Chromium-free insulation coating material for non-oriented silicon steel

A technology of insulating coating and oriented silicon steel, which is applied in coatings, organic insulators, epoxy resin coatings, etc., can solve the problems of dull coating, poor annealing, rejection by downstream users, etc., achieve excellent insulation, eliminate hair loss, etc. sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

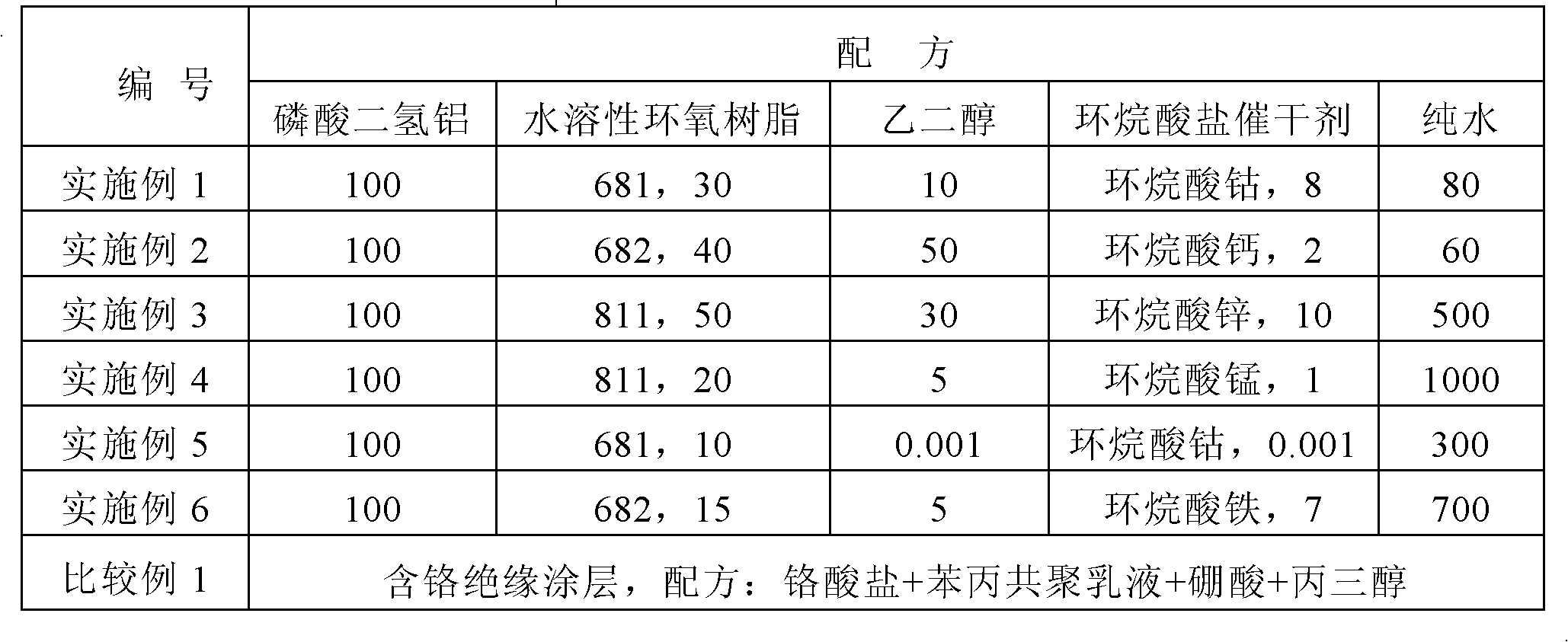

[0034] 1) Formula (in parts by mass): including aluminum dihydrogen phosphate, naphthenate driers, water-soluble epoxy resin, ethylene glycol and pure water, see Table 1 for details.

[0035] 2) Preparation and application: After mixing the above components at room temperature, use a stirring device to stir at a low speed to make it into a homogeneous solution, and use a roller coater to coat the surface of a non-oriented silicon steel plate with a thickness of 0.5 mm to maintain the coating amount. 1.8g / m 2 , using an open flame baking furnace, baked at a plate temperature of 200-500 ° C to form a film. The performance results of each coating are shown in Table 2.

