Patents

Literature

126 results about "Octadecyl Alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stearyl alcohol (also known as octadecyl alcohol or 1-octadecanol) is an organic compound classified as a fatty alcohol with the formula CH 3 (CH 2) 16 CH 2 OH. It takes the form of white granules or flakes, which are insoluble in water.

Scented tea whitening skin-moistening cream and preparation method thereof

ActiveCN103565730AEfficient whitening and emollient effectImprove efficacyCosmetic preparationsToilet preparationsBletilla striataWhitening Agents

The invention discloses a scented tea whitening skin-moistening cream and a preparation method thereof. The scented tea whitening skin-moistening cream comprises a plurality of traditional Chinese medicine whitening components, a plurality of biochemical whitening components, whitening and protective components extracted from scented tea and green tea, and base raw materials. The whitening and protective components of traditional Chinese medicines and scented tea are self-prepared from licorice root, bletilla striata, bighead atractylodes rhizome, white poria cocos, Japanese ampelopsis root, white peony root, rose, peony and wintersweet flower. The biochemical whitening components comprise purchased ascorbyl tetraisopalmitate and an amino acid whitening agent. The base raw materials comprise a hexadecanol-octadecanol mixture, jojoba oil, an amino acid moisture-retention agent, fucoidin, a cetyl alcohol-octadecyl alcohol mixture and a cetyl glucoside-octadecyl glucoside mixture. Through uniform blending and scientific composition of the whitening and oxidation-resistant components and the moisture-retention and skin-care base raw materials, the scented tea whitening skin-moistening cream is a novel, safe and reliable scented tea whitening skin-moistening cream product having lasting effects.

Owner:吴俊良

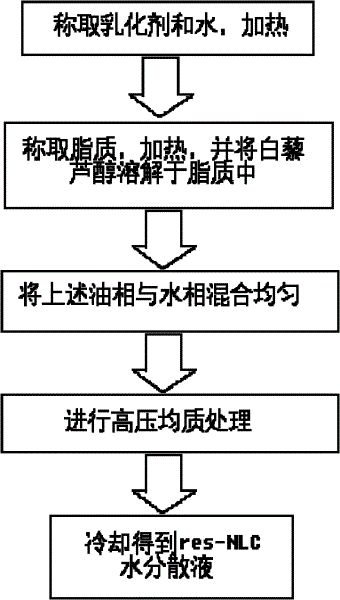

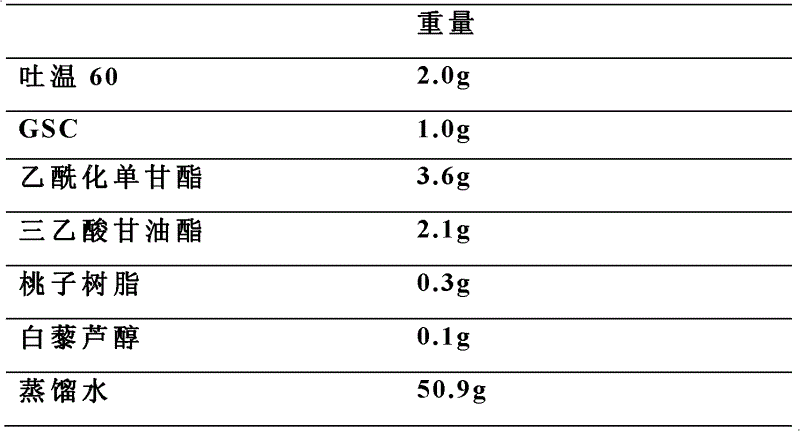

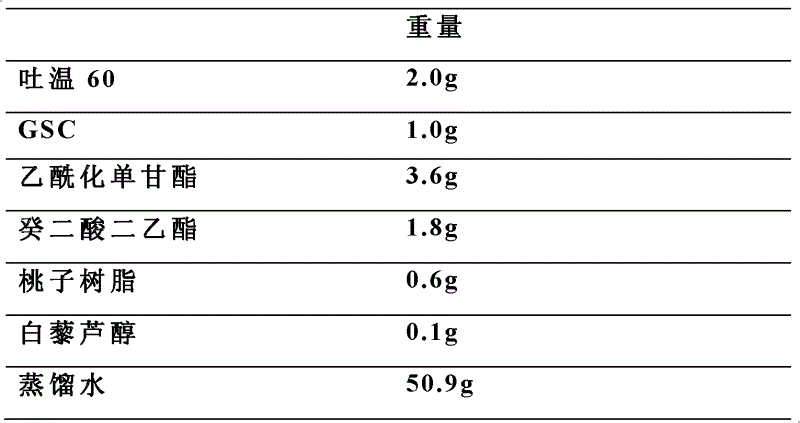

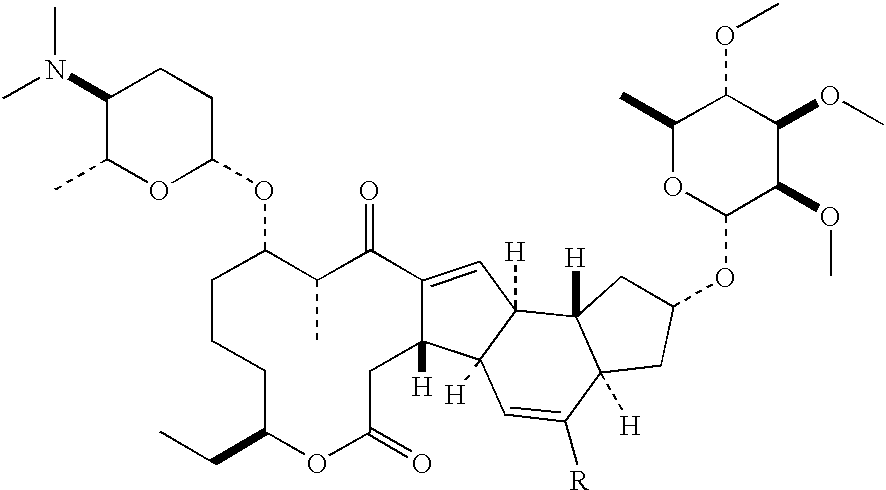

Resveratrol nanostructured lipid carrier and preparation method thereof

InactiveCN102614091AStructural disorderImprove stabilityCosmetic preparationsToilet preparationsLipid formationSolubility

The invention discloses a resveratrol nanostructured lipid carrier. The resveratrol nanostructured lipid carrier is loaded with active pharmaceutical ingredients of resveratrol and is characterized by comprising 0.1 to 1wt% of resveratrol, 2 to 20wt% of at least one emulsifier, 2 to 30wt% of a composite lipid material and the balance water, wherein the composite lipid material is a mixture of at least one solid lipid material and at least one liquid lipid material. The at least one solid lipid material and the at least one liquid lipid material are selected from glyceryl triacetate, acetylated monoglyceride, diethyl sebacate, diisopropyl adipate, diisopropyl sebacate, glycerol monolaurate, peach resin and an octadecyl alcohol. The resveratrol nanostructured lipid carrier has good stability and water-solubility. The preparation method of the resveratrol nanostructured lipid carrier is simple and controllable and has good repeatability. The resveratrol nanostructured lipid carrier can be utilized in preparation of resveratrol-containing cosmetics.

