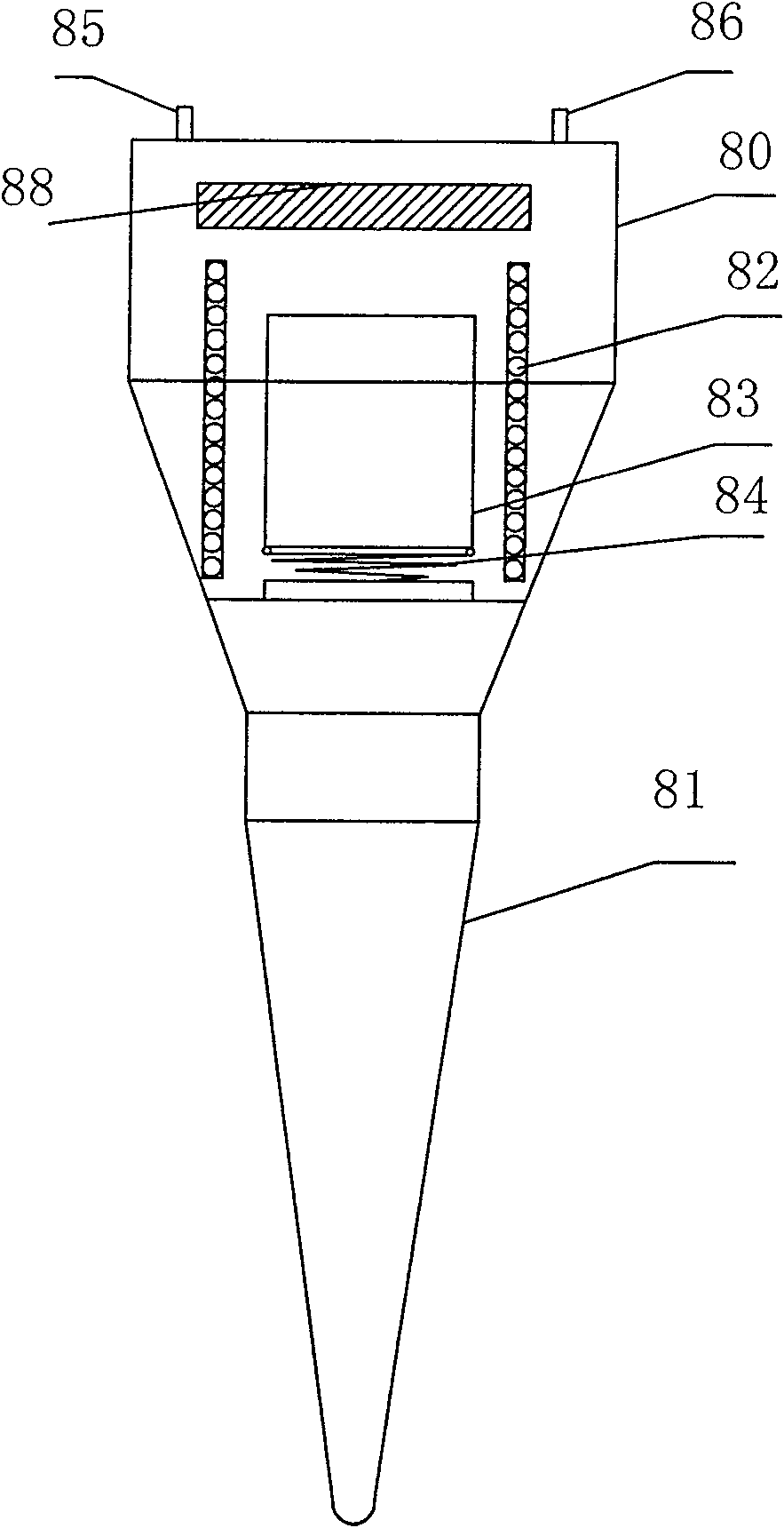

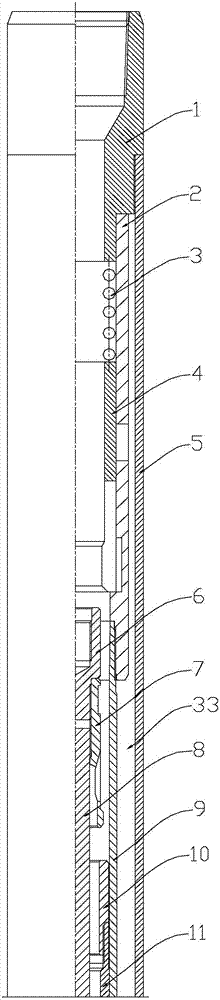

Seismic prospecting data collecting system

InactiveCN100554998CEasy to learnEasy maintenanceSeismic signal transmissionData connectionIp address

