A kind of oil recovery method that nitrogen foam inhibits edge water propulsion in thermal recovery of heavy oil

A thermal recovery of heavy oil, nitrogen foam technology, applied in the direction of production fluid, earth drilling, wellbore/well components, etc., can solve the problems of small steam sweep range, low oil recovery efficiency, edge water intrusion, etc., and achieve the expansion of steam sweep range, increase oil recovery efficiency, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

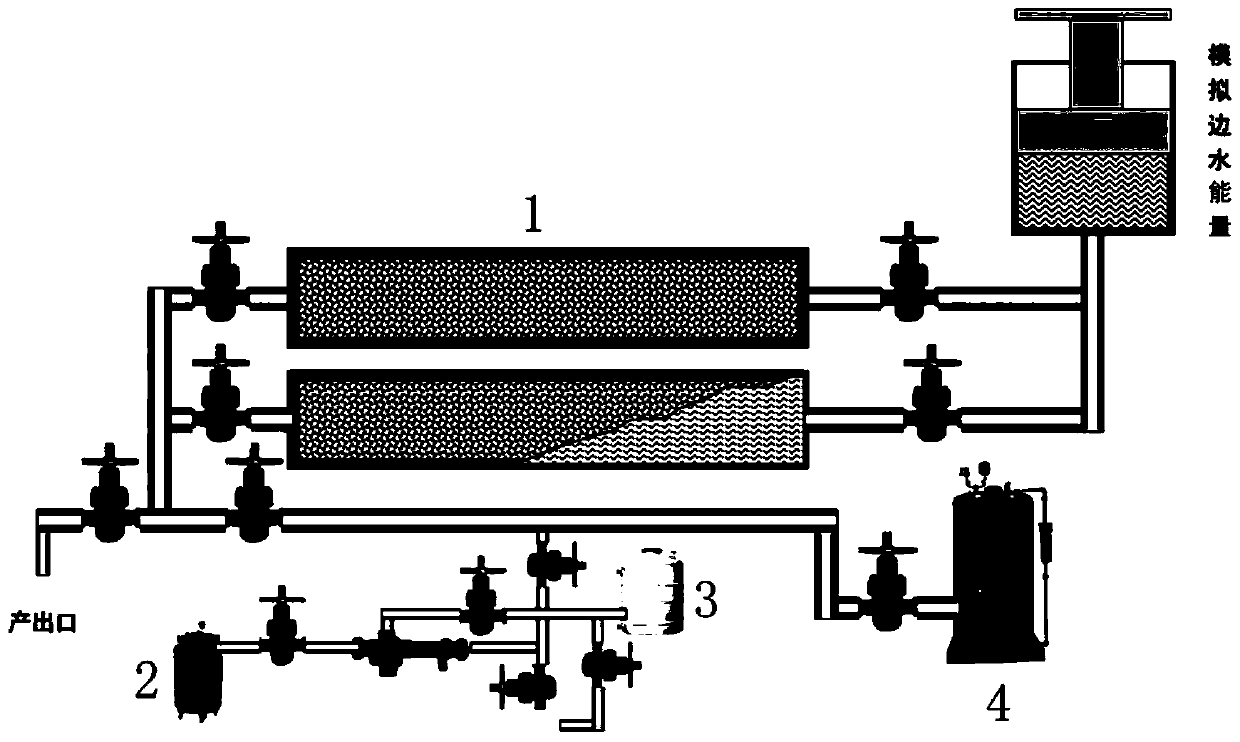

[0025] The oil production method in which nitrogen foam suppresses edge water propulsion in thermal recovery of heavy oil in this embodiment comprises the following steps:

[0026] 1) When the periodical comprehensive water content of the oil production well is 95%, nitrogen is injected to form a pre-nitrogen slug before steam injection in the oil production well, and the injection amount of the pre-nitrogen is 1 / 3 of the total nitrogen design injection amount, and the total nitrogen design The injection volume is 40 times of the high-temperature steam design injection volume;

