Patents

Literature

172results about How to "Improve oil washing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

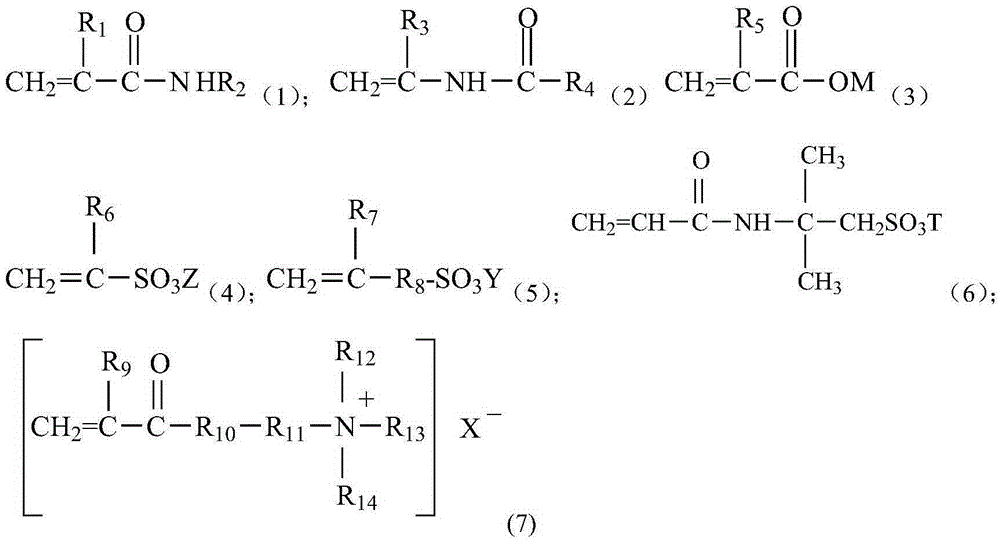

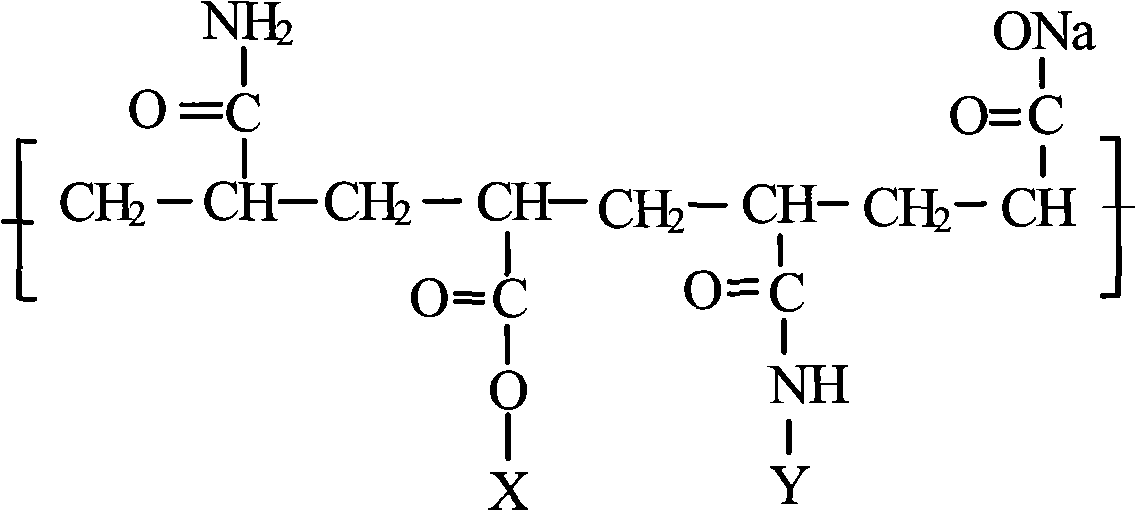

Preparation method of profile control and oil displacement system of polyacrylamide nanometer microsphere with low interfacial tension

InactiveCN101759838AReduce interfacial tensionEnhanced overall recoveryDrilling compositionOrganic acidMicrosphere

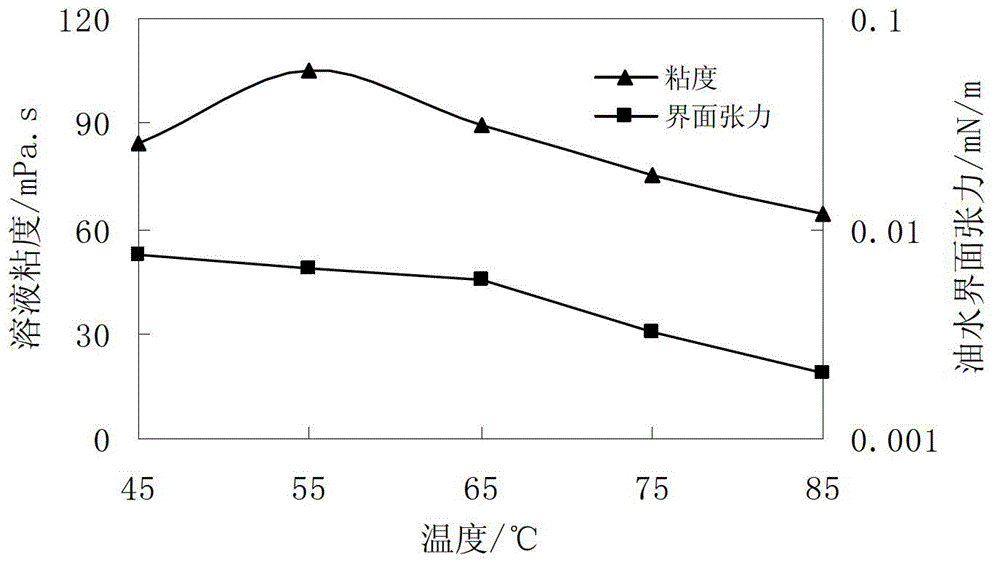

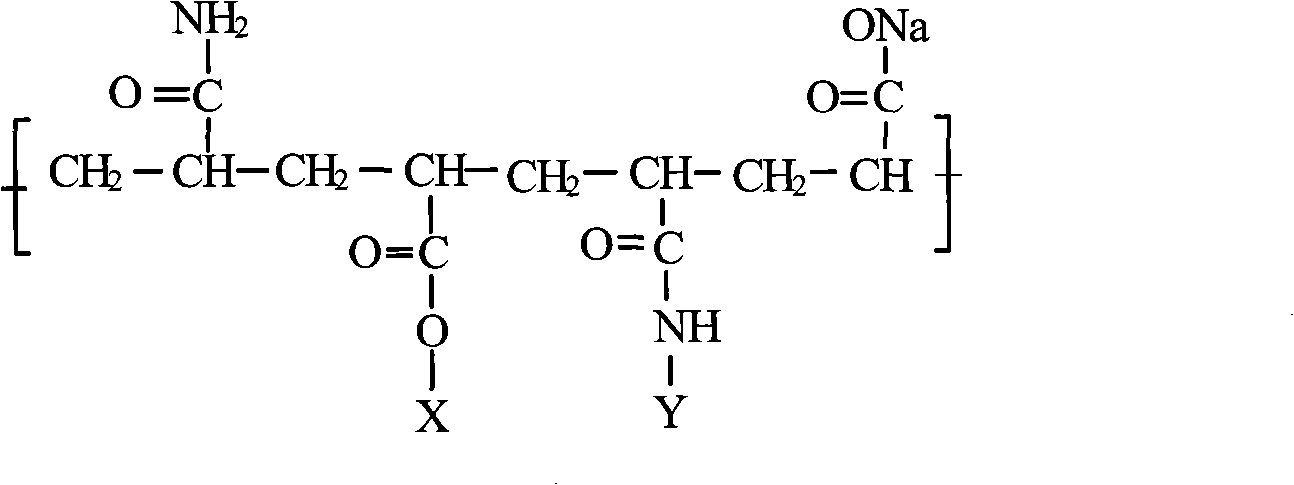

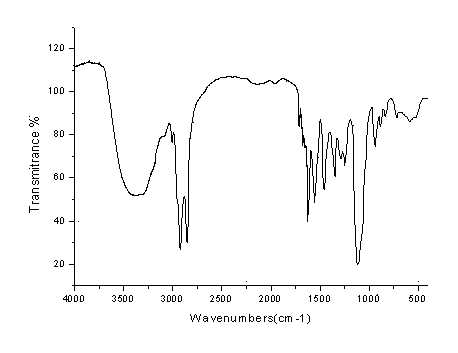

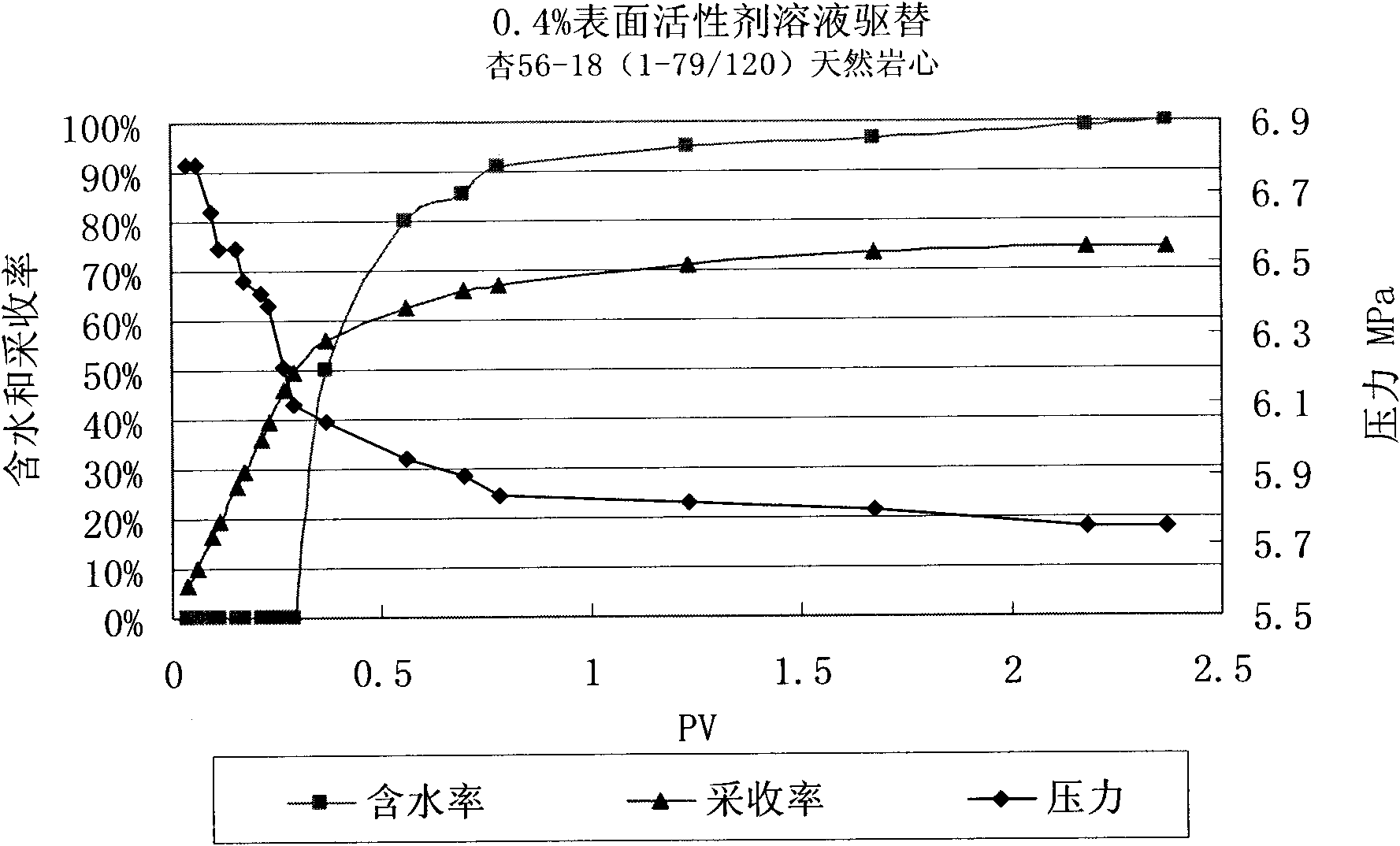

The invention relates to a preparation method of a profile control and oil displacement system of polyacrylamide nanometer microsphere with low interfacial tension, which comprises the steps of: inversely preparing microemulsion with oil phase, combined emulsifying agents and water phase containing crosslinking agents, initiating polyreaction with a redox initiation system used as initiating agents, neutralizing the obtained polyacrylamide nanometer microsphere with alkali, and preparing highly active sulphonate or carboxylate surfactants with the reaction of the alkali and the substance of organic acid in the combined emulsifying agents; the oil water interfacial tension can be greatly reduced by the surfactants. The profile control and oil displacement system is applied to enhancing enhanced recovery ratio, has good effect on enhancing oil cleaning efficiency, and is a novel profile control and oil displacement system with the dual functions of profile control and oil displacement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

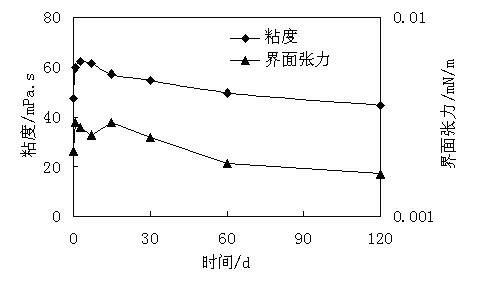

Hydrophobically associating polymer and mixed surfactant binary compound oil displacement system

InactiveCN102504794ATemperature resistanceImprove salt toleranceDrilling compositionSalt resistancePolymer science

The invention relates to a hydrophobically associating polymer and mixed surfactant binary compound oil displacement system for use in tertiary oil extraction. The system mainly comprises the following components in percentage by weight: 0.1 to 0.3 percent of hydrophobically associating polymer, 0.1 to 0.6 percent of surfactant and 99.2 to 99.8 percent of water. The hydrophobically associating polymer in the system has high temperature resistance, high salt resistance and viscosity increasing capacity and can largely reduce dosage of polymer; and with high solubilizing capacity, the polymer can increase the dissolution of the surfactant in sewage, thereby increasing the use concentration of the surfactant. The oil displacement system which is dissolved by sewage from extraction can save lots of fresh water; with high viscosity increasing capacity, the system can effectively control flow rate, increase swept volume, increase oil water interface tension to 10<-3>mN / m and increase the oil extraction rate; and because of high stability and injection property, the system can be injected in large dose. According to an indoor oil displacement experiment, the binary compound oil displacement system can improve the extraction rate by over 20 percent compared with that of water displacement. The system without alkali avoids serious damage to the oil layer and corrosion and damage to oilpipes and has a great application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

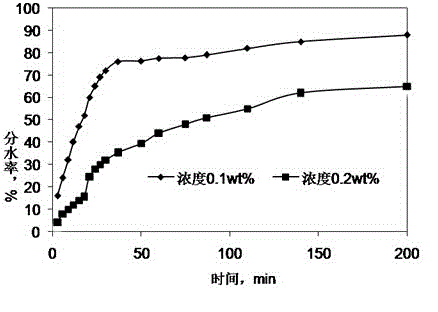

Gel foam selective water blockoff agent and use thereof

InactiveCN101481604AImprove stabilityLong water blocking periodDrilling compositionFoaming agentHexamethylenetetramine

