Organic six-proof rodless hydraulic drive double-acting reciprocating pump

A hydraulically driven, reciprocating pump technology, applied to pumps with flexible working elements, machines/engines, components of pumping devices for elastic fluids, etc., can solve power fluid loss and replenishment troubles, and reversing valves are reliable Disadvantages of sex and life, increased construction investment and management difficulties, etc., to achieve excellent electrical performance and excellent anti-scaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

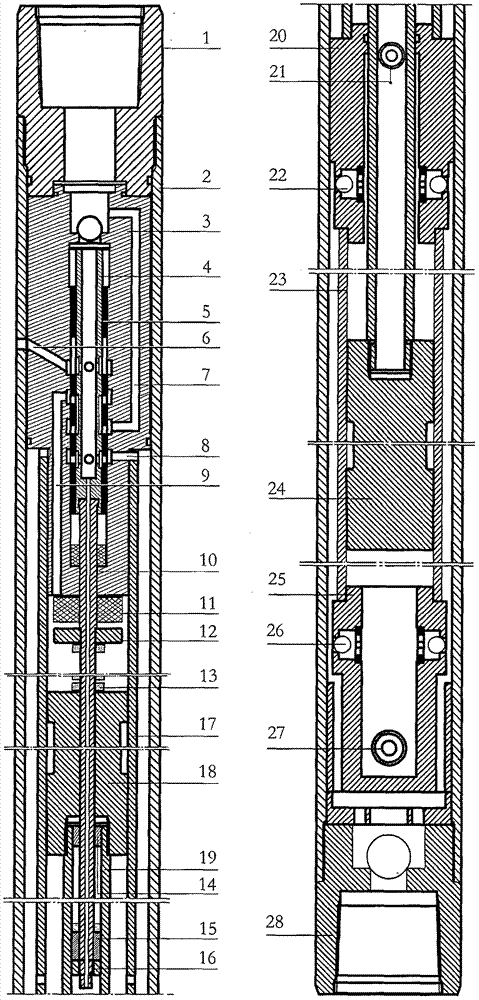

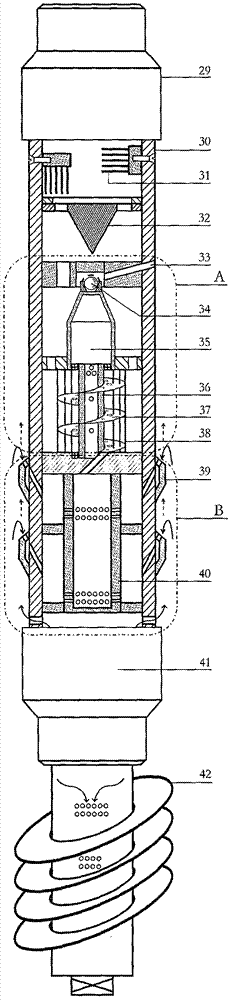

[0077] Such as figure 1 with figure 2As shown: the organic six-proof rodless hydraulic drive double-acting reciprocating pump of the present invention is composed of an upper male and female buckle joint 1, a lower joint and a fixed Vall integrated valve 28 connected in series from top to bottom. The assembly, hydraulic cylinder assembly, and liquid discharge cylinder assembly are composed of organic components. The lower joint and the fixed valve 28 are selectively equipped with sand removal and anti-gas devices. Among them, the hydraulic cylinder assembly, liquid discharge cylinder assembly According to different well depths, pressures and fluid displacement requirements, it can be serially optimized and combined into single-drive single-row or single-drive multi-row or multi-drive single-row or multi-drive multi-row hydraulic displacement devices.

[0078] The organic six-proof rodless hydraulically driven double-acting reciprocating pump is preferably one of the followin...

Embodiment 2

[0114] Such as figure 2 As shown: the main structure of the embodiment of the present invention is the same as that of Example 1, and the hydraulic cylinder assembly and the liquid discharge cylinder assembly are optimized in series.

[0115]The hydraulic cylinder assembly and the liquid discharge cylinder assembly can be optimally combined according to different well depths, pressures and liquid discharge volume requirements, and connected in series into one of the following six types of displacement structures:

[0116] The first type is that the first-stage hydraulic cylinder assembly is connected in series with the one-stage or multi-stage liquid discharge cylinder assembly to form a single-drive single-row or single-drive multi-row hydraulic drive device;

[0117] The second type is that the two-stage hydraulic cylinder assembly and the one-stage or multi-stage liquid discharge cylinder assembly are connected in series to form a double-drive single-row or double-drive mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com