Owner:夏强 +1

Pediculicidal and ovacidal treatment compositions and methods for killing head lice and their eggs

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Method for preparing anti-phase suspension polymeric polyacrylic acid/acrylamide high water absorption resin

The invention relates to a process for preparing a high water absorbing resin of anti-phase suspension polymerization polyacrylic acid / acrylamide, which is characterized in that cyclohexane is dissolvent, alkylating agent and acrylamide are monomers, ammonium peroxodisulfate is initiating agent, N,N'-methylene methylene is cross linker, octadecyl alcohol phosphatides is dispersing agent. polyacrylic acid / acrylamide high water absorbing resin is prepared by adopting an anti-phase suspension polymerization method, and the water absorption ratio of the high water absorbing resin which is prepared by the invention is 298ml / g-346ml / g.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

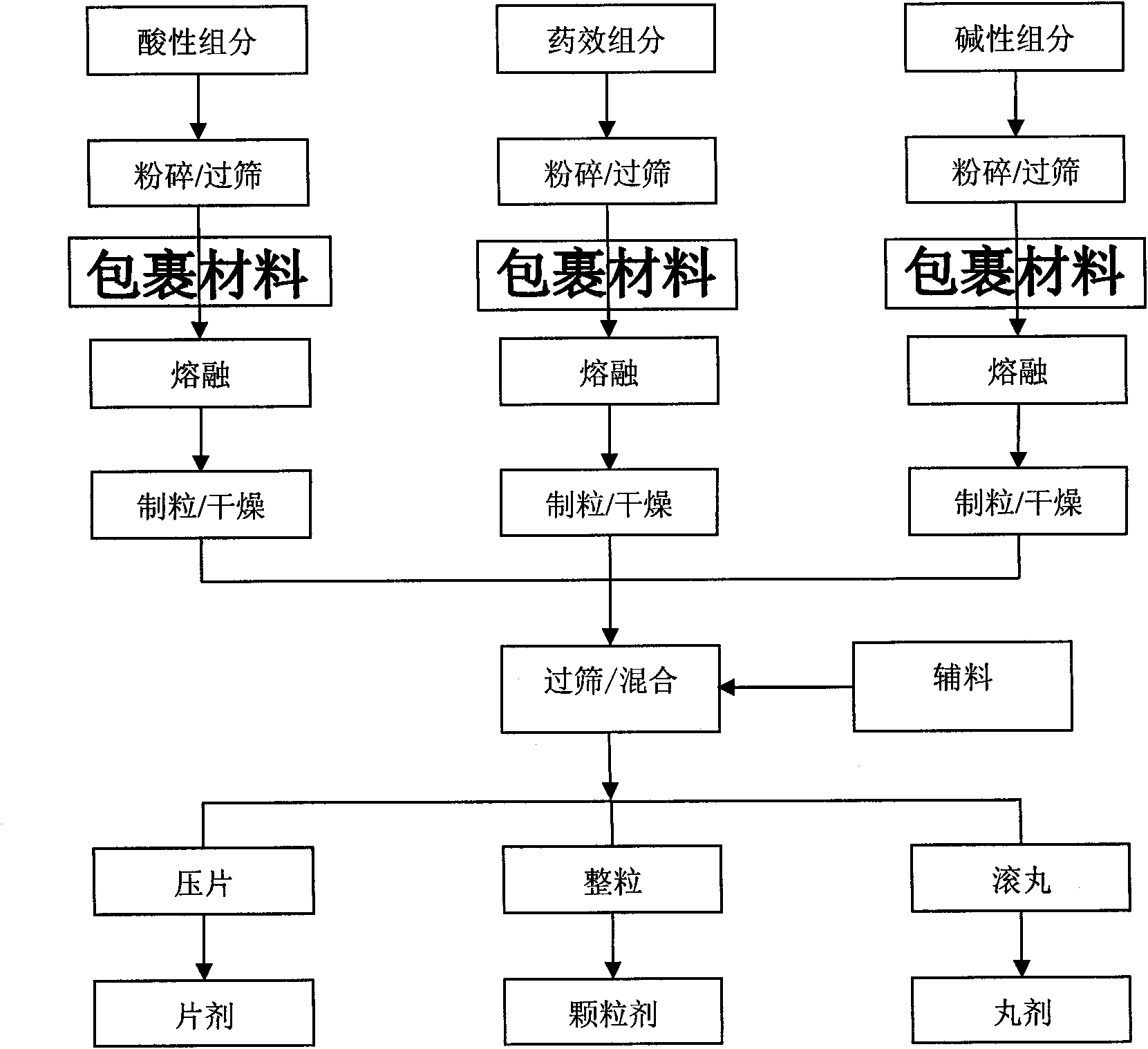

Solid effervescent mixture for oral absorption

InactiveCN101919801AEasy to carryEasy to takeNervous disorderHydroxy compound active ingredientsCoffea eugenioidesAlkaline earth metal

The invention relates to an effervescent mixture, specifically relates to a solid effervescent mixture for the oral absorption and a preparation method thereof. The invention comprises the alkalic component of a mixture consisting one or more than one of alkali metal carbonate, alkali metal bicarbonate, alkaline earth metal carbonate or pearl powder; the acid component of a mixture consisting one or more than one of tartaric acid, citric acid, adipic acid, fumaric acid, maleic acid, malic acid, folic acid andacid phosphate; the medical component of a mixture consisting one or more than one of ginseng extract, octacosanol, glucurolactone, taurine, natural caffeine, D-ribose; the wrapper and auxiliary material of a mixture consisting one or more than one of polyethylene glycol (PEG), panthenol and glycerin monostearate. The invention comprises, by weight, 5-50% of alkalic component; 5-50% of acid component; 1-40% of medical component; 0.5-35% of wrapper; 1-10% of auxiliary material. The invention has advantages of being fast in effect, and convenient in medicine taking and carrying.

