Combined polyether, raw material composition, polyurethane foam as well as preparation method and application thereof

A technology of combining polyether and polyether polyol, applied in mechanical equipment, heat exchange equipment, thermal insulation, etc., can solve the problem of increasing the workload of the construction site and the speed of laying pipes, the filling effect at the head is not necessarily good, and the scope of application It is not widely used to achieve the effect of reducing the phenomenon of hot and cold bridges, good sealing and high dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

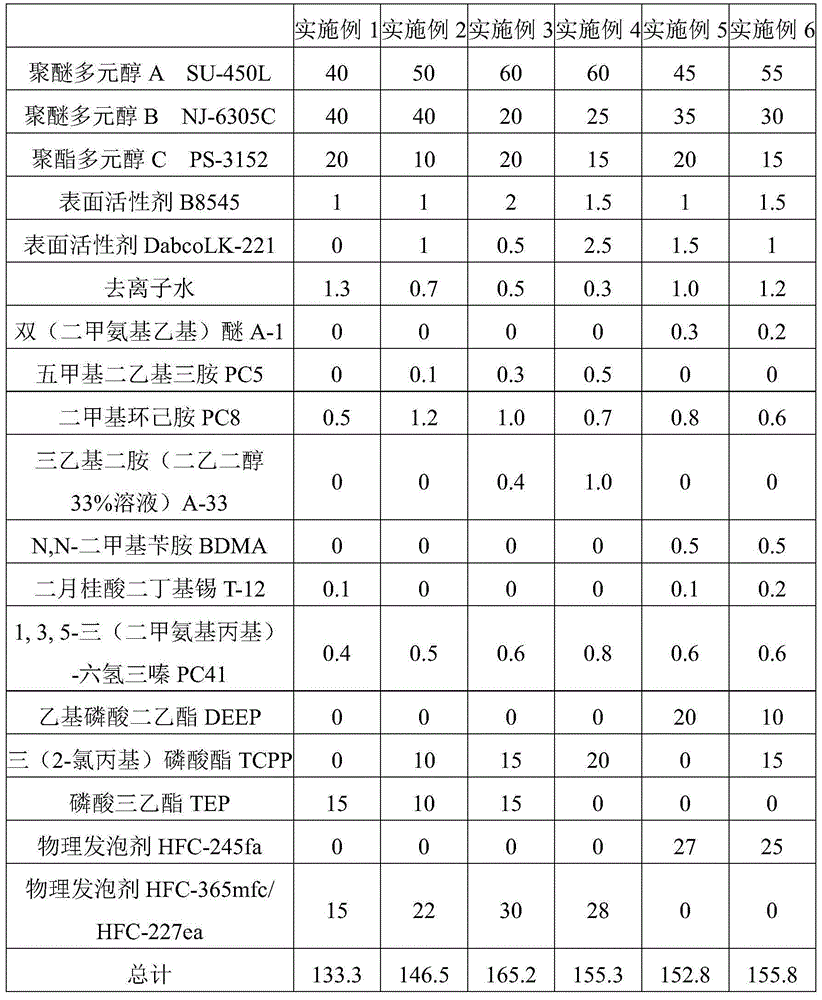

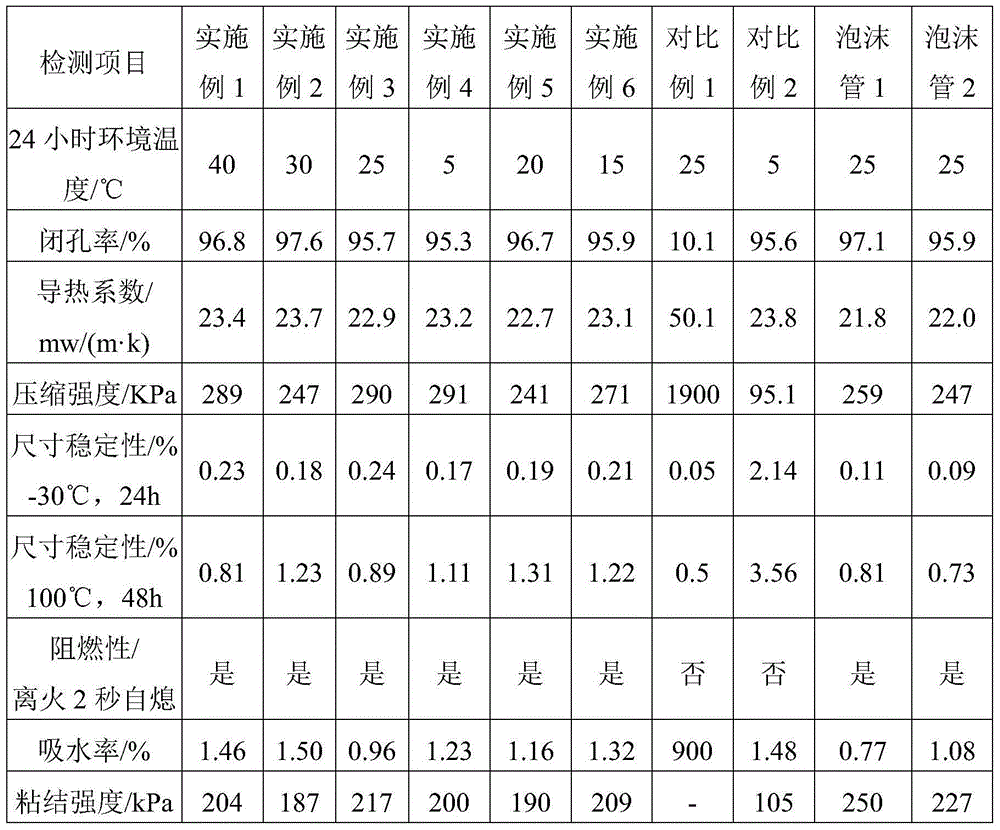