The invention relates to gel-foam selective plugging agent and the application thereof, belonging to the technical field of oilfield chemistry. The plugging agent comprises the components: 30-50% of acrylamide, 20-40% of hexamethylenetetramine, 5-15% of phenol, 5-15% of tetraethylene pentamine and 5-15% of foaming agent. The aqueous solution with the mass ratio of 0.5-2% can be prepared in site and is injected into a well after being evenly dissolved, so that the plugging agent is used for plugging water in the oil well at the temperature of 90-150 DEG C. The plugging agent uses organic cross linker for cross bonding polymer to form gel foam under the condition of high temperature, so as to be resistant to the high temperature of 90-150 DEG C and have long period of validity in plugging water.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Foaming agent with low gas liquid ratio foam for common heavy oil reservoir and injection method thereof

InactiveCN101580705AReduce interfacial tensionHigh interface activityFluid removalDrilling compositionFoaming agentLiquid ratio

The invention provides a foaming agent for low gas liquid ratio foam flooding for improving recovery ratio of common heavy oil reservoir and an injection method thereof. The foaming agent is prepared from a nonionic-anionic surfactant, a betaine type amphoteric surfactant and water, wherein the nonionic-anionic surfactant accounts for 0.01 to 0.03 weight percent of the total weight; the betaine type amphoteric surfactant accounts for 0.05 to 0.3 weight percent of the total weight; and the balance is oil field injection water. The foaming agent has good foaming tendency, can reduce the interfacial tension of oil and water to the lowest under the condition of not adding alkali, and can give full play to the foam flooding and the improvement of conformance factor and displacement efficiency. On the basis of the foaming agent, when the gas liquid ratio is between 0.1:1 and 0.3:1 (volume ratio), the generated foam can improve the recovery ratio by over 10 percent, and the technology with low cost and good effect for improving the recovery ratio of the heavy oil reservoir is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

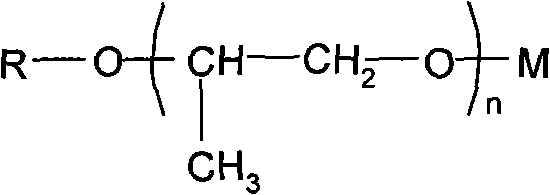

Synthesis of aliphatic alcohol polyoxyethylene sulfonate and complex formulation used for tertiary oil recovery displacement agent

InactiveCN101255127AEnhanced Oil RecoveryReduce interfacial tensionDrilling compositionSulfonic acid preparationSurface-active agentsEther

The invention relates to synthesis of polyoxyethylene fatty alcohol ether sulphonate, and complex formulation for tertiary oil recovery displacement agent, and belongs to chemical displacement agent technic field. The invention discloses a synthesis method of a surface active agent for tertiary oil recovery for a high-temperature, high salinity and high calcium and magnesium ion oil reservoir, and complex formulation for highly effective displacement agents. Polyoxyethylene fatty alcohol ether sulphate is reacted with a sulfonating agent under the action of catalyst to produce polyoxyethylene fatty alcohol ether sulphonate. Polyoxyethylene fatty alcohol ether sulphonate are used as main material which is complex formulated with heavy alkyl benzene sulfonate, water, polymerisate, etc. Compared with existing products, the displacement agent of the invention in the three-high system reduces the oil-water boundary tension ultra-low (10<-3>mN / m), and the boundary tension is not affected by temperature, degree of mineralization and the concentration of calcium and magnesium ions.

Owner:JIANGNAN UNIV

Profile controlling and flooding composition for high-temperature oil reservoirs with high salinity

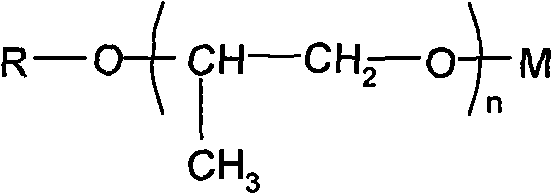

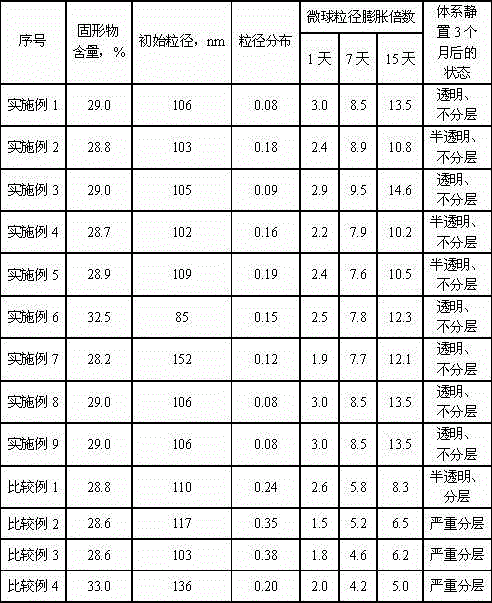

ActiveCN104559992AGood temperature and salt resistanceNarrow particle size distributionDrilling compositionThermodynamicsMicrosphere

The invention relates to a profile controlling and flooding composition for high-temperature oil reservoirs with high salinity and an application of the composition in tertiary oil recovery of the high-temperature oil reservoirs with high salinity, and mainly aims at solving the problems of poor heat resistance and salt tolerance and low oil displacement efficiency of an oil displacement agent under the conditions of high temperature and high salinity in the prior art. The problems are well solved by virtue of the following technical scheme: the profile controlling and flooding composition for high-temperature oil reservoirs with high salinity is prepared from the following components in percentage by weight: (1) 0.01-3.0% of heat-resistant and salt-tolerant polyacrylamide microspheres, (2) 0.01-5.0% of anionic-nonionic surfactant and (3) 92.0-99.98% of injected water; and the profile controlling and flooding composition can be applied to field applications for increasing the recovery rate such as depth profile controlling, water plugging and oil displacement for tertiary oil recovery of the high-temperature oil reservoirs with high salinity.

Owner:CHINA PETROLEUM & CHEM CORP +1

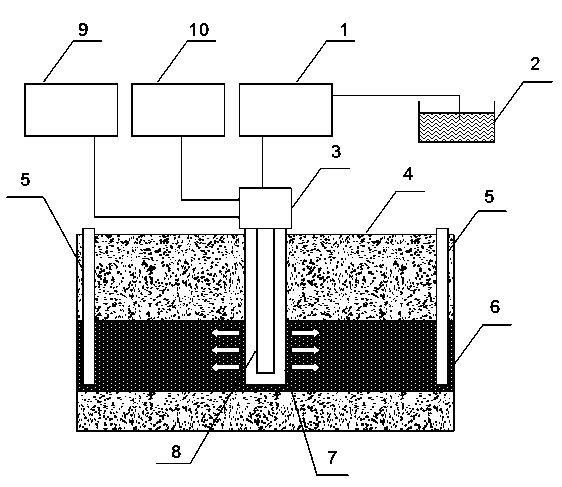

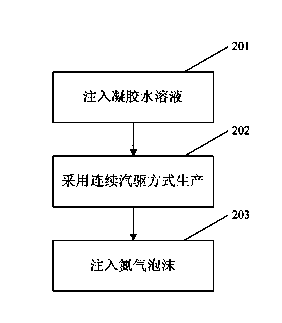

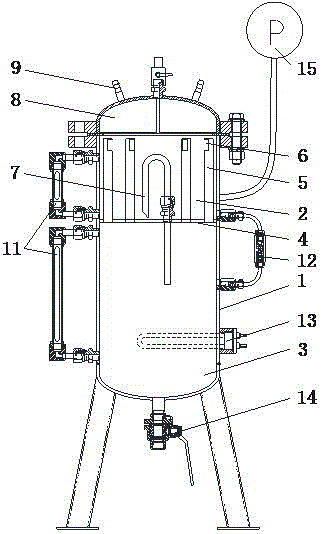

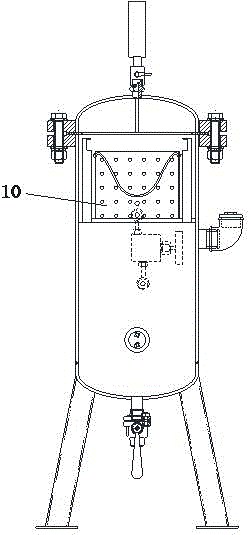

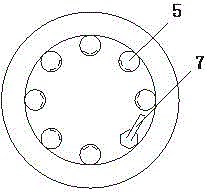

High-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding

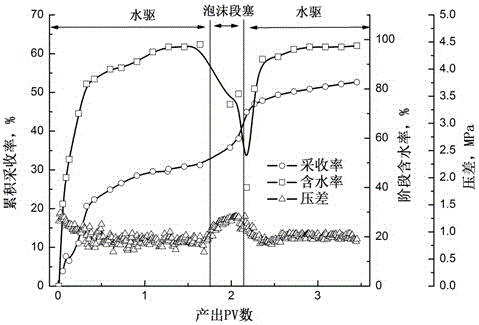

ActiveCN103541705AExpand the affected volumeReduce water contentFluid removalFoaming agentGas oil ratio

The invention provides a high-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding. The high-temperature blocking and adjusting device for super-heavy oil reservoir steam flooding comprises an injection device, a thermal-recovery steam injection well mouth, a nitrogen injection device and a steam injection device. The injection device is connected with the thermal-recovery steam injection well mouth for injecting gel solutions or foaming agent solutions, the nitrogen injection device is connected with the thermal-recovery steam injection well mouth and used for generating and injecting high-purity nitrogen, and the steam injection device is connected with the thermal-recovery steam injection well mouth and used for generating and injecting high-dryness steam. According to the high-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding, gel and nitrogen foams are combined, comprehensive water content of a steam flooding well group can be obviously lowered, the gas oil ratio can be obviously improved, the high-temperature blocking and adjusting effect of a super-heavy oil reservoir can be greatly improved, and blocking and adjusting cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

