A kind of crude oil surfactant and its preparation method and application

A surfactant and crude oil technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of unsatisfactory protection, cost reduction of medium and low permeability reservoirs, etc., to increase production efficiency and reduce adhesion work , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare according to the following steps on the basis of 100% of the total weight of surfactant prepared:

[0042] 1. First, add 1% fatty acid diethanolamide into water to dissolve, and stir with a stirrer at a speed of 800r / min to fully mix it with water.

[0043] 2. After stirring evenly, add 5% polyoxyethylene fatty acid amide successively (preparation method: 1. Use oleic acid and diethanolamine (molar ratio: 2:5) to react at a reaction temperature of 140-150°C for 3 hours to obtain oil 2. Use oleic acid diethanolamide and ethylene oxide (molar ratio 1:3.5) to react for 4 hours at a reaction temperature of 160-180°C to obtain polyoxyethylene fatty acid amide. Performance parameters: average Molecular weight: 500, density 1.029g / cm 3, 0.1% surface tension 28.9mN / m) and 10% heptadecyl dimethyl betaine, fully stirred for 60 minutes to form a surfactant complex solution.

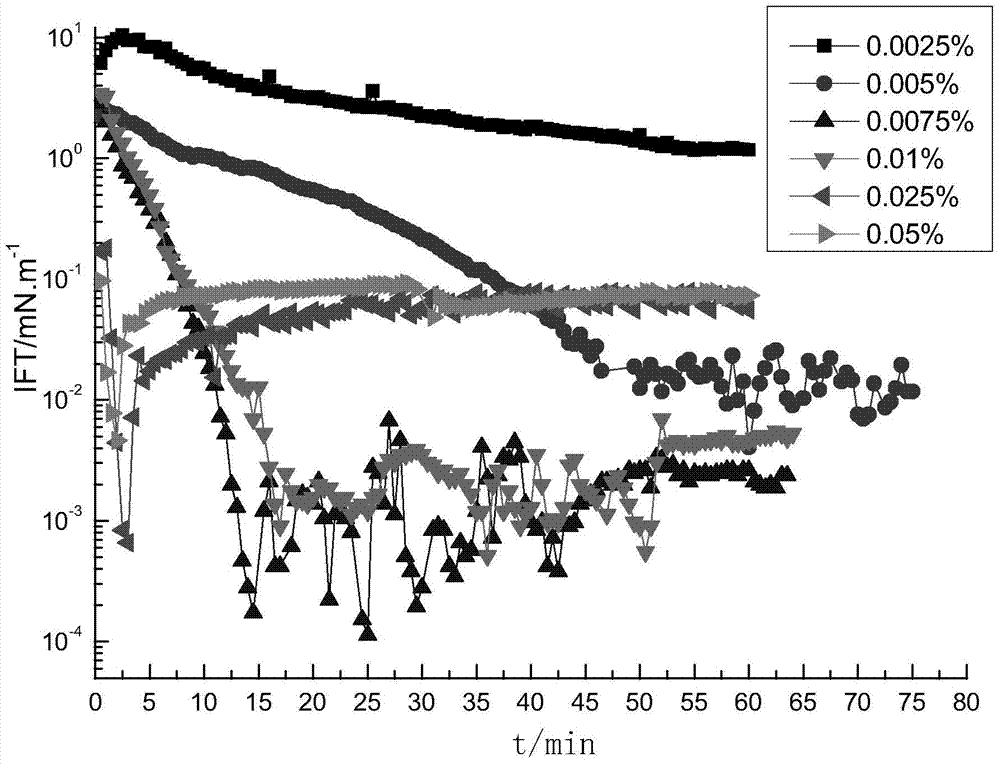

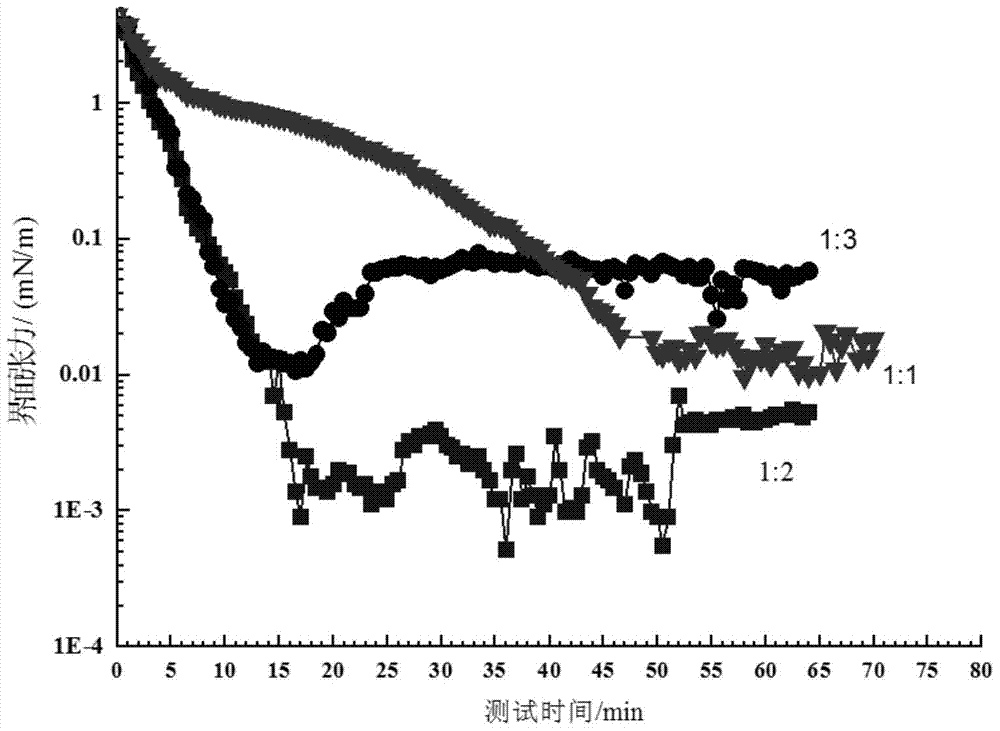

[0044] Laboratory tests show that the surfactant compound solution can form 10% with crude oil a...

Embodiment 2

[0047] 1. First, add 1% fatty acid diethanolamide into water to dissolve, and stir with a stirrer at a speed of 800r / min to fully mix it with water.

[0048] 2. After stirring evenly, add 10% polyoxyethylene fatty acid amide (prepared according to Example 1) and 20% heptadecyldimethyl betaine respectively in sequence, and stir fully for 100 minutes to form a surfactant compound solution.

[0049] Laboratory tests have shown that the surfactant compound solution can form 10% dehydrated crude oil with crude oil at 45°C in the concentration range of 0.0085% for Hainan 3 blocks of dehydrated crude oil. -3 ~10 -4 Ultra-low interfacial tension of mN / m.

Embodiment 3

[0051] 1. First, add 1.5% fatty acid diethanolamide into water to dissolve, and stir with a stirrer at a speed of 800r / min to fully mix it with water.

[0052] 2. After stirring evenly, add 8% polyoxyethylene fatty acid amide (prepared according to Example 1) and 16% heptadecyl dimethyl betaine successively respectively, and fully stir for 100 minutes to form a surfactant compound solution.

[0053] Laboratory tests have shown that the surfactant compound solution can form 10% dehydrated crude oil with crude oil at 45°C in the concentration range of 0.0082% for Hainan 3 blocks of dehydrated crude oil. -3 ~10 -4 Ultra-low interfacial tension of mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com