Owner:无锡健而乐医药科技有限公司

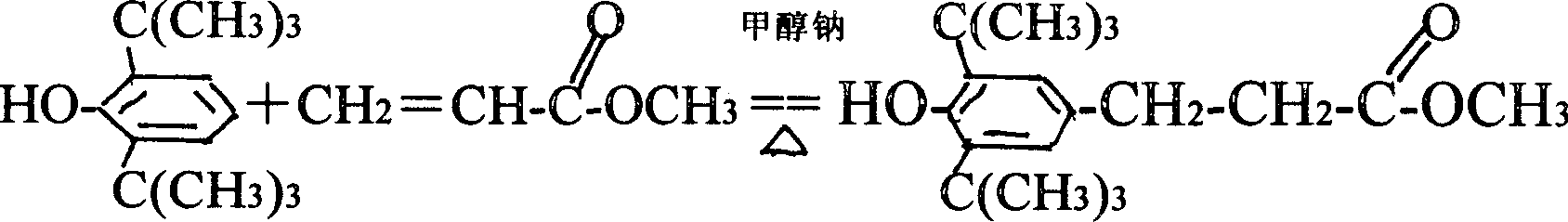

Two-step industrial synthesis method of beta-(3,5-di tertiary butyl-4-hydroxyl phenyl )octadecyl propionate

InactiveCN1733692AWill not oxidizeWhite colorPreparation by transesterificationSodium methoxideReaction temperature

The invention provides a process for two-step industrial synthesis of octadecyl-Beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate, wherein the first step comprises hot melting 2,6-ditertiary butyl phenol at 46-56 deg C, purging nitrogen and charging sodium methoxide as catalyst, between a reaction temperature of 90-105 deg. C, dripping methylacrylate, maintaining 4-4.5 hours at 110-124 deg. C, charging acetic acid and water solution of methanol at 8-80 deg C, carrying out crystallization separation, and the second step comprises reacting octadecyl alcohol, 3,5 methyl ester and dibutyl stannic oxide catalyst, after the reaction finishes, charging acetic acid and water solution of methanol for crystallization.

Owner:TIANJIN CHENGUANG CHEM

High-hardness wear-resistant rubber shoe sole

The invention discloses a high-hardness wear-resistant rubber shoe sole which is prepared from the following raw materials in parts by weight: 7-14 parts of natural rubber, 6-10 parts of sorbitan fatty acid ester, 9-15 parts of antimonous oxide, 5-10 parts of salicylic acid, 11-17 parts of triphenyl phosphite, 20-30 parts of heavy calcium carbonate, 9-18 parts of butadiene styrene rubber, 11-15 parts of magnesium oxide, 6-10 parts of white carbon black, 5-10 parts of zinc carbonate, 10-15 parts of stearyl alcohol polyglycol ether, 8-15 parts of zirconium fluoride, 7-14 parts of stearic acid, 6-9 parts of sulfur, 10-20 parts of high styrene, 8-15 parts of nano zinc oxide and 6-12 parts of solid coumarone. The shoe sole provided by the invention is relatively high in hardness; the ageing resistance and wear resistance of shoe rubber are greatly improved.

Owner:QINGDAO LAOXIANG TEA PROD

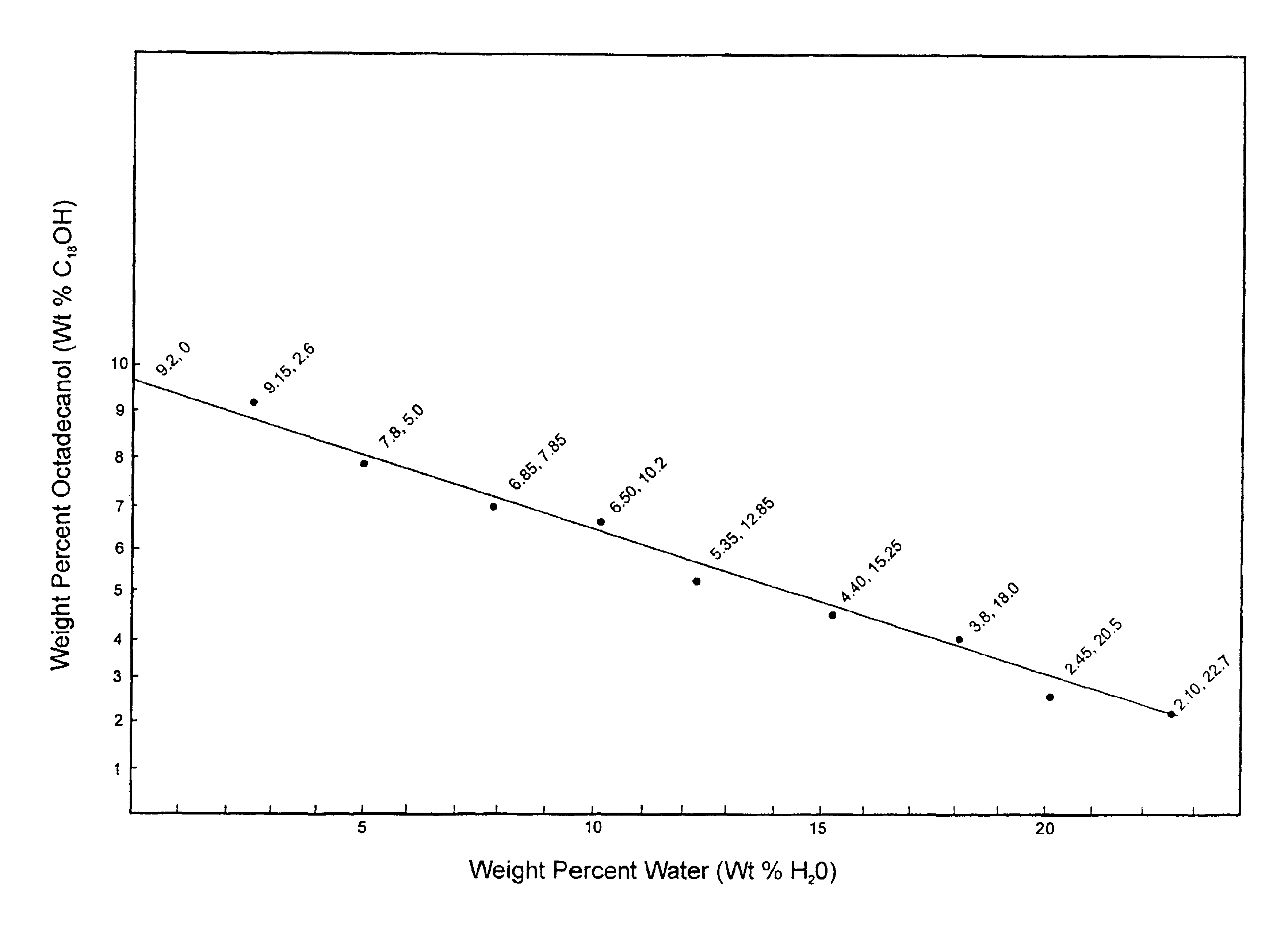

Process for making a liquid evaporation retardant solution

A process for manufacturing a liquid evaporation retardant product that combines isopropanol-water azeotrope with up to 5% octadecanol by weight of the total solution, and upon which improved capability to remain precipitate free in the event of colder temperatures than normal is conferred by adding n-butanol at 10% by weight of the pre-made basic product.

