Patents

Literature

30results about How to "Oil increasing effect is obvious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

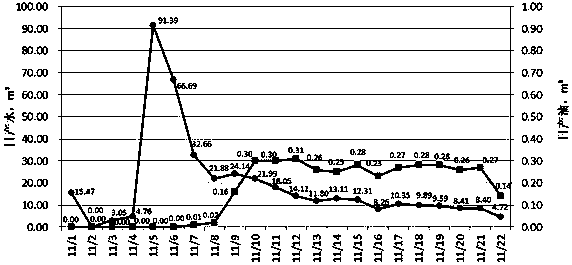

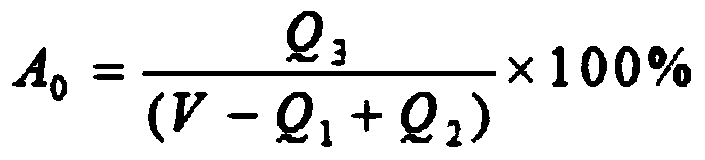

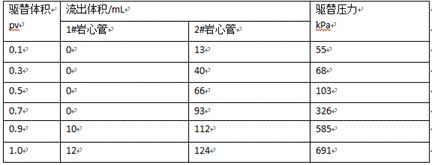

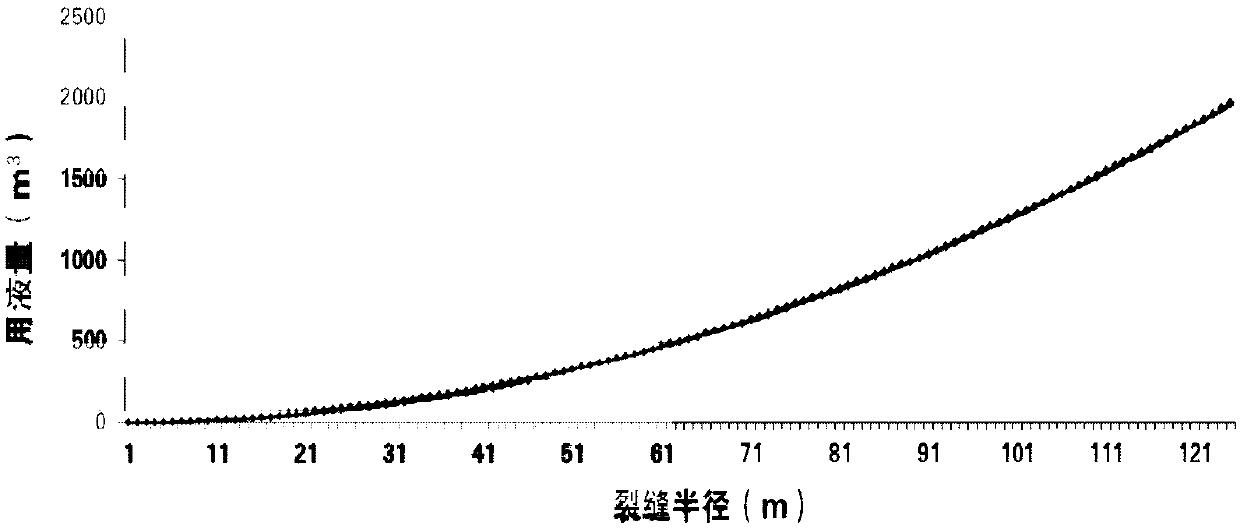

Method for injecting oil displacing agent into oil reservoir to improving oil recovery by using fracturing

ActiveCN106837274AReduce penetrationLess corrosiveFluid removalDrilling compositionViscosityPetroleum engineering

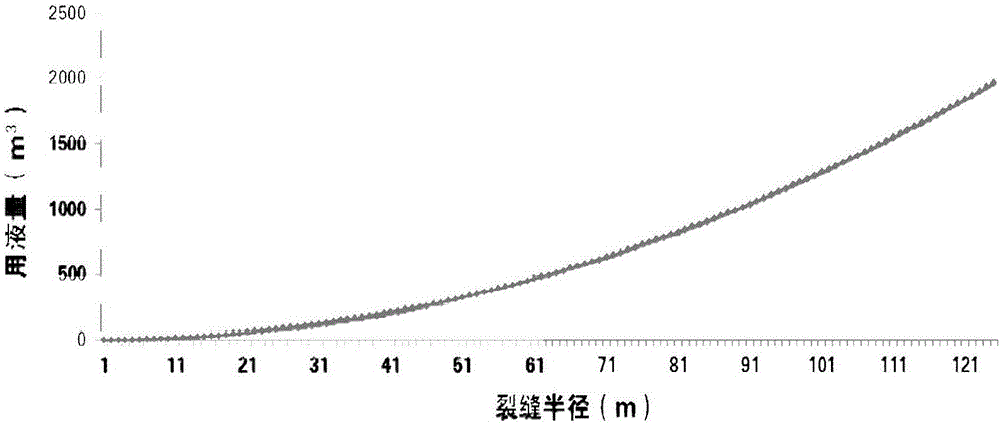

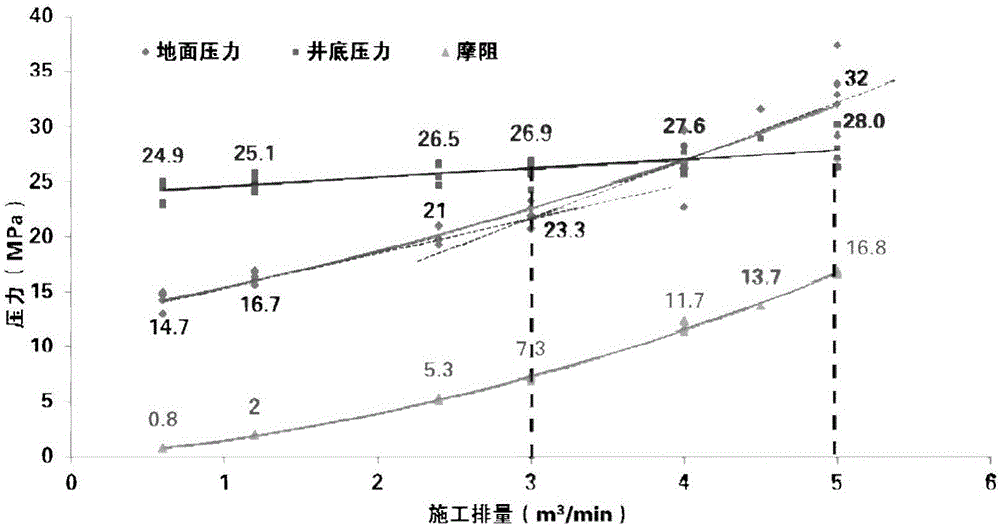

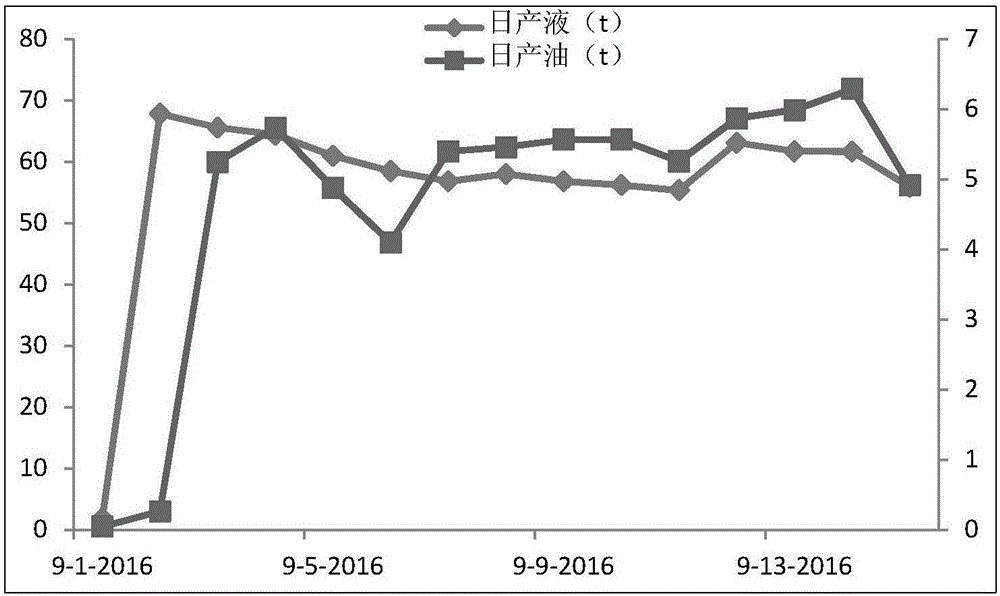

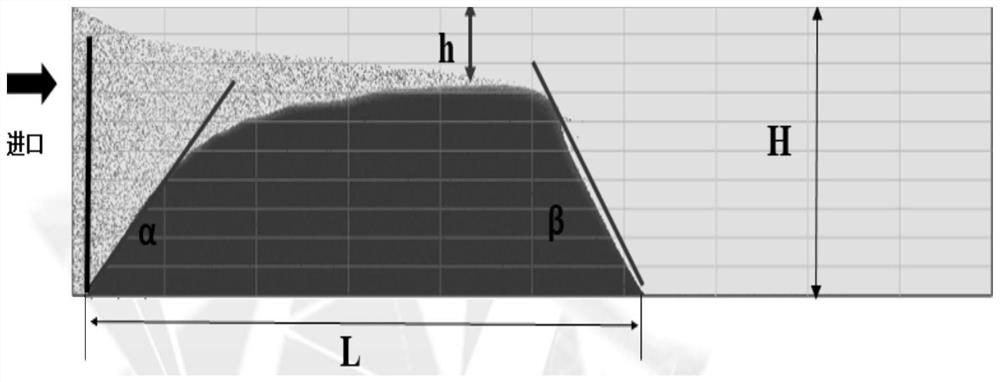

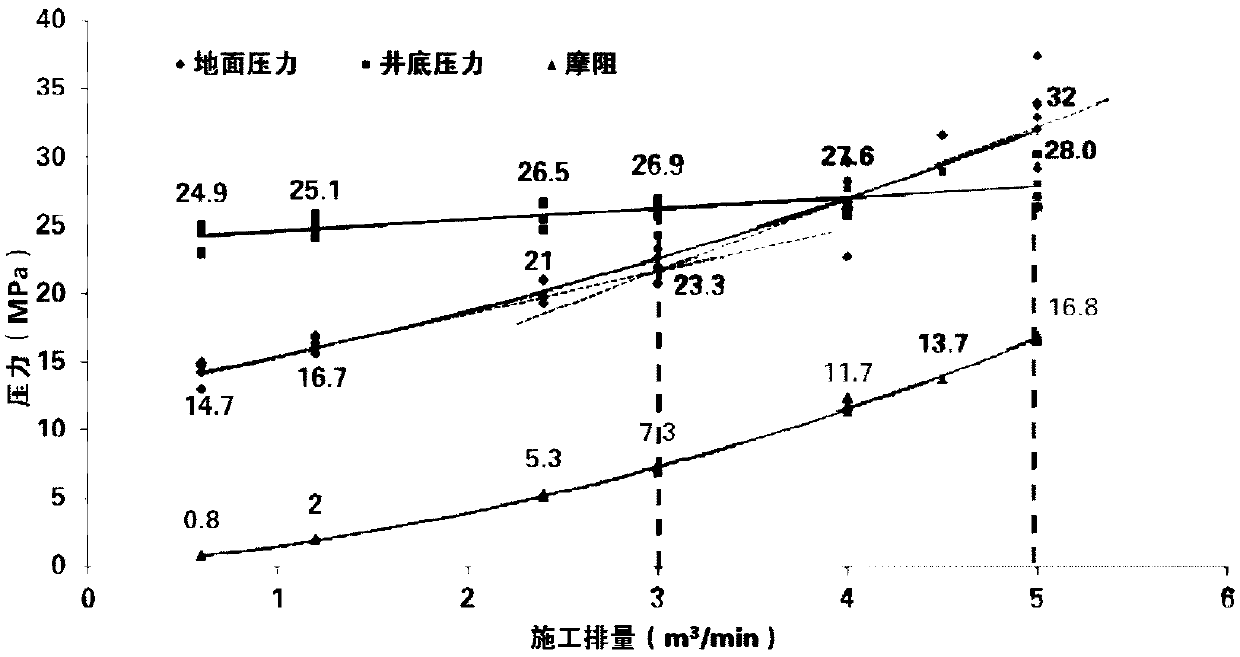

The invention relates to a method for injecting oil displacing agent into an oil reservoir to improve oil recovery by using fracturing. The method for injecting the oil displacing agent into the oil reservoir to improving oil recovery by using fracturing mainly solves the problems of large viscosity loss and low injection efficiency during the injection process of the existing three kinds of oil reservoir oil displacement agents. The method for injecting the oil displacing agent into oil reservoir to improving oil recovery by using fracturing is characterized in that (1) dividing a target stratum to the well fracturing section; (2) determining a half fracture length for the well fracturing section of the target stratum; (3) determining the oil displacement agent dosage for the well fracturing section of the target stratum; (4) determining a construction displacement the well fracturing section; (5) determining construction procedure of a pumping injection; and (6) mixing and injecting the oil displacement agent. The method for injecting the oil displacing agent into oil reservoir to improving oil recovery by using fracturing can greatly improve the injection efficiency and reduce the displacement efficiency loss, thus greatly improve the recovery efficiency and single well production.