[0036] Table 1

[0037]

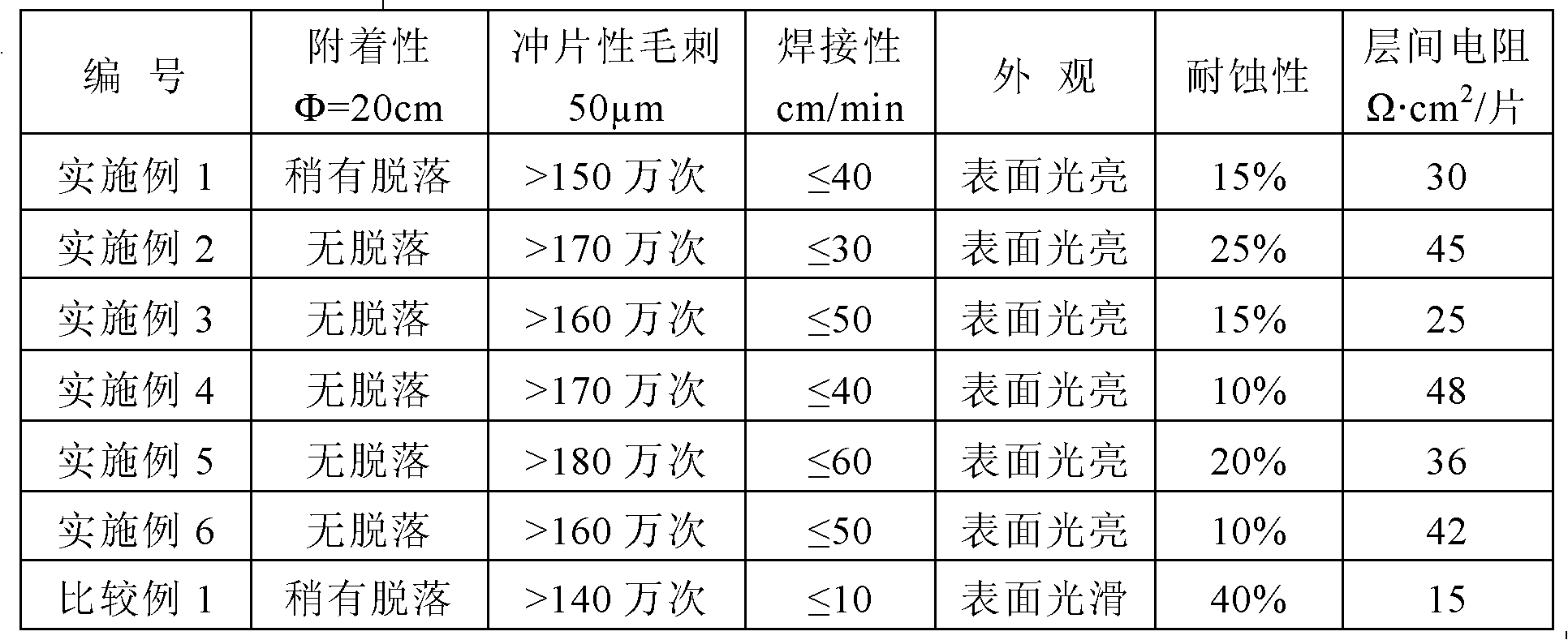

[0038] Table 2

[0039]

[0040] The performance test conditions are as follows (the same below):

[0041] Adhesion test: GB 2522-88.

[0042] Punching test: the number of punching times when the burr height is > 50 μm.

[0043] Weldability test conditions (the same below): Ine...

