Polyurethane flexible foam continuous powdering device and powdering method thereof

A technology of polyurethane flexible foam and milling device, which is used in grain processing, cocoa, plastic recycling, etc., can solve the problems of decreased application performance, inactivation of prepared particles, and difficult to control severe heat generation, and achieves low density and increased retention. time, the effect of realizing automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

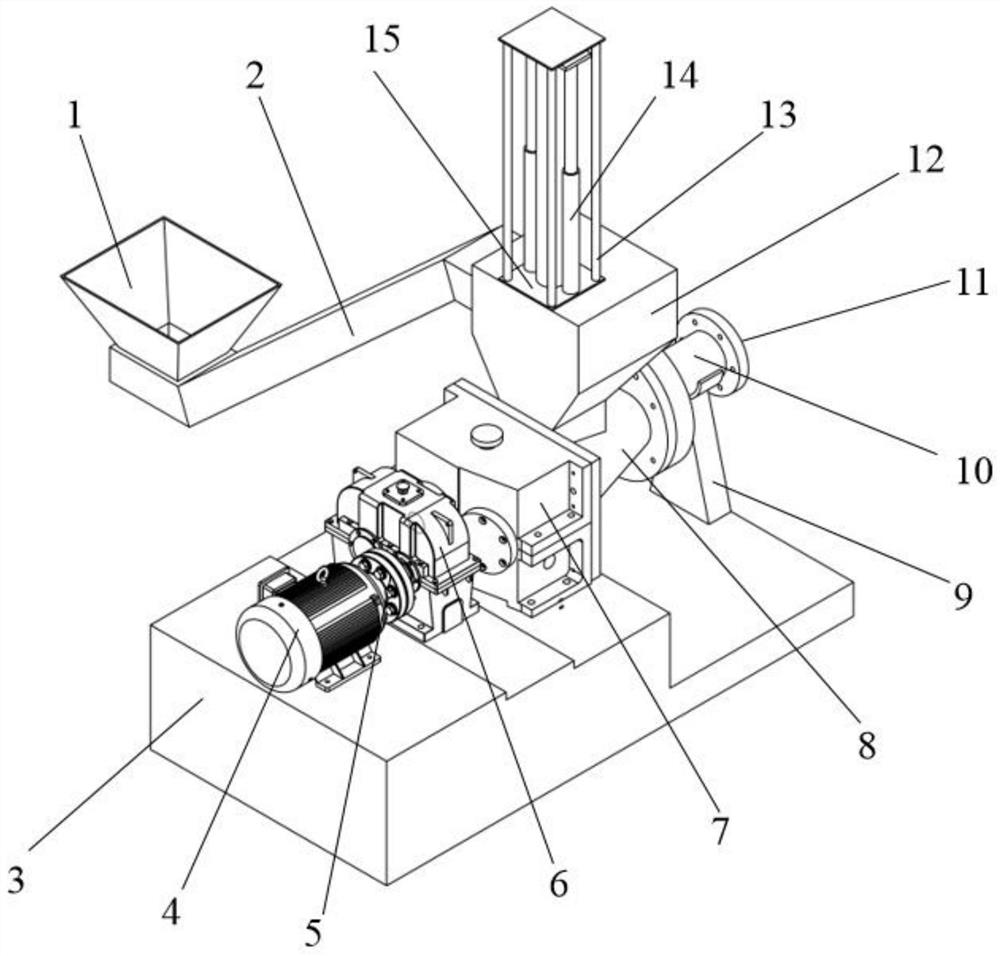

[0049] The polyurethane soft foam waste is placed in a constant temperature conveying and feeding module, and the polyurethane soft foam waste enters the first section of the extruder of the mechanical shearing powder making module, and one of the extruders is a pin-type single-screw extruder, and the number of pins is A row of 6, a total of 10 rows, open the drive device, the drive device through the transmission device to drive the double-headed screw with a speed of 90r / min, a compression ratio of 6, and a length-to-diameter ratio of 1:20 to rotate in the barrel, so that the material is continuously It is conveyed forward, and then the material is transported through the first stage of the extruder to the roller head, and the material passing through the roller head will enter the quantitative metering conveying device, and then be conveyed to the second stage extruder, of which the second stage extruder is a pin Type single-screw extruder, the number of pins is 12 in a row,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com