Owner:PETROCHINA CO LTD +1

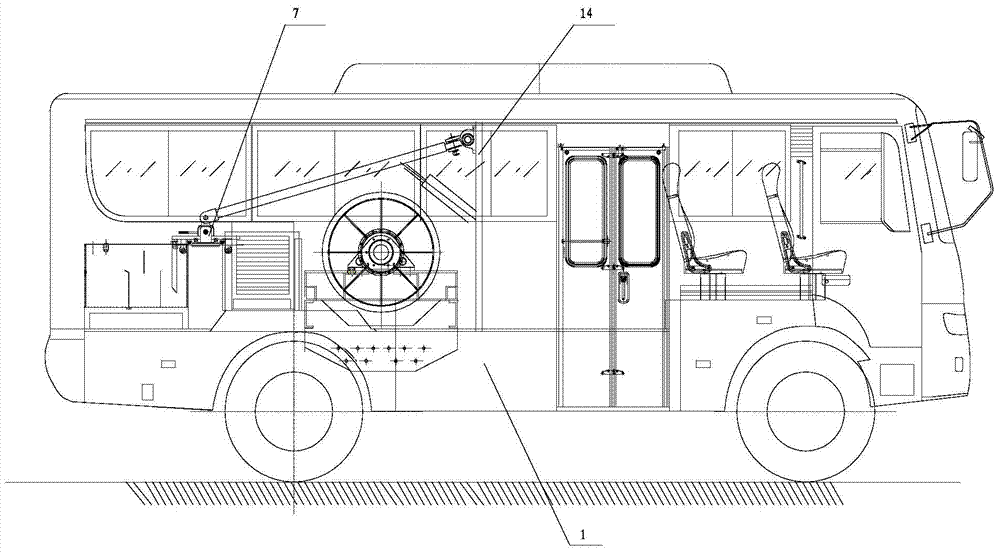

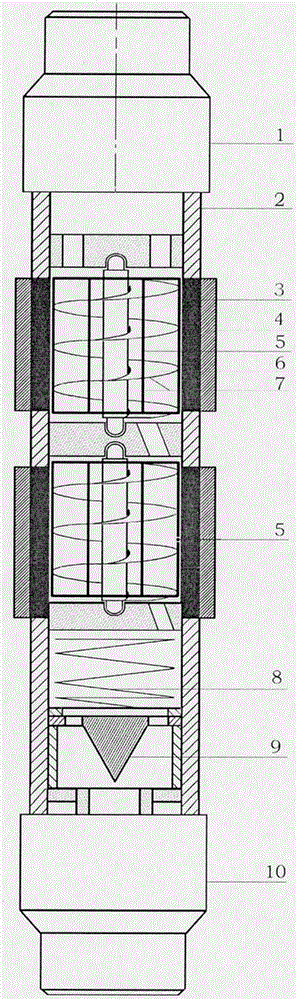

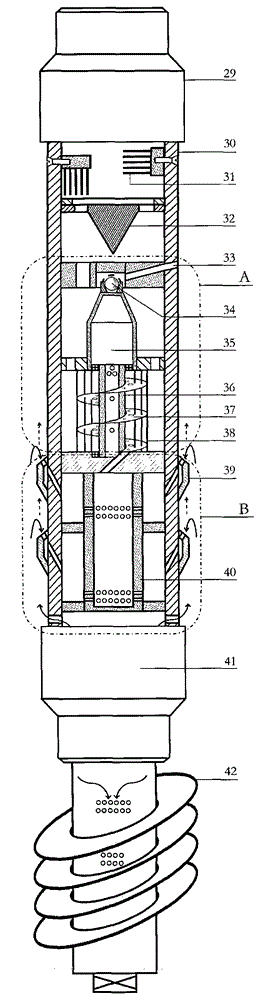

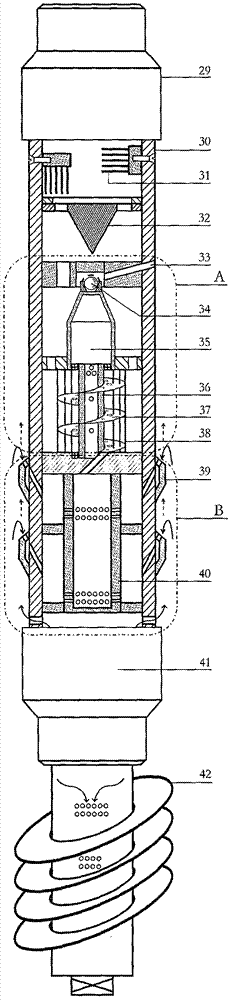

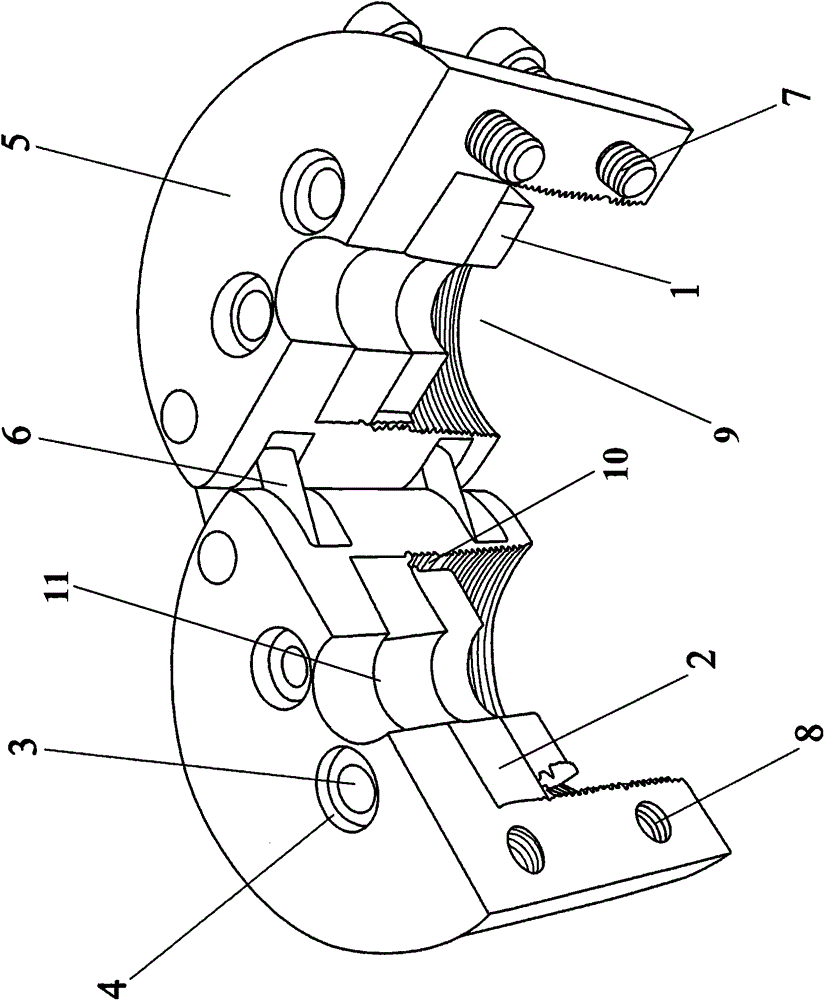

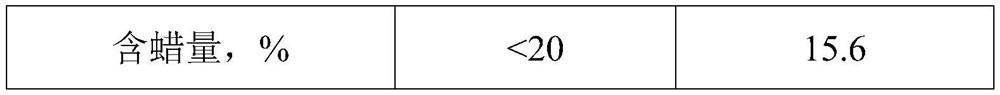

Ultrasonic blockage removal technology and blockage removal device

InactiveCN104712292AEffective pollutionEffectively decontaminateCleaning apparatusConvertersEngineering

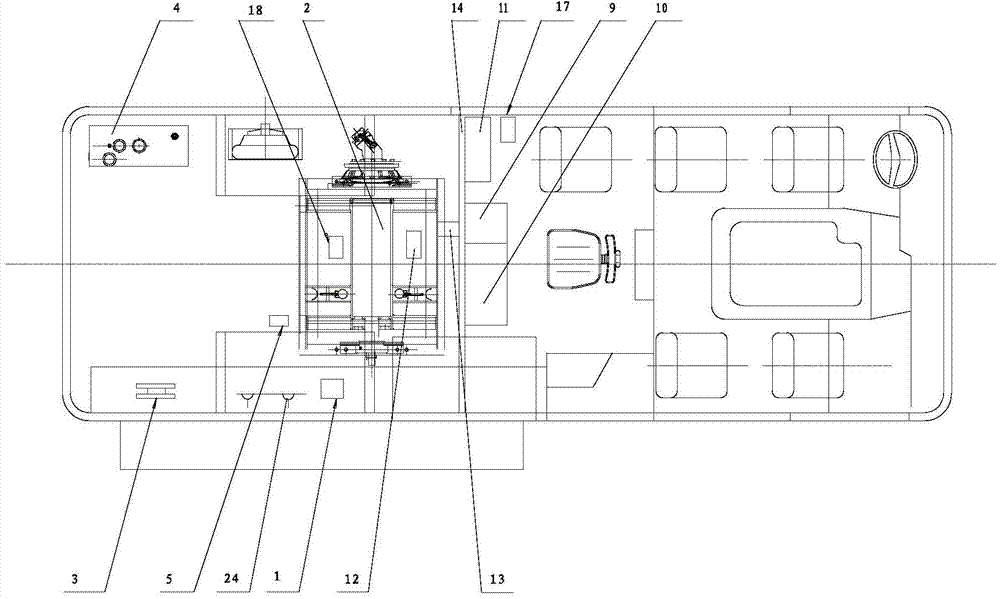

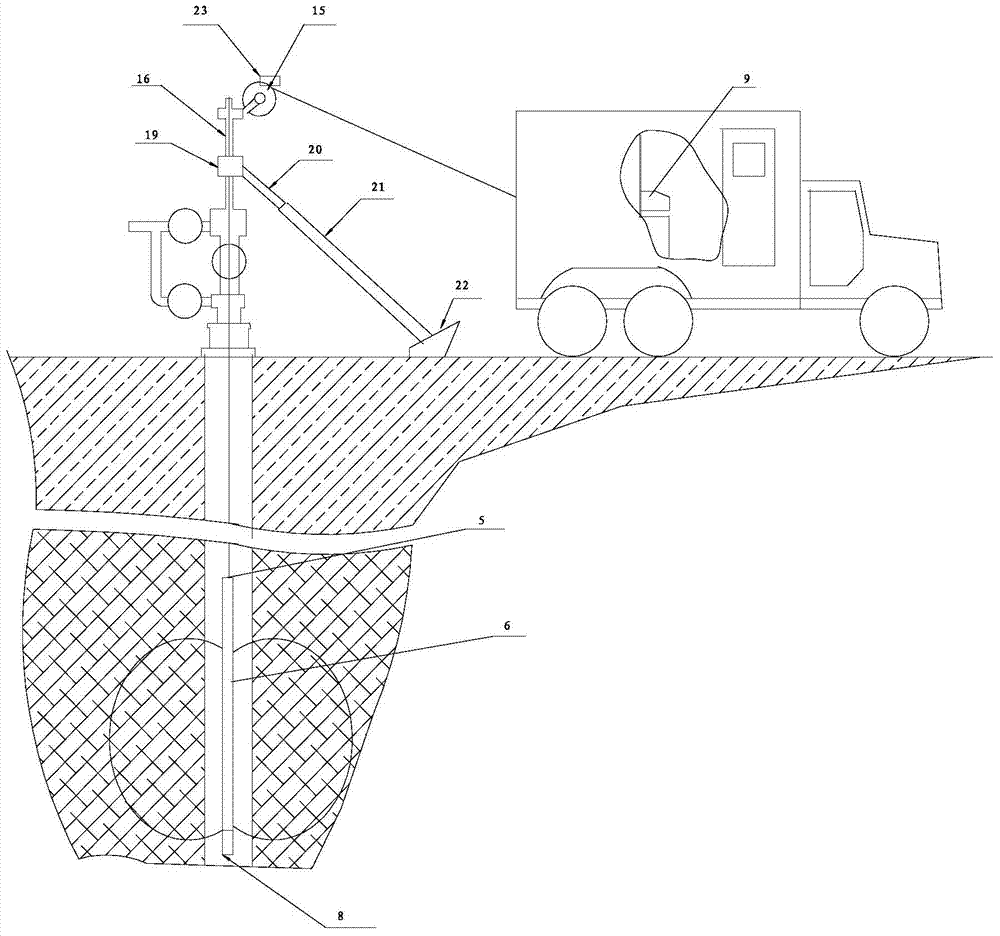

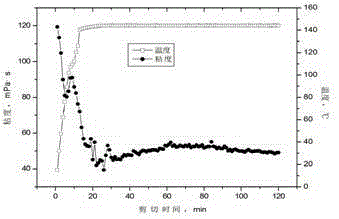

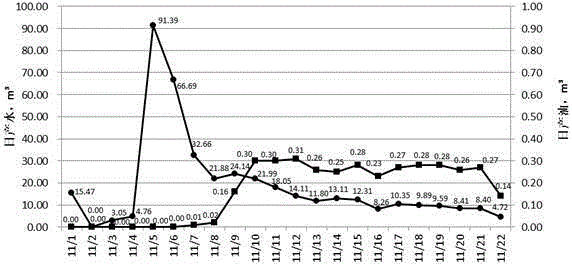

The invention relates to an ultrasonic blockage removal technology and a blockage removal device which are used for clearing blockages formed in an oil well during oil extraction. The device is mainly composed of a well testing truck, a transmission cable, a high-power ultrasonic electric signal transmitter and an ultrasonic electro-acoustic transducer. High-power pulse electric oscillation signals generated by the vehicle-mounted high-power ultrasonic transmitter on the ground are transmitted to the piezoelectric ceramic electro-acoustic transducer on an oil layer through the special transmission cable, then converted into ultrasonic waves through the electro-acoustic transducer, and injected into an oil bearing formation, so that the physical property and flow state of fluid in the oil layer are changed, the circulating condition and permeability of the bottom of the well and a near-well oil layer are improved, blockages are removed, scale prevention and removal are achieved, paraffin control is achieved, oil production capacity is improved, the viscosity of crude oil is reduced, and then permeability and recovery efficiency can be improved, injection rate is increased, and injection allocation is achieved.

Owner:牛连江

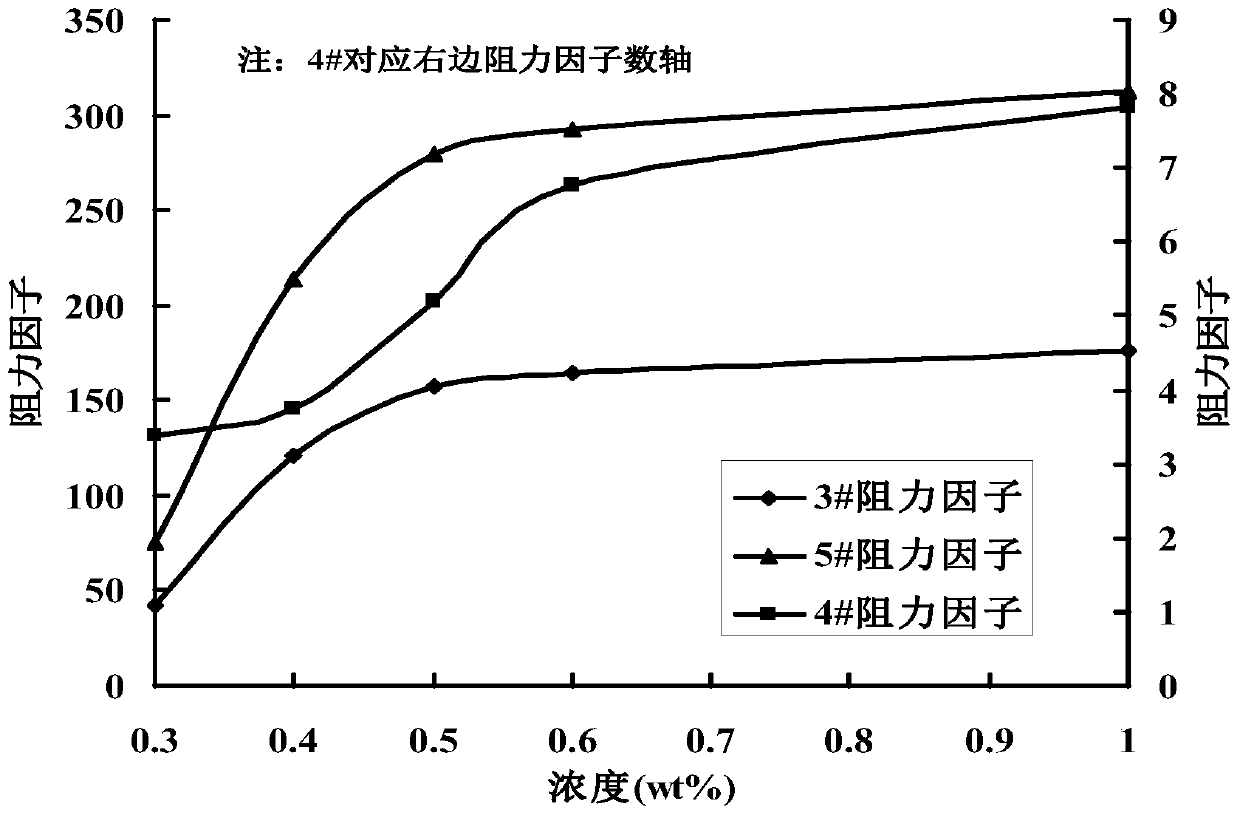

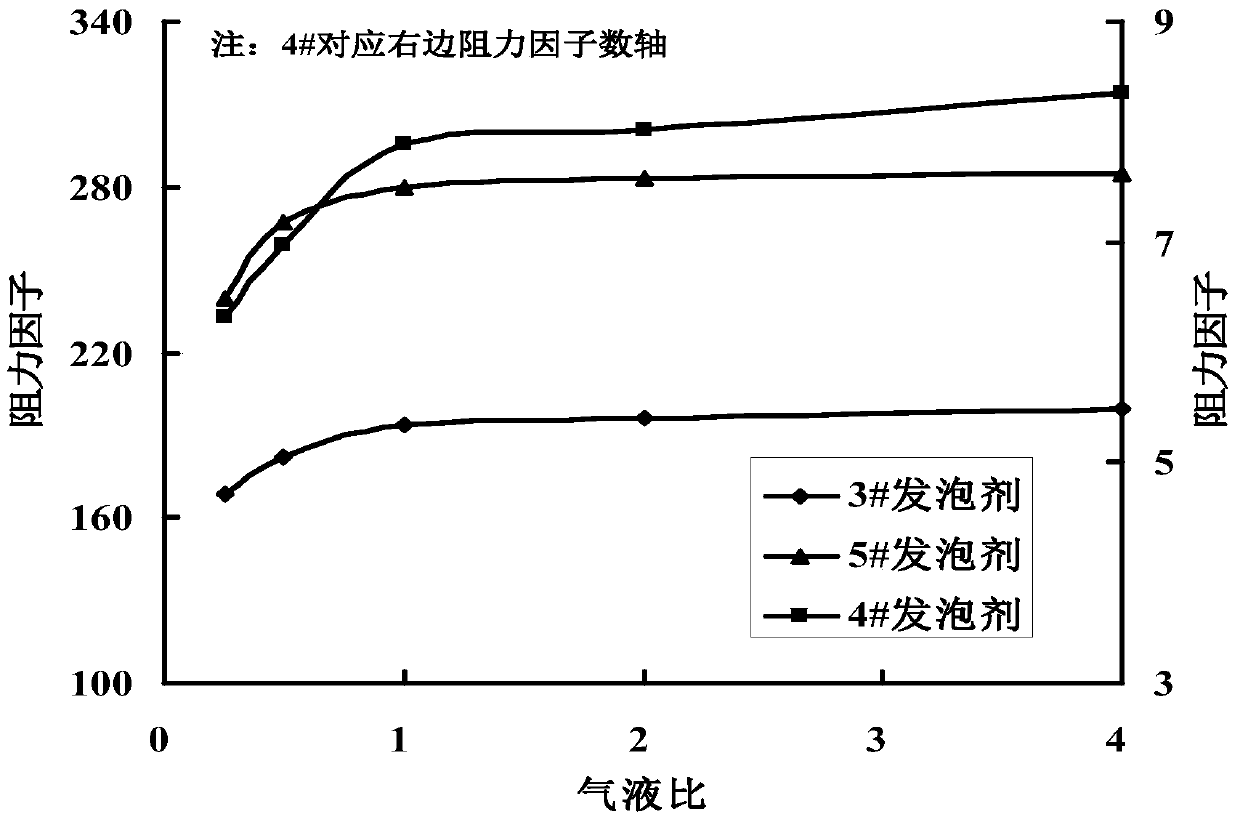

Foamed gel blocking agent for blocking gas coning and construction method of foamed gel blocking agent

InactiveCN108219761ALow densityImprove high temperature resistanceFluid removalDrilling compositionBetaineGas phase

The invention discloses a foamed gel blocking agent for blocking gas coning and a construction method of the foamed gel blocking agent and belongs to the technical field of oil exploitation. The foamed gel blocking agent is prepared from a liquid-phase component and a gas-phase component through mixing and foaming, wherein the liquid-phase component comprises the following components in percentageby mass: 5.5-6.5% of xanthan gum with the relative molecular weight of 1*10<6>-5*10<6>, 0.2-0.3% of hydrated polyacrylamide with the molecular weight of 9-12 million, 0.2-0.25% of a phenolic resin cross-linking agent, 0.5-0.8% of an alkyl glycine betaine surfactant, 0.5-0.6% of a dodecyl dimethyl amino oxide foam stabilizer and the balance of water. The foamed gel blocking agent is small in density, can be accumulated into a high-angle crack to infiltrate into the top of a bottom water reservoir, is capable of retarding advancing of an oil-water interface, improving the percolating resistanceof a permeable layer, inhibiting gas channeling, and meanwhile increasing waves and sizes of displacing mediums to less permeable layers.