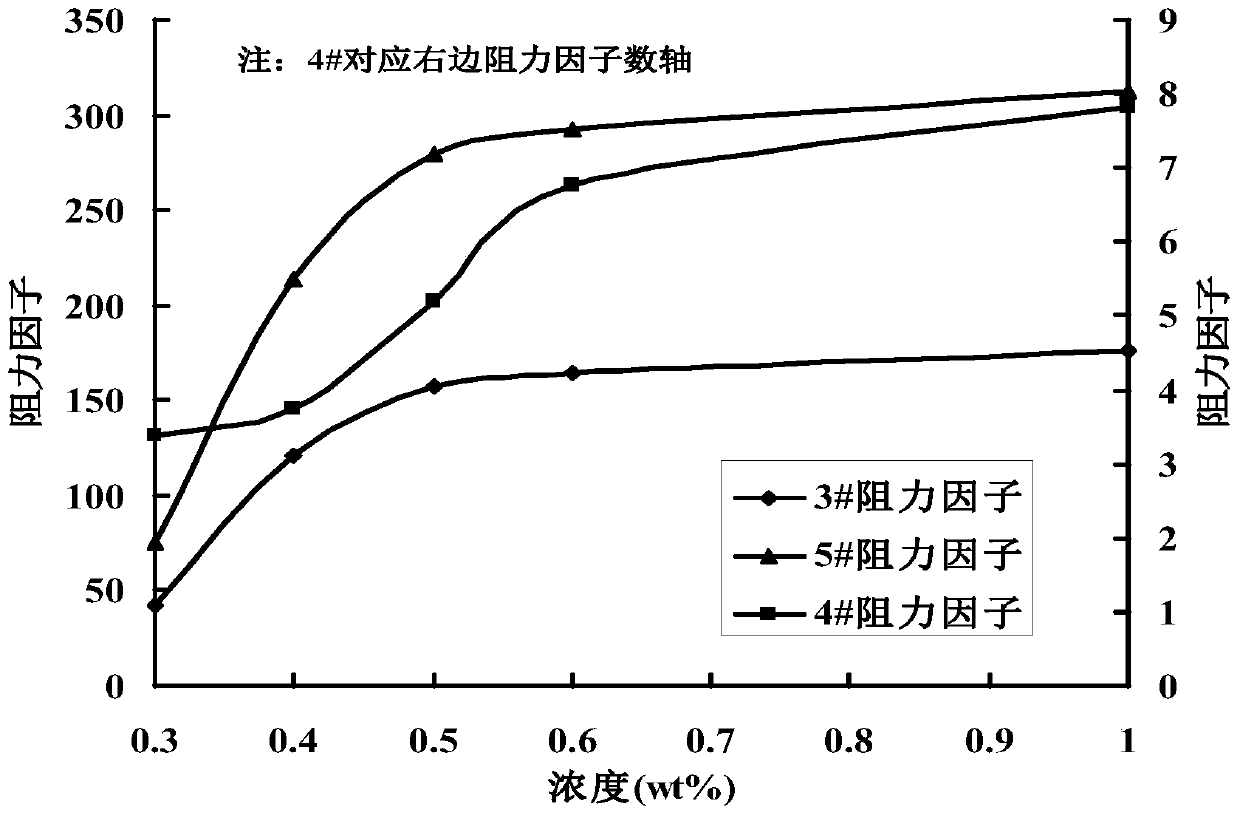

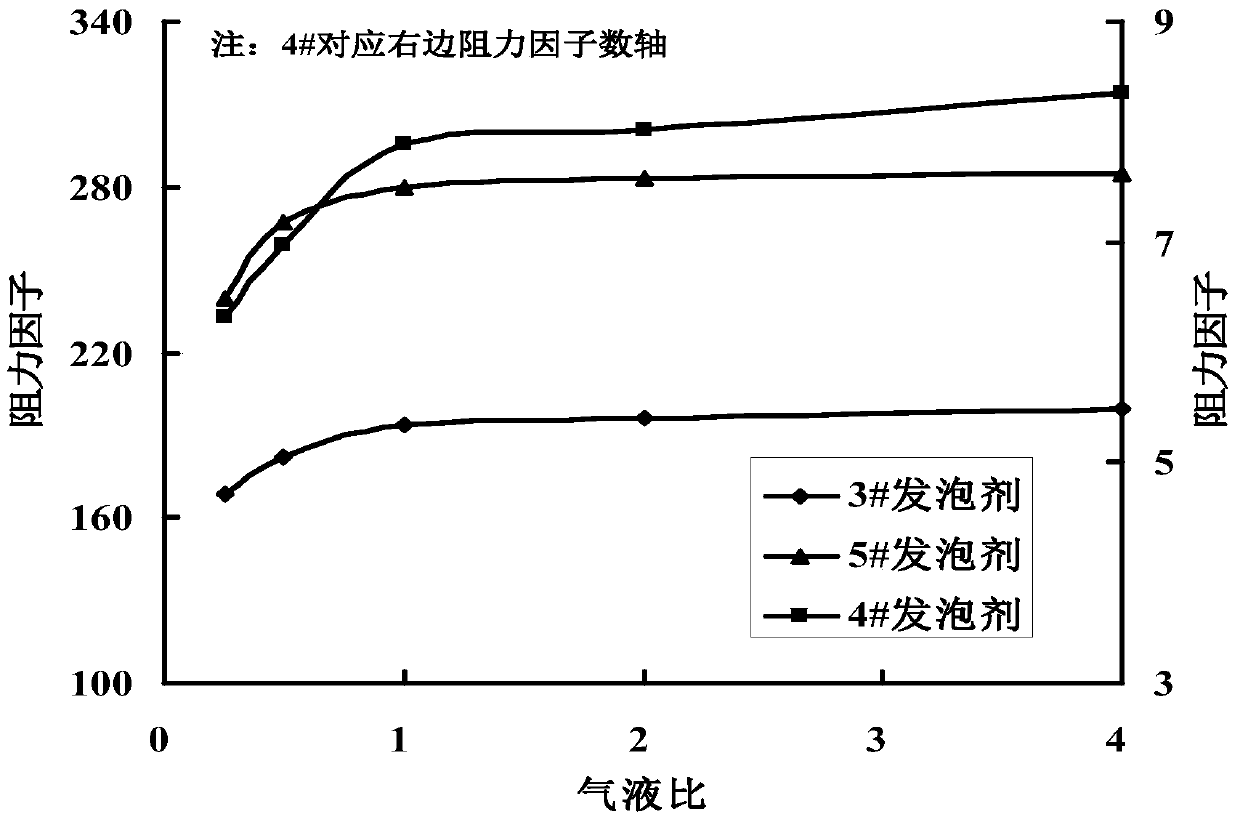

[0027] 2) Inject foaming liquid into the oil production well, the mass percentage of the foaming agent in the foaming liquid is 0.5%, the foaming liquid is contacted with the pre-nitrogen to foam, and the gas-liquid ratio is 1:1;

[0028] 3) Inject nitrogen gas into the production well to form a central nitrogen slug, and the injection rate of the central nitrogen gas is 2 / 3 of the total nitrogen desig...

Embodiment 2

[0032] The oil production method in which nitrogen foam suppresses edge water propulsion in thermal recovery of heavy oil in this embodiment comprises the following steps:

[0033] 1) Before the steam injection in the production well, when the comprehensive water content of the production well is 92%, nitrogen is injected to form a pre-nitrogen slug, and the pre-nitrogen injection amount is 1 / 2 of the total nitrogen design injection amount The injection volume is 60 times of the high-temperature steam design injection volume;

[0034] 2) Inject foaming liquid into the oil production well, the mass percentage of the foaming agent in the foaming liquid is 0.4%, the foaming liquid is contacted with the front nitrogen to foam, and the gas-liquid ratio is 1.5:1;

[0035] 3) Inject nitrogen gas into the oil production well to form a central nitrogen slug, and the injection rate of the central nitrogen gas is 1 / 2 of the total nitrogen design injection rate;

[0036] 4) Inject a desi...

Embodiment 3

[0039] The oil production method in which nitrogen foam suppresses edge water propulsion in thermal recovery of heavy oil in this embodiment comprises the following steps:

[0040] 1) Before steam injection in oil production wells, when the periodic comprehensive water content of oil production wells is 90%, nitrogen is injected to form a pre-nitrogen slug, and the injection amount of pre-nitrogen is 1 / 3 of the total nitrogen design injection amount. The injection volume is 80 times of the high-temperature steam design injection volume;

[0041] 2) Inject foaming liquid into the oil production well, the mass percentage of the foaming agent in the foaming liquid is 0.6%, the foaming liquid is contacted with the front nitrogen to foam, and the gas-liquid ratio is 2:1;

[0042] 3) Inject nitrogen gas into the production well to form a central nitrogen slug, and the injection rate of the central nitrogen gas is 2 / 3 of the total nitrogen design injection rate;

[0043] 4) Inject a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com