Quantum wax scale prevention and control integrated device

A quantum and wax scale technology, applied in descaling and water softening, chemical instruments and methods, wellbore/well components, etc., can solve problems such as hidden safety hazards, chemical pollution, oil well production reduction, etc. The effect of increasing aggregation and increasing crude oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

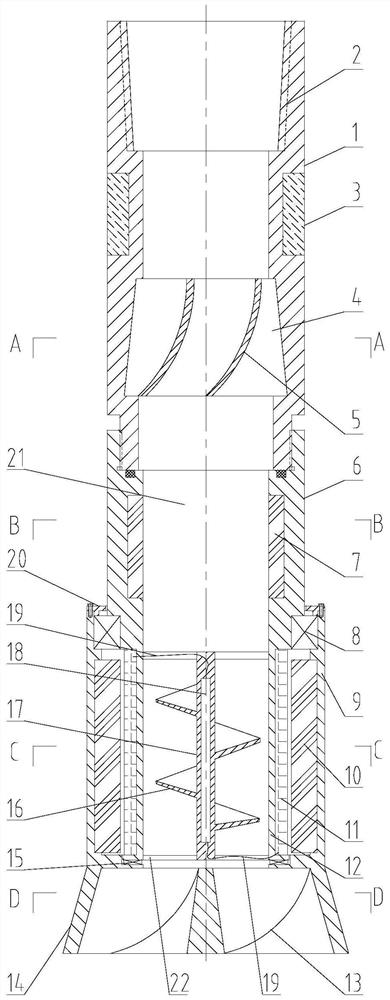

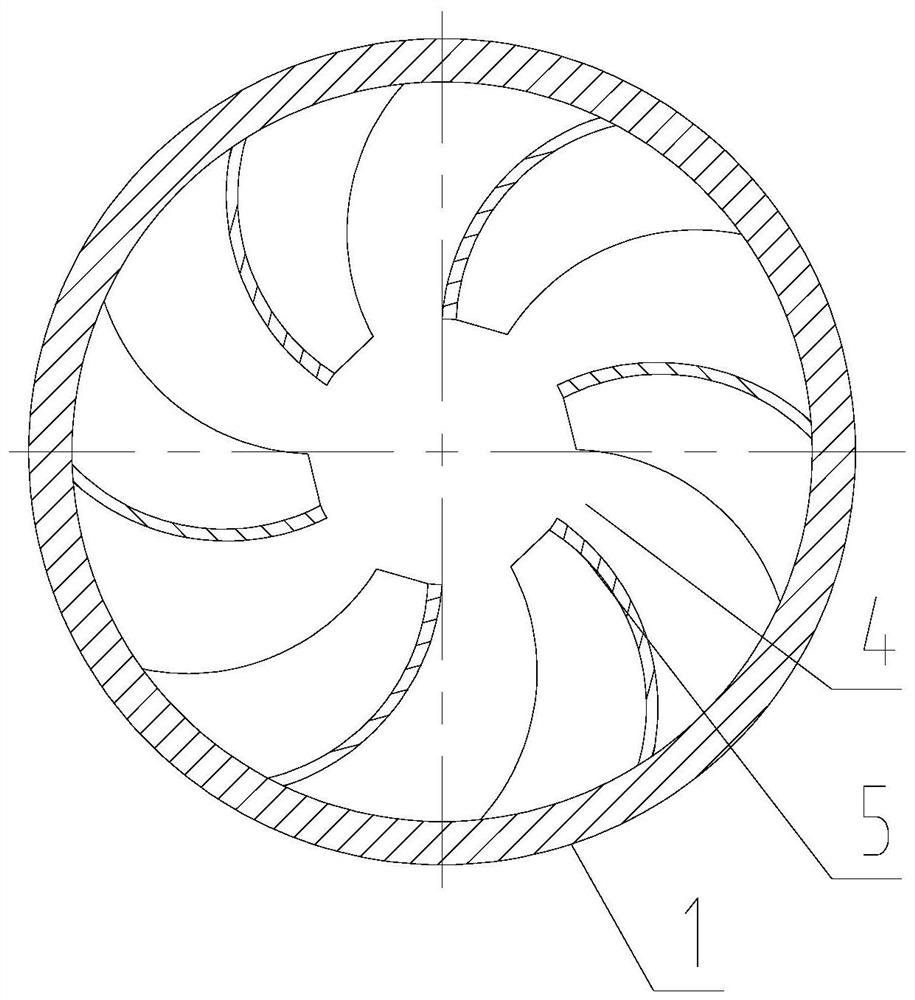

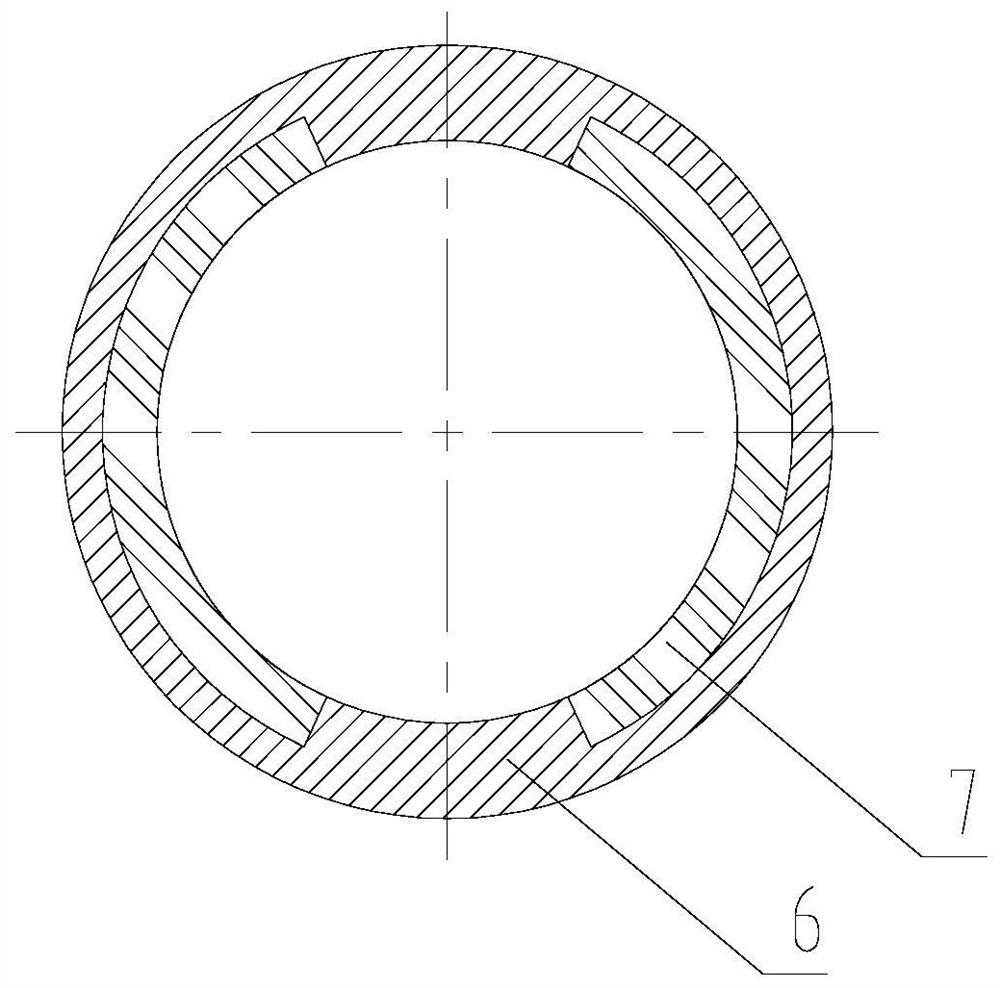

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Depend on figure 1 combine Figure 2-5 As shown, the quantum wax scale prevention and control integrated device includes an upper cylinder body 1, an upper joint 2 is provided on the upper part of the upper cylinder body 1 for connecting the oil well pump, and a quantum water processor 3 is provided outside the central hole at the lower part of the upper joint 2. The water processor 3 is installed in the annular groove outside the upper cylinder 1 in a ring shape. The quantum water processor 3 is an emitter with the function of storing and emitting penetrable descaling vibration waves. The crystal lattice vibration wave of the body is consistent. The descaling vibration wave is mainly aimed at calcium and calcium salts. Calcium and calcium salts are easy to accumulate from small particles to large particles, thus forming the characteristics of scaling. The dissolvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com