Owner:FLEXIBLE SOLUTIONS

Momestasone furoate cream and preparation method thereof

ActiveCN102000023ASmooth and delicate appearanceBroaden applicationOrganic active ingredientsAerosol deliveryParaffin waxGlyceryl monostearate

The invention relates to the technical field of an external preparation medicament, in particular to an external preparation medicament containing momestasone furoate. The external preparation medicament is prepared from the following raw materials in part by weight: 15 parts of the momestasone furoate, 45 parts of hexadecyl-octadecyl alcohol, 7.5 parts of glyceryl monostearate, 5 parts of beeswax, 8 parts of triethanolamine, 35 parts of light liquid paraffin, 2 parts of sodium lauryl sulfate, 8 parts of sodium lauryl sulfate, 25 parts of propylene glycol, 1 part of Hydroxy acetate, 2 parts of tween-80, and the balance of purified water which is added to ensure that the total weight is 500 parts. The cream has better moisture retention and stability because the humectant combination of the triethanolamine and the propylene glycol is adopted.

Owner:华润三九(南昌)药业有限公司

Composite crude oil demulsifying agent

ActiveCN102226098AImprove surface propertiesImprove permeabilityDewatering/demulsification with chemical meansMaterial resourcesPropanediol

The invention relates to a composite crude oil demulsifying agent, which comprises the following materials in parts by weight: 24-35 parts of polyoxypropylene polyoxyethylene octadecyl alcohol, 15-25 parts of propanediol polyoxypropylene polyoxyethylene ether, 7-15 parts of sodium lauryl sulfate, 8-20 parts of ammonium chloride, 8-16 parts of polyether-modified trisiloxane, and 5-10 parts of methanol. The composite crude oil demulsifying agent provided by the invention has good surface activity, wetting property and enough flocculation and agglutination capacity, can rapidly reach the oil-water interface to replace natural interfacial active substances to form a new unstable oil-water interfacial film, and has good performance of demulsifying crude oil emulsion. Also, the composite crude oil demulsifying agent saves time, manpower and material resources, and can be widely applied in crude oil extraction, crude oil refining and other fields.

Owner:石家庄卫科生物科技有限公司

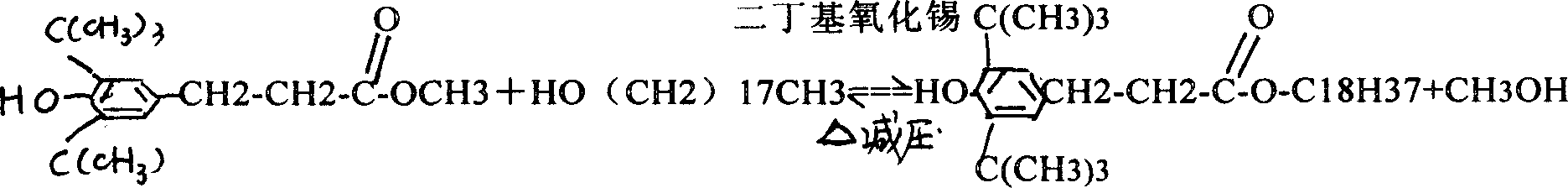

Method for synthesizing antioxidant 1076 by use of novel titanium-containing catalyst

InactiveCN105348103AImprove catalytic performanceSimplify the process of recrystallizationPreparation by ester-hydroxy reactionPotassium hydroxidePhenol

A method for synthesizing an antioxidant 1076 by the use of a novel titanium-containing catalyst comprises the following steps: 2,6-phenol and methyl ester are subjected to an addition reaction to prepare 3,5-ester; 3,5-ester and octadecyl alcohol are subjected to an ester-exchange reaction to generate an antioxidant 1076; and finally, recrystallization is carried out to obtain a product. The method is characterized in that a catalyst used in the addition reaction and the ester-exchange reaction is a titanium-containing catalyst. The novel titanium-containing catalyst used in the invention has good catalytic performance in the ester-exchange reaction for synthesis of the antioxidant 1076. By the method, product content reaches 99% and above, light transmittance 425 nm reaches 98.8% and above, and yield reaches 97% and above. The novel titanium catalyst has more excellent performance than catalysts such as sodium methylate, potassium hydroxide, lithium amide, organo-tin and the like when used in the esterification reaction of the antioxidant 1076. By the use of the titanium catalyst, the reactions are accelerated, the process of aftertreatment-recrystallization is simplified, and high yield is obtained.

Owner:TIANJIN CHENGUANG CHEM

Degradable liquid mulch film and preparation method thereof

InactiveCN101255275ASolve pollutionKeep from drainingOrganic fertilisersBuilding insulationsGround temperatureSprayer