Owner:PETROCHINA CO LTD

Multifunctional thickened oil treating agent and preparation method thereof

InactiveCN106190079AReduce interfacial tensionStrong salt toleranceDrilling compositionVitamin CCocamidopropyl dimethylamine

The invention discloses a multifunctional thickened oil treating agent and a preparation method thereof. The treating agent is prepared from, by weight, 15.35%-17.65% of octanol polyoxyethylene ether, 13.37%-15.54% of lauroyl diethanolamide, 12.66%-15.74% of sodium dodecyl benzene sulfonate, 21.53%-24.57% of odium nonylphenol polyoxyethylene ether sulfate, 8.62%-11.87% of fatty acid methyl ester ethoxylate sodium sulfonate, 0.005%-0.006% of cocamidopropyl betaine, 0.005%-0.006% of cocamidopropyl dimethylamine oxide, 10.00%-15.00% of n-butyl alcohol, 0.001%-0.002% of vitamin A, 0.001%-0.002% of vitamin C and 6.566%-9.037% of water. The multifunctional thickened oil treating agent is an active agent product developed on the basis of tertiary oil recovery and used for increasing the recovery efficiency of an oil field, and the agent is a chemical assistant integrating oil well profile control and displacement, viscosity reduction and coagulation reduction, oil well cleaning and plug removal, and is good in production increasing effect on thickened oil recovery; the advantages of being good in thickened oil recovery oil output increase effect and treatment performance and wide in application range are achieved, and the yield increasing and effect improving functions on multiple kinds of thickened oil and high-viscosity and hypercoagulable oil wells can be achieved by adjusting the formula.

Owner:上海亚润能源技术有限公司

Multi-round polymer gel deep fine profile control method

ActiveCN105298438AChange or increase invasivenessImprove wettabilityFluid removalSealing/packingHigh water contentINCREASED EFFECT

The invention discloses a multi-round polymer gel deep fine profile control method. According to the method, slugs having different functions are injected in multiple rounds, so that deep profile control can be realized. According to the functions of the slugs in deep profile control, the slugs are classified into four types: the I slug which is a gel flow-guiding agent capable of guiding gel and makes preparations to make the gel enter the stratum; the II slug which is the weak gel for assisting the blocking, effectively connects the gel flow-guiding agent and medium and strong gel, and guarantees that the fluid can effectively and continuously enter the stratum; the III slug which is the medium and strong gel used for medium and deep blocking; and the IV slug which is weak gel used for disturbing flows. During a using process, the I, II and III slugs are injected as required in the first round; the II and III slugs are repeatedly used in the second (third) round; the next injection round is performed after injection requirements are met according to pressure and working parameters; and the IV slug is injected in the last round. The method is more targeted as the slugs are finely injected in multiple rounds, a longer responding period is achieved, the water absorption status of a reservoir is effectively improved, the utilization rate of injected water is improved, the swept volume is enlarged, and finally the oil displacement efficiency is improved. The method has an obvious oil increasing effect, is simple and easy to carry out, is suitable for filed construction, and is especially suitable for wells which have multiple small layers to be explored, are large in interlayer difference, and have high water content; the profile control success rate can be improved to be 90%; the validity period can be prolonged by one year or two years; and the method has a wide popularization and application prospect.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

High-temperature microemulsion cleanup additive used for fracturing, and preparation method thereof

ActiveCN106244131AImprove surface activityHigh discharge rateDrilling compositionMass ratioFracturing fluid

The invention provides a high-temperature microemulsion cleanup additive used for fracturing, and a preparation method thereof. The preparation method comprises the following steps: 1, adding 10-20 parts by mass of water into a reactor, adding 40-60 parts by mass of a cosurfactant to water, and stirring the cosurfactant and water at room temperature until the cosurfactant is completely dissolved; and 2, sequentially adding 20-40 parts by mass of a gemini surfactant and 3-4 parts by mass of a nonionic surfactant into the reactor, supplementing water to the reactor until the mass part number of a mixture obtained in the reactor is 100, and uniformly stirring the mixture at room temperature to obtain the high-temperature microemulsion cleanup additive. The high-temperature microemulsion cleanup additive is directly added to a fracturing fluid or an acidifying liquid according to a mass ratio of 0.1-0.3:100 when used.