The invention discloses a seismic exploration data acquisition system, which stores, manages, processes and outputs received signals; connects several digital detectors with independent IP addresses in series to form an SMGS data chain with the same digital channel structure , the road distance is 5 meters, 10 meters. Each large-line interface unit SLIM is connected to two strings of digital sensor SMGS data chains, and the data of each SMGS is connected in two-dimensional SEG-Y format or in three-dimensional SEG-D format or IBM32-bit floating point through a data transmission cable The format is recorded on magnetic media; the central recording system performs data storage management and drawing; and screen playback; a computer with RAM memory is set in the large line interface unit; a data arrangement management unit is used for each data receiving line IXU. The transmission rate of the data transmission cable is 100Mbps; it can transmit samples in real time. When the system is produced, two-dimensional: 2000 channels / 1ms sampling; three-dimensional: 30000 channels / 1ms sampling.

Owner:侯树麒

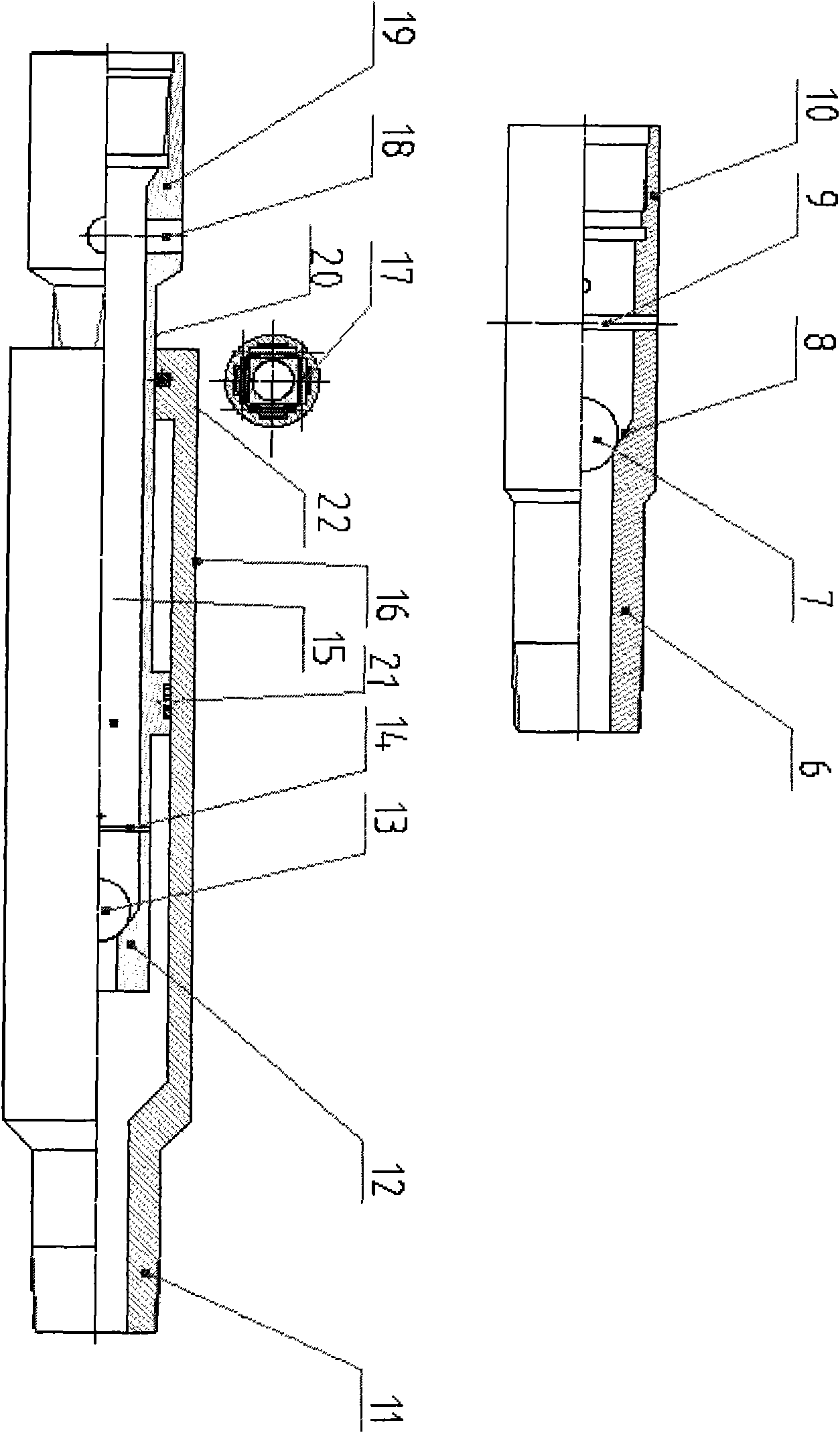

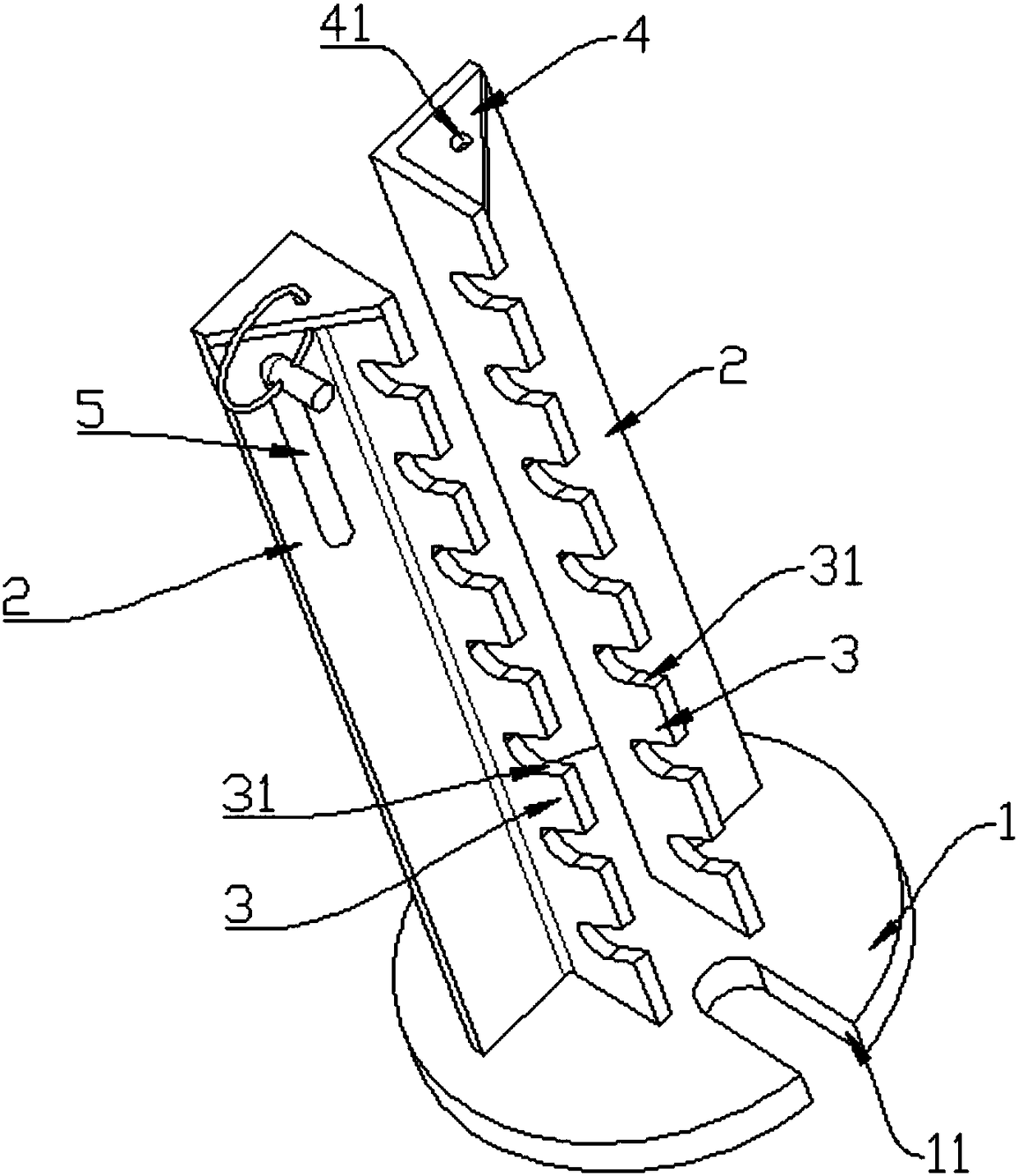

Downhole oil well pump

ActiveCN105756909BImprove production timelinessReduce homeworkDrilling rodsPositive displacement pump componentsEngineeringOil production

The invention discloses an underground oil well pump which comprises a sliding sleeve, a pawl spring, a lifting mechanism, an outer tube and a two-way joint, wherein the sliding sleeve is provided with a through hole; the pawl spring is arranged inside the sliding sleeve; sliding can be generated between the pawl spring and the sliding sleeve so as to enable the through hole to have two open and closed states; the lifting mechanism is arranged at the lower end of the pawl spring and is used for lifting liquid; the outer tube sleeves the sliding sleeve and the lifting mechanism; an annular space is formed by the outer tube and the sliding sleeve as well as the lifting mechanism; the two-way joint is arranged at the lower ends of the outer tube and the lifting mechanism; the two-way joint is provided with a passage for communicating the annular space with an opening below the two-way joint and communicating the lifting mechanism with the lateral part of the two-way joint; when the through hole is in the open state, a first flow passage is formed by the opening, the annular space and the through hole; when the through hole is in a closed state, a second flow passage is formed by the passage and the lifting mechanism. The underground oil well pump disclosed by the invention can achieve integration of steam injection and oil production, and solves the problem of damage of high-temperature steam to parts inside a pump barrel of the underground oil well pump.

Owner:PETROCHINA CO LTD

Combination automatic line for workpiece transmission, positioning and clamping

ActiveCN112173657BScience of Design ConceptImprovement of design conceptConveyor partsEngineeringMechanical engineering

The invention discloses a combined automatic line for workpiece transmission, positioning and clamping, which includes a lathe, a floating lifting adjustment transmission roller system for the transmission of workpieces with various diameters, and a workpiece rotation lifting system for adjusting the coaxiality of workpieces in transmission Centralizing wheel system, workpiece transmission positioning and clamping limiter for workpiece positioning, workpiece channel centralizing and clamping balancer for workpiece guidance and clamping, storage of workpieces to be processed and processed workpieces, and workpiece transfer workpiece storage rack. The invention can carry out mixed application and frequent alternate operation for multiple workpieces such as long and short bodies, and creates an automatic line production environment, which has the effect of efficient connection and conversion application.

Owner:CNPC BOHAI DRILLING ENG +1

Sand flushing method

ActiveCN109469453BReduce lifting operationsReduce labor intensityFlushingMechanical engineeringCement

The invention provides a sand-flushing and well-dredging method, which is carried out by adopting a sand-flushing and well-dredging device, and the sand-flushing and well-dredging method comprises thefollowing steps of: 10, putting a sand-flushing and well-dredging device into a set position in a well and carrying out sand detection operation; 20, connecting the sand-washing and well-dredging device with a cement tank car for sand flushing operation, and lifting the sand-washing and well-dredging device to an upper boundary set position of an oil layer after the sand flushing is finished; 30,throwing balls into a central pipe to pressurize, wherein a pressing driving component can drive a frustum body to taper into a reducing sleeve and increase the diameter of the reducing sleeve; 40, lowering a detection pipe column to an artificial well bottom, and detecting the casing condition between the artificial well bottom and the upper boundary of the oil layer; 50, after the detection isfinished, lifting the sand-washing and well-dredging device, when the lifting is blocked, increasing the lifting pulling force to reset the frustum body, so that the diameter of the reducing sleeve isrestored, and lifting the sand-washing and well-dredging device to the ground at the moment. According to the invention, the sand-flushing and well-dredging process can be completed by carrying out one-time pipe column lifting operation, so that the labor intensity of workers can be reduced, and the production time is improved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com