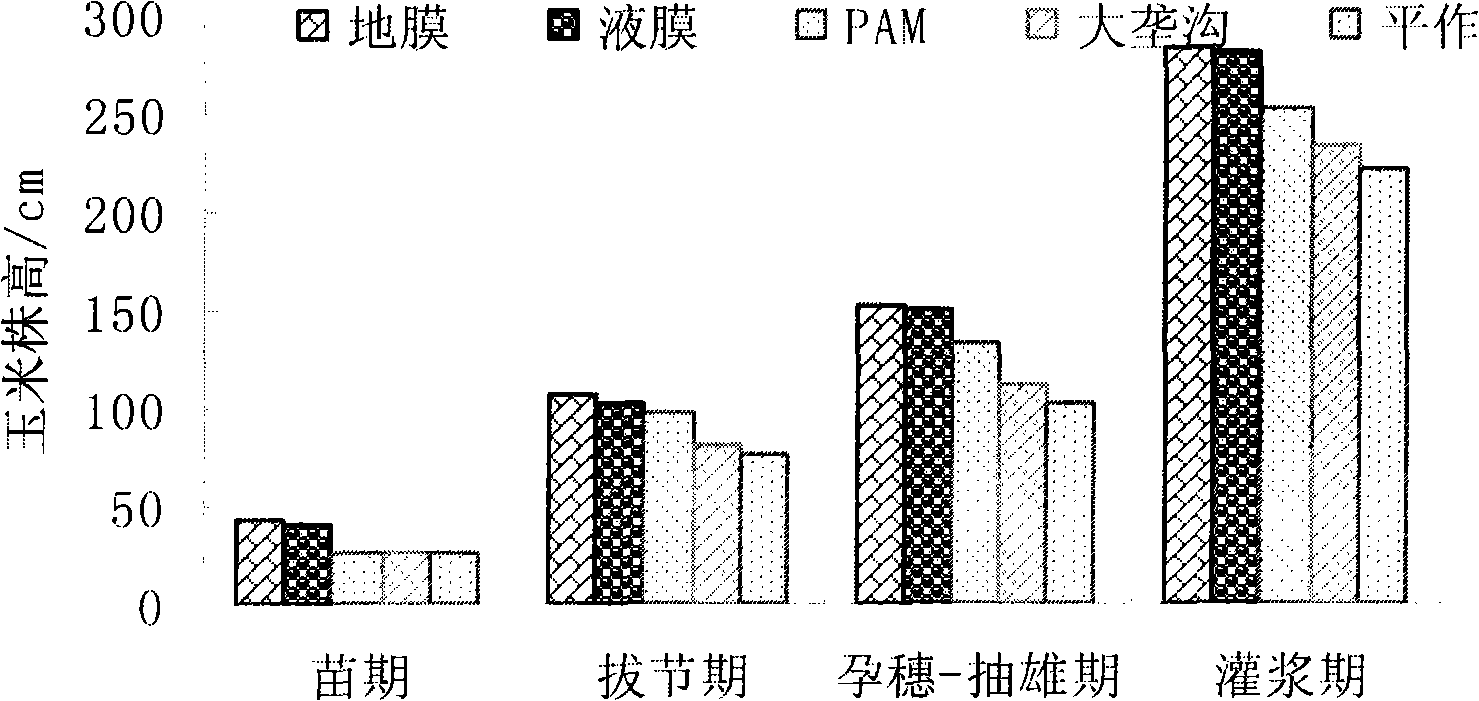

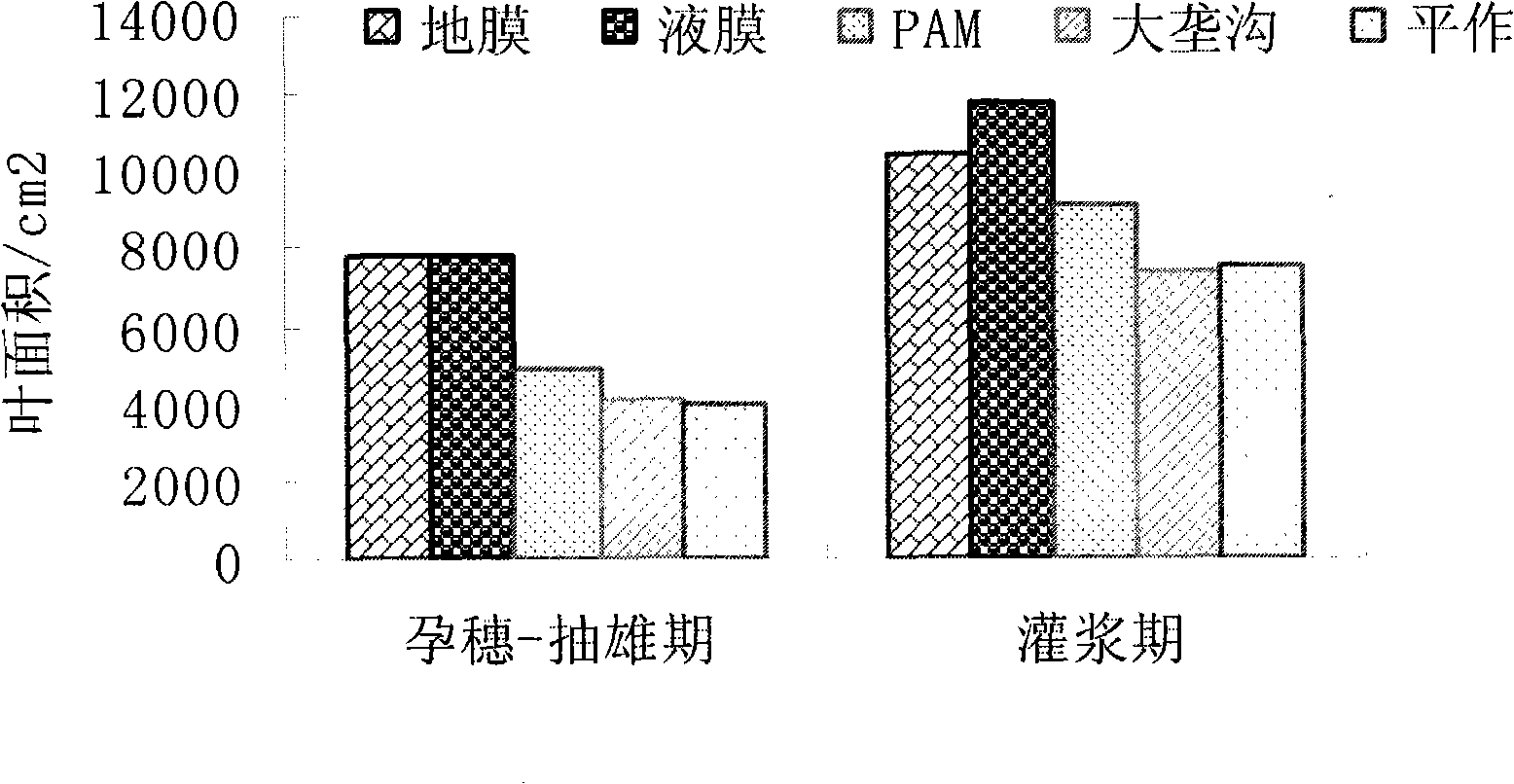

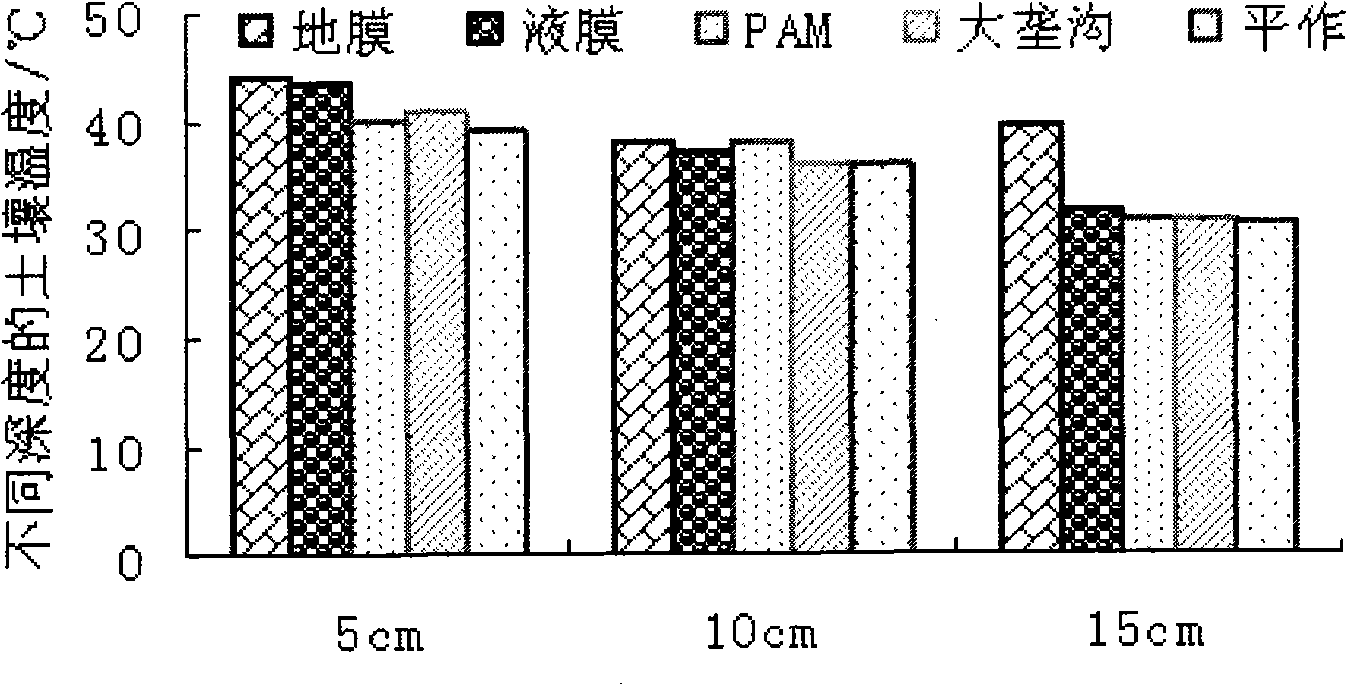

The invention discloses a degradable liquid mulching film, comprising( by weight parts): asphaltum 300-450 parts, oil 15-25 parts, potassium hydroxide 3-10 parts, octadecyl alcohol 10-25 parts, OP-10 1.0-2.5 parts, sapn 80 1.0-2.5 parts, tween 85 3-10 parts, water 150-350 parts. The mulching film solves the pollution problem resulted from polyethylene mulching film used in drought, semiarid lands. The liquid mulching film is formed through spraying by general agricultural sprayer and drying, with function of preservating the soil moisture and heating. The film is broken without human when the plant seed emerges. The mulching film can be automatically degraded into fertilizer after 3-6 months to furnish the plant. The mulching film has great effects that wind proofing and fixing sand, avoiding water and soil loss, reducing the evaporation of water in soil, increasing ground temperature, promoting the growth of the cropper and success ratio of tree.

Owner:YANGLING MINGRUI CHEM IND TECH

Method for making hindered phenolic antioxidant

InactiveUS20100210872A1Improve conversion rateSpeedPreparation by ester-hydroxy reactionOrganic compound preparationPropionateTransesterification

A method for making a hindered phenolic antioxidant based on Octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate uses a methanol solution containing alkali metal methoxide as a catalyst solution, wherein the catalyst solution is filtered with a filter device with a filter pore diameter of less than 50 μm to remove insoluble matters therefrom before used in a transesterification process where methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate and 1-Octadecanol are taken as reactants to obtain a crude product of Octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate having high conversion rate and low color, and the crude product further undergoes a purification process for crystallization, filtering and drying to obtain a product of Octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate having high purity and low color.