Embodiment 7~13

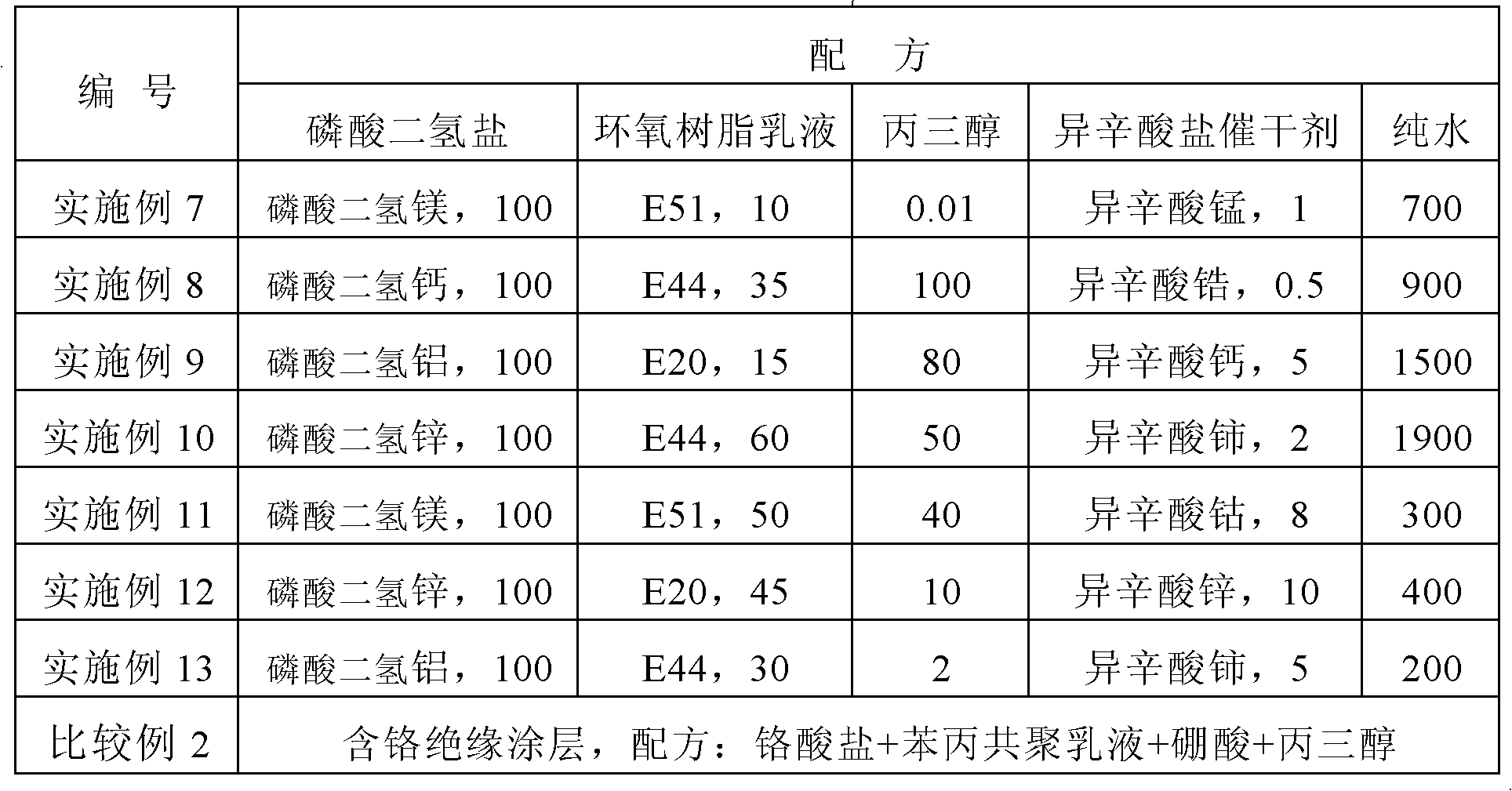

[0048] 1) Formula (in parts by mass): dihydrogen phosphate (aluminum dihydrogen phosphate, magnesium dihydrogen phosphate, calcium dihydrogen phosphate or zinc dihydrogen phosphate), epoxy resin emulsion (in dry parts), isooctyl Salt driers, glycerol and pure water, see Table 3 for details.

[0049] 2) Preparation and application: Mix the above-mentioned components at room temperature and stir with a magnetic stirring device for 10 minutes, then use a roller coater to coat the surface of a non-oriented silicon steel plate with a thickness of 0.5mm, and keep the coating amount at 1.8g / m 2 , using an open flame baking furnace, and baked at a plate temperature of 200-500 ° C to form a film. The performance results of each coating are shown in Table 4.

[0050] table 3

[0051]

[0052] Table 4

[0053]

[0054] in:

[0055] P (phosphorus) dissolution test: put the coating sample with a fixed area in the waste water and boil for 10 minutes, then use ICP to test the P diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com