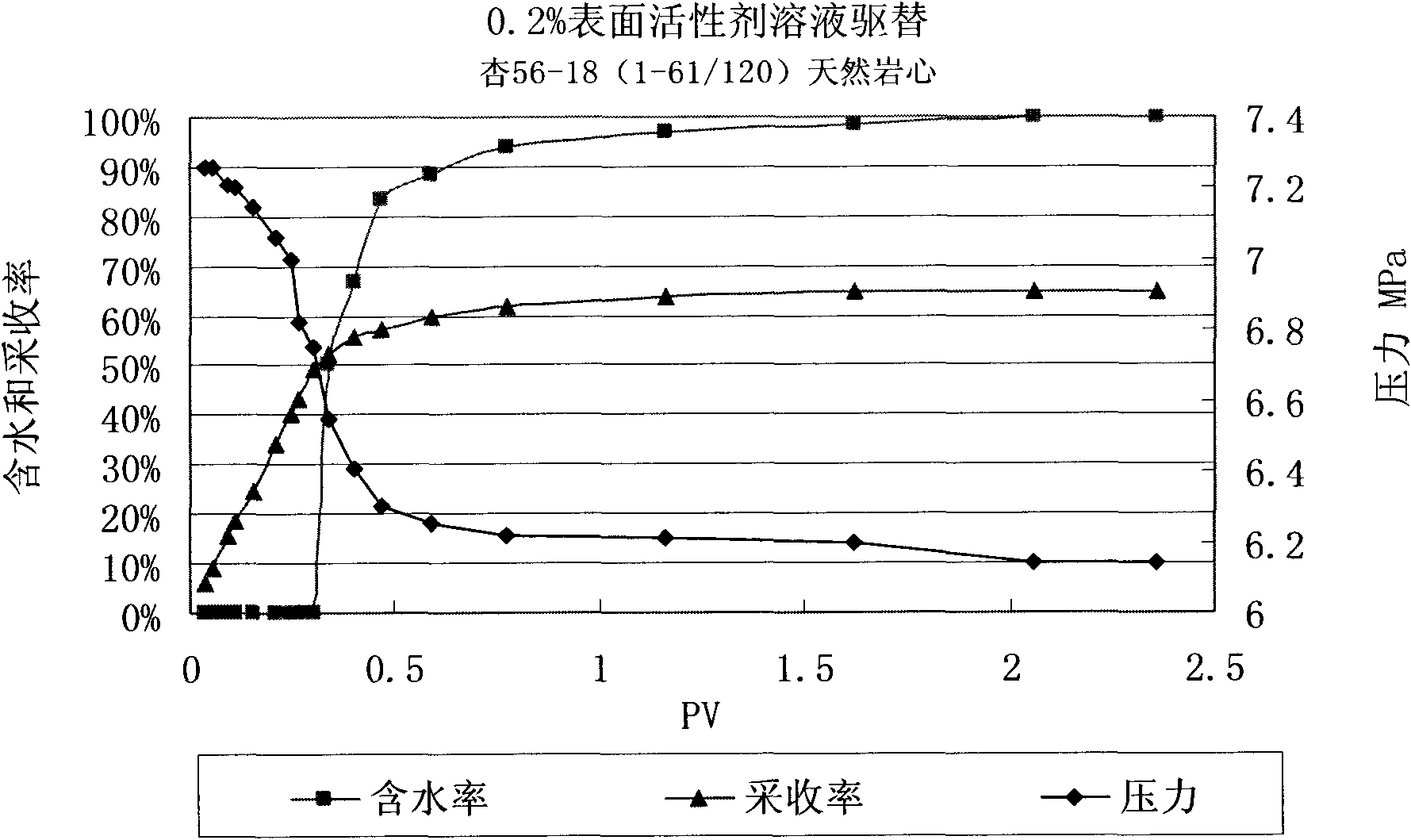

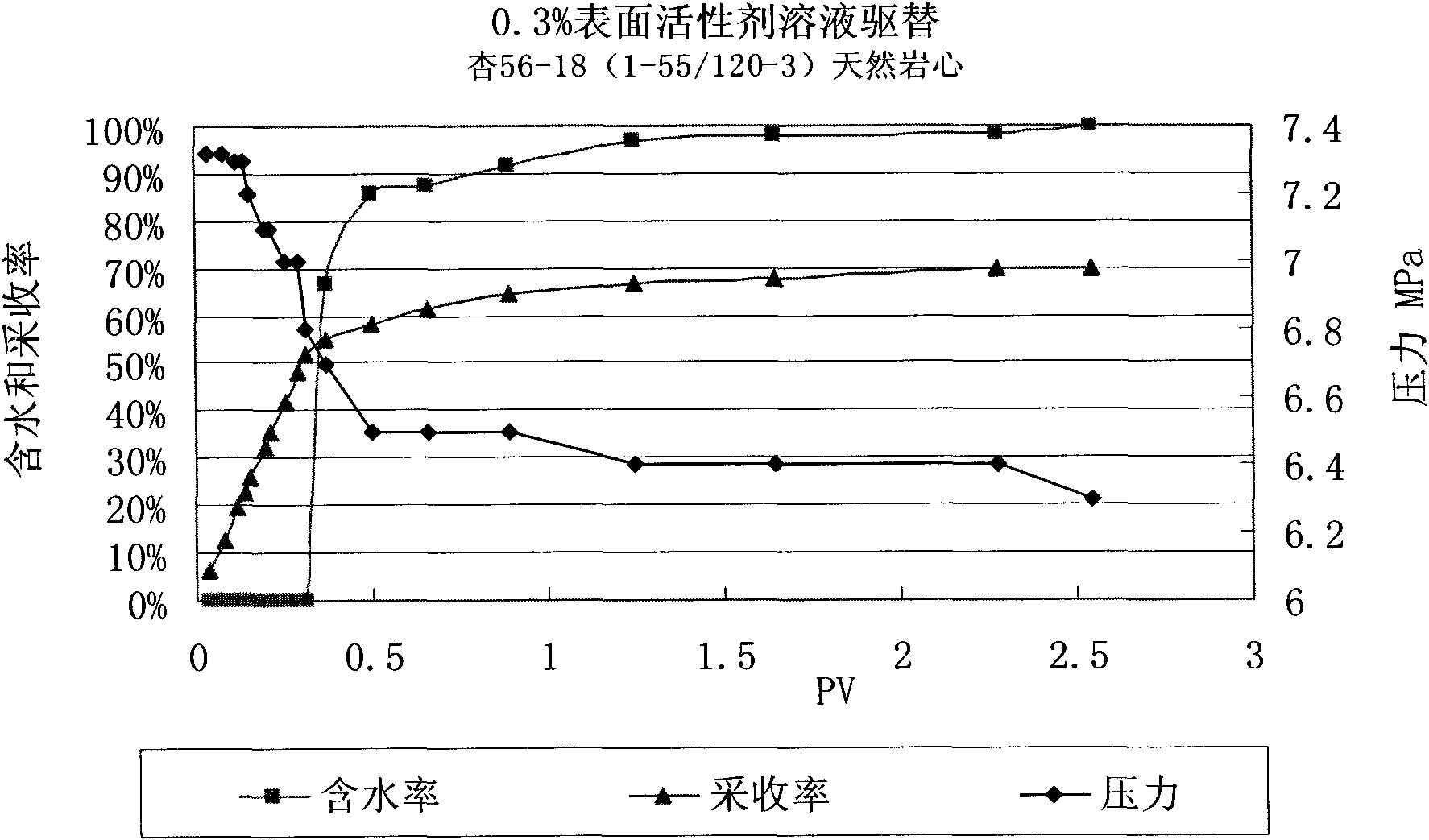

Foam oil displacement system with ultralow interfacial tension and use method of foam oil displacement system

ActiveCN105154055AReduce interfacial tensionImprove oil washing efficiencyFluid removalDrilling compositionCelluloseCocamidopropyl dimethylamine

The invention provides a foam oil displacement system with ultralow interfacial tension and a use method of the foam oil displacement system. The oil displacement system is formed by mixing raw materials in percentage by weight as follows: 0.1%-0.3% of a foaming agent, 0.05%-0.15% of an inorganic reagent, 0.01%-0.10% of a foam stabilizer and the balance of water, wherein the foaming agent is dodecyl dimethyl betaine, dodecyl hydroxysulfobetaine, dodecyl hydroxypropyl sulphobetaine, lauramide propyl hydroxysulfobetaine, lauramide propyl betaine, cocamidopropyl dimethylamine oxide, gemini oxidized tertamine, polyoxyethylene dodecanol ether sulfate or sodium dodecyl sulfate; the inorganic reagent is sodium hydroxide, anhydrous sodium carbonate or sodium metaborate; the foam stabilizer is partially HPAM (hydrolyzed polyacrylamide), acrylamide copolymer, PACHV (high-viscosity polyanionic cellulose) or HPMC (hydroxypropyl methyl cellulose).

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for carrying out profile control on fracture-type oil reservoir

The invention relates to a method for carrying out profile control on a fracture-type oil reservoir, which comprises the following steps of injecting 0.1 to 0.3 percent of zwitterionic polymer solution into an oil layer; suspending and carrying expansion-retarding 0.2 to 1.0 percent of salt-resistance high-intensity water-absorbent resin particles by a zwitterionic gel profile control agent and injecting the obtained product into a fracture of the oil layer; injecting 30 to 50m<3> of acrylamide gel; suspending 0.2 to 0.5 percent of water insoluble solid particles by the zwitterionic gel profile control agent and injecting the obtained product into the fracture; and alternately injecting 1,000m<3> of partially hydrolyzed polyacrylamide solution with a molecular weight of 15 million, degree of hydrolysis of 10 to 20 percent and 1,000m<3> of petroleum sulfonate surfactant solution, wherein the concentration of the hydrolyzed polyacrylamide solution is 0.05 to 0.15 percent and the concentration of the petroleum sulfonate surfactant solution is 0.2 to 0.5. According to the method, profile control and flooding effects of the fracture-type oil reservoir can be improved; water content of a fracture main direction oil well is reduced; and yield of crude oil of a fracture side direction oil well is increased.

Owner:PETROCHINA CO LTD

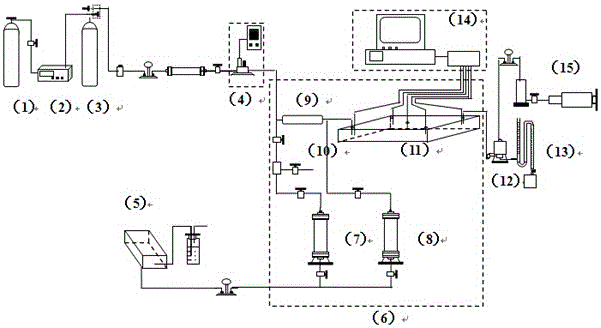

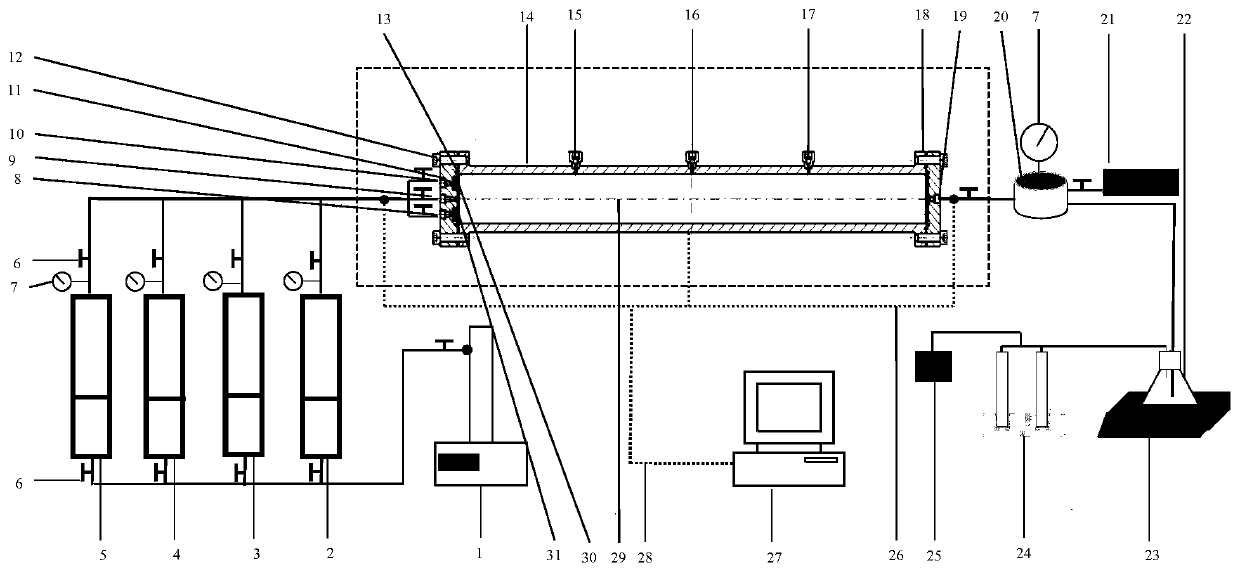

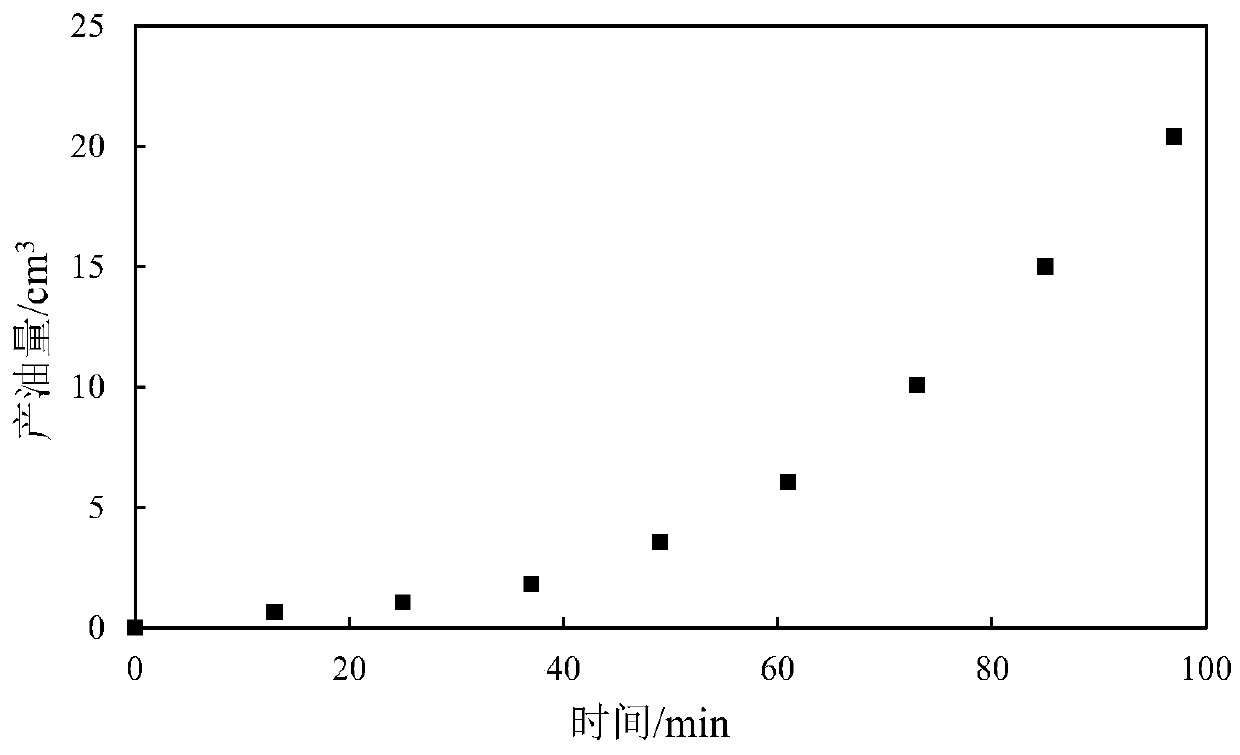

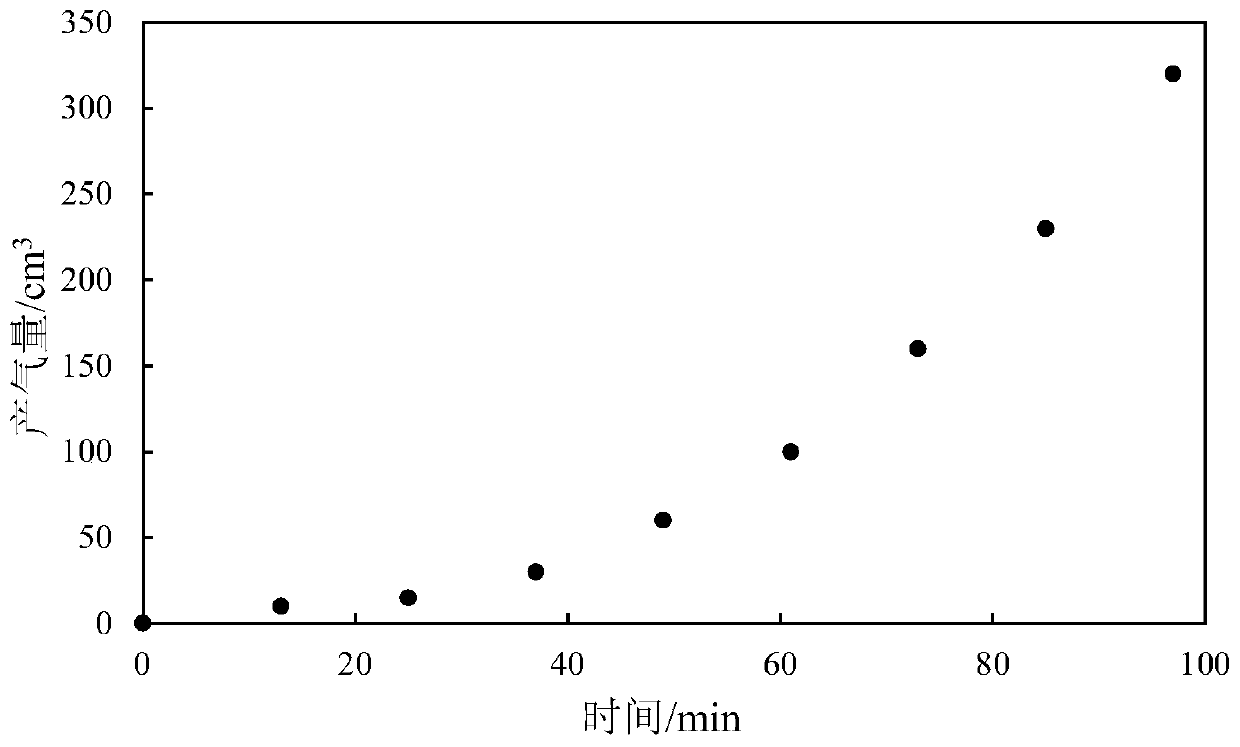

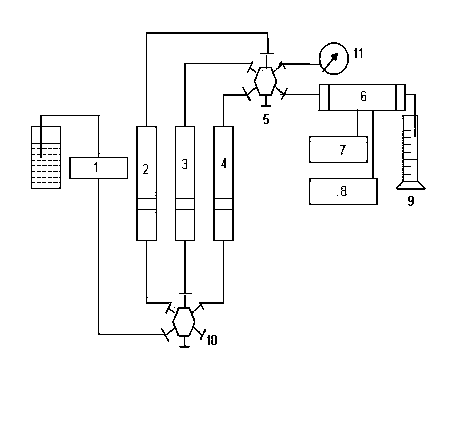

Experimental device and experimental method for thickened oil pool mixed nano-fluid alternating CO2 microbubble flooding

ActiveCN110130859AReduce oil-water interfacial tension and heavy oil viscosityChange wettabilitySurveyFluid removalOil pullingOil viscosity

