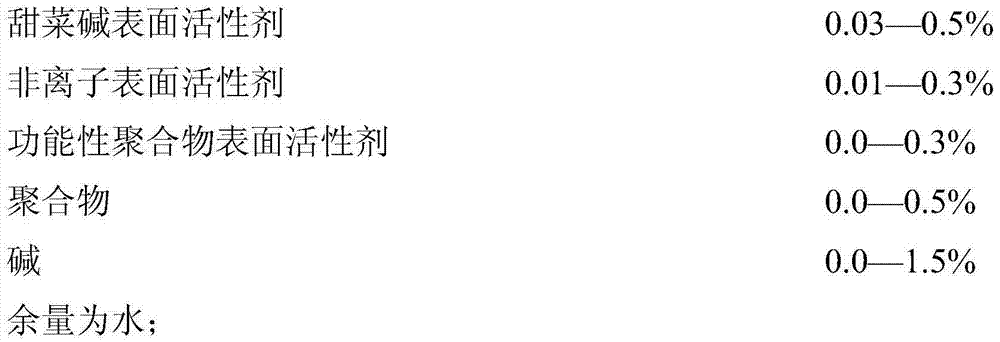

Betaine surfactant combination flooding composition and application thereof

A technique of surfactant and compound flooding, which is applied in the direction of drilling composition, production fluid, wellbore/well components, etc., and can solve the problems of small charge repulsion and poor stability of emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

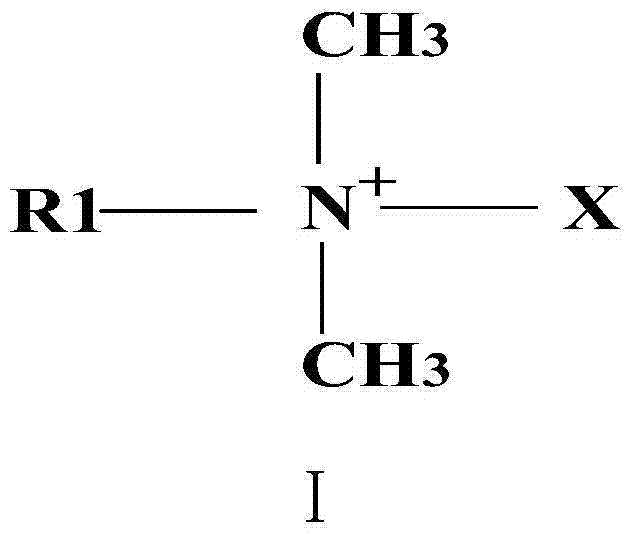

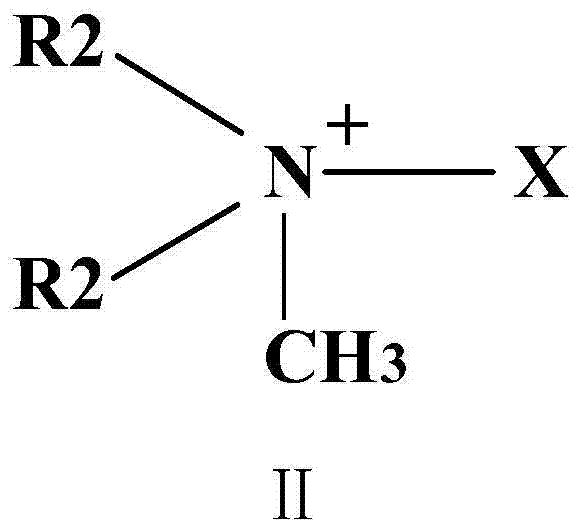

Method used

Image

Examples

Embodiment 1

[0069] Application of Betaine Surfactant Compound Flooding Composition in Enhanced Recovery of Low Permeability Reservoir:

[0070] (1) Betaine surfactant: a mixture of octadecyl hydroxypropyl sultaine: didodecyl hydroxypropyl sultaine = 70:30 (w / w).

[0071] Octadecyl hydroxypropyl sultaine and didodecyl hydroxypropyl sultaine: Octadecyl tertiary amine or didodecyl tertiary amine in combination with sodium 3-chloro-2-hydroxypropane sulfonate The ratio is 1:1.1 (molar ratio), methanol is used as solvent at 125°C, the quaternization reaction is carried out for 8 hours, and the product is obtained by demethanolization.

[0072] (2) Nonionic surfactant: m-xylyl octadecyl alcohol polyoxypropylene (5) polyoxyethylene (20) ether: Friedel-Crafts alkylation of m-xylene and methyl oleate under the action of an acidic catalyst Reaction to obtain methyl m-xylyl octadecane carboxylate, further hydrogen reduction to obtain m-xylyl octadecyl alcohol, and then carry out addition reaction wi...

Embodiment 2

[0088] Application of Betaine Surfactant Compound Flooding Composition in Enhanced Recovery of Medium and Low Permeability Reservoirs:

[0089] (1) Betaine surfactant: a mixture of octadecyl hydroxypropyl sultaine: didodecyl hydroxypropyl sultaine = 70:30 (w / w).

[0090] Octadecyl hydroxypropyl sultaine and didodecyl hydroxypropyl sultaine are the same as in Example 1.

[0091] (2) Nonionic surfactant: m-xylyl octadecyl alcohol polyoxypropylene (5) polyoxyethylene (20) ether, with embodiment 1.

[0092] (3) functional polymer surfactant: with embodiment 1.

[0093] (4) Polymer: The water-soluble polymer is partially hydrolyzed polyacrylamide HPAM, with a molecular weight of 17-19 million, produced by Daqing Refining and Chemical Company.

[0094] The composition of composite flooding composition of the present invention:

[0095] Betaine surfactant (self-synthetic) 0.2%

[0096] Nonionic surfactant (self-synthesized) 0.08%

[0097] Functional polymer surfactant (self-synt...

Embodiment 3

[0109] Application of Betaine Surfactant Compound Flooding Composition in Enhanced Recovery of Medium and Low Permeability Reservoirs:

[0110] (1) Betaine surfactant: a mixture of octadecyl hydroxypropyl sultaine: didodecyl hydroxypropyl sultaine = 80:20 (w / w).

[0111] Octadecyl hydroxypropyl sultaine and didodecyl hydroxypropyl sultaine are the same as in Example 1.

[0112] (2) Nonionic surfactant: stearyl alcohol polyoxypropylene (5) polyoxyethylene (20) ether, provided by Tianjin University of Technology.

[0113] (3) functional polymer surfactant: with embodiment 1.

[0114] (4) Polymer: The water-soluble polymer is partially hydrolyzed polyacrylamide HPAM, with a molecular weight of 25 million, produced by Daqing Refining and Chemical Company.

[0115] The composition of composite flooding composition of the present invention:

[0116]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com