Owner:NANYA PLASTICS CORP

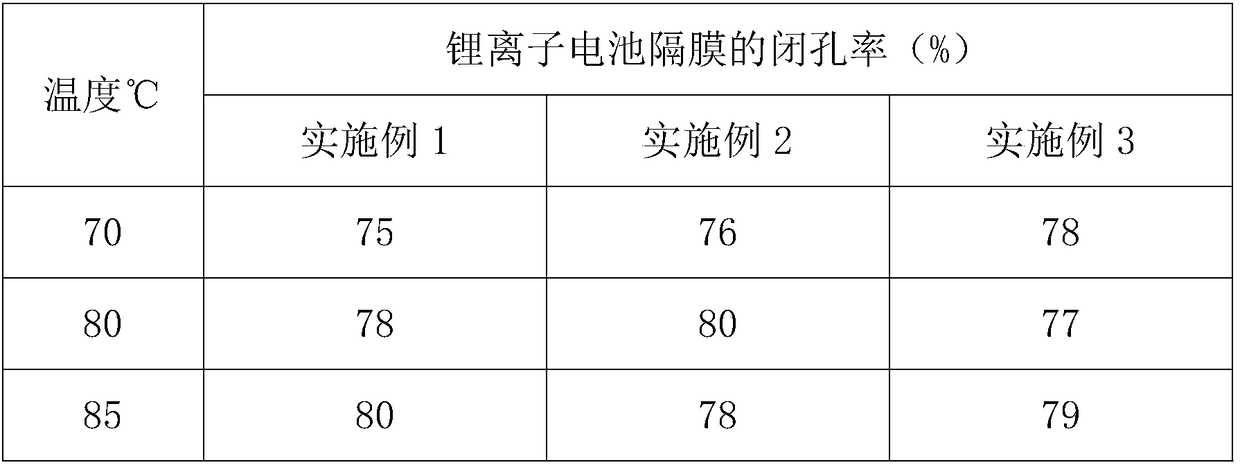

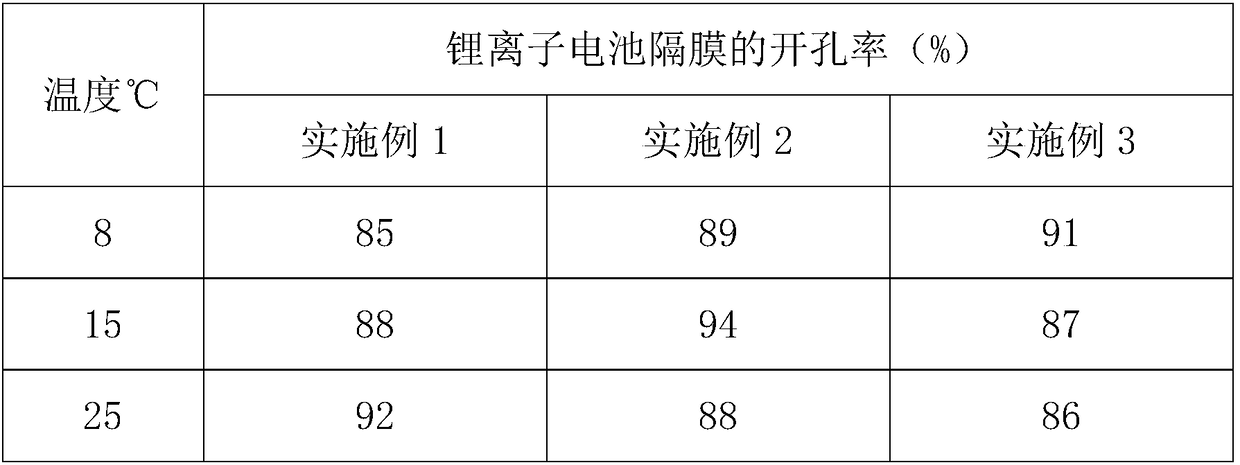

Lithium ion battery separator for new energy automobile and preparation method thereof

InactiveCN108539096AStrong penetrating powerPrevent short circuitsSecondary cellsCell component detailsDiaminodiphenyl etherCeramic coating

The invention discloses a lithium ion battery separator for a new energy automobile, the lithium ion battery separator comprises a modified non-woven material separator, wherein the surfaces of both sides of the modified non-woven material separator are coated with a modified ceramic coating, and the modified non-woven material separator includes the following materials: polyethylene, polypropylene, lithium phosphate, lithium sulfonate, n-octadecyl alcohol, triphenyl phosphite, acetone, tetrahydrofuran, deionized water, 4,4-diaminodiphenyl ether, N, N-dimethyl acetamide and pyromellitic dianhydride; the invention also discloses a preparation method of the lithium ion battery separator for the new energy automobile. The preparation method solves the technical problems that when the existinglithium ion battery separator has a large pore diameter, positive and negative electrodes are easy to directly contact or easily pierced by lithium dendrites to cause short circuit, when the existinglithium ion battery separator has a too small pore diameter, electrical resistance is increased, and when temperature is raised, the heat shrinkage rate of the separator is large, and the shrinkage of the separator causes direct contact between the positive and negative electrodes, so that the short circuit is prone to occur.