Owner:CHINA PETROLEUM & CHEM CORP +1

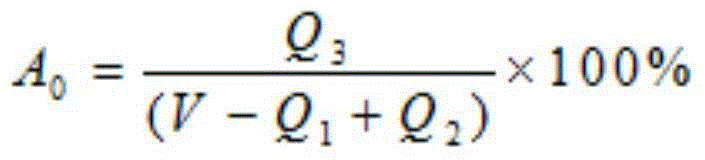

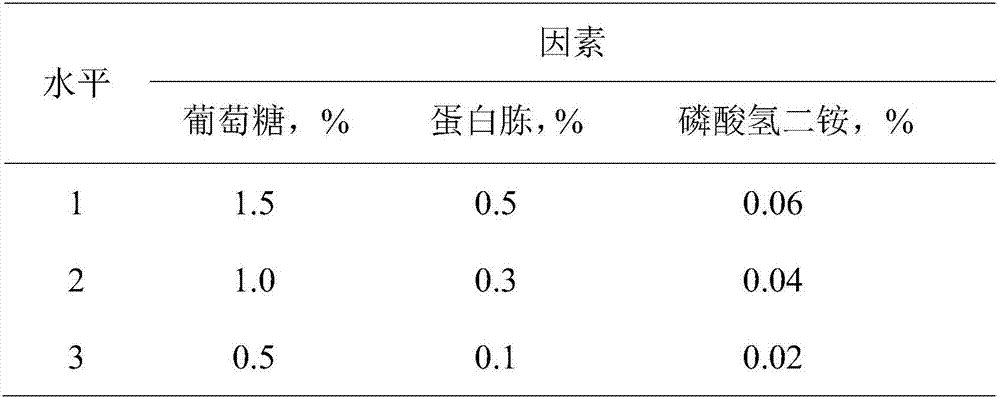

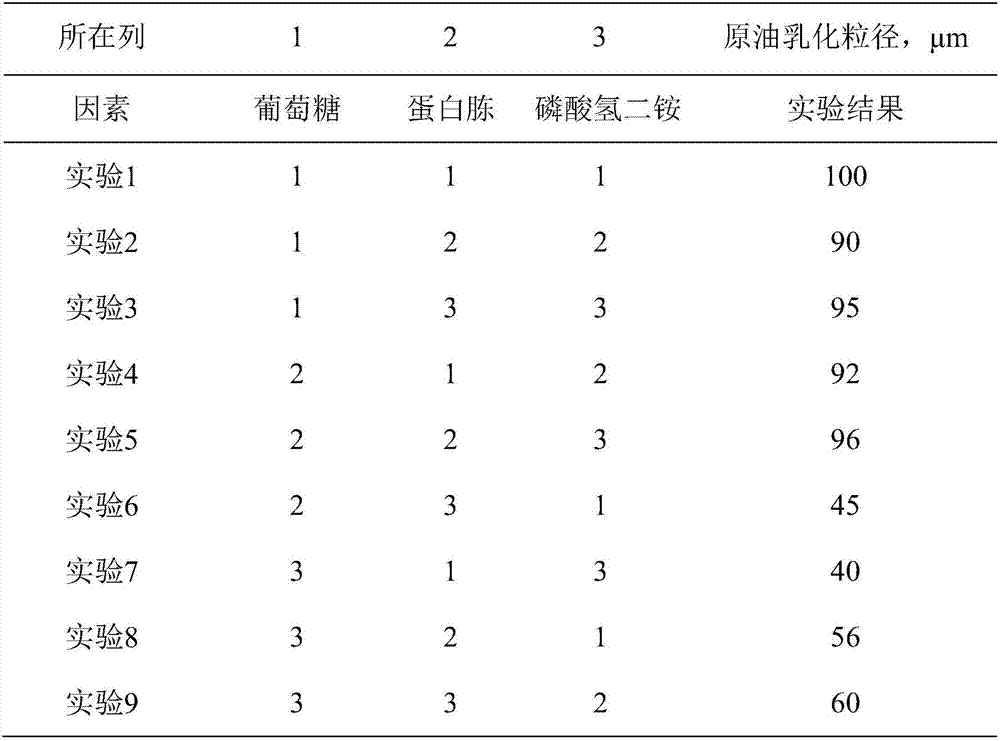

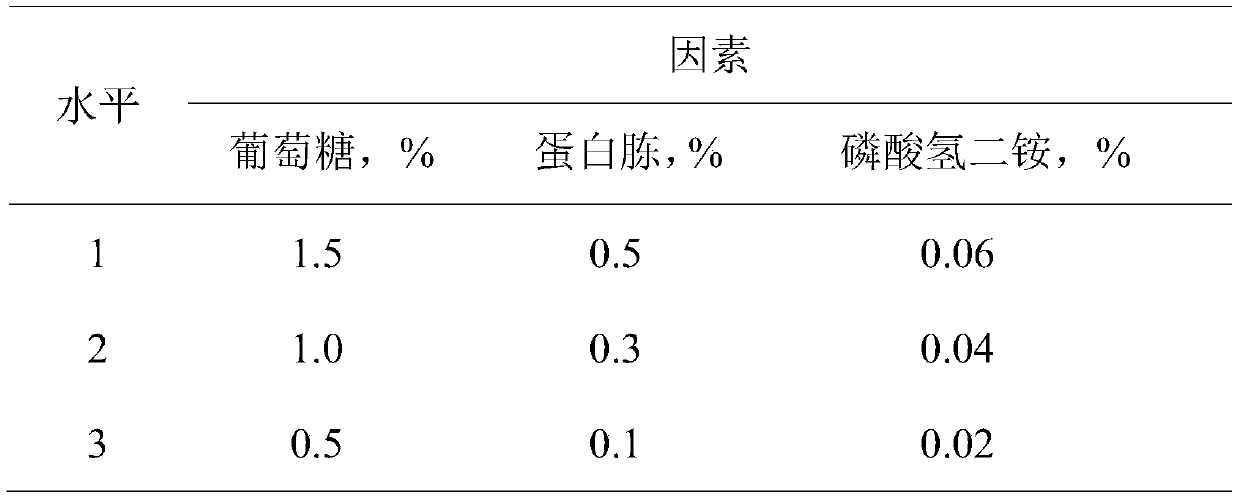

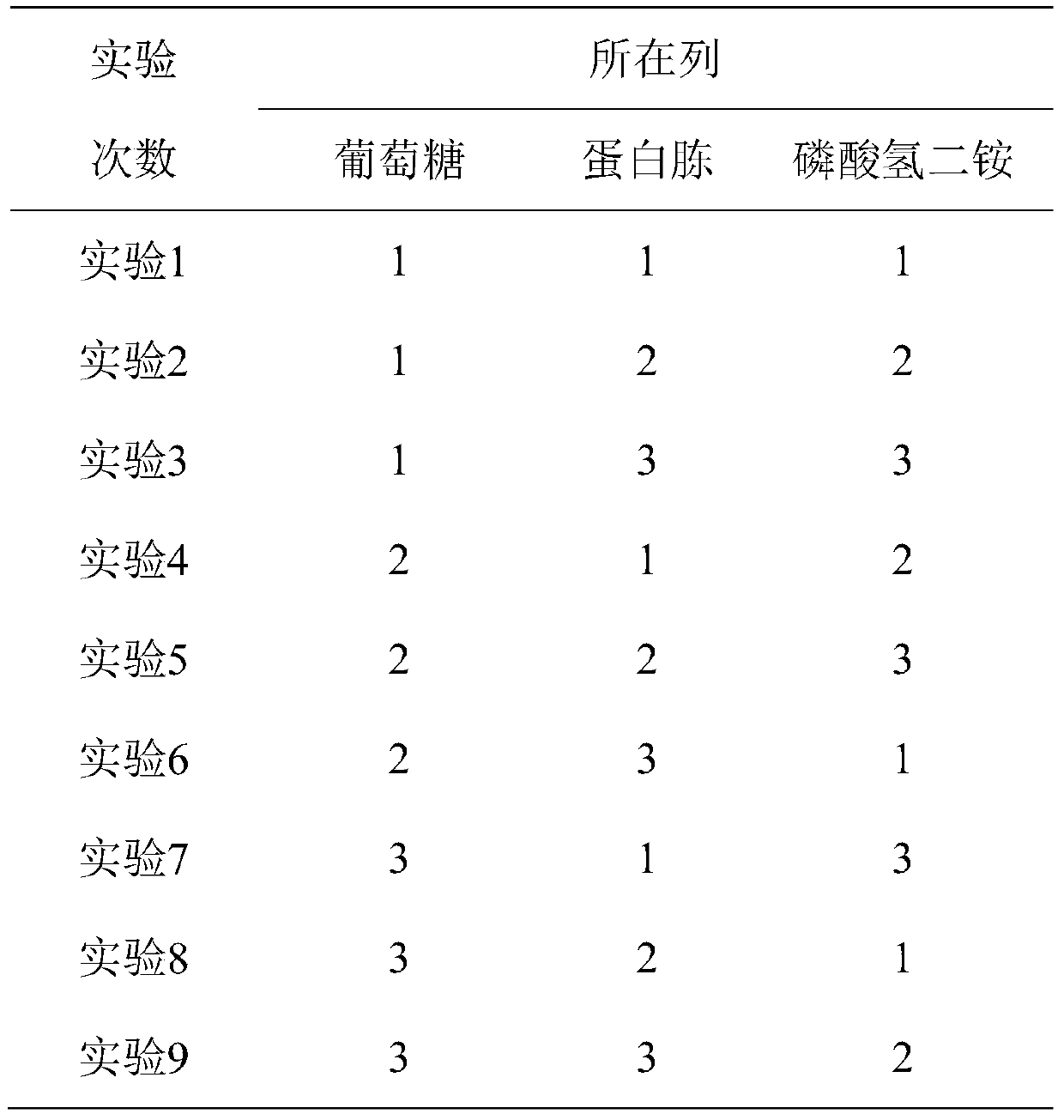

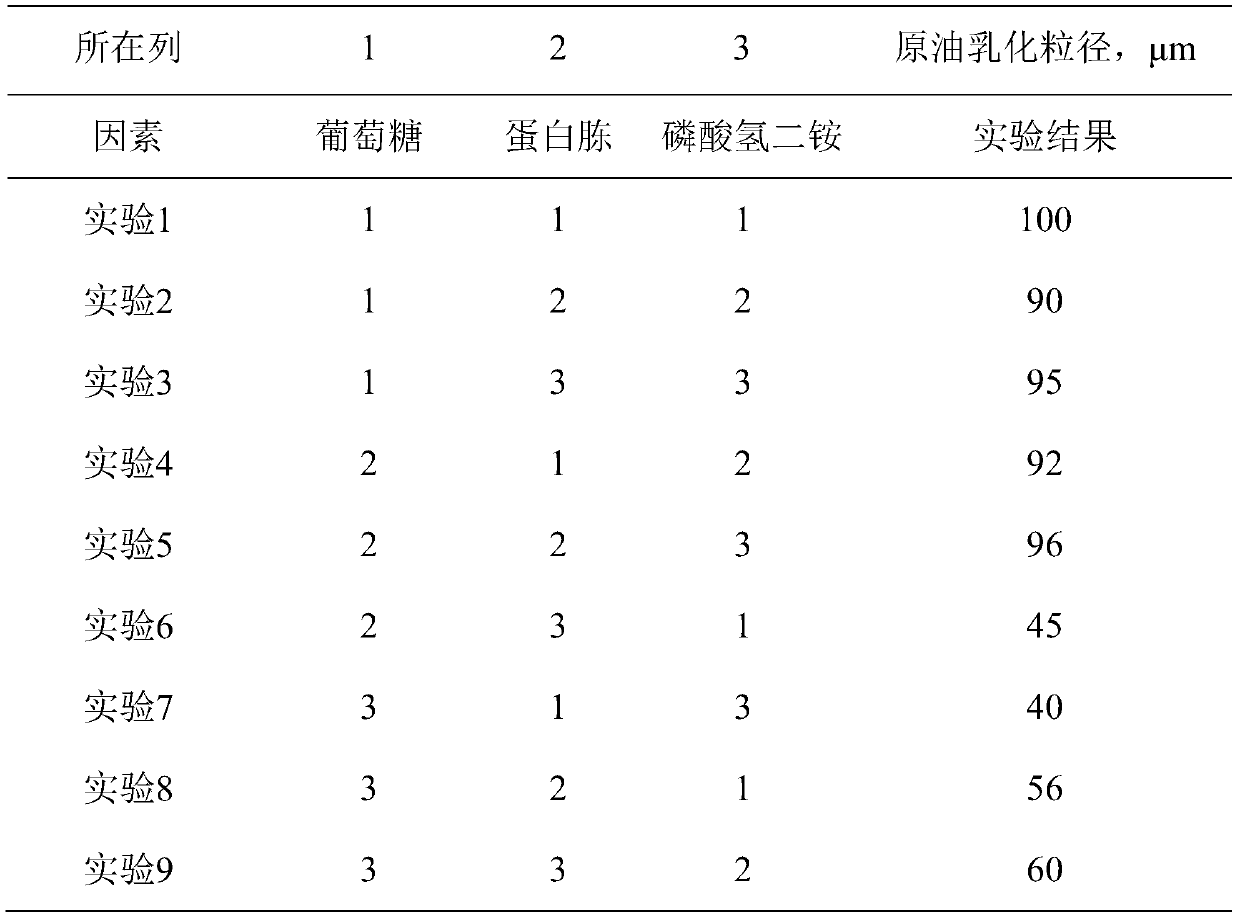

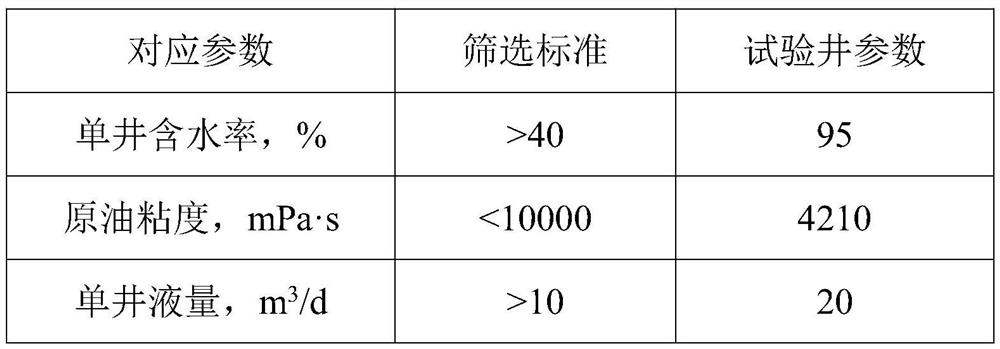

Oil well water plugging method adopting emulsifying agent generated by activating oil reservoir microorganisms

The invention belongs to the technical field of oil and gas field development and particularly relates to an oil well water plugging method adopting an emulsifying agent generated by activating oil reservoir microorganisms. The oil well water plugging method specifically comprises the following steps of screening of a test oil well, preliminary screening of an activating agent, determining of the activating agent, determining of the water plugging radius, determining of the injection rate of the activating agent and conducting of a field test and evaluating of a field test result. The oil well water plugging method adopting the emulsifying agent generated by activating the oil reservoir microorganisms has the characteristics of being simple in technology and high in pertinence and operability, and field application and popularization are facilitated; the validity period of the field test is long, the oil increasing effect is good, the input-output ratio is high, the validity period is longer than 12 months, the average daily oil increasing amount of a single well is larger than 5 t, and the input-output ratio is larger than 1:5. Thus, the oil well water plugging method adopting the emulsifying agent generated by activating the oil reservoir microorganisms can be widely applied to an oil well water plugging technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

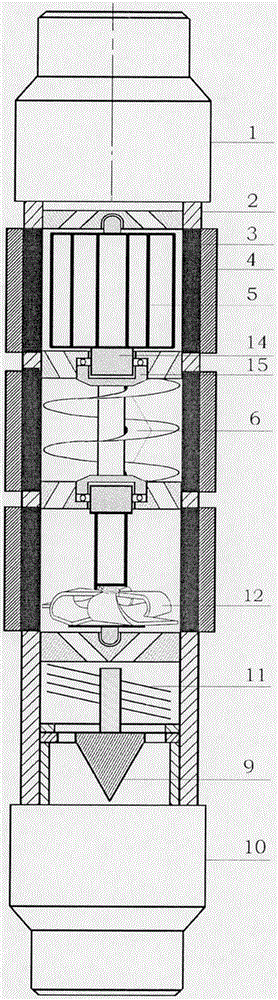

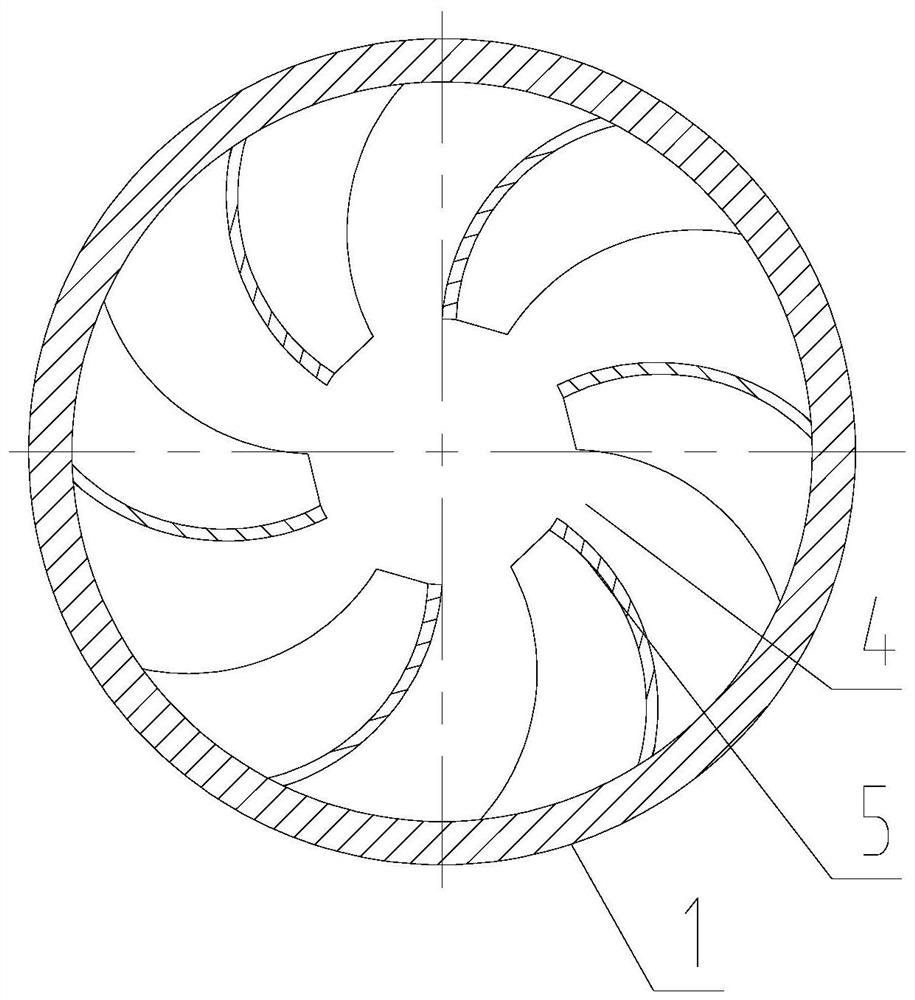

Strong magnetic swirl self-generating vacuum superconducting four-effect wax-proof and viscosity-reducing device

InactiveCN104033127BReduce resistanceSave development investmentCleaning apparatusInsulationWaxCyclone

The invention is a strong magnetic swirling self-generating vacuum superconducting four-effect wax-preventing and viscosity-reducing device, which belongs to the new field of electromagnetic application and vacuum superconducting heat transfer technology. The device includes a single-stage or multi-stage high-frequency pulse hydraulic oscillation wax anti-viscosity reducer connected in series from bottom to top with threads, a strong magnetic swirl self-generating device, and an upper variable button joint connected to the oil well pump on the upper part of the device and The lower part of the device is connected with the tailpipe. The connection positions of the above devices can be randomly combined and interchanged. The number of assembly stages can be adjusted according to the heating requirements. The oblique jet holes that are conducive to the formation of spiral swirl are arranged between the stages. connected. Compared with the existing anti-wax viscosity reduction device, the device has high-frequency pulse hydraulic oscillation anti-wax viscosity reduction, strong magnetic magnetization anti-wax viscosity reduction, strong magnetic swirl self-power generation anti-wax viscosity reduction, vacuum superconducting high-efficiency heat transfer anti-wax reduction Viscosity has multiple functions, can greatly reduce oil flow resistance, and has obvious oil-increasing effect. It is a long-term long-term device for viscous oil development with less investment in viscous oil development, long service life, simple and convenient construction, and is suitable for large-scale promotion and application.

Owner:王颖

Temperature control liquid expanded rubber and preparation method thereof

InactiveCN101314671AOil increasing effect is obviousGood precipitation effectDrilling compositionSolventToluene diisocyanate

The invention discloses a temperature-controlled liquid swellable rubber, which contains (by weight), polyether glycol 30 to 60 percent, toluene diisocyanate 5 to 40 percent, unsaturated resin 2 to 30 percent, phenol-formaldehyde resin 2 to 30 percent, natural rubber 2 to 20 percent, catalyst 0.01 to 3 percent, reaction temperature controlling agent 5 to 40 percent, solvent 2 to 30 percent, plasticizer 2 to 10 percent, thermal stabilizer 0.5 to 2 percent, and foam regulator 0.5 to 2 percent. The preparation method comprises the following steps: adding polyether glycol into a reaction kettle at the weight percentage of 30 to 60 percent, heating to 120 DEG C, dehydrating for 30 min, cooling to 45 DEG C, adding toluene diisocyanate 5 to 40 percent, heating to 80 DEG C to 95 DEG C, keeping the temperature for 1.5 to 4 hr, cooling to 45 DEG C, adding the solvent 2 to 30 percent, adding reaction temperature controlling agent 5 to 40 percent and catalyst 0.01 to 3 percent into the reaction kettle, heating to a reaction control temperature 60 to 95 DEG C, keeping the temperature for 4 to 8hr, cooling to 45 DEG C, adding the plasticizer 2 to 10 percent, unsaturated resin 2 to 30 percent, phenol-formaldehyde resin 2 to 30 percent, natural rubber 2 to 20 percent, thermal stabilizer 0.5 to 2 percent, and foam regulator 0.5 to 2 percent, stirring for 0.5 to 1 hr, discharging, and packaging to obtain the product.

Owner:天津新技术产业园区北洋新技术工程有限公司

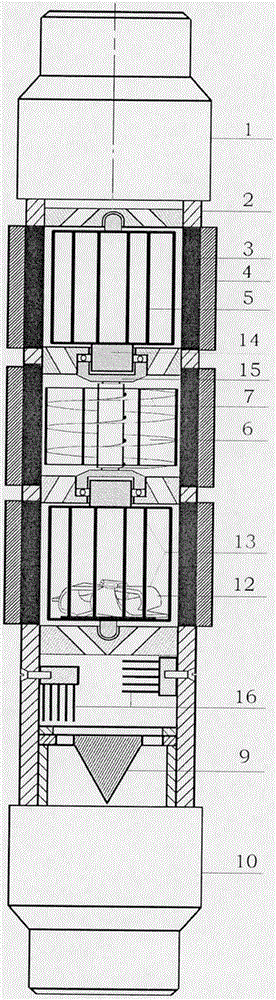

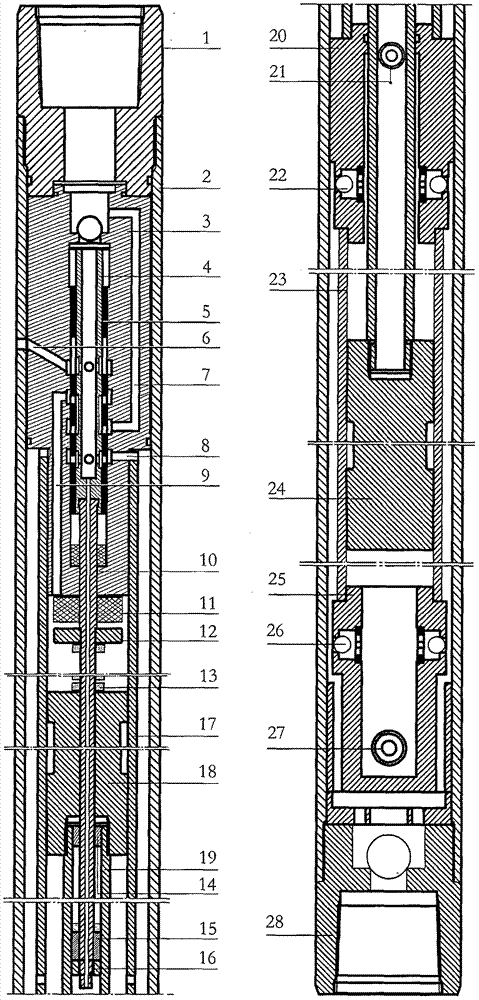

Organic six-prevention-effect rodless hydraulic driving double-action reciprocating pump

InactiveCN105089995AGood anti-aging lifeReduce coefficient of frictionPositive displacement pump componentsFlexible member pumpsHydraulic cylinderWax

The invention relates to an organic six-prevention-effect rodless hydraulic driving double-action reciprocating pump integrating corrosion prevention, scale prevention, wax prevention, viscosity prevention, gas prevention and sand prevention, and belongs to the new field of a mechanical oil production technology. The reciprocating pump consists of organic components of a reversing valve assembly, a hydraulic cylinder assembly and a liquid discharging cylinder assembly wich are connected in series by an upper male and female buckle joint, a lower joint and a fixed valve integral valve from top to bottom, wherein a sand removing and gas prevention device is selectively arranged under the lower joint and the fixed valve integral valve; and the hydraulic cylinder assembly and the liquid discharging cylinder can be connected in series and optimally combined into a single-driving single-discharging or single-driving multi-discharging or multi-driving single-discharging or multi-driving and multi-discharging hydraulic driving and discharging device according to different well depths, pressure and liquid discharging requirements. The pump has the obvious oil increase effect and various efficiencies including corrosion prevention, scale prevention, wax prevention, viscosity prevention, gas prevention and sand prevention, and is suitable for being popularized and applied in scales.

