Formaldehydeless fine wooden board and its preparing method

A technology of blockboard and production method, which is applied in wood processing equipment, jointing of wooden veneers, veneer presses, etc., and can solve problems such as threats to people's health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments.

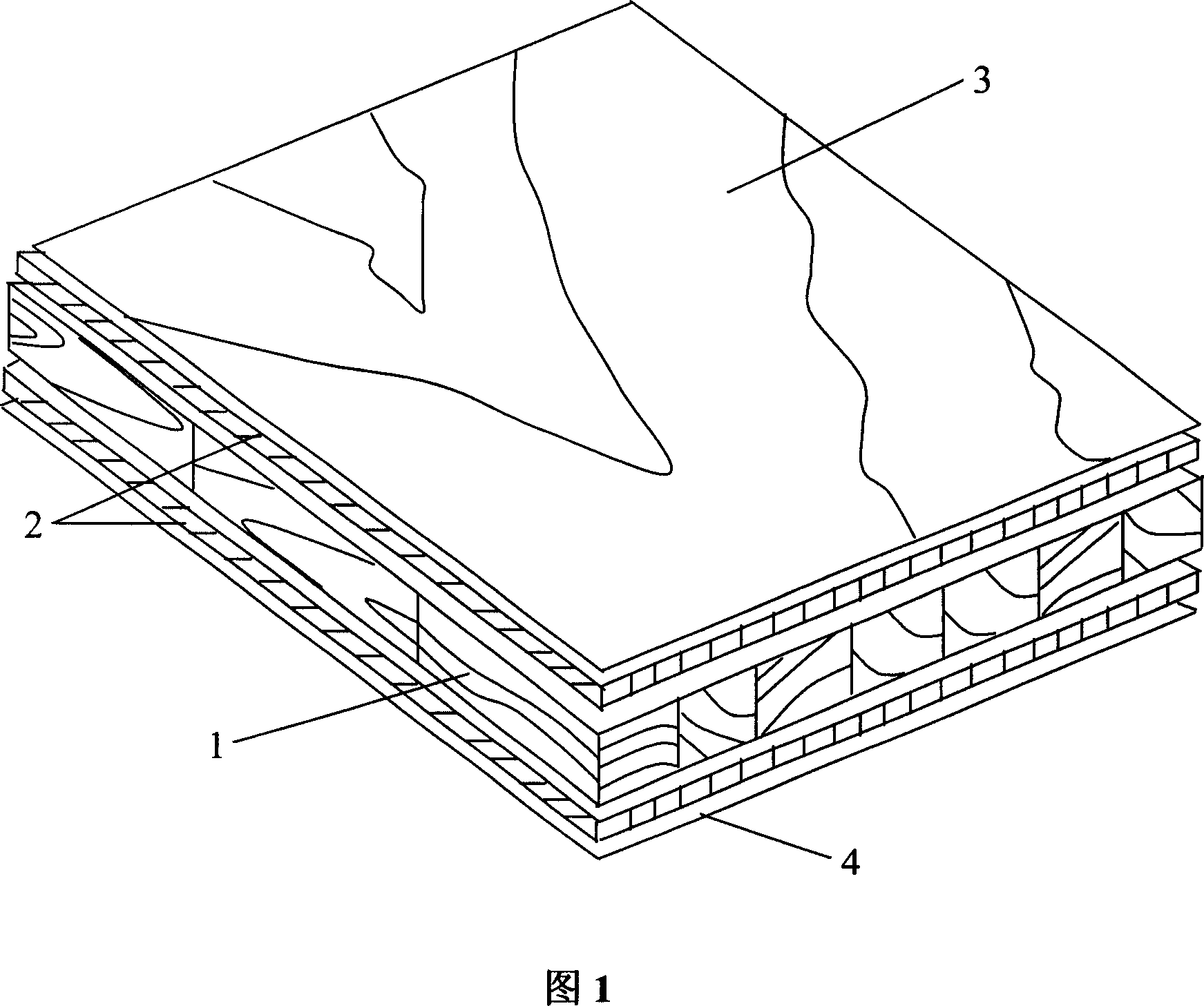

[0019] The formaldehyde-free blockboard provided by the present invention is composed of 5 layers, the middle layer is a layer of wooden square strips, and the upper and lower layers of wooden square strips are respectively provided with a layer of wooden middle boards, and the two layers of wooden middle boards are respectively provided with a A layer of surface boards and a layer of bottom boards are bonded with formaldehyde-free adhesives between the layers.

[0020] The used tool and equipment of the preparation method of the present invention are commonly used plywood, blockboard production equipment (such as cold press, hot press, gluing machine, glue spraying machine, paving machine, sanding machine, edge sawing machine) Wait).

[0021] The materials are middle boards, wooden strips, surface boards, and bottom boards of any wood species, and the adhesives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com