Owner:胡金友

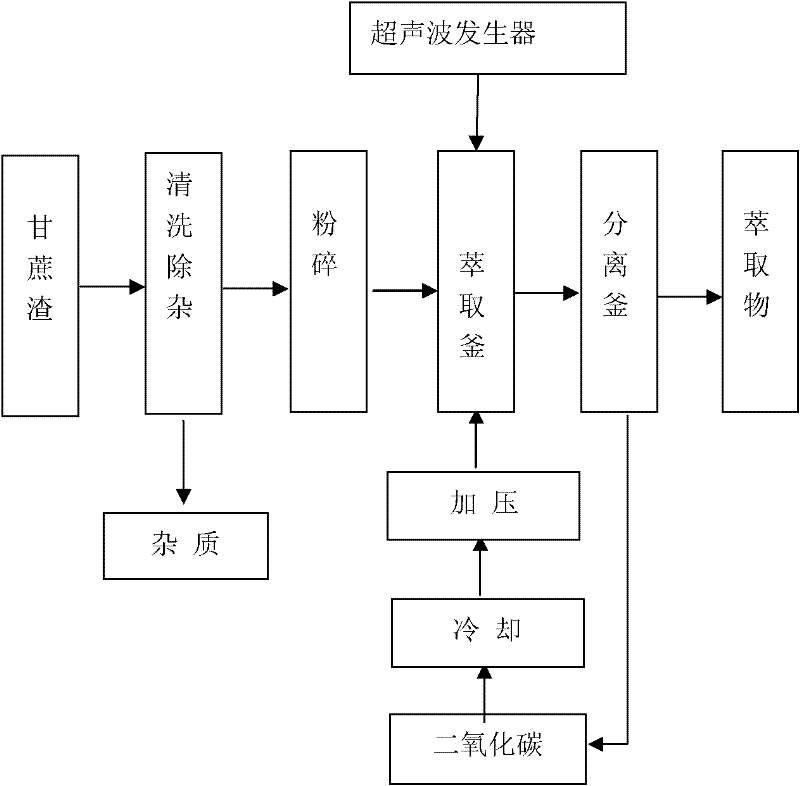

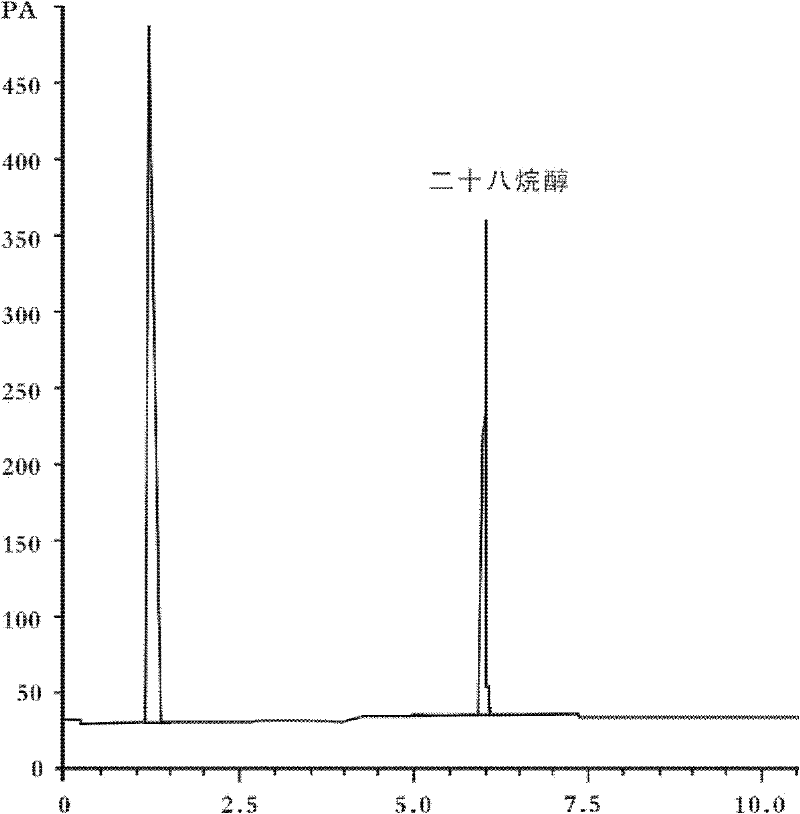

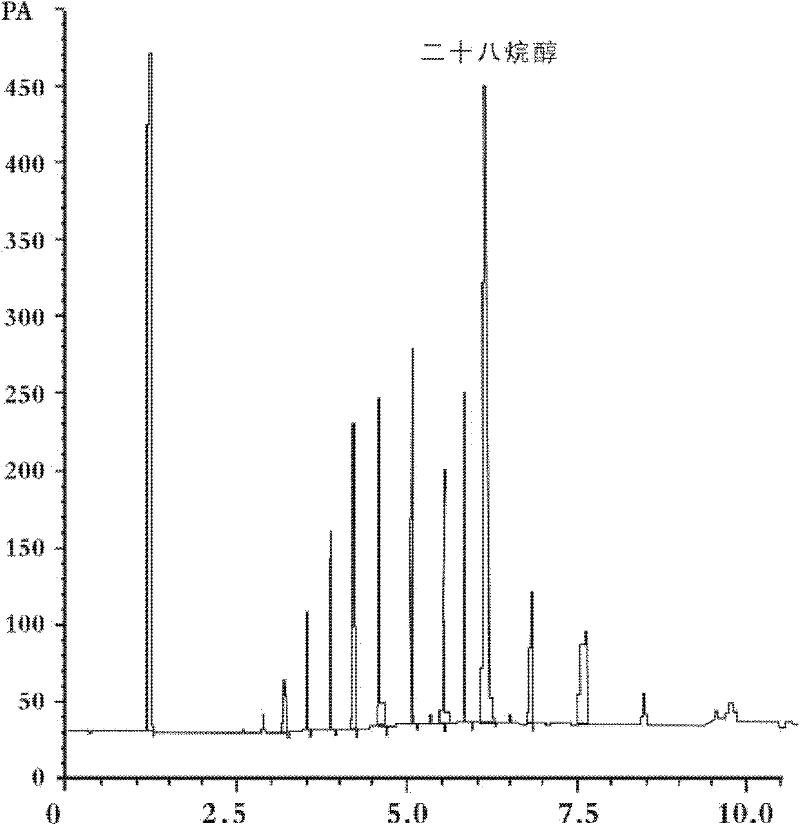

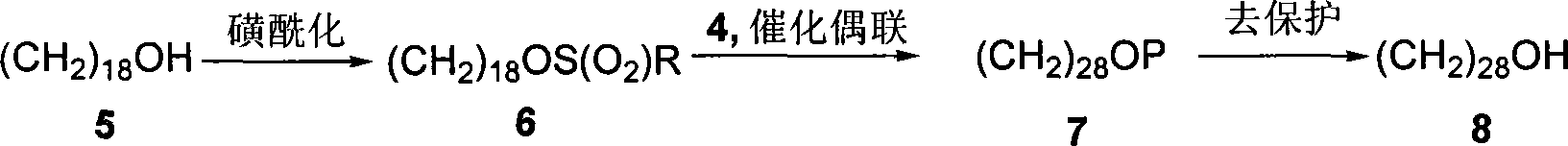

Method for extracting 1-octacosanol from bagasse

ActiveCN102399129AImprove extraction efficiencyRelieve pressureOrganic compound preparationHydroxy compound preparationOrganic solventUltrasonic radiation

The invention discloses a method for extracting 1-octacosanol from bagasse. The method is characterized by comprising the following steps of: (1) grinding the bagasse into powder; (2) putting the bagasse powder obtained in the step (1) into an extraction kettle to form a packing layer; (3) extracting, namely introducing supercritical carbon dioxide into the extraction kettle through the bottom of the extraction kettle, allowing the supercritical carbon dioxide to flow through the bagasse powder of the packing layer, flow out of the extraction kettle through the top of the extraction kettle and enter a separation kettle, and performing ultrasonic radiation on the supercritical carbon dioxide in the extraction kettle in the extracting process; and (4) separating 1-octacosanol dissolved in the carbon dioxide in the separation kettle. The 1-octacosanol is extracted by an ultrasound-enhanced supercritical carbon dioxide fluid, so the production efficiency is high, the cost is low, the product purity is high, organic solvents are not contained, and the 1-octacosanol can serve as an important raw material for health foods, cosmetics and medicines.

Owner:SOUTH CHINA UNIV OF TECH

Face cleaning skin lotion product and method of producing the same

The invention belongs to the field of manufacture of chemical product for daily use, in particular relates to a face cleansing and skin nurturing product and a preparation method thereof. The face cleansing and skin nurturing product comprises the following steps: cleansing cream and cleansing gel, wherein, the cleansing cream comprises the following components: 0.8% to 1.5% of span-60, 2.4% to 3.5% of tween-60, 1% to 6% of monoglyceride, 2% to 5% of cetyl alcohol / octadecyl alcohol, 30% to 55% of white mineral oil, 2% to 3% of simethicone, 3% to 5% of jojoba oil, 5% to 10% of plant extracting solution, 5% to 10% of glycerin, 0.05% to 0.2% of nipagin methyl ester, 0.05% to 0.2% of nipagin propyl ester, 0.05% to 0.2% of liquid antiseptics, 0.02% to 0.04% of plant essential oil, and deionized water in balancing amount; the cleansing gel comprises the following components: 6% to 10% of glycerin, 5% to 10% of plant essential oil, 12% to 15% of glycerin polyacrylic acid, 0.01% to 0.02% of plant essential oil, 0.1% to 0.2% of liquid antiseptics, and deionized water in balancing amount. The cleansing combination cleanses the dirt of skin in a method of reemulsification of the cream body on the skin, so that the skin can be cleansed effectively without stimulation and greasiness, thereby being a novel cleansing product for taking good care of the health of the skin.

Owner:肖力

Method for preparing octacosanol ester through enzyme catalysis

InactiveCN104498546AIncrease fat solubilityImprove bioavailabilityFermentationChemical industryCatalytic effect