Owner:王颖

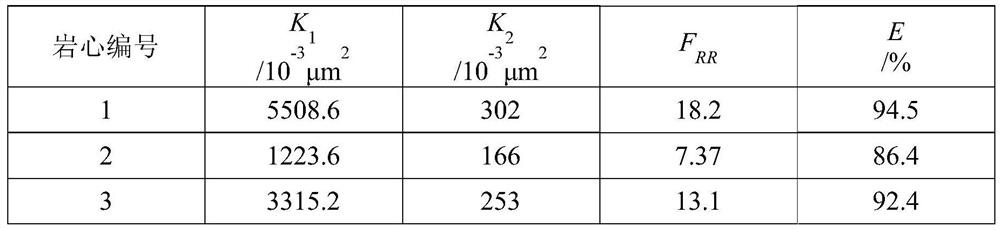

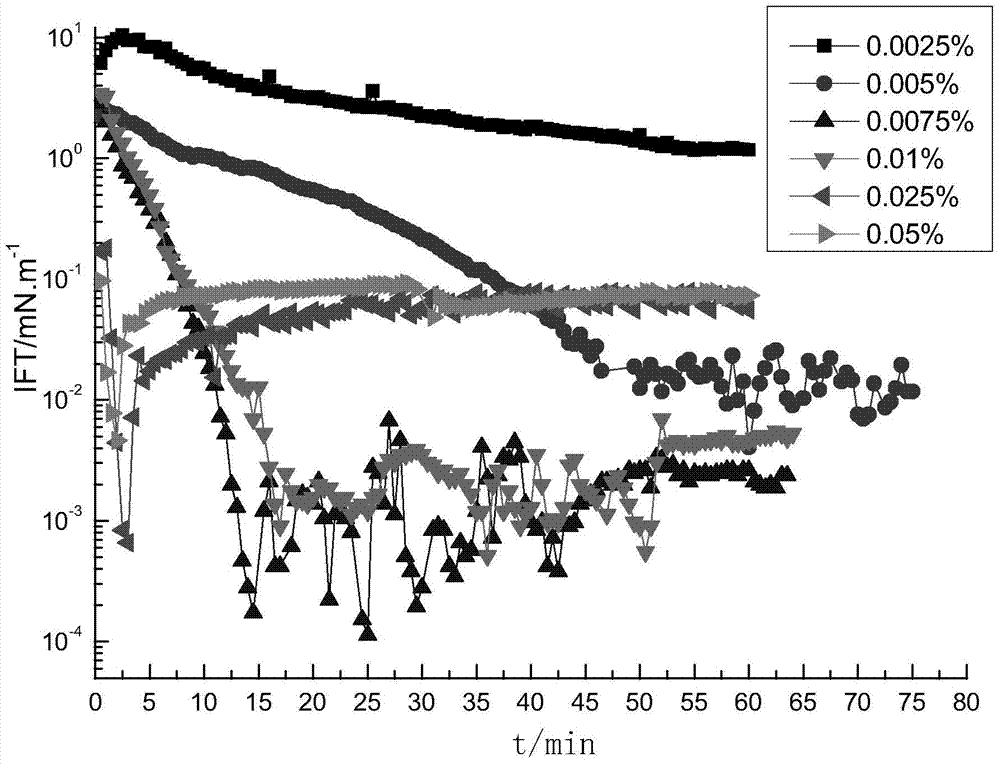

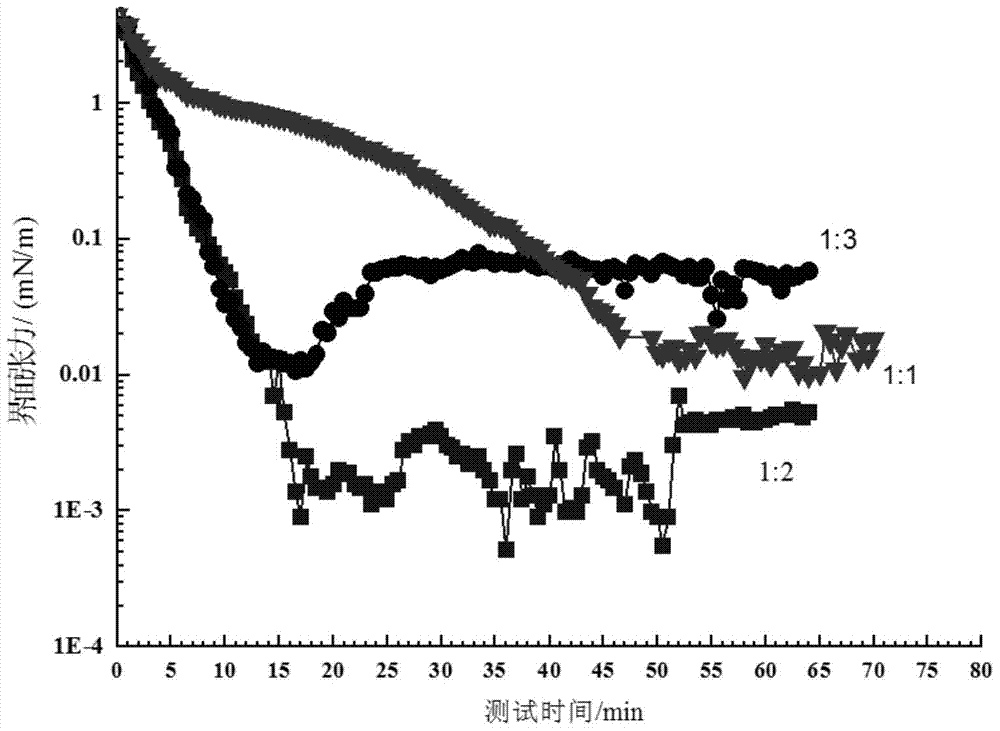

Crude oil surface active agent as well as preparation method and application thereof

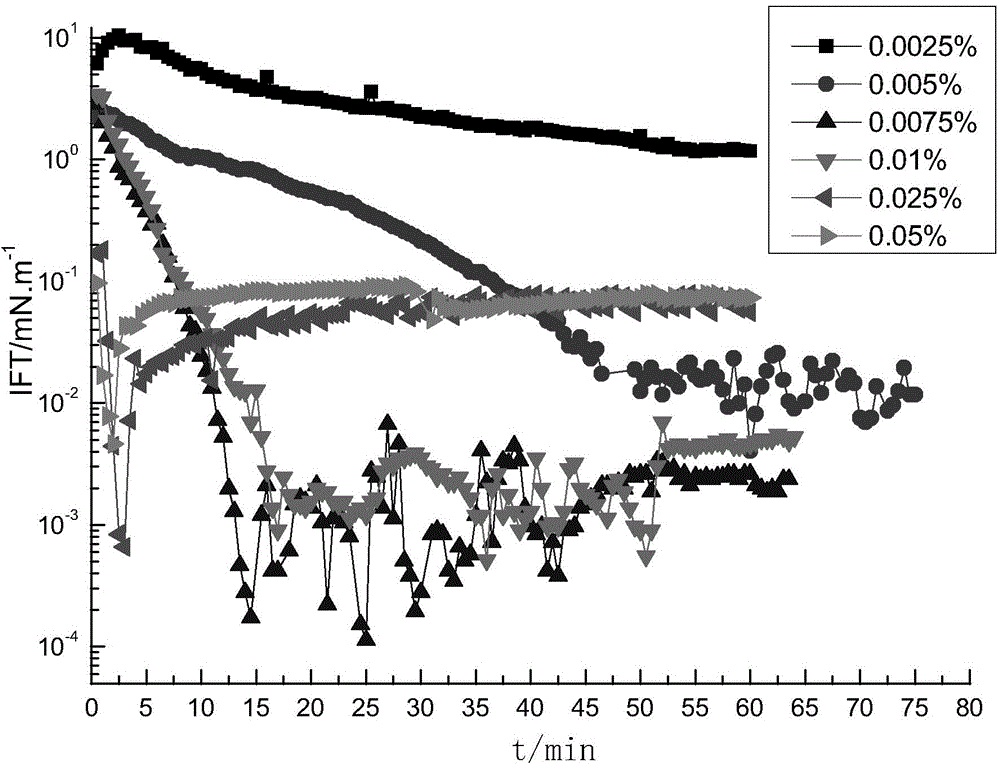

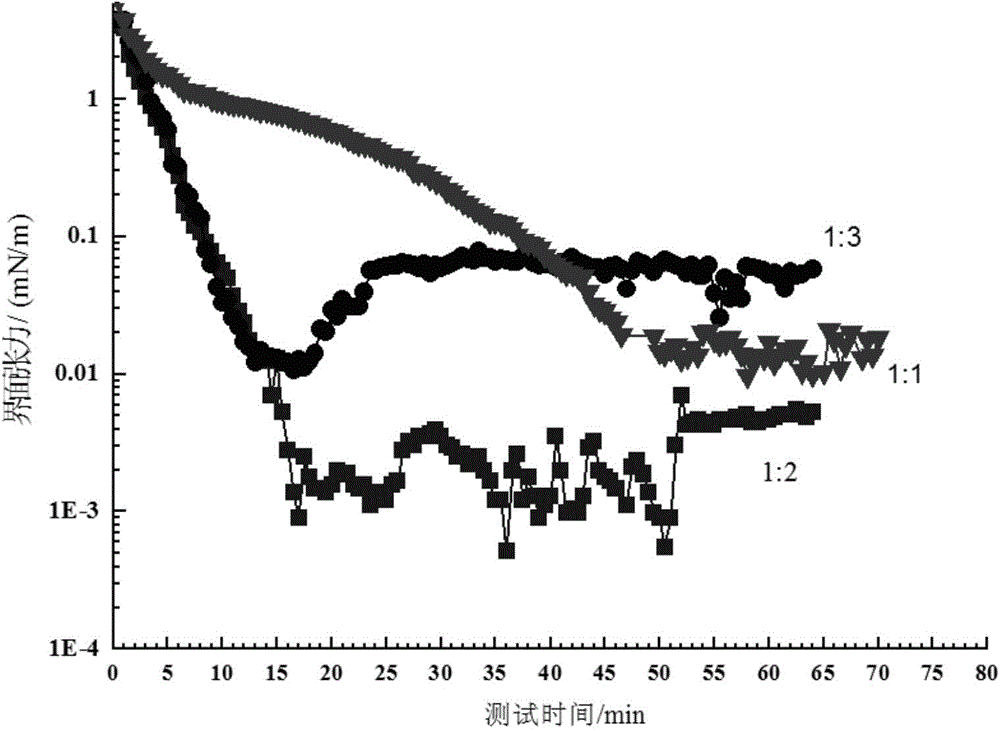

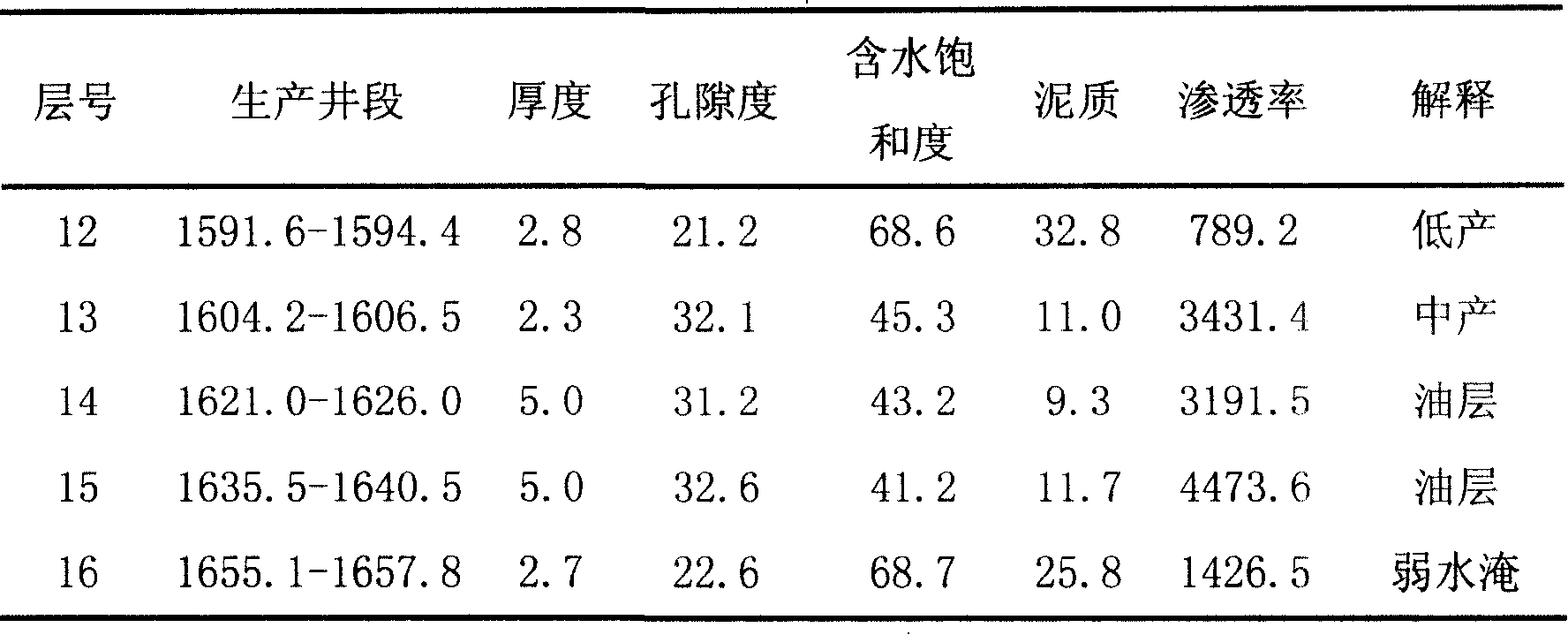

ActiveCN104449633ADecrease work of adhesionReduce manufacturing costDrilling compositionBetaineAlkali free

The invention relates to a crude oil surface active agent as well as a preparation method and an application thereof. The crude oil surface active agent comprises the following components in percentage by weight under an alkali-free condition: 1%-2% of fatty acid diethanol amide, 5%-10% of polyoxyethylene fatty acid amide, 10%-20% of heptadecyl dimethyl betaine and the balance of water, wherein the compounding weight ratio of the polyoxyethylene fatty acid amide to the heptadecyl dimethyl betaine is 1:2. A surface active agent compound system can form the ultra-low interfacial tension of 10<-3>-10<-4> mN / m with stratum dewatered crude oil at 45 DEG C when the use concentration is 0.0075%-0.01% under the alkali-free condition. In addition, the surface active agent compound system is less influenced by stratum water salinity, achieves the adsorption quantity on three oil sands of in the Liaohe oilfield Hainan less than 0.5 mg / g, is suitable for a mono-system flooding or binary system flooding technology adopted in the middle and later period of the waterflooding development of an oil deposit and provides certain technical support for the tertiary oil recovery of an oilfield.

Owner:PETROCHINA CO LTD

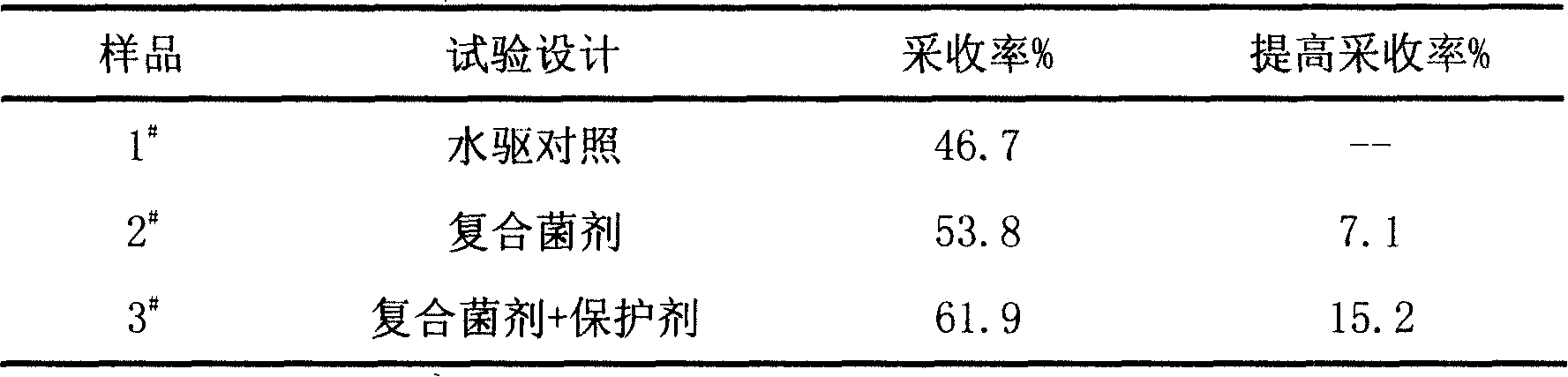

Microorganisms agent active protecting agent used for microorganism oil extraction of high-salinity oil well

InactiveCN101205460ALow costImprove resistance to mineralizationDrilling compositionMicroorganismInorganic salts

The invention relates to an inoculum active protectant used in a highly mineralized oil well in biological process for oil production, wherein inorganic salt containing K<+>, Na<+>, Mg<2+> and Mn<2+> is dissolved to form inorganic salt mixed solution. The invention has the advantages that: (1) the mixed solution which is formed through mixing the protectant with composite microbial inoculum is injected into the oil well, thereby not only improving the mineralization resistant capability of microorganism to ensure the normal growth of the composite microbial inoculum under highly mineralized conditions, but also having an action on crude oil to increase the recovery ratio of the crude oil; (2) the protectant has low cost and does not increase recovery cost when substantially increasing recovery ratio; (3) with the essential component being inorganic salts existing in nature, the protectant does not cause great influence on the environment when added in substrate; (4) the protectant can ensure effective development and utilization of national highly mineralized oil wells so as to obtain considerable economic benefit.