The invention discloses an experimental device and experimental method for thickened oil pool mixed nano-fluid alternating CO2 microbubble flooding. The experimental device and experimental method forthickened oil pool mixed nano-fluid alternating CO2 microbubble flooding introduces mixed nano-particles and combines the advantages of CO2 microbubbles, the phenomena of gas channeling and gravity override of a thickened oil pool occurred during conventional CO2 gas-water alternate flooding can be effectively controlled through a mode of alternating injection, and the recovery efficiency of thethickened oil pool is improved. Compared with CO2 gas, dissolving and diffusing abilities of the CO2 microbubbles are greater in crude oil, buoyancy is smaller, thickened oil viscosity can be better reduced, the volume of thickened oil is expanded, and the sweep coefficient is increased; the mixed nano-fluid can fully combine the advantages of various nano-particles, wettability of oil pull rockscan be changed, the oil-water interfacial tension can be reduced, and the oil washing efficiency is improved; and in addition, the experimental device and experimental method for thickened oil pool mixed nano-fluid alternating CO2 microbubble flooding adopts the method of injecting a mixed nano-fluid slug on the upper part of an oil pool and a CO2 microbubble slug on the lower part, controlling ofthe phenomena of the gas channeling and the gravity override and improvement of the vertical sweep coefficient are helped.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

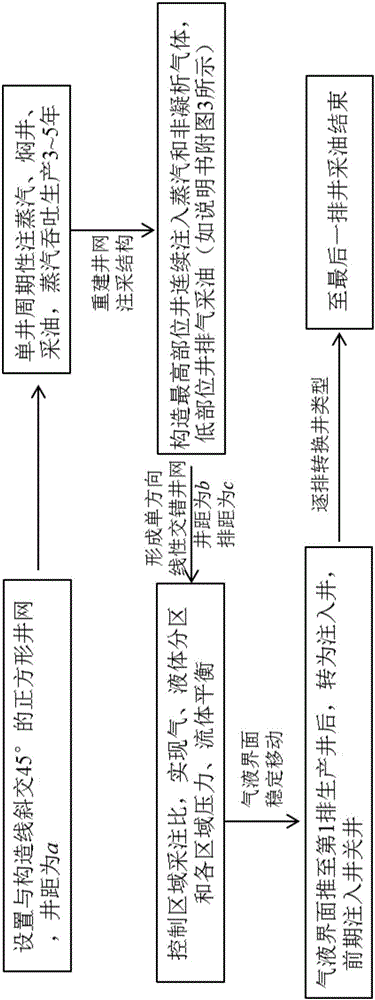

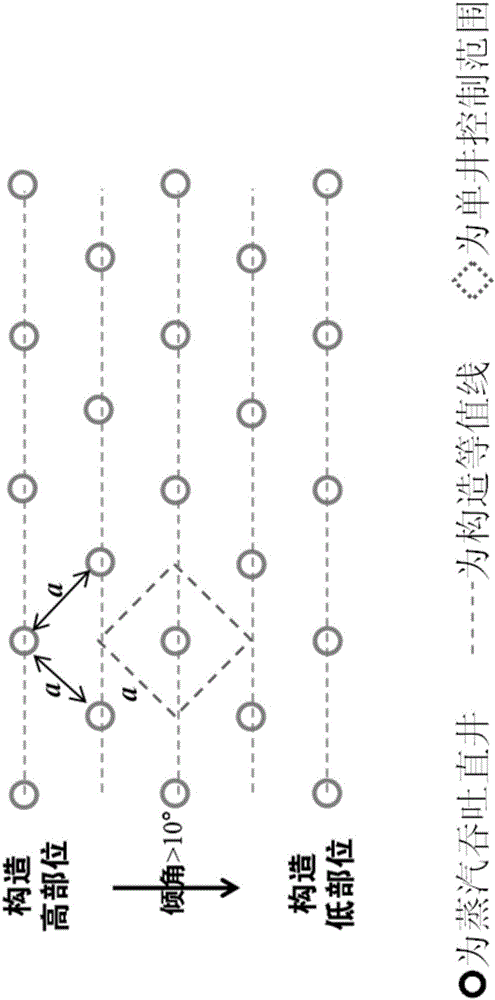

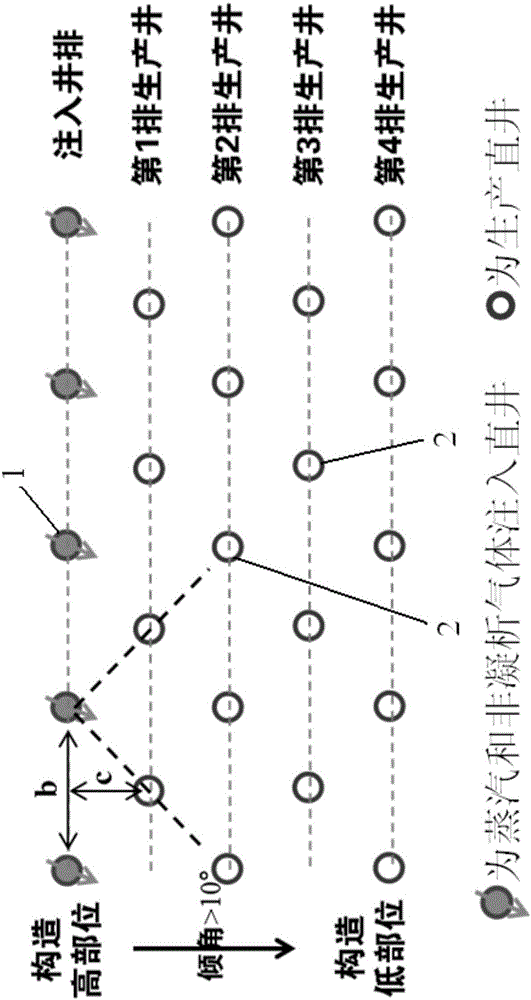

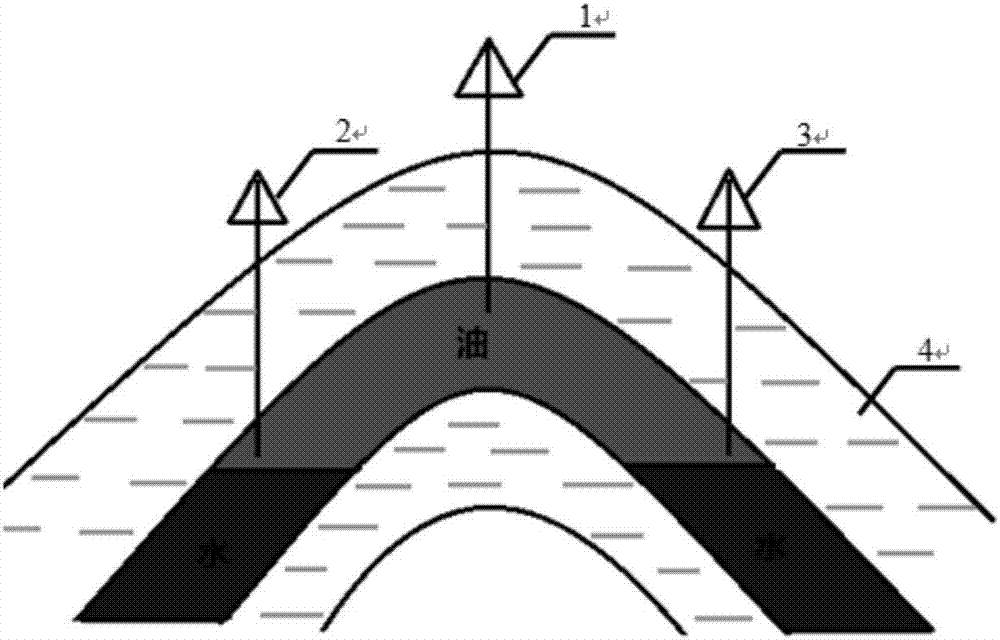

Method for exploiting high-inclined-angle heavy oil reservoir by plane gravity displacement

ActiveCN107435535AGuaranteed one-way advancementImprovement factorFluid removalDensity differenceHot Temperature

The invention provides a method for exploiting a high-inclined-angle heavy oil reservoir by plane gravity displacement. According to the method for exploiting the high-inclined-angle heavy oil reservoir by plane gravity displacement, a plane gravity oil displacement mode using steam injection as a major measure and non-condensable gas injection as an auxiliary measure is designed. Steam and non-condensable gas are proportionally injected; high-temperature hot water and non-condensable gas in the stratum can easily form a secondary gas cap and a secondary water zone with the obvious spatial variation effects due to the density differences; the high-temperature secondary water zone provides a heating resource for a downstream cold oil zone; and the breakthrough of the injection gas towards a production well in a low structure position is prevented. Meanwhile, the oil reservoir integral scaled development is realized; the unidirectional linear staggered well network development is used; and the plane conformance coefficient and the recovery efficiency are improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Profile controlling and flooding composition and application thereof

InactiveCN106589226AGood temperature and salt resistanceNarrow particle size distributionDrilling compositionState of artMicrosphere

The invention relates to a profile controlling and flooding composition of a high-temperature, high-salinity and low-permeability oil reservoir and application thereof in tertiary oil recovery of the high-temperature, high-salinity and low-permeability oil reservoir. The profile controlling and flooding composition aims at solving the problems that in the prior art, the heat resistant and salt resistant performance of an oil-displacing agent are poor and the flushing efficiency is low under the condition of the high-temperature, high-salinity and low-permeability oil reservoir. According to the technical scheme, the profile controlling and flooding composition of the high-temperature, high-salinity and low-permeability oil reservoir comprises, by weight, 0.01-3.0% of temperature and salt resistant polyacrylamide microspheres, 0.01-5.0% of anionic-nonionic surface active agent, and 92.0-99.98% of injected water, the problems are favorably solved, and the profile controlling and flooding composition can be used for on-spot application of oil recovery enhancement of deep profile controlling, water plugging, reservoir oil displacing and the like used in the tertiary oil recovery of the high-temperature, high-salinity and low-permeability oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