[0036] The parts by weight of each component of the raw material composition combined with polyether in Examples 1-6 are specifically shown in Table 1.

[0037] Table 1

[0038]

[0039] (1) Preparation of combined polyether

[0040] Mix the materials uniformly according to the weight components in Table 1 to obtain the composite polyether.

[0041] (2) Preparation of rigid polyurethane foam

[0042] The above-prepared combined polyether and isocyanate were mixed manually at 40°C according to the weight ratio of 1:1.40 (electric drill stirring at a speed of 2000r / min for 10 seconds), and foamed for 20s to obtain rigid polyurethane foam.

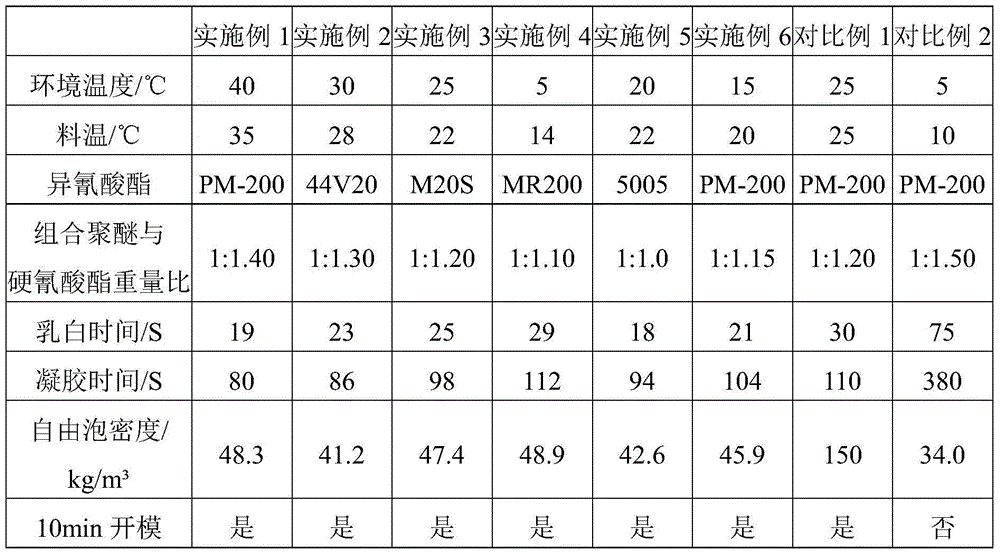

[0043] See Table 2 for the different temperatures and reaction indicators described in Examples 1-6.

[0044] Table 2

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com