Owner:天津市工业微生物研究所有限公司

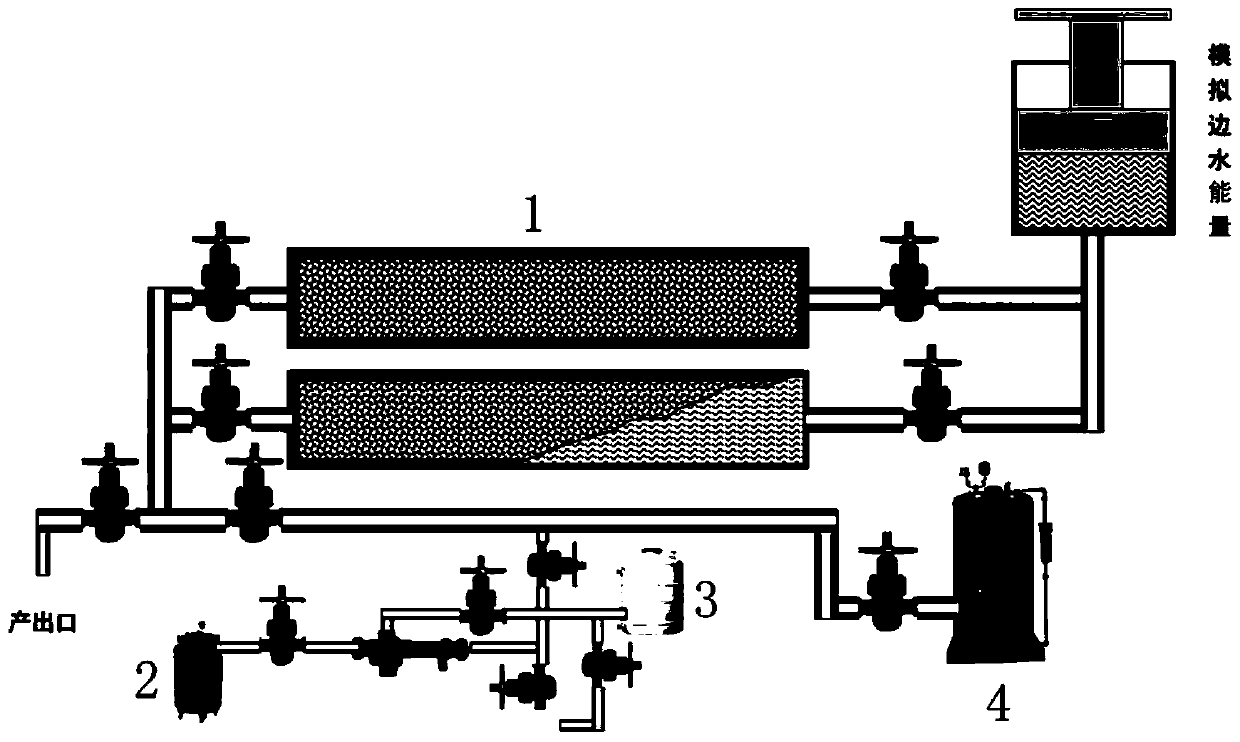

A kind of oil recovery method that nitrogen foam inhibits edge water propulsion in thermal recovery of heavy oil

ActiveCN105064962BAvoid high temperature degradationHigh efficiencyFluid removalOil productionChemistry

The invention discloses an oil recovery method for restraining thickened oil thermal recovery edge water propulsion by means of nitrogen foam. The oil recovery method comprises that 1) before steam is injected into an oil recovery well, and nitrogen is injected to form a preposed nitrogen section plug; 2) foaming liquid is injected into the oil recovery well, and the foaming liquid is contacted with the preposed nitrogen to foam; 3) nitrogen is injected into the oil recovery well to form a mid-arranged nitrogen section plug; and 4) steam is injected into the oil recovery well. In the oil recovery method for restraining thickened oil thermal recovery edge water propulsion by means of nitrogen foam, processes of preposing nitrogen section plug, injecting foaming agent, mid-arranging nitrogen section plug and injecting steam are carried out sequentially, the preposed nitrogen section plug pushes edge water to a deep part of the oil reservoir, the foaming liquid is fully contacted with the preposed nitrogen to foam the mid-arranged nitrogen section plug pushes the foaming agent to a deep part of the oil reservoir, and separates the foaming agent from high-temperature steam, and the foaming agent is prevented from being degraded at a high temperature. The oil recovery method is used for thickened oil field thermal recovery steam huff-puff wells, the propulsion of edge water can be effectively restrained, the spread range of steam is increased, the oil recovery efficiency is improved, and the oil recovery method is suitable for popularization and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

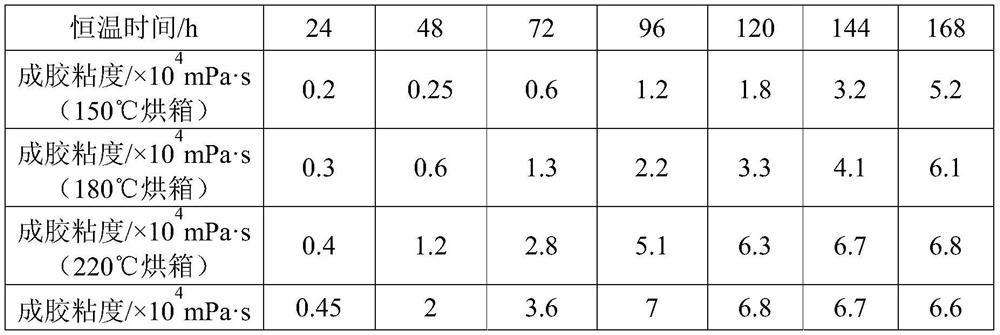

In-depth profile control channeling sealing agent and preparation method and application method thereof

ActiveCN113444506AThe validity period is adjustableHigh strengthDrilling compositionCelluloseThiourea

The invention provides an in-depth profile control channeling sealing agent and a preparation method and an application method thereof. The in-depth profile control channeling sealing agent is prepared from the following raw materials: potassium humate and / or sodium humate, polyanionic cellulose, urotropine, phenol, sodium tripolyphosphate, beta-cyclodextrine and / or a beta-cyclodextrine derivative, thiourea and / or a thiourea derivative and water. The invention also provides an application method of the in-depth profile control channeling sealing agent in a steam-drive oil reservoir channeling sealing measure, the method comprises the step of injecting the deep profile control channeling sealing agent into a stratum with the temperature of 80-290 DEG C, wherein the injection amount is more than 500m < 3 >. The in-depth profile control channeling sealing agent has good pumping performance and temperature resistance, long gelling time and high high-temperature plugging rate, and has an obvious oil increasing effect when being applied to profile control channeling sealing construction.

Owner:PETROCHINA CO LTD

A kind of crude oil surfactant and its preparation method and application

ActiveCN104449633BReduce interfacial tensionImprove oil washing efficiencyDrilling compositionBetaineAlkali free

The invention relates to a crude oil surface active agent as well as a preparation method and an application thereof. The crude oil surface active agent comprises the following components in percentage by weight under an alkali-free condition: 1%-2% of fatty acid diethanol amide, 5%-10% of polyoxyethylene fatty acid amide, 10%-20% of heptadecyl dimethyl betaine and the balance of water, wherein the compounding weight ratio of the polyoxyethylene fatty acid amide to the heptadecyl dimethyl betaine is 1:2. A surface active agent compound system can form the ultra-low interfacial tension of 10<-3>-10<-4> mN / m with stratum dewatered crude oil at 45 DEG C when the use concentration is 0.0075%-0.01% under the alkali-free condition. In addition, the surface active agent compound system is less influenced by stratum water salinity, achieves the adsorption quantity on three oil sands of in the Liaohe oilfield Hainan less than 0.5 mg / g, is suitable for a mono-system flooding or binary system flooding technology adopted in the middle and later period of the waterflooding development of an oil deposit and provides certain technical support for the tertiary oil recovery of an oilfield.

Owner:PETROCHINA CO LTD

A method for oil well water plugging by activating reservoir microorganisms to produce emulsifier

The invention belongs to the technical field of oil and gas field development and particularly relates to an oil well water plugging method adopting an emulsifying agent generated by activating oil reservoir microorganisms. The oil well water plugging method specifically comprises the following steps of screening of a test oil well, preliminary screening of an activating agent, determining of the activating agent, determining of the water plugging radius, determining of the injection rate of the activating agent and conducting of a field test and evaluating of a field test result. The oil well water plugging method adopting the emulsifying agent generated by activating the oil reservoir microorganisms has the characteristics of being simple in technology and high in pertinence and operability, and field application and popularization are facilitated; the validity period of the field test is long, the oil increasing effect is good, the input-output ratio is high, the validity period is longer than 12 months, the average daily oil increasing amount of a single well is larger than 5 t, and the input-output ratio is larger than 1:5. Thus, the oil well water plugging method adopting the emulsifying agent generated by activating the oil reservoir microorganisms can be widely applied to an oil well water plugging technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-round polymer gel deep fine profile control method

ActiveCN105298438BChange or increase invasivenessImprove wettabilityFluid removalSealing/packingEngineeringWater well

The multi-round polymer gel deep fine profile control method achieves the purpose of deep profile control by injecting slugs with different functions in multiple rounds. According to the role of slug in deep profile control, it can be divided into four types: first slug: gel diversion, providing preparation for the effective entry of gel into the formation; second slug: weak gel auxiliary plugging, effective connection and diversion agent and medium and strong gel to ensure that the fluid enters the formation effectively and continuously; the third slug: middle and deep plugging of the medium and strong gel; the fourth slug: active weak gel turbulence; Inject slugs I, II, and III as required, and reuse slugs II and III in the second (third) round. According to the pressure and working parameters, after the injection requirements are met, the next round of injection is performed; the last round of injection of the fourth slug. The slugging effect of multiple rounds of refined injection is more targeted and has a longer effective period, which can effectively improve the water absorption status of the reservoir, improve the utilization rate of injected water, expand the swept volume, and finally improve the oil displacement efficiency; the oil increase effect is obvious, and the method Simple and easy to implement, suitable for on-site implementation, especially suitable for wells with multi-layer mining, large interlayer differences, and high water content. The success rate of profile control can be increased to 90%, and the validity period can be increased by 1 or 2 years. It has a wide range of popularization and application prospect.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

Method for injecting oil-displacing agent into oil layer by utilizing fracturing prepad fluid to improve recovery efficiency

ActiveCN113187458AEnhanced overall recoveryIncrease productionFluid removalDrilling compositionChemical agentPetroleum engineering

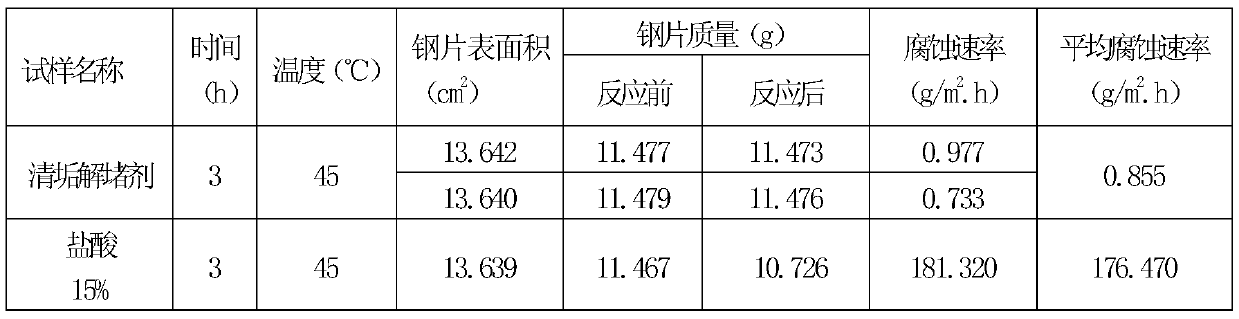

The invention relates to a method for injecting an oil-displacing agent into an oil layer by utilizing fracturing prepad fluid to improve the recovery efficiency. By utilizing the opportunity of only one-time fracturing transformation, energy-increasing, huff and puff, replacement and imbibition three-time oil recovery chemical agents are added into the fracturing prepad fluid, the energy-increasing, huff and puff, imbibition and oil-displacing chemical agents are injected into the oil layer to improve the recovery efficiency, the yield of a fractured well can be greatly increased, the oil increasing effect is obvious, the yield increasing effect of fracturing transformation is improved, and the single well recovery efficiency is increased. The huff and puff, imbibition and oil-displacing chemical agent system has the advantages of high oil washing effect, low viscosity, high permeability, low corrosivity and the like. According to the method for injecting the oil-displacing agent into the oil layer by utilizing fracturing prepad fluid to improve the recovery efficiency, secondary and tertiary oil recovery processes are combined with fracturing transformation, huff and puff, imbibition and oil-displacing chemical agents are injected into an oil layer to improve the recovery efficiency, the yield of the fractured well can be greatly increased, the oil increasing effect is obvious, the yield increasing effect of fracturing transformation is improved, the single well recovery efficiency is increased, and important significance is achieved on development of unconventional tight oil reservoirs at home and abroad at present.

Owner:XINJIANG ZHENGTONG OIL & GAS CO LTD

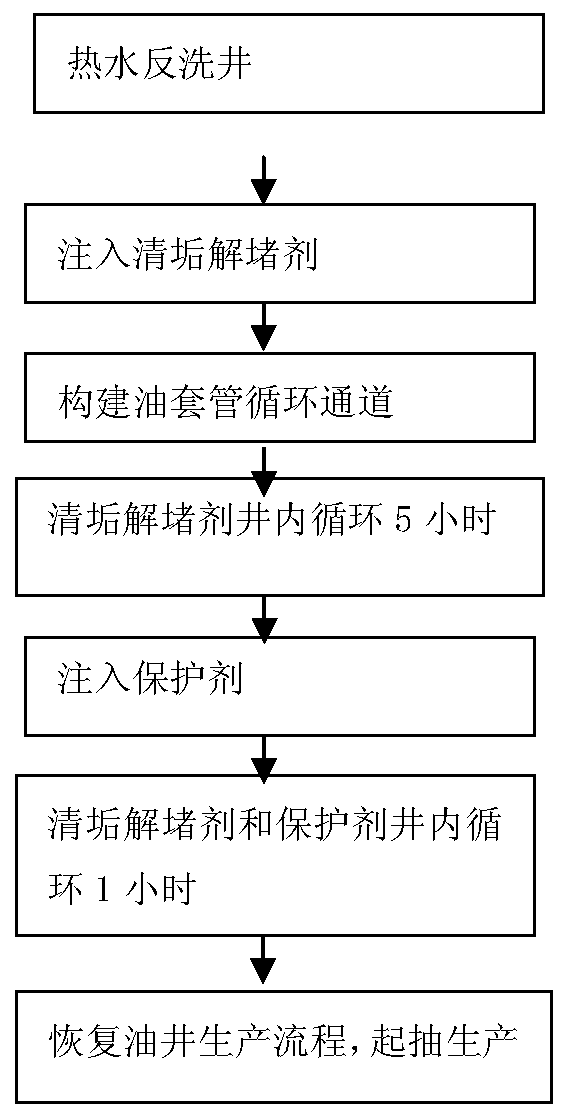

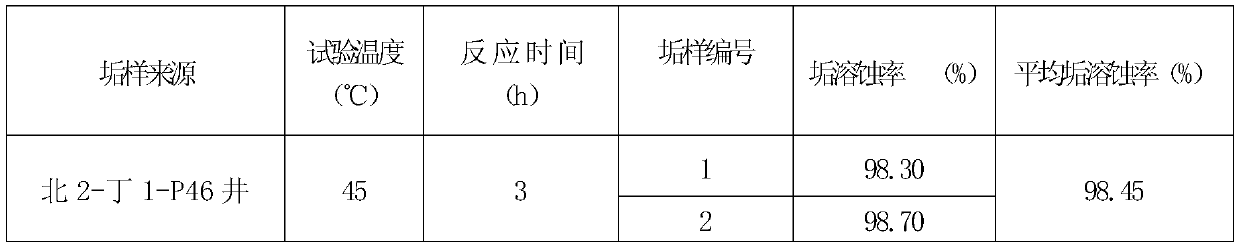

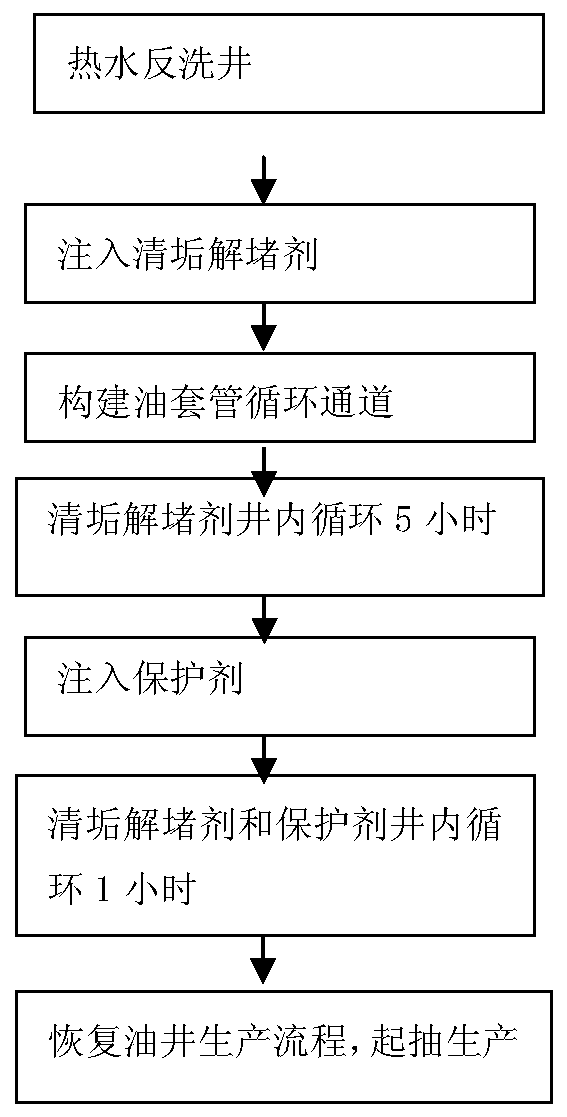

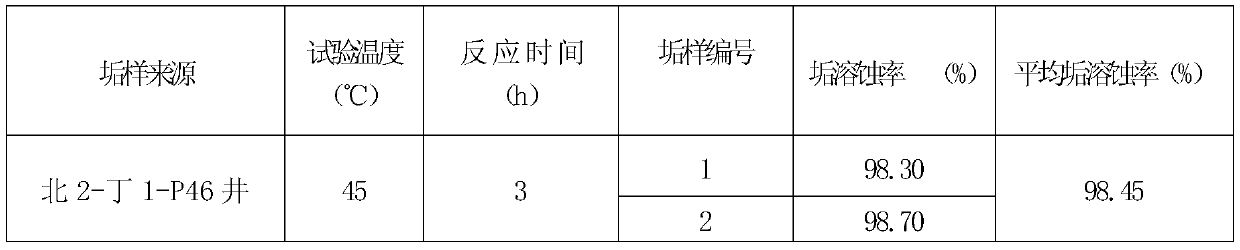

An integrated working fluid and process suitable for ASP flooding wells without external drainage, plugging and jamming

ActiveCN110439516BImprove runtime rateIncrease productionChemical industryCleaning apparatusAlkylphenolDioxyethylene Ether

The invention relates to non-discharge plug-removing stick-releasing integrated working fluid and process for a ternary compound combination flooding oil well. The problems that in an existing process, the utilization rate of medicaments is low, the overall cost is high, the construction time is long, and reaction residual liquid needs to be discharged are mainly solved. The non-discharge plug-removing stick-releasing integrated working fluid is characterized by being prepared from a scale clearing agent and a protective agent, and the scale clearing agent is prepared from the components in percentage by weight: 5%-7% of hydrochloric acid, 3%-5% of solid nitric acid, 0.3%-0.5% of alkylphenol ethoxylates, 1.0%-2.0% of triethanolamine, 0.5%-1.0% of imidazoline-ammonium-salt corrosion inhibitor and 90.2%-84.5% of water; the protective agent is prepared from the components in percentage by weight: 3.0%-5.0% of sodium hydroxide, 0.5%-1.0% of ethylenediaminetetraacetic acid disodium salt, 0.5%-1.0% of nonionic demulsifier SP169 and 96.0%-93.0% of water. The invention further provides a non-discharge plug-removing stick-releasing integrated process for the ternary compound combination flooding oil well. The non-discharge plug-removing stick-releasing integrated working fluid and process have the advantages of high efficiency of scale clearing and plug removing, low cost, safety and environmental protection.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

Organic six-proof rodless hydraulic drive double-acting reciprocating pump

InactiveCN105089995BAnti-corrosionAnti-foulingPositive displacement pump componentsFlexible member pumpsHydraulic cylinderOil field

The invention is an organic six-proof rodless hydraulically driven double-acting reciprocating pump integrating anti-corrosion, anti-scaling, anti-wax, anti-stickiness, anti-gas and anti-sand, which belongs to the new field of mechanical oil recovery technology. The pump is composed of an upper male and female buckle joint, a lower joint and a reversing valve assembly connected in series from top to bottom, a hydraulic cylinder assembly, and a liquid discharge cylinder assembly. The lower joint Selectively configure sand removal and gas prevention devices under the fixed valve, in which the hydraulic cylinder assembly and liquid discharge cylinder assembly can be optimally combined in series according to different well depths, pressures and liquid discharge requirements to form a single drive and single row Or single-drive multi-row or multi-drive single-row or multi-drive multi-row hydraulic drive device. The pump has multiple functions of anti-corrosion, anti-scaling, anti-wax, anti-sticky, anti-gas, anti-sand, anti-wear and obvious oil-increasing effect, suitable for large-scale promotion and application.