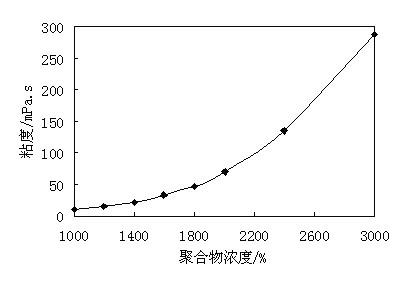

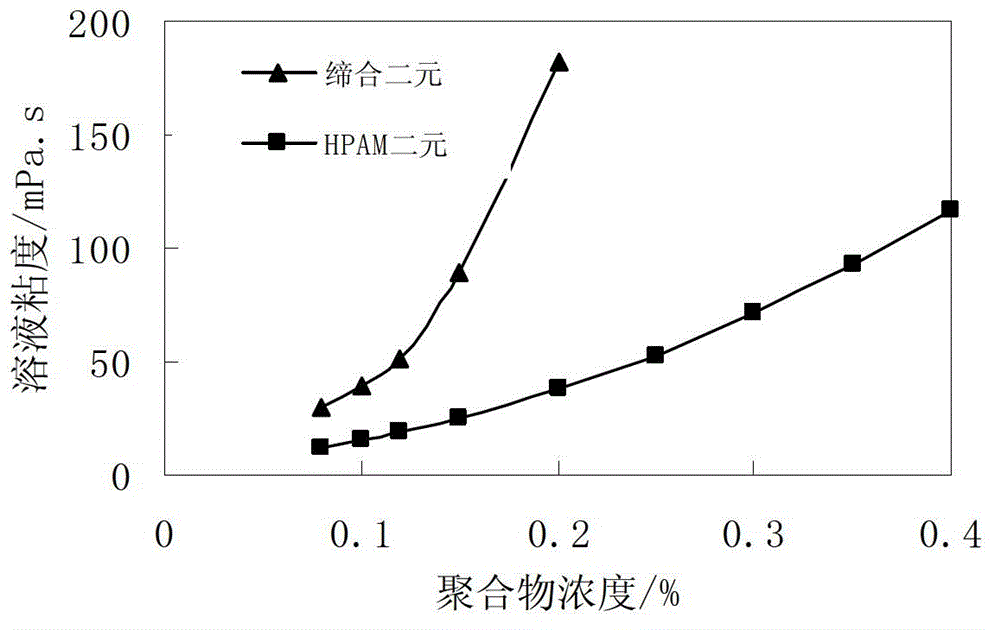

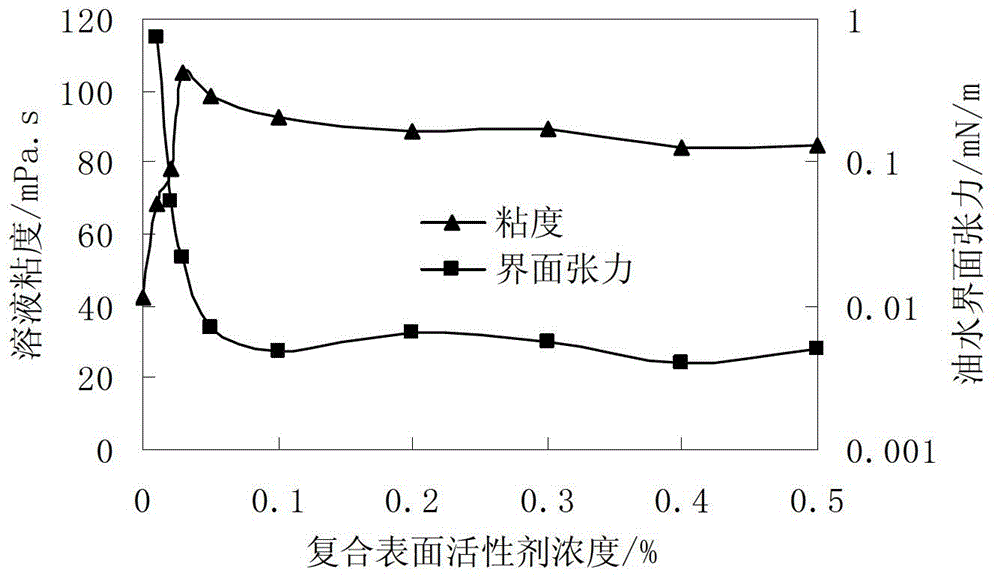

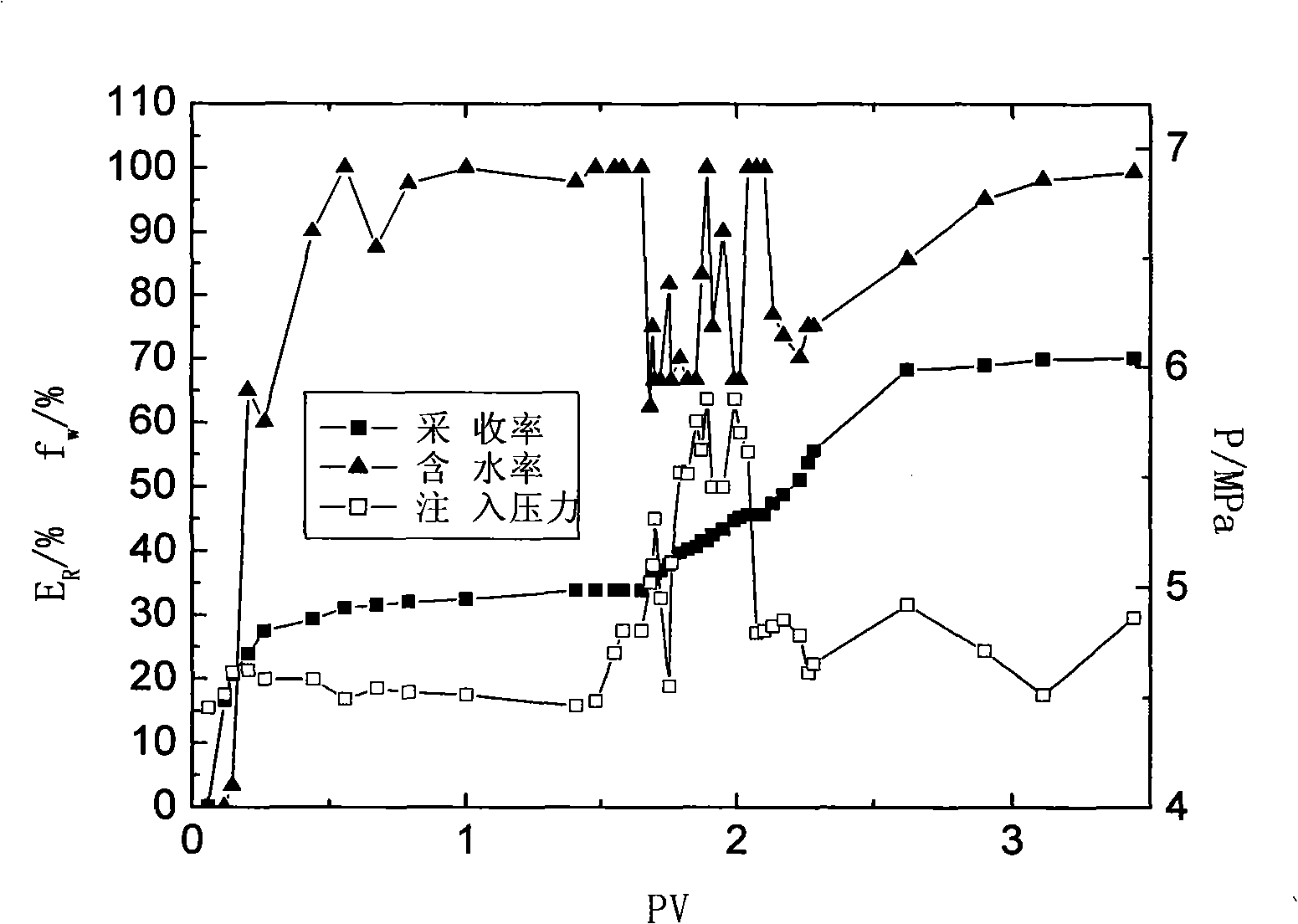

Hydrophobically associated polymer-composite surfactant binary combination flooding system and method

The invention discloses a hydrophobically associated polymer-composite surfactant binary combination flooding system and method. The hydrophobically associated polymer-composite surfactant binary combination flooding system mainly comprises the following components in percentage by weight: 0.08-0.3 wt% of hydrophobically associated polymer, 0.05-0.5 wt% of composite surfactant and 99.2-99.87 wt% of water. The composite surfactant is composed of the following components in percentage by weight: 50-70 wt% of fatty acid diester disulfonate and 30-50 wt% of oleic acid diglycollic amide. The hydrophobically associated polymer-composite surfactant binary combination flooding system has favorable tackifying property, and enables the oil-water interfacial tension to reach 10<-3>nM / m under low surfactant concentration (0.05%), thereby enhancing the displacement efficiency; and the hydrophobically associated polymer-composite surfactant binary combination flooding system can enhance the recovery rate by more than 30% on the basis of water flooding, lowers the polymer consumption by more than 50% as compared with the 250-million ultrahigh-molecular-weight polyacrylamide binary combination flooding system with close properties, and enhances the recovery rate by 6%, thereby greatly lowering the oil displacement cost on the premise of increasing the yield.

Owner:SICHUAN GUANGYA POLYMER CHEM

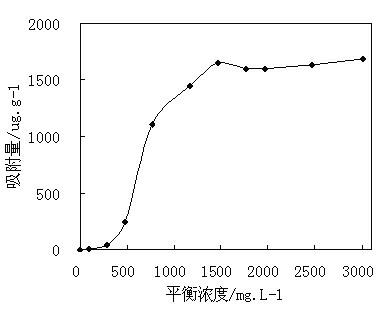

Elastic particle oil displacement profile control agent, displacement of reservoir oil system and displacement of reservoir oil method

ActiveCN101314711AEnhanced overall recoveryImprove the spread factorFluid removalDrilling compositionEconomic benefitsWater circulation

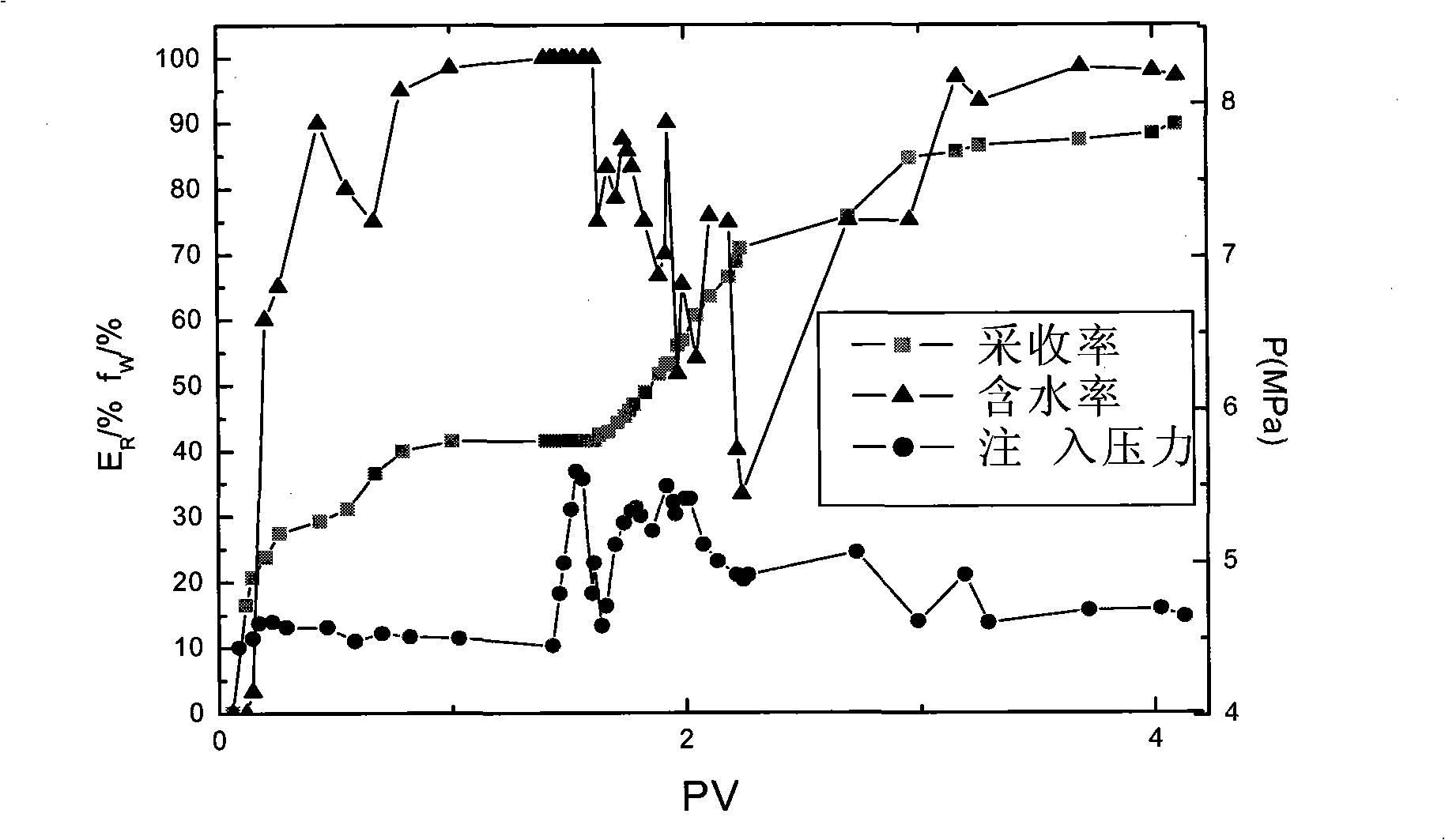

The invention discloses an elastic granule profile control and displacement agent used for petroleum exploitation, which is a dispersion system prepared from 1,500mg / L functional polymer solution and elastic granules by mixing in water, wherein the elastic granules have a concentration of 0.05 to 3wt percent. The invention further discloses an oil displacement system formed by using the foam profile control and displacement agent and an oil displacement method. The oil displacement is achieved by using a combined slug consisting of functional polymers from high viscosity to low viscosity and the elastic grains, and is suitable for multiple kinds of anisotropic oil layers to effectively improve oil recovery, reduce ineffective water circulation, and improve economic benefits. Through the effective combination, the system can improve the recovery greatly, improve the total recovery to 90 percent or above and reduce the oil recovery cost greatly, and can be widely used for tertiary oil recovery.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Viscoelastic weak gel profile control agent

ActiveCN101712865AAdjustable intensityGel forming time is adjustableDrilling compositionSulfite saltAmmonium chloride mixture

The invention discloses a viscoelastic weak gel profile control agent which is applied in oil field and oil well water injection operation. The viscoelastic weak gel profile control agent comprises the following components in parts by weight: 0.15-0.25 part of viscoelastic surface activity polymer, 0.05-0.15 part of cross-linking agent, 0.001-0.005 part of conditioning agent, and 99.8-99.6 parts of water. The viscoelastic surface activity polymer comprises the following components in parts by weight: 20-30 parts of acrylic amide, 1-2 parts of 3,3-dimethylacrylic acid, 1.5-3.5 parts of 2-acrylamido-2-dodecyl ethanesulfonic acid and / or 1-4 parts of N,N-dimethyl-allyl-hexadecyl ammonium chloride, 60-75 parts of deionized water and 0.3-1 part of initiating agent. The initiating agent comprises the following components in parts by weight: 2.5-3.5 parts of ammonium persulphate and 1 part of sodium sulfite. The viscoelastic weak gel profile control agent of the invention has a certain gel strength, capacity for lowering oil-water surface tensility and adjustable gel forming time, can improve water injection profile, lower oil-water surface tensility, wash away residual oil in a pore canal and improve water injection recovery ratio.

Owner:PETROCHINA CO LTD

Microsphere oil displacement profile control agent, displacement of reservoir oil system and displacement of reservoir oil method

ActiveCN101314712AEnhanced overall recoveryImprove the spread factorFluid removalDrilling compositionMicrosphereEconomic benefits

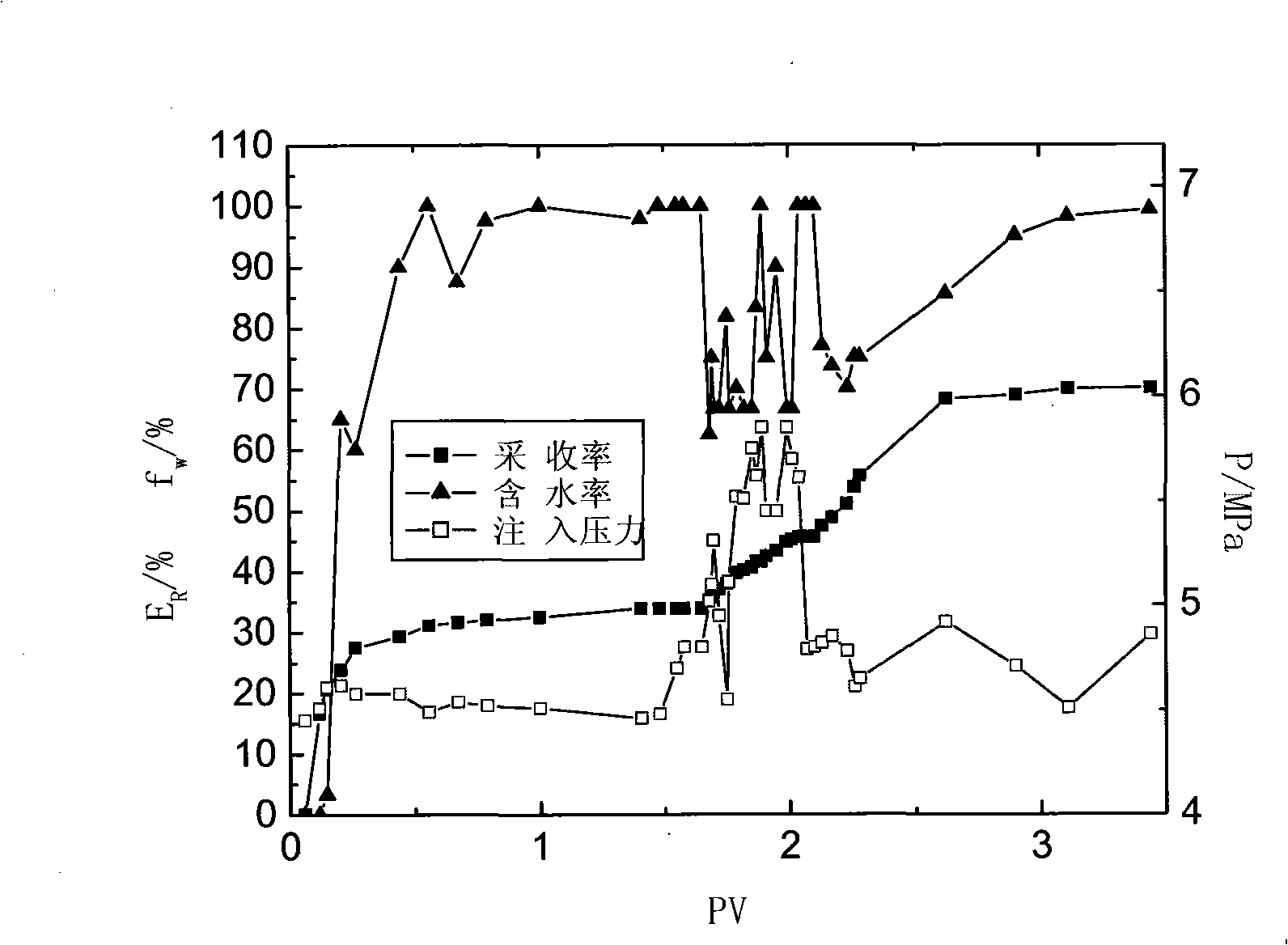

The invention discloses a microsphere profile control and displacement agent used for petroleum exploitation, which is a dispersion system prepared from functional polymer solution and microspheres with diameter of 0.2 to 20 mum by mixing, wherein the microspheres have a concentration of 0.05 to 0.2wt percent. The invention further discloses a combined oil displacement system formed by using the foam profile control and displacement agent and a combined oil displacement method. The oil displacement is achieved by using a combined slug consisting of functional polymers from high viscosity to low viscosity and the microspheres, and is suitable for multiple kinds of anisotropic oil layers to effectively improve oil recovery, reduce ineffective water circulation, and improve economic benefits. Through the effective combination, the system can improve the recovery greatly, improve the total recovery to 70 to 89 percent or above and reduce the oil recovery cost greatly, and can be widely used for tertiary oil recovery.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Strengthened oil displacement method

