In-depth profile control channeling sealing agent and preparation method and application method thereof

A technology of deep profile control and plugging agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of insufficient plugging strength, scattered residual oil distribution, small plugging radius, etc., and achieve high temperature plugging. The effect of high rate, good pumping performance, good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a deep profile modification and sealing agent, which is prepared by the following steps:

[0032] Step 1, taking the total weight of the deep profile control sealing agent as 100%, weighing 9% potassium humate, 0.16% polyanionic cellulose (viscosity greater than 50mPa·s), 1.5% urotropine, 0.14% phenol, 0.04% sodium tripolyphosphate, 0.025% β-cyclodextrin and 0.06% thiourea, the balance is water with a salinity of 4500mg / L.

[0033] Step 2, mix the weighed potassium humate, polyanionic cellulose, urotropine and water in a liquid mixing tank, and stir at room temperature for 20 minutes to obtain the mixture.

[0034] Step 3: Add weighed phenol, sodium tripolyphosphate, β-cyclodextrin and thiourea to the mixture in sequence, and stir at room temperature for 12 minutes to obtain a deep profile-modifying sealing agent.

Embodiment 2

[0059] This embodiment provides a deep profile modification and sealing agent, which is prepared by the following steps:

[0060] Step 1, taking the total weight of the deep profile control sealing agent as 100%, weigh 10% potassium humate, 0.2% polyanionic cellulose (viscosity greater than 50mPa·s), 1.8% urotropine, 0.16% phenol , 0.045% sodium tripolyphosphate, 0.04% β-cyclodextrin and 0.08% thiourea, and the balance is water with a salinity of 3860mg / L.

[0061] Step 2: Mix the weighed potassium humate, polyanionic cellulose, urotropine and water in a liquid mixing tank in sequence, and stir at room temperature for 30 minutes to obtain the mixture.

[0062] Step 3: Add weighed phenol, sodium tripolyphosphate, β-cyclodextrin and thiourea to the mixture in sequence, and stir at room temperature for 15 minutes to obtain a deep profile-modifying sealing agent.

Embodiment 3

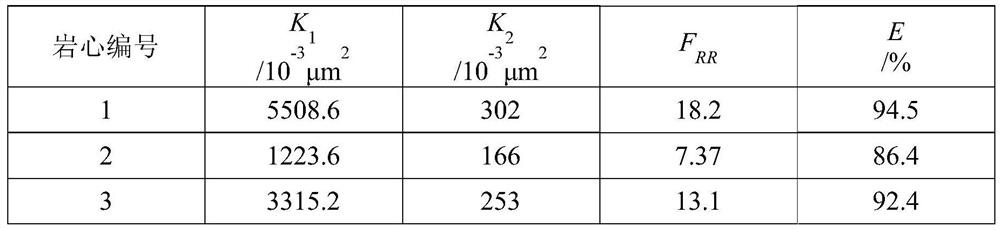

[0086]This example provides the application of the deep profile control and channeling agent in profile control and channeling sealing of heavy oil steam flooding injection wells. Take the steam injection well Q20 in Liaohe Oilfield as an example. The well absorbs steam unevenly in the vertical direction, and there are high-permeability channels and large pores in the plane, and the production effect of the corresponding well group becomes poor. In order to effectively control the adverse effects of steam channeling, the deep profile control and sealing channeling agent prepared in Example 2 was used to implement profile control and channeling sealing measures to improve the production effect.

[0087] The specific construction process is as follows: under the condition of formation temperature of 240℃, the 550m 3 The deep profile control and channeling agent is sequentially injected into the formation through a 5-slug injection process.

[0088] After the measures were take...

PUM

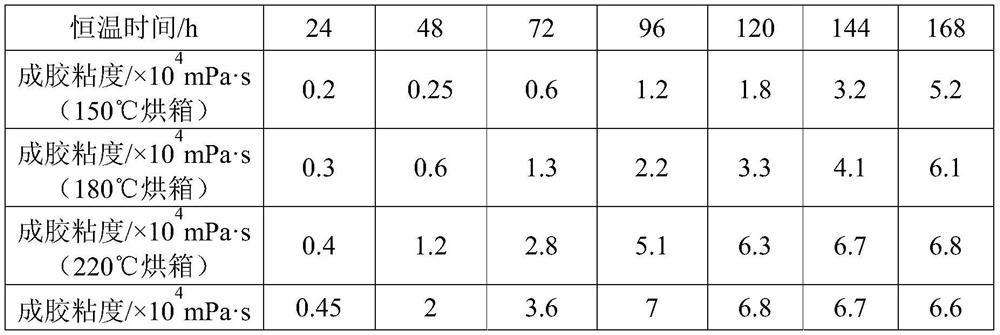

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com