Owner:王颖

Temperature control liquid expanded rubber and preparation method thereof

InactiveCN101314671BEffective blockingOil increasing effect is obviousDrilling compositionPolymer sciencePtru catalyst

Owner:天津新技术产业园区北洋新技术工程有限公司

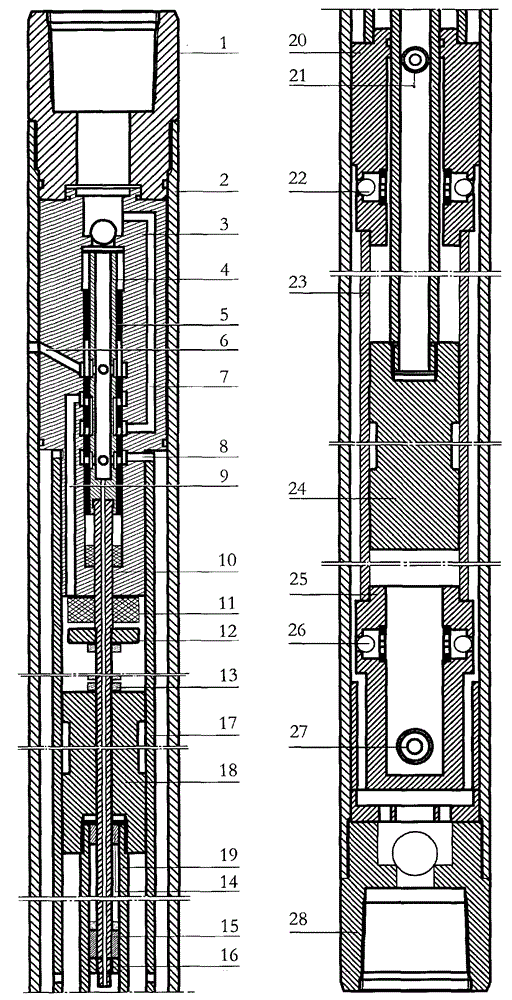

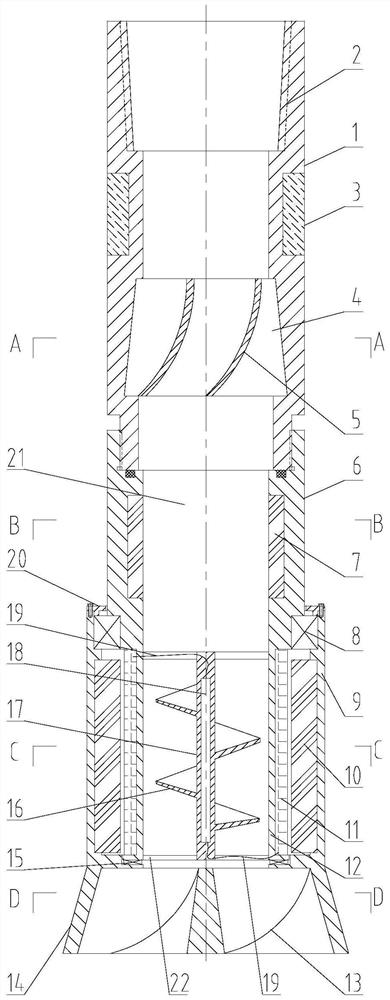

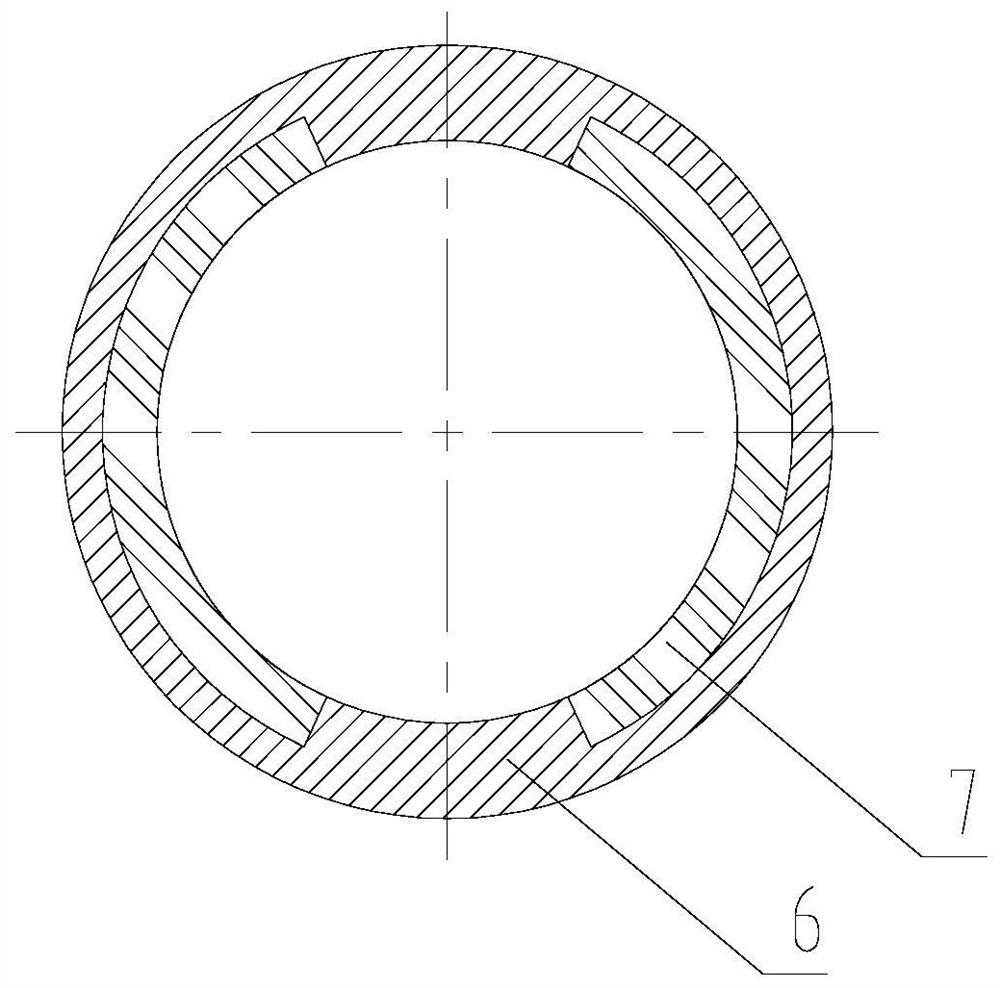

Quantum wax scale prevention and control integrated device

ActiveCN112253047BIncrease temperatureIncrease productionScale removal and water softeningCleaning apparatusUpper jointCruise control

Quantum wax scale prevention and control integrated device. It relates to the technical field of oil field recovery. A quantum water processor is installed outside the center hole of the lower part of the upper joint. The lower part of the upper cylinder is threaded and sealed to connect with the lower cylinder. The upper part of the lower cylinder is a magnetization chamber. The lower cylinder is connected to the rotating cylinder through bearings and glands. Blades; the inner wall of the rotating cylinder is inlaid with a permanent magnet II and an induction coil, and the inner side of the spacer is provided with a shaft and an electric heating rod. The upper and lower ends of the electric heating rod are respectively electrically connected to the two ends of the induction coil. The present invention has the following beneficial effects: the temperature of the oil flow is increased by sucking the oil flow through the oil well pump as power generation, which has an obvious effect of increasing oil, and the temperature of the oil flow can be increased underground without introducing electric power from the ground, and the oil flow passes through the magnetization chamber The magnetization effect can achieve the effects of reducing viscosity and preventing wax, improving the production conditions of oil wells and increasing crude oil production, and then through the descaling and vibration effect of the quantum water processor, it plays the role of anti-scaling.

Owner:大庆市凤凰能源科技有限公司

Non-discharge plug-removing stick-releasing integrated working fluid and process for ternary compound combination flooding oil well

ActiveCN110439516AImprove runtime rateIncrease productionChemical industryCleaning apparatusWorking fluidAlkylphenol

The invention relates to non-discharge plug-removing stick-releasing integrated working fluid and process for a ternary compound combination flooding oil well. The problems that in an existing process, the utilization rate of medicaments is low, the overall cost is high, the construction time is long, and reaction residual liquid needs to be discharged are mainly solved. The non-discharge plug-removing stick-releasing integrated working fluid is characterized by being prepared from a scale clearing agent and a protective agent, and the scale clearing agent is prepared from the components in percentage by weight: 5%-7% of hydrochloric acid, 3%-5% of solid nitric acid, 0.3%-0.5% of alkylphenol ethoxylates, 1.0%-2.0% of triethanolamine, 0.5%-1.0% of imidazoline-ammonium-salt corrosion inhibitor and 90.2%-84.5% of water; the protective agent is prepared from the components in percentage by weight: 3.0%-5.0% of sodium hydroxide, 0.5%-1.0% of ethylenediaminetetraacetic acid disodium salt, 0.5%-1.0% of nonionic demulsifier SP169 and 96.0%-93.0% of water. The invention further provides a non-discharge plug-removing stick-releasing integrated process for the ternary compound combination flooding oil well. The non-discharge plug-removing stick-releasing integrated working fluid and process have the advantages of high efficiency of scale clearing and plug removing, low cost, safety and environmental protection.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

Portable well mouth sealer

The invention discloses a portable well mouth sealer, which comprises a pressure-bearing rigid body (5) and a polished rod or sucker rod packaging hole (11), wherein the pressure-bearing rigid body (5) consists of two cylinder parts which can be opened and closed; semi-cylindrical recesses are formed on opposite surfaces of the two cylinder parts; and when the two cylinder parts are enclosed, the two semi-cylindrical recesses form the polished rod or sucker rod packaging hole (11). The portable well mouth sealer disclosed by the invention has a small size and a simple structure, and is convenient to install and detach; the well killing operation procedure of small-sized well mouth operation is eliminated, so that field operation is convenient and safe, and time and labor are saved; and the operating efficiency is increased, the operation cost can be reduced greatly, and the production effectiveness is enhanced, so that a remarkable oil increasing effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP

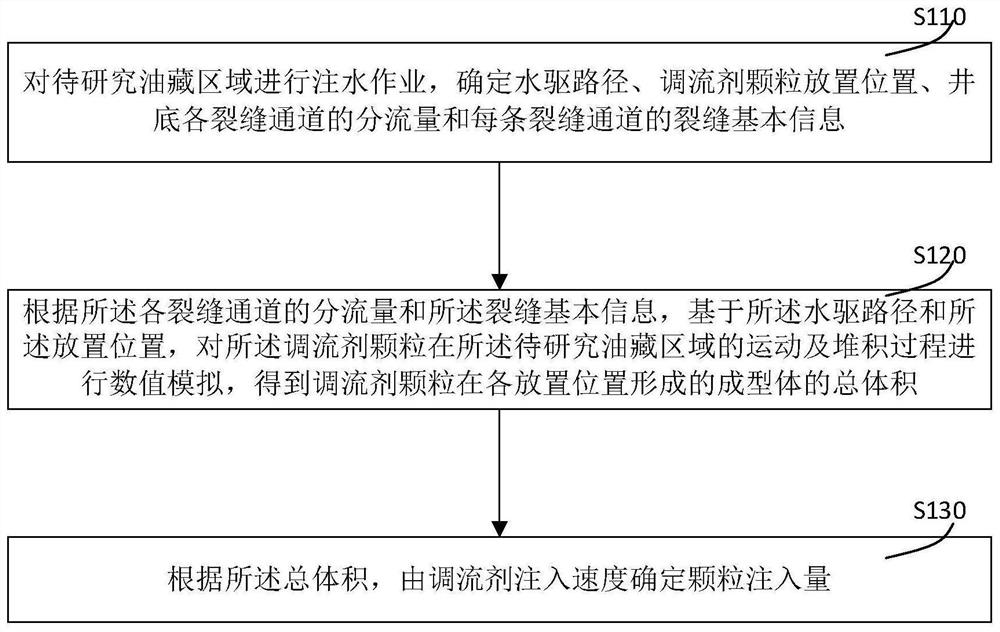

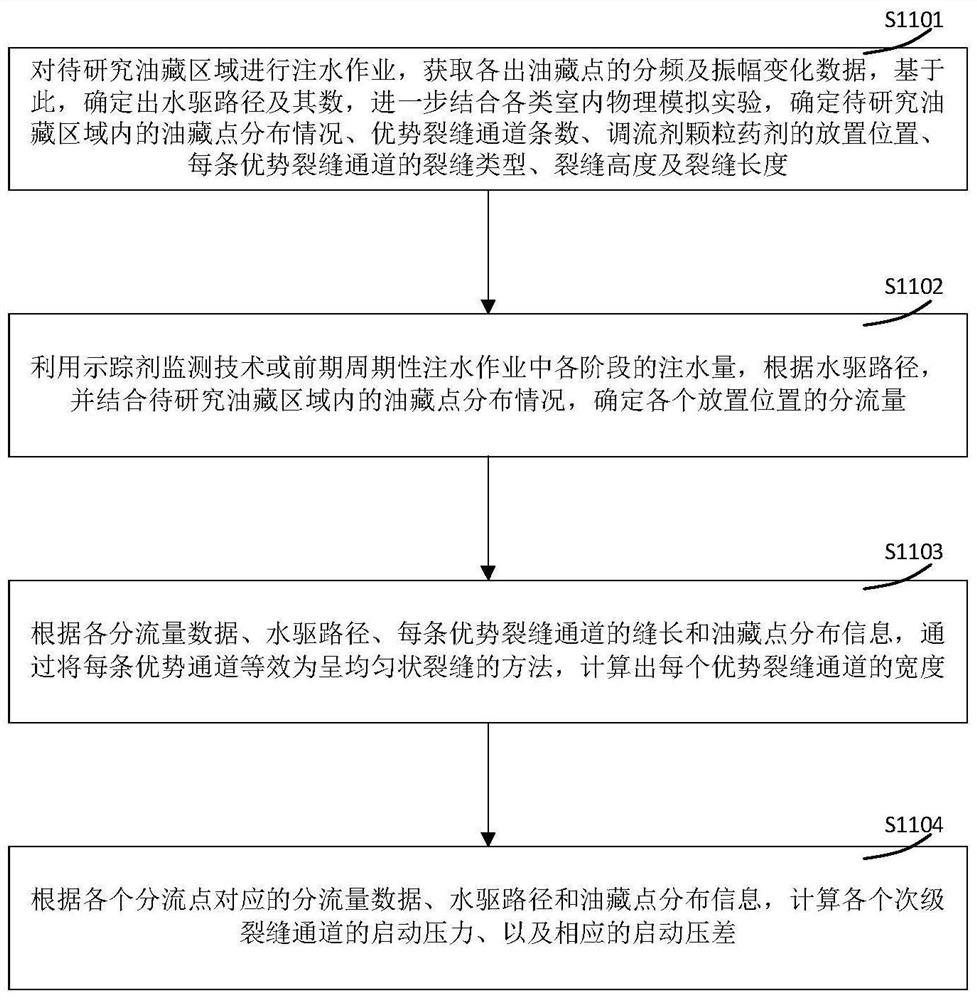

Particle injection amount determination method and system for fracture-vuggy reservoir flow regulation technology