ActiveCN103967463AAvoid liquid crystallizationAvoid precipitation and other phenomenaFluid removalDrilling compositionTotal dissolved solidsSURFACTANT BLEND

The invention relates to an active water oil displacement method used for low permeability reservoirs, in particular to a strengthened oil displacement method, and mainly solves the problem of low efficiency of oil displacement of the low permeability reservoirs in the prior art. According to the oil displacement method, a positive-negative system surfactant containing a 0.01-1.0wt% anionic-nonionic surfactant and a cationic surfactant in a molar ratio of 1:0.01-0.99 is injected into a water solution to form active water, dehydrated crude is enabled to be in contact with the active water under the condition of injected water at the oil displacement temperature of 40-100 DEG C with total mineralization (total dissolved solid) TDS more than 200mg / L, and crude in the core is displaced sufficiently. The problem is well solved, and the strengthened oil displacement method can be applied to tertiary recovery production of the low permeability reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemical cold-production method applicable to medium-deep low-permeability heavy oil reservoir

InactiveCN103510932AHas the effect of reducing viscosity and increasing energyExpand the viscosity reduction radiusFluid removalPorosityLiquid carbon

The invention provides a chemical cold-production method applicable to a medium and deep stratum low-permeability heavy oil reservoir. The method includes the first step of selecting a medium-deep low-permeability heavy oil reservoir, wherein the depth of the selected oil layer is 1500-2800m, the permeability of the selected oil layer is smaller than or equal to 50*10-3 square microns, the total thickness of the selected oil layer is larger than or equal to 3.0m, the total net thickness ratio of the selected oil layer is larger than or equal to 0.3, the porosity of the selected oil layer is larger than or equal to 0.10, and the permeability variation coefficient of the selected oil layer is small than or equal to 0.8, the second step of squeezing microemulsion viscosity reduction systems and liquid carbon dioxide into the selected oil layer alternately in a staged plugging mode, the third step of carrying out well shut-in, well soaking, well opening and blowout prevention, and the fourth step of continuing extracting oil through a downhole pump. The chemical cold-production method has the advantages that microemulsion can enable crude oil to be stripped to be oil droplets with hydrophilic surfaces, heavy oil spontaneously diffuses on the surface of system water solution, carbon dioxide has functions of reducing viscosity and increasing energy can enlarge the viscosity reduction radius of the microemulsion, the water recovery rate is improved, and the output and the recovery efficiency of the medium-deep low-permeability heavy oil through a synergistic effect are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-field largest swept volume chemical-flooding oil production method

The invention relates to an oil-field largest swept volume chemical-flooding oil production method, which is applied to the technical field of oil production in oil fields. The method is applicable to all reservoirs which can be exploited by water flooding but are not exploited by water flooding. When oil is exploited, the self energy of the strata of a reservoir is first utilized to carry out flowing production or swabbing production; when an oil field adopting flowing production or swabbing production reaches the economic benefit limit of production, flowing production or swabbing production is ended, subsequent water-flooding production is not carried out any more, but chemical flooding injecting surfactant as main agent is directly adopted to intensify oil production. The method has the following advantages that: at the moment, the swept volume of the displacement of the chemical displacing fluid is the largest, which is best favorable for the exertion of the oil-washing effect ofthe surfactant, and thereby the yield of oil production can be increased to the max.

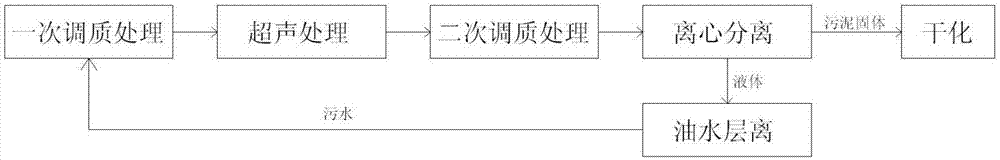

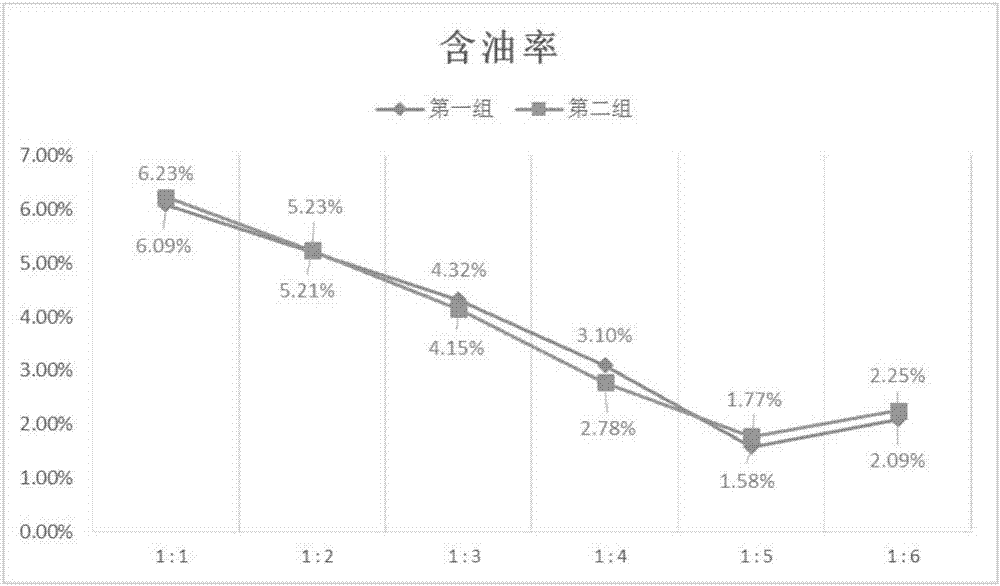

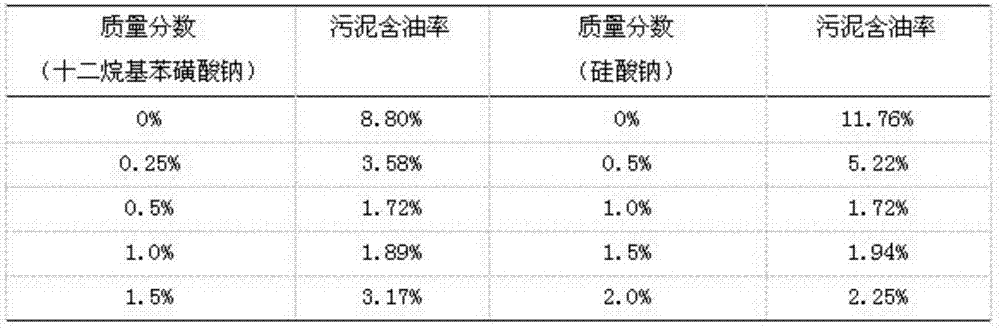

Treatment method of oily sludge

ActiveCN107879572AIncrease profitImprove oil washing efficiencyWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningMedicineSludge

The invention relates to a treatment method of oily sludge. The treatment method is characterized by comprising the following steps of primary tempering treatment, ultrasonic treatment, secondary tempering treatment, centrifugal separation, drying and oil-water delamination. The method is scientific and reasonable in design, has the advantages of being easy to operate, easy to implement, low in energy consumption, small in investment, high in oil washing efficiency and high in economic benefit, and is a highly innovative treatment method of the oily sludge.

Owner:东隆环保科技有限公司

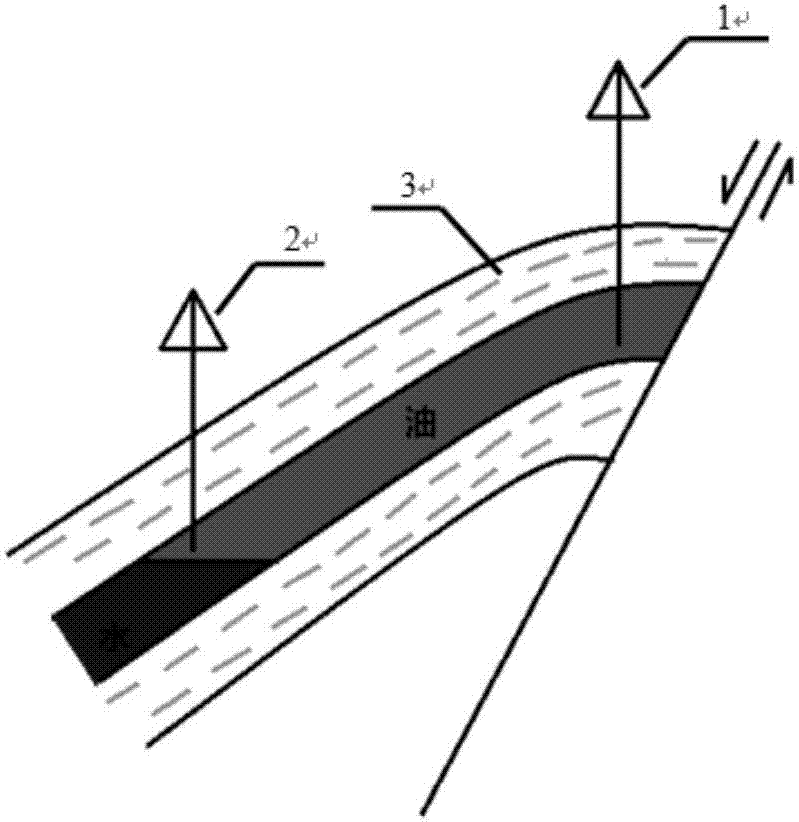

Foam-assisted gravity oil driving method

InactiveCN107575191AGood profile control effectInhibit channelingFluid removalInjection volumeSURFACTANT BLEND

The invention relates to a foam-assisted gravity oil driving method. The foam-assisted gravity oil driving method comprises the steps that a well is drilled as a production well at the lower part of an oil reservoir, a straight well is drilled as an injection well at the top of the oil reservoir, foam is continuously injected into the injection well, and the foam injection volume is controlled tobe 0.01-0.2 PV, oil is pushed in high and low permeable parts by using the foam, after being broken, the foam is accumulated to form a secondary gas cap to displace top attic oil, so that the more foam can enter the low permeable part, the high and low permeable parts achieve the effect of simultaneous propulsion, and sweep coefficient is improved; after the foam is broken, released gas enters thehigh part of a structure under the action of gravity differentiation, the gas is gathered continuously to form the secondary gas cap, the top attic oil is displaced, and the sweep coefficient is further improved; and a surfactant in a foam system can greatly reduce interfacial tension of oil and water, so that original oil in a restrained state becomes flowable oil, and the oil washing efficiencyis improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

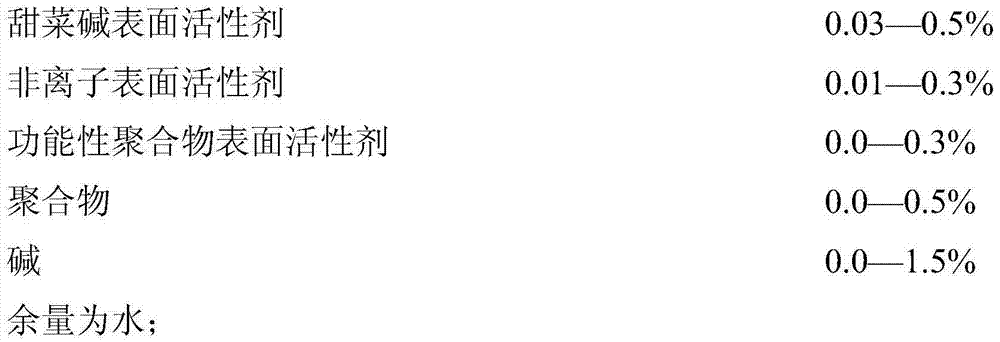

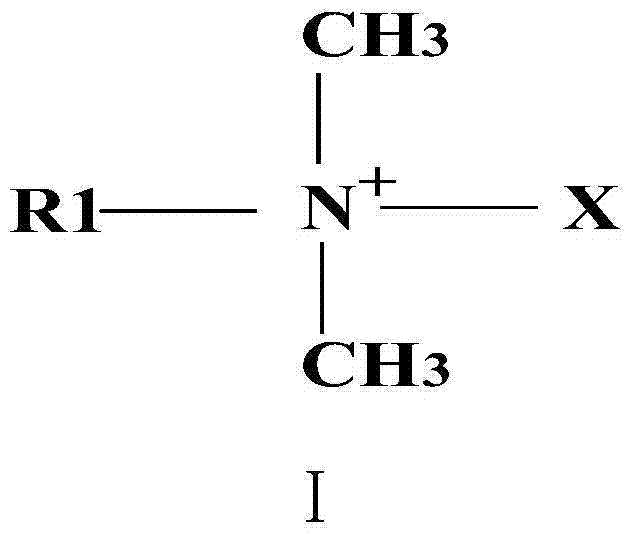

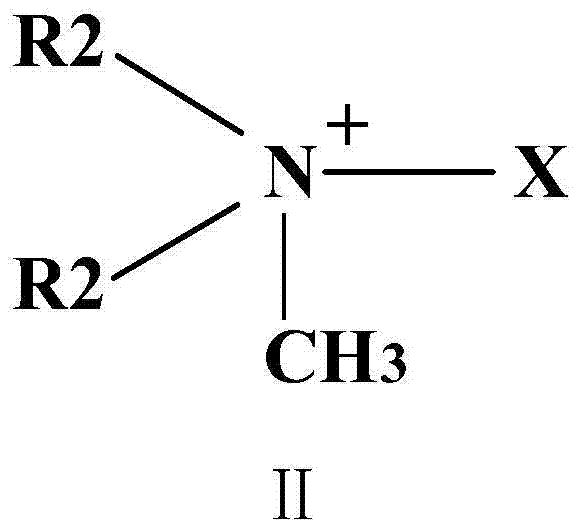

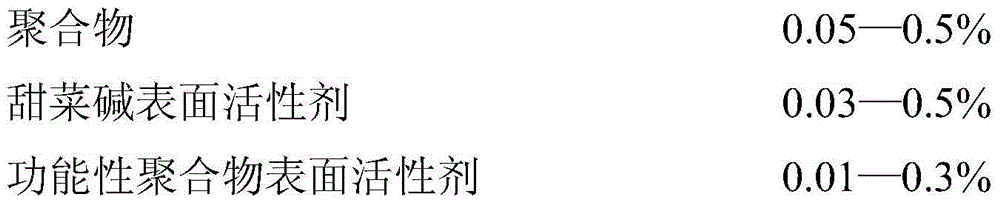

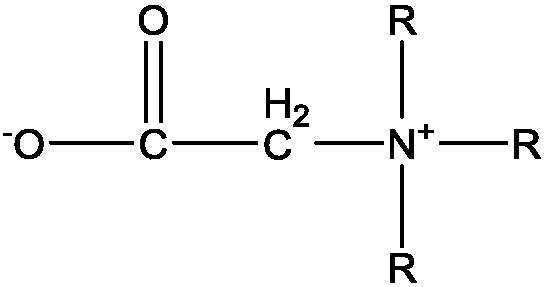

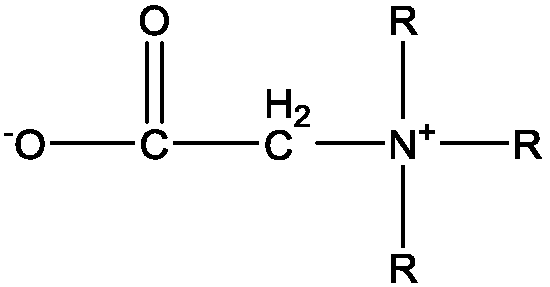

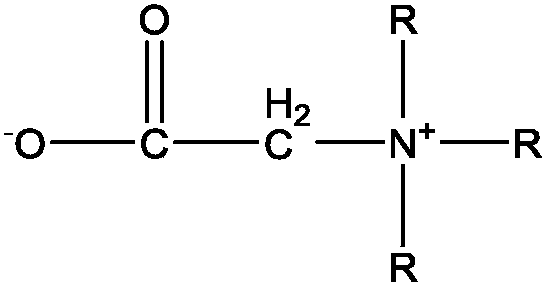

Betaine surfactant combination flooding composition and application thereof

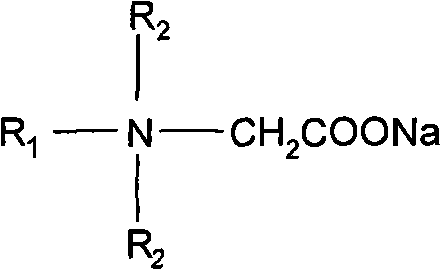

InactiveCN104263344AReduce interfacial tensionFast mergeFluid removalDrilling compositionPolymeric surfaceBetaine