The invention discloses a method for preparing octacosanol ester through enzyme catalysis, belonging to the technical fields of foods, medicines, chemical industry, cosmetics and the like. The octacosanol ester is synthesized under the catalytic action of a nonaqueous-phase lipase by taking octacosanol as a raw material and fatty acid as an acyl donor. The method is mild in reaction condition, little in side reaction, simple in separation, environment-friendly and the like. By using the method, the oil solubility of octacosanol can be improved, the bioavailability of octacosanol can be increased, and the actual application range of octacosanol is greatly widened.

Owner:JIANGSU UNIV

Preparation method of linear low density polyethylene

ActiveCN102485783AGood flexibilityHigh printability linearityLow-density polyethyleneLinear low-density polyethylene

The invention relates to a preparation method of linear low density polyethylene. The preparation method comprises the following steps: 1, taking methyl methacrylate and benzoyl peroxide, adding polyisobutylene, and reacting to obtain methyl methacrylate grafting polyisobutylene at 85-105DEG C, wherein the weight of the methyl methacrylate accounts for 5-15% of the weight of polyisobutylene, and the weight of the benzoyl peroxide accounts for 1-5% of the weight of polyisobutylene; 2, taking methyl methacrylate grafting polyisobutylene, an organic anti-block agent stearamide, a dispersant zincstearate and an oxidant beta-(3,5-di-t-butyl-4-hydroxyphenyl)propionic acid n-octadecyl alcohol ester, wherein the weight of methyl methacrylate grafting polyisobutylene accounts for 3-15% of the weight of the linear low density polyisobutylene, the weight of the organic anti-block agent accounts for 0.1-1% of the weight of the linear low density polyisobutylene, the weight of the dispersant accounts for 0.05-0.5% of the weight of the linear low density polyisobutylene, and the weight of the antioxidant accounts for 0.1-0.5% of the weight of the linear low density polyisobutylene; and 3, mixing above materials in a high speed mixer, and extruding by a double screw extruder to prepare a low density polyethylene film. The method has the advantages of low cost, high softness, good stability and high speed printing performance.

Owner:PETROCHINA CO LTD

Ultraviolet-proof modified nylon 6 material for automobile plastic parts

The invention belongs to the field of high-polymer materials, and particularly relates to an ultraviolet-proof modified nylon 6 material for automobile plastic parts. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 6, 12-14 parts of aluminum nitrate, 5-8 parts of polyaluminum chloride, 3-4 parts of ferrous sulfate, 3-4 parts of acrylamide, 1-2 parts of oleamide, 16-18 parts of dibutyl phthalate, 2-3 parts of lithium laurate, 1-2 parts of dimethyl bis(isooctylmercaptoacetate) tin, 3-4 parts of bis(octadecyl alcohol ester), and 12-15 parts of auxiliaries. According to the ultraviolet-proof modified nylon 6 material, the nylon 6 is modified by utilizing the raw materials of aluminum nitriate, polyaluminum chloride, ferrous sulfate and the like, and the nylon 6 has excellent processiability and mechanical performance, so that the prepared material is high in hardness, high-temperature-resistant, difficult to age, ultraviolet irradiation-proof, and safe to use, and can be widely used for producing various automobile plastic parts.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