PendingCN113343403AOil increasing effect is obviousAvoid inefficiencyData processing applicationsDesign optimisation/simulationPetrologyGeotechnical engineering

The invention discloses a particle injection amount determination method for a fracture-vuggy reservoir flow regulation technology, which comprises: performing water injection operation on a to-be-researched reservoir area, and determining a water drive path, a flow regulation agent particle placement position, a shunt volume of each fracture channel at the bottom of a well and basic fracture information of each fracture channel; performing numerical simulation on the movement and accumulation process of the flow regulating agent particles in the oil reservoir area to be researched on the basis of the water drive path and the placement positions according to the shunt volume of each fracture channel and the basic fracture information, so as to obtain the total volume of a forming body formed by the flow regulating agent particles in each placement position; and according to the current total volume, determining the particle injection amount through the flow regulating agent injection speed. According to the invention, ineffectiveness caused by insufficient injection amount is overcome, and meanwhile, the phenomenon of complete blockage caused by too much injection amount is avoided, so that the oil increasing effect of an oil well is obvious.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nitrogen-assisted microbial system as well as preparation method and application thereof

PendingCN114426833AImprove stabilityConvey evenlyFluid removalDrilling compositionMicrobial oilBiopolymer

The invention belongs to the technical field of microbial oil recovery, and particularly relates to a nitrogen-assisted microbial system as well as a preparation method and application thereof. The system is composed of a biological compound system and nitrogen, and the biological compound system is composed of functional microorganisms, a biological surfactant and a biopolymer. The preparation method comprises the following specific steps: uniformly mixing functional microorganisms, a biosurfactant and a biopolymer to obtain a mixture of a biological compound system; and injecting the biological compound system mixture pressurized by the plunger pump and nitrogen pressurized by the gas booster pump into ground foaming equipment at the same time to form a nitrogen-assisted microbial system. The method has the advantages of being long in field test validity period, good in oil increasing effect and high in input-output ratio, the validity period is longer than 12 months, the average daily oil increasing amount of a single well is larger than 5 t, and the input-output ratio is larger than 1: 5.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of high-temperature microemulsion drainage aid for fracturing and preparation method thereof

ActiveCN106244131BImprove surface activityImprove liquidityDrilling compositionEmulsionFracturing fluid

The invention provides a high-temperature microemulsion cleanup additive used for fracturing, and a preparation method thereof. The preparation method comprises the following steps: 1, adding 10-20 parts by mass of water into a reactor, adding 40-60 parts by mass of a cosurfactant to water, and stirring the cosurfactant and water at room temperature until the cosurfactant is completely dissolved; and 2, sequentially adding 20-40 parts by mass of a gemini surfactant and 3-4 parts by mass of a nonionic surfactant into the reactor, supplementing water to the reactor until the mass part number of a mixture obtained in the reactor is 100, and uniformly stirring the mixture at room temperature to obtain the high-temperature microemulsion cleanup additive. The high-temperature microemulsion cleanup additive is directly added to a fracturing fluid or an acidifying liquid according to a mass ratio of 0.1-0.3:100 when used.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of water blocking agent and its preparation method and application

ActiveCN113122213BEvenly dispersedGood storage stabilityDrilling compositionSealing/packingPolymer adhesiveActive agent

The application discloses a water shutoff agent and its preparation method and application, belonging to the field of oilfield chemicals. The water blocking agent includes the following raw material components by weight: 50-70 parts of asphalt, 5-7 parts of polymer latex, 1-3 parts of surfactant, 0.01-1 part of collector, 0.01-0.5 parts of nano silicon dioxide 0.01-0.05 parts of glycerin and 40-70 parts of deionized water. The water blocking agent is evenly dispersed, the asphalt particles are not bonded to each other, and has good storage stability; and the water blocking agent has a small initial viscosity, strong migration ability, good injection performance, and can penetrate deep into the formation to achieve Effective plugging of medium and high permeability reservoirs, with remarkable oil-increasing effect.

Owner:SHANDONG DESHI CHEM IND CO LTD +1

A method of injecting oil displacement agent into oil layer by fracturing to enhance recovery

ActiveCN106837274BReduce penetrationLess corrosiveFluid removalDrilling compositionViscosityPetroleum engineering

The invention relates to a method for injecting oil displacing agent into an oil reservoir to improve oil recovery by using fracturing. The method for injecting the oil displacing agent into the oil reservoir to improving oil recovery by using fracturing mainly solves the problems of large viscosity loss and low injection efficiency during the injection process of the existing three kinds of oil reservoir oil displacement agents. The method for injecting the oil displacing agent into oil reservoir to improving oil recovery by using fracturing is characterized in that (1) dividing a target stratum to the well fracturing section; (2) determining a half fracture length for the well fracturing section of the target stratum; (3) determining the oil displacement agent dosage for the well fracturing section of the target stratum; (4) determining a construction displacement the well fracturing section; (5) determining construction procedure of a pumping injection; and (6) mixing and injecting the oil displacement agent. The method for injecting the oil displacing agent into oil reservoir to improving oil recovery by using fracturing can greatly improve the injection efficiency and reduce the displacement efficiency loss, thus greatly improve the recovery efficiency and single well production.

Owner:PETROCHINA CO LTD +1

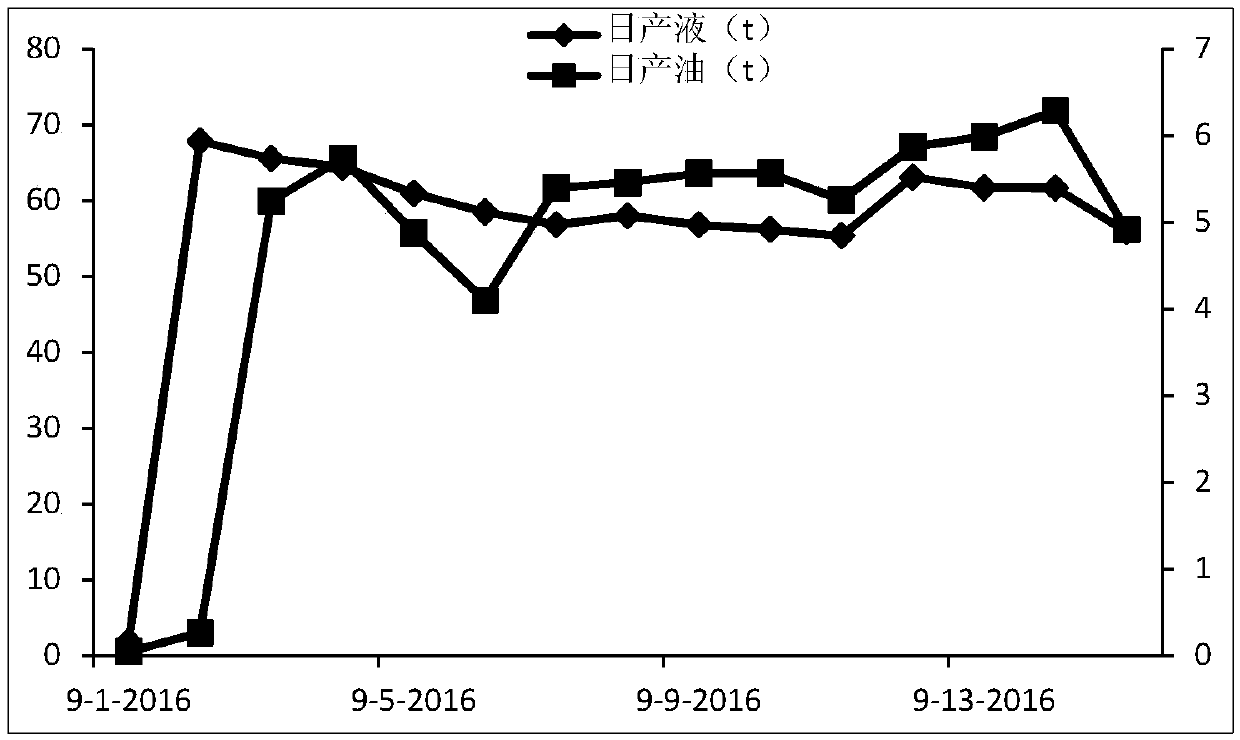

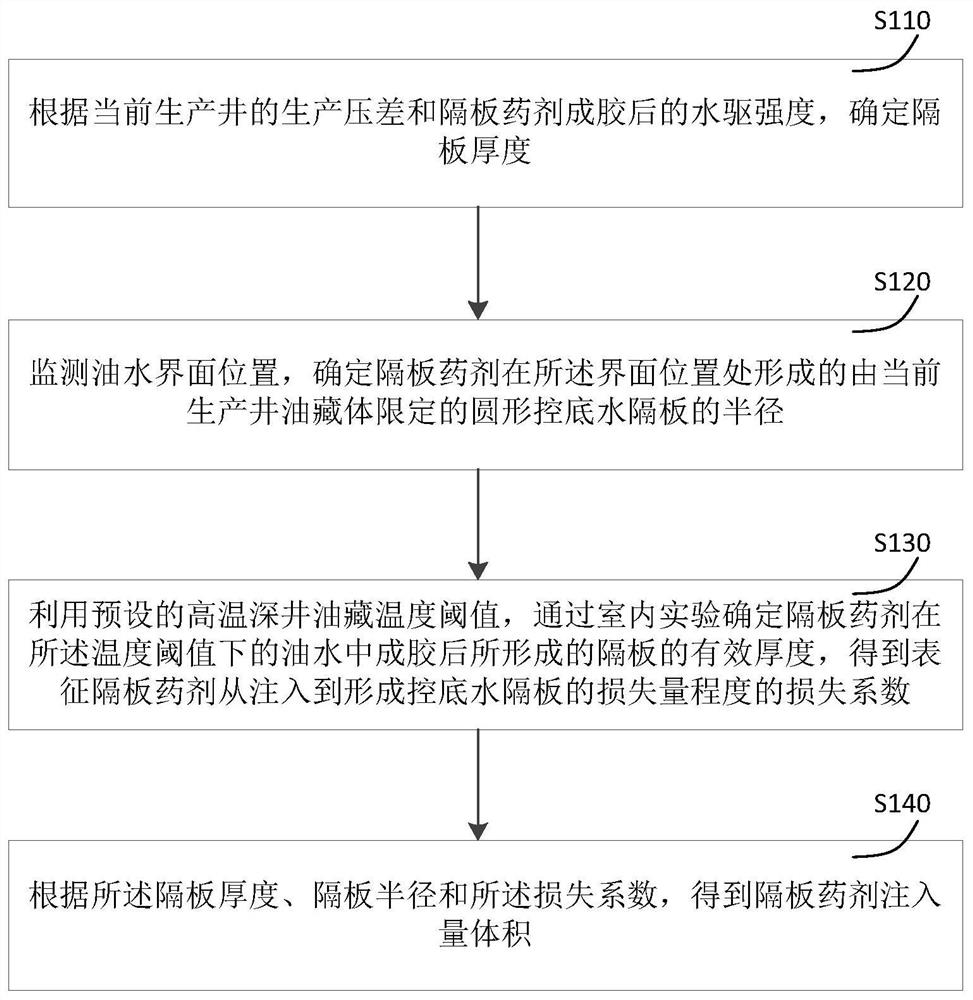

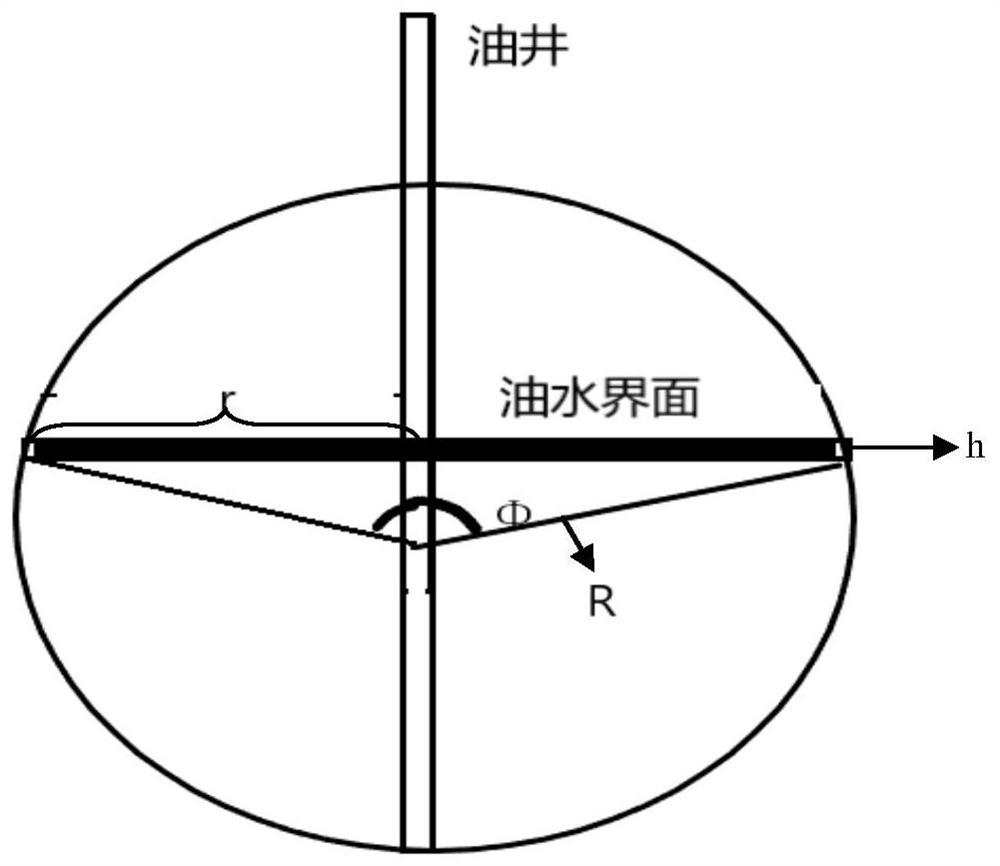

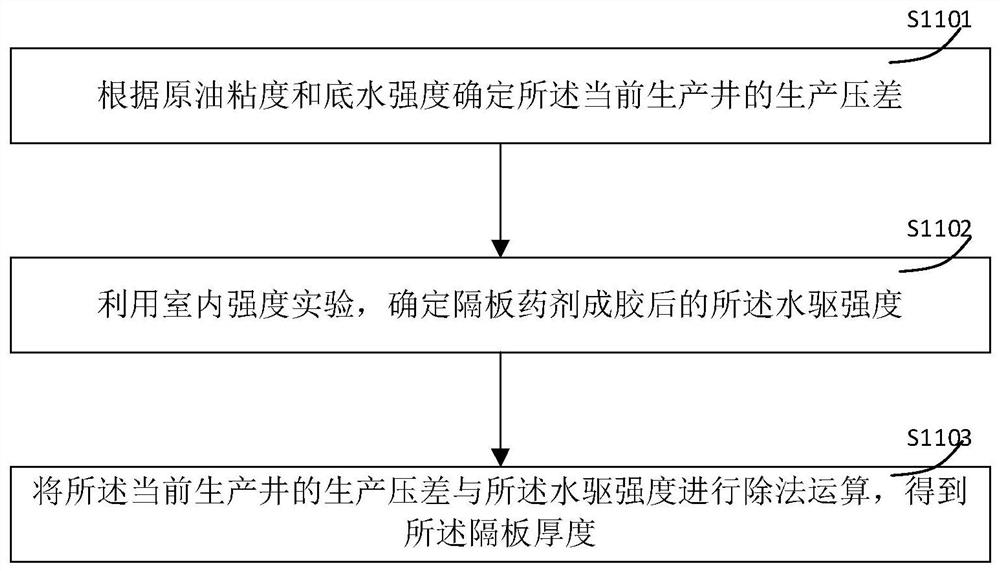

Method and system for determining medicament injection rate for fracture-vug type oil reservoir partition plate bottom water control

ActiveCN113338882AOil increasing effect is obviousEnhanced overall recoveryClimate change adaptationFluid removalOil waterOil well

The invention discloses a method for determining the medicament injection rate fracture-vug type oil reservoir partition plate bottom water control. The method comprises the following steps: determining the thickness of a partition plate according to the production pressure difference of a current production well and the water drive strength after a partition plate medicament is gelatinized; monitoring the position of an oil-water interface, and determining the radius of a circular bottom water control partition plate formed by the partition plate medicament at the position of the interface and limited by a current production well oil reservoir body; determining the effective thickness of the partition plate formed after the partition plate medicament is gelatinized in oil-water under a preset temperature threshold value of a high-temperature deep well reservoir through an indoor experiment, and obtaining a loss coefficient representing the loss degree of the partition plate medicament from injection to formation of the bottom water control partition plate; and obtaining the partition plate medicament injection rate according to the thickness, radius and loss coefficient of the partition plate. According to the method, the ineffectiveness caused by insufficient injection rate is overcome, the phenomenon of complete blockage caused by too much injection rate is also avoided, the oil increasing effect of an oil well is obvious, and the recovery efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com