The invention relates to a betaine surfactant combination flooding composition and application thereof. The combination flooding composition comprises the following components in percentage by weight: 0.03-0.5% of betaine surfactant, 0.01-0.3% of nonionic surfactant, 0.0-0.3% of functional polymer surfactant, 0.0-0.5% of polymer, 0.0-1.5% of alkali and the balance of water. The functional polymer surfactant, polymer and alkali are not 0 at the same time. By using the cheaper betaine surfactant and integrating multiple mechanisms for enhancing the recovery rate, the surfactant combination flooding composition achieves good coordination between recovery rate enhancement effect and cost, can greatly enhance the oil recovery rate, and has economic effect of forced production in low-permeability reservoirs and reservoirs after polymer flooding.

Owner:大连东方创新科技有限公司

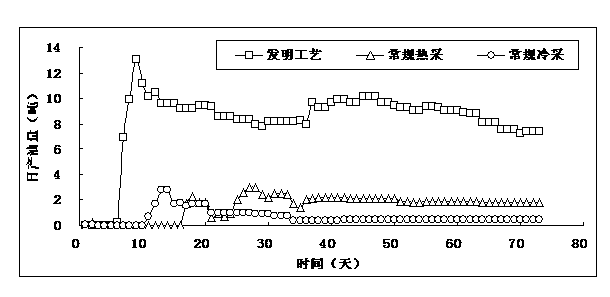

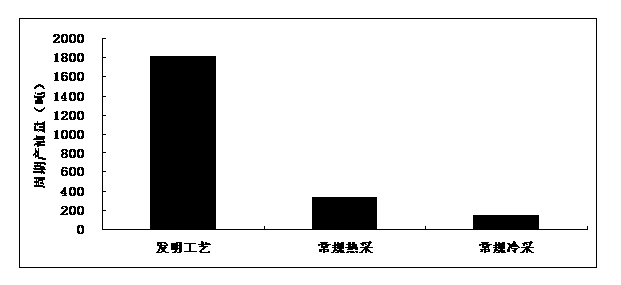

Method for improving recovery ratio of sensitive heavy oil reservoir

ActiveCN103573231AEfficient developmentReduce interfacial tensionCleaning apparatusFluid removalThermodynamicsHorizontal wells

The invention provides a method for improving the recovery ratio of a sensitive heavy oil reservoir. The method utilizes combined application of a high-temperature clay stabilizer, a sustained-release acidizing fluid system, an efficient oil-displacing agent and carbon dioxide in the development of the sensitive heavy oil reservoir to improve the single-well development effect and the recovery ratio of the sensitive heavy oil reservoir. The technical scheme is that the method comprises the steps of first utilizing the temperature-sensitive sustained-release acidizing fluid system to treat a polluted treat near-well-bore zone, then injecting the liquid carbon dioxide, utilizing the high-temperature clay stabilizer to protect an oil layer before steam injection and injecting a high-temperature oil-displacing agent system while the steam injection; then performing well shut-in for soaking and well opening for gushing and putting a pump into a well to perform continuous oil extraction. A field test shows that the oil-steam ratio of an average period of a vertical well reaches to 0.4, the oil-steam ratio of an average period of a horizontal well reaches to 0.6, and the periodic oil yield exceeds 1000t. A laboratory test shows that the final recovery ratio can reach to higher than 35% by adopting a process related to the method for improving the recovery ratio of the sensitive heavy oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

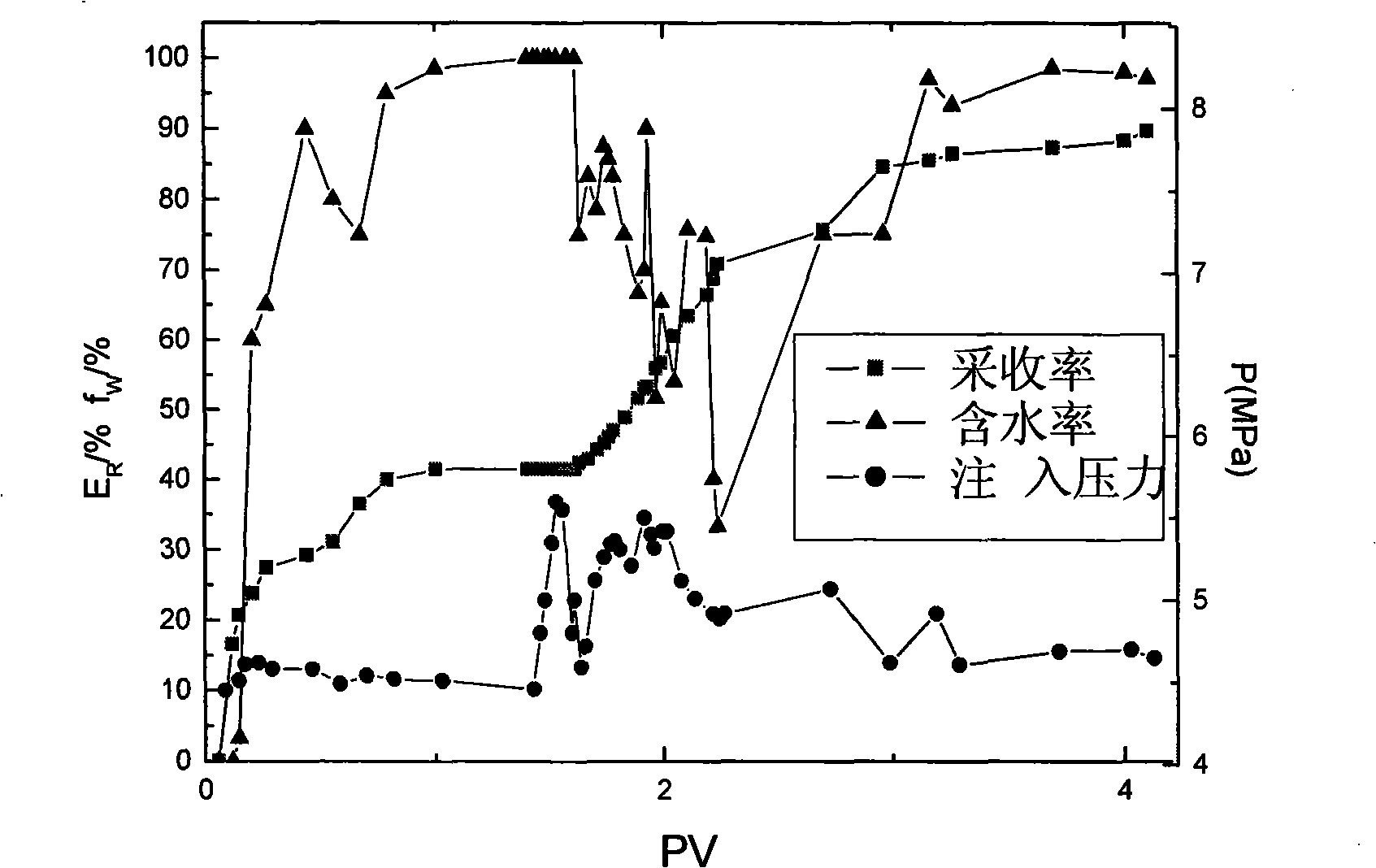

Functional polymeric surfactant-reinforced betaine composite flooding system and use thereof

InactiveCN104312566AExpand the affected volumeImprove oil washing efficiencyFluid removalDrilling compositionPolymeric surfaceBetaine

The invention discloses a functional polymeric surfactant-reinforced betaine composite flooding system and a use thereof. The functional polymeric surfactant-reinforced betaine composite flooding system comprises, by weight, 0.05-0.5% of a polymer, 0.03-0.5% of a betaine surfactant, 0.01-0.3% of a functional polymeric surfactant, 0.01-0.3% of a nonionic surfactant, 0.0-1.5% of an alkali and the balance water. The functional polymeric surfactant-reinforced betaine composite flooding system utilizes combination of a plurality of oil flooding mechanisms, can greatly improve crude oil extraction ratio, can realize further oil extraction of oil reservoir subjected to polymer flooding, can greatly improve final oil extraction ratio of the oil reservoir and has effects better than those of the existing oil flooding system.

Owner:大连东方创新科技有限公司

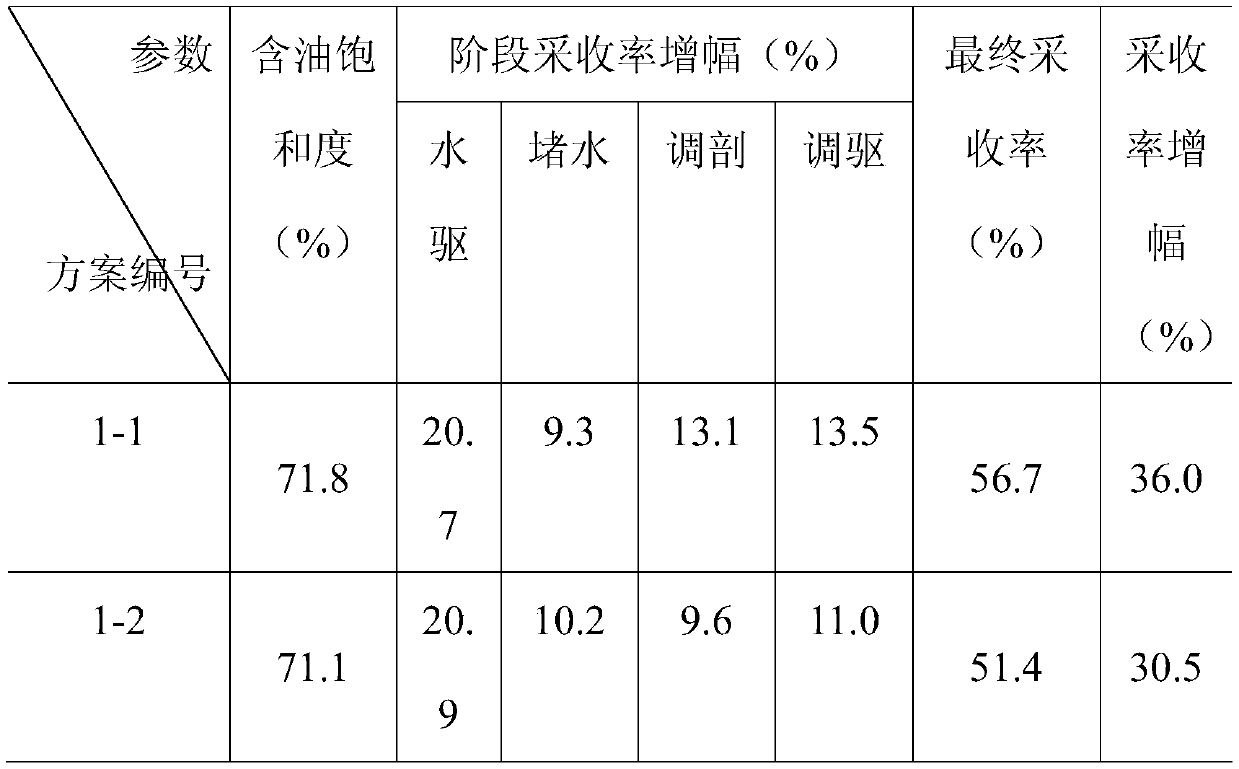

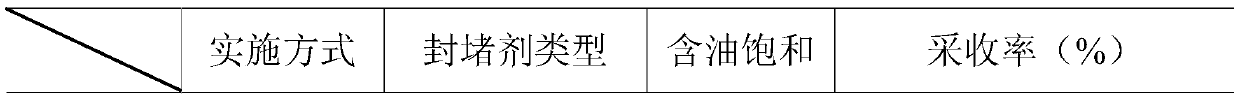

Method for improving oil reservoir recovery rate by integration of plugging, regulating and flooding

ActiveCN109915093AAvoid harmStrong injectionFluid removalDrilling compositionPolymer scienceMicrosphere

The invention belongs to the technical field of oil extraction, and particularly relates to a method for improving the oil reservoir recovery rate by integration of plugging, regulating and flooding,which comprises the following steps: 1, preparing composite gel, 2.5% of polyaluminum chloride, 4.5% of acrylamide, 0.9% of urea, 0.3% of ammonium persulfate and 0.3% of N, N-methylenebisacrylamide; 2, preparing a polymer microsphere / efficient oil displacement agent composite system, wherein a polymer microsphere material is hydrophobic association polymer gel, the microsphere concentration is 0.3%, the microsphere initial particle size is 2.7 [mu]m, the particle size median is 2.00 [mu]m, the particle size median is 18.92 [mu]m, and the expansion multiple is 10; and 3, injecting the compositegel into a dominant channel of an oil reservoir, waiting for gelling for 24 h, wherein the slug size is as follows: a main slug of 0.05 PV and a displacement slug of 0.025 PV; injecting the polymer microsphere / efficient oil displacement agent composite system into an oil reservoir from a water well, wherein the slug size is 0.1 PV; and carrying out subsequent water drive until the water content reaches 98%.

