Ultrasonic enhanced low-pressure superheated steam drying device and method

A technology of superheated steam and ultrasonic enhancement, applied in the direction of drying gas arrangement, drying solid materials, local agitation dryers, etc., can solve the problems of low drying rate, loss, enzymatic oxidation and browning of nutrients, etc., to improve the activity level , Improve the organizational structure, the effect of high drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

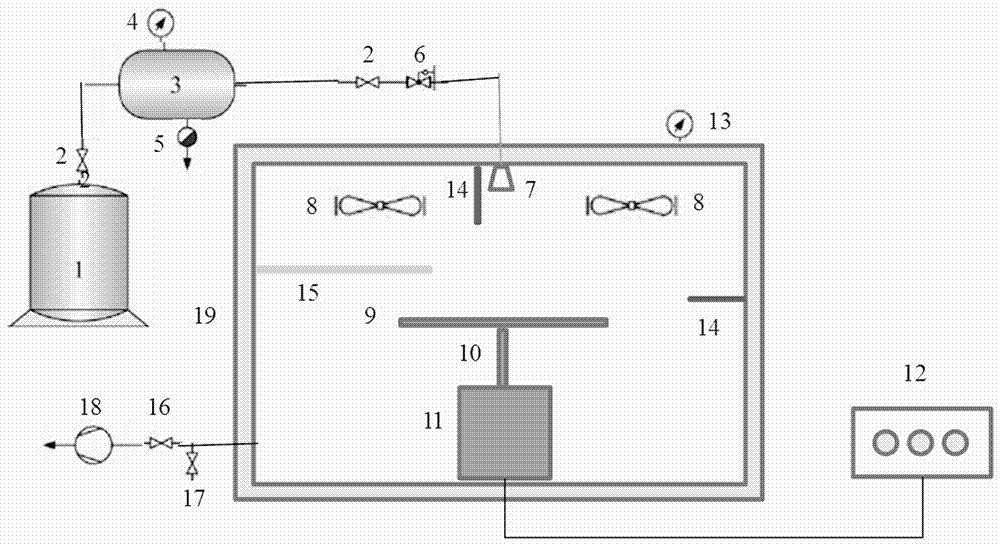

[0031] After pears are washed, peeled, cut, and cored, cut into pear slices with a thickness of 4mm, spread the pear slices of about 50g on the ultrasonic radiation plate, close the door of the drying box 19; open the vacuum pump 18, and vacuumize Make the pressure in the drying box 19 drop from normal pressure to the range of 5 ~ 10kPa within 1min, turn off the vacuum pump 18; 3 The flow rate of / min is passed into the drying oven 19. After 10s, the pressure in the drying oven 19 rises to normal pressure, and the process of inactivating the enzyme by steam is carried out. The corresponding temperature is 100°C, and the inactivation time is maintained for 30s. If the time is too short, the enzyme inactivation will not be complete. If the time is too long, the tissue structure will be damaged due to overheating; after the steam kills the enzyme, turn on the vacuum pump 18, and after the pressure is reduced to 10kPa again, adjust the vacuum rate by controlling the vacuum regulati...

Embodiment 2

[0034] After fresh jujube is washed, peeled, pitted and cut, cut into jujube slices with a thickness of 4 mm, spread the jujube slices of about 50 g on the ultrasonic radiation plate 9, close the door of the drying box 19, and turn on the vacuum pump 18 for vacuuming , the pressure in the drying box 19 is reduced from normal pressure to the range of 5~10kPa within 1min, and the vacuum pump 18 is turned off; 3 The flow rate of / min is passed into the drying oven 19. After 10s, the pressure in the drying oven 19 rises to normal pressure, and the process of inactivating the enzyme by steam is carried out. The corresponding temperature is 100°C, and the inactivation time is maintained for 30s. If the time is too short, the enzyme inactivation will not be complete. If the time is too long, the tissue structure will be damaged due to overheating; after the steam kills the enzyme, turn on the vacuum pump 18, and after the pressure is lowered to 7kPa, adjust the vacuum rate by controll...

Embodiment 3

[0037] Pick Eucommia ulmoides that are mature, bright in color and uniform in size, weigh about 50g and spread them on the ultrasonic radiation plate 9, close the door of the drying box 19, and turn on the vacuum pump 18 to evacuate, so that the pressure in the drying box 19 is within 1min Drop the vacuum pump 18 from normal pressure to the range of 5-10kPa; 3 The flow rate per minute is passed into the drying oven 19, and after 10 seconds, the pressure in the drying oven 19 rises to normal pressure, and the process of inactivating enzymes by steam is carried out, and the corresponding temperature is 100°C. Maintain the enzyme inactivation time for 30s. If the time is too short, the enzyme will not be completely inactivated. If the time is too long, the tissue structure will be damaged due to overheating; Adjust the vacuum rate, and at the same time pass steam to provide dry medium, use steam valve 2 to control the flow. By controlling the vacuum regulating valve 16 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com