Pollution-free well workover process for oil field

A pollution-free and workover technology, applied in the field of pollution-free workover technology, can solve problems such as increased conflicts between layers, formation pollution, and increased formation additional pressure, and achieve the effects of improving production timeliness, reducing pollution, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

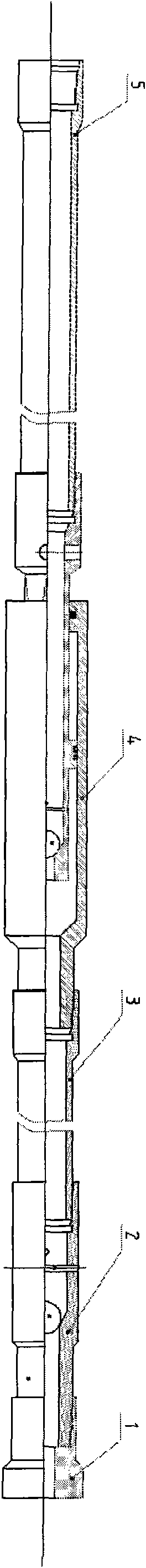

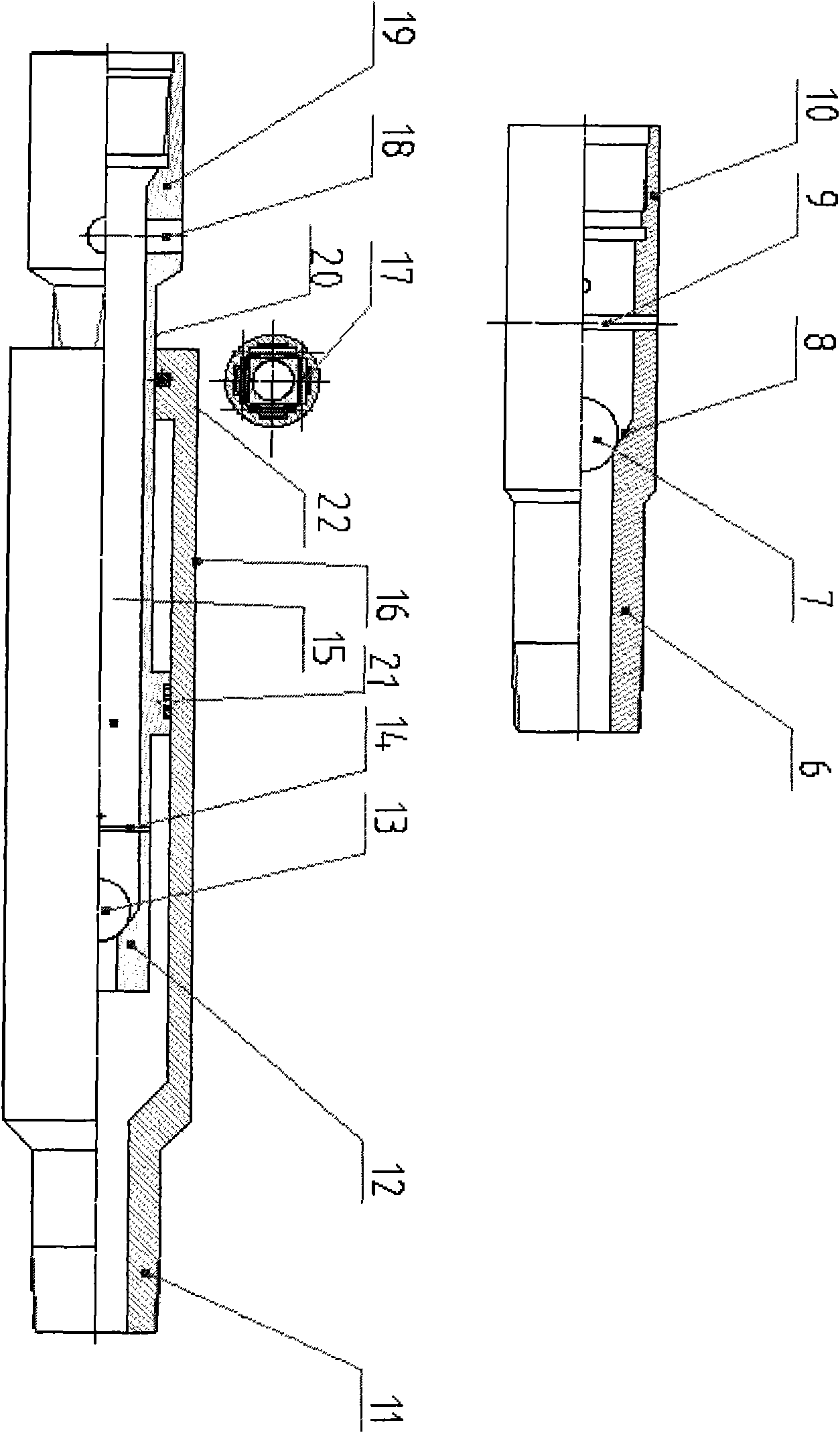

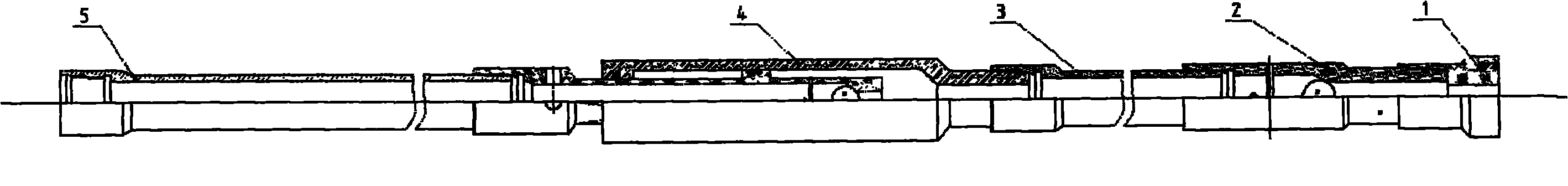

[0010] During the specific implementation, select the appropriate downhole tool according to the specific downhole situation and the purpose of the workover. The combined drilling tool is connected by screws in turn from the downhole tool, the bottom valve, the sand settling pipe string section, the suction pump, and the upper pipe string from bottom to top. Descend to the bottom of the well. During operation, the upper pipe string is lifted to drive the piston and the square pull rod to move upward, the moving valve in the piston is closed, the bottom valve is opened, the fluid in the well enters the sand settling pipe string through the bottom of the downhole tool, and carries solid particles from the bottom of the well into the pipe. Inside the column: lower the piston of the upper pipe string, the square tie rod goes down, the moving valve in the piston opens, the bottom valve closes, the fluid inside the sand settling pipe column enters the square tie rod of the suction pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com