Owner:NORTHEAST GASOLINEEUM UNIV +1

Oil displacement agent composition and preparation method and application thereof

ActiveCN109810685AReduce interfacial tensionGood emulsificationDrilling compositionProduction rateAlcohol

The invention relates to the field of oil displacement agents, and discloses an oil displacement agent composition and application thereof. The oil displacement agent composition comprises a cationicsurfactant, air, an ampholytic surfactant, alcohol, macromolecular polymer and water, wherein the cationic surfactant is tetraalkyl ammonium chloride and / or tetraalkyl ammonium bromide; the ampholyticsurfactant is trialkyl betaine; the alcohol is monohydric alcohol with 1 to 12 carbon atoms; the stabilizing time of thick oil emulsion is longer than 8h by the macromolecular polymer at the temperature of 50 DEG C. The oil displacement agent composition has the advantages that the interface tension is ultralow, the emulsifying property is good, and the foaming ability is strong; when the oil displacement agent composition is used for water drive, the flowing drag of water phase is increased, so that the application efficiency is effectively improved, and the production rate of oil reservoiris increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

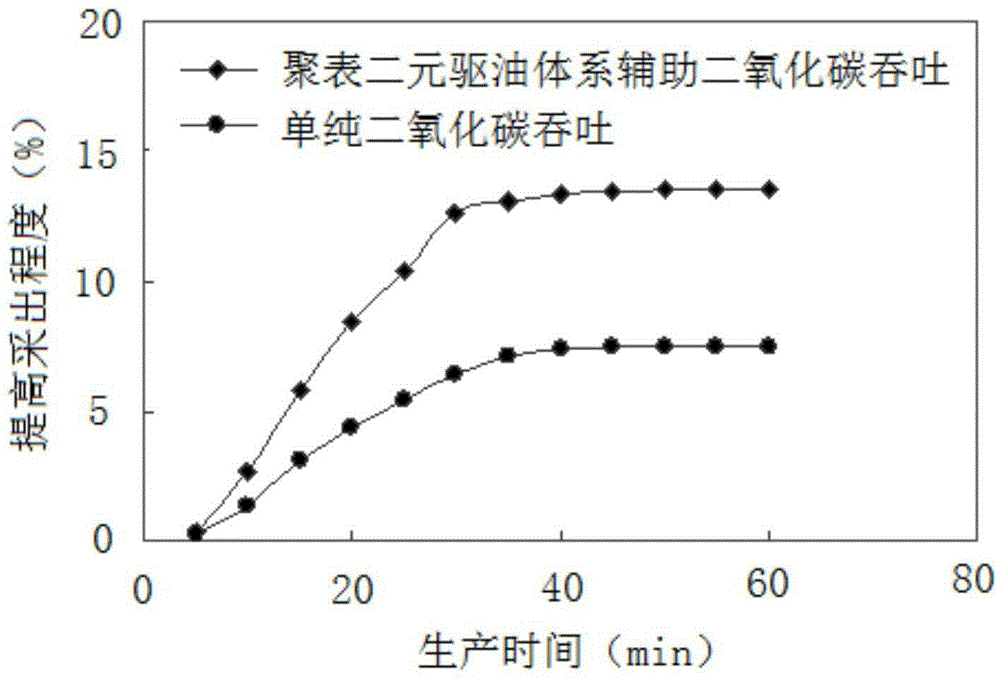

Oil extraction method with polymer-surfactant binary oil displacement system assisting in carbon dioxide huff and puff

ActiveCN106812509AReduce the impact of the sweepAdvance evenlyFluid removalDrilling compositionAmmonium bromideSURFACTANT BLEND

The invention discloses an oil extraction method with a polymer-surfactant binary oil displacement system assisting in carbon dioxide huff and puff and belongs to the technical field of increasing the crude oil recovery rate. The method includes the steps that a polymer-surfactant binary oil displacement system front plug, a carbon dioxide main plug, a polymer-surfactant binary oil displacement system rear plug, a blocking agent plug and water are sequentially injected into an oil reservoir; well opening is carried out after well shutting-in is carried out for a preset time, and crude oil extraction is carried out. The polymer-surfactant binary oil displacement system front plug and the polymer-surfactant binary oil displacement system rear plug are prepared from, by mass, 0.10%-0.40% of polyacrylamide, 0.05%-0.20% of surfactant compounded by N-dodecyl-N,N-dimethylglycine and hexadecyl trimethyl ammonium bromide and the balance water. The blocking agent plug is prepared from, by mass, 0.25%-0.50% of partially hydrolyzed polyacrylamide, 0.20%-0.50% of cross-linking agent, 0.01%-0.03% of stabilizer, 0.01%-0.02% of pH modifier and the balance water. By means of the method, the mobility ratio can be reasonably controlled, the displacement efficiency is improved, the carbon dioxide utilization rate is increased, and the recovery rate is increased.

Owner:PETROCHINA CO LTD

Rock core oil washing instrument

InactiveCN106483002AImprove oil washing efficiencyProtect environmentPreparing sample for investigationBall valveEngineering

Owner:南通市中京机械有限公司

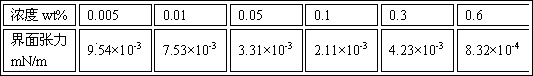

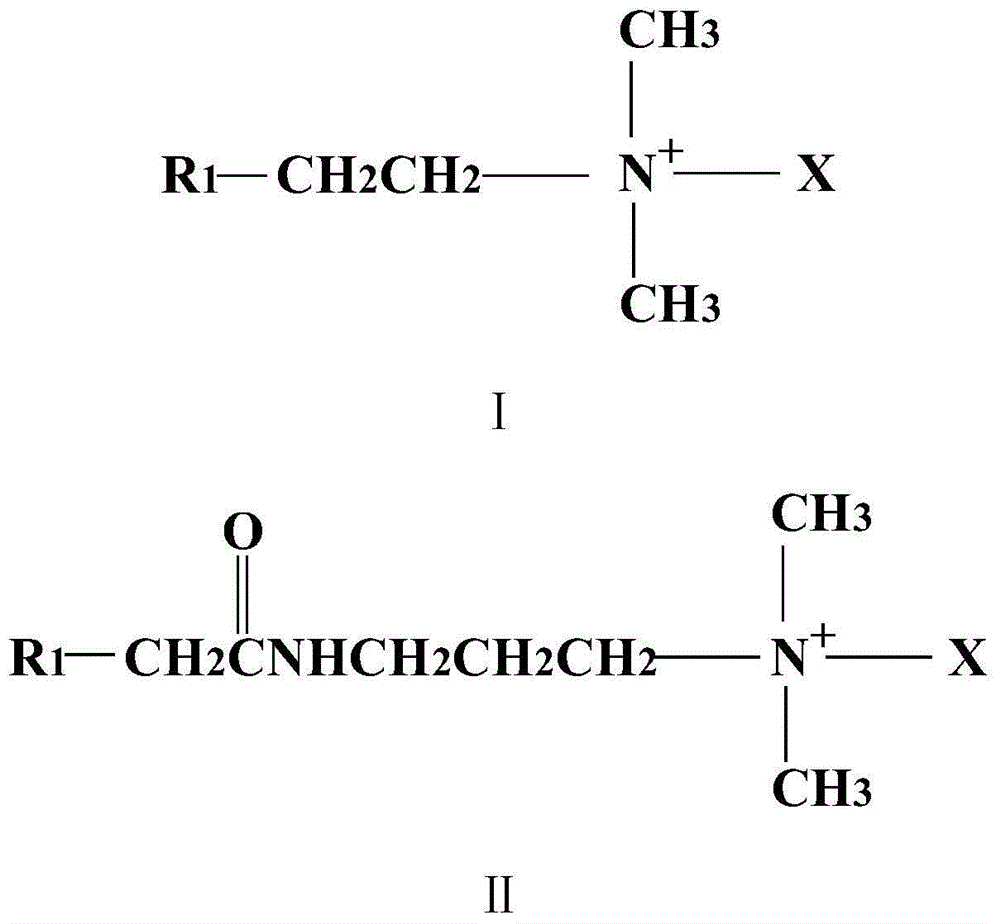

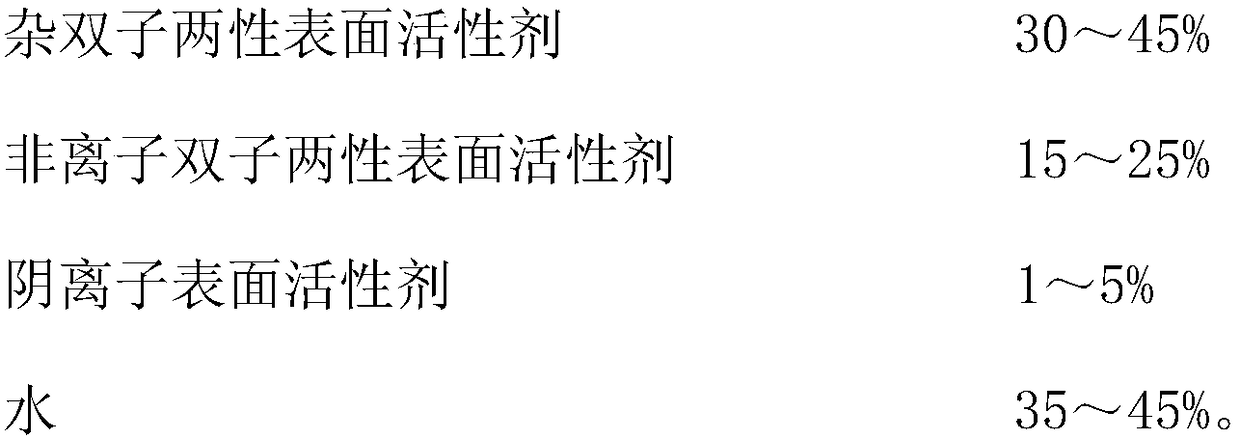

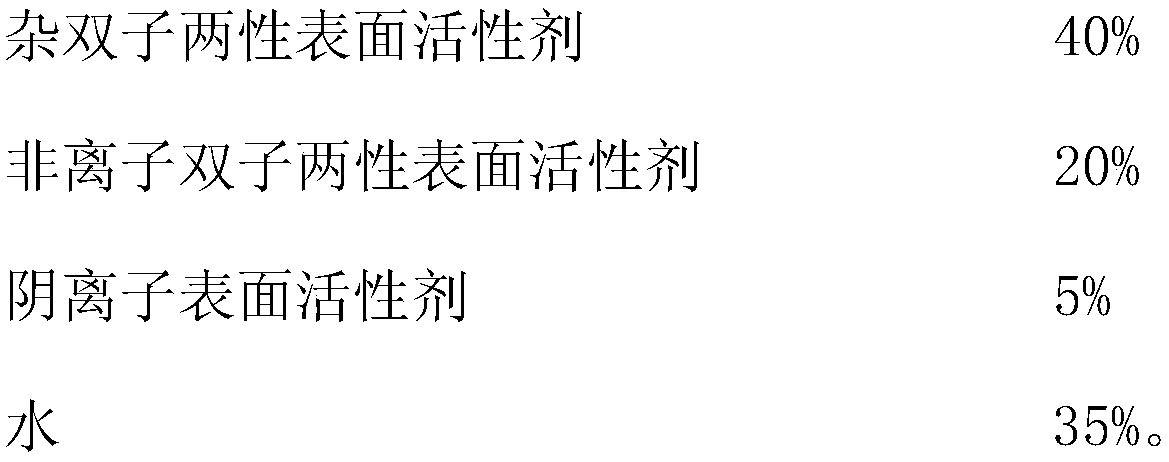

A decompression and injection-stimulation gemini surfactant system for oil fields and a preparing method thereof

InactiveCN109111908AReduce water injection pressureIncrease the areaDrilling compositionSalt resistanceSalt content

A decompression and injection-stimulation gemini surfactant system for oil fields and a preparing method thereof are provided. The system is a mixed system consisting of a heterogemini amphoteric surfactant as a main component, a nonionic amphoteric gemini surfactant as an auxiliary agent, an anionic surfactant and water. Compared with products in the prior art, the system has a wide spectrum anda wide adaption range; the system has a wide application concentration range, and the interfacial tension of the system can still be 10<-3> mN / m with a low application concentration (0.1%); the systemhas good wettability, high permeability, high oil washing efficiency, and good salt resistance, and is free of precipitate and turbid phenomena in an aqueous solution having a salt content of 100,000ppm (with the content of calcium and magnesium ions being 5,000 ppm); the system is resistant to high temperature and wide in application temperature range; the system is neutral, free of organochlorine and free of alkali and does not cause harm to stratums; and the system can greatly reduce water injection pressure for a water injection well and increase the water injection efficiency.

Owner:东营利丰化工新材料有限公司

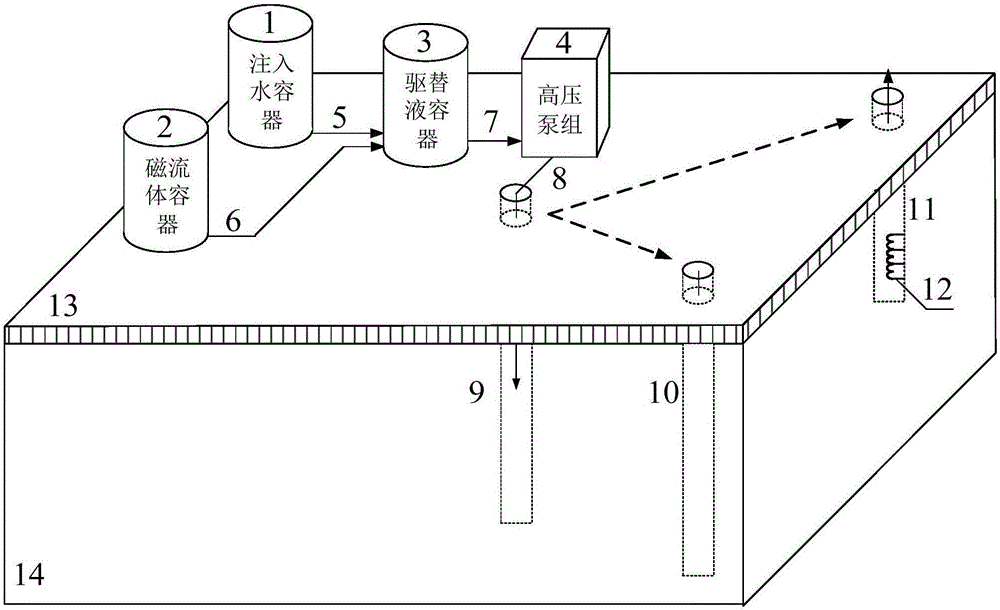

Oil production system and oil production method based on nano-magnetic fluid

The invention relates to an oil production system and oil production method based on nano-magnetic fluid. The oil production system based on the nano-magnetic fluid comprises an injected water container, a magnetic fluid container, a displacing fluid container, a high-pressure pump unit and an electromagnet; water and the nano-magnetic fluid are mixed to be uniform in the displacing fluid container, an obtained mixture enters the high-pressure pump unit through a first displacing fluid delivery pipeline to be pressurized, and then the pressurized mixture enters a water injection well through a second displacing fluid delivery pipeline. According to the oil production system and oil production method based on the nano-magnetic fluid, the displacing front edge is monitored along with the displacing process, the oil displacing direction and speed are adjusted through the strong attraction force of a magnetic field on the displacing fluid in a low-wave and regional newly-drilled magnetic source well, remaining oil is effectively utilized, and the displacing efficiency is improved. Compared with a traditional new well drilling and injection-production pattern improving method, the oil production method has the advantages of being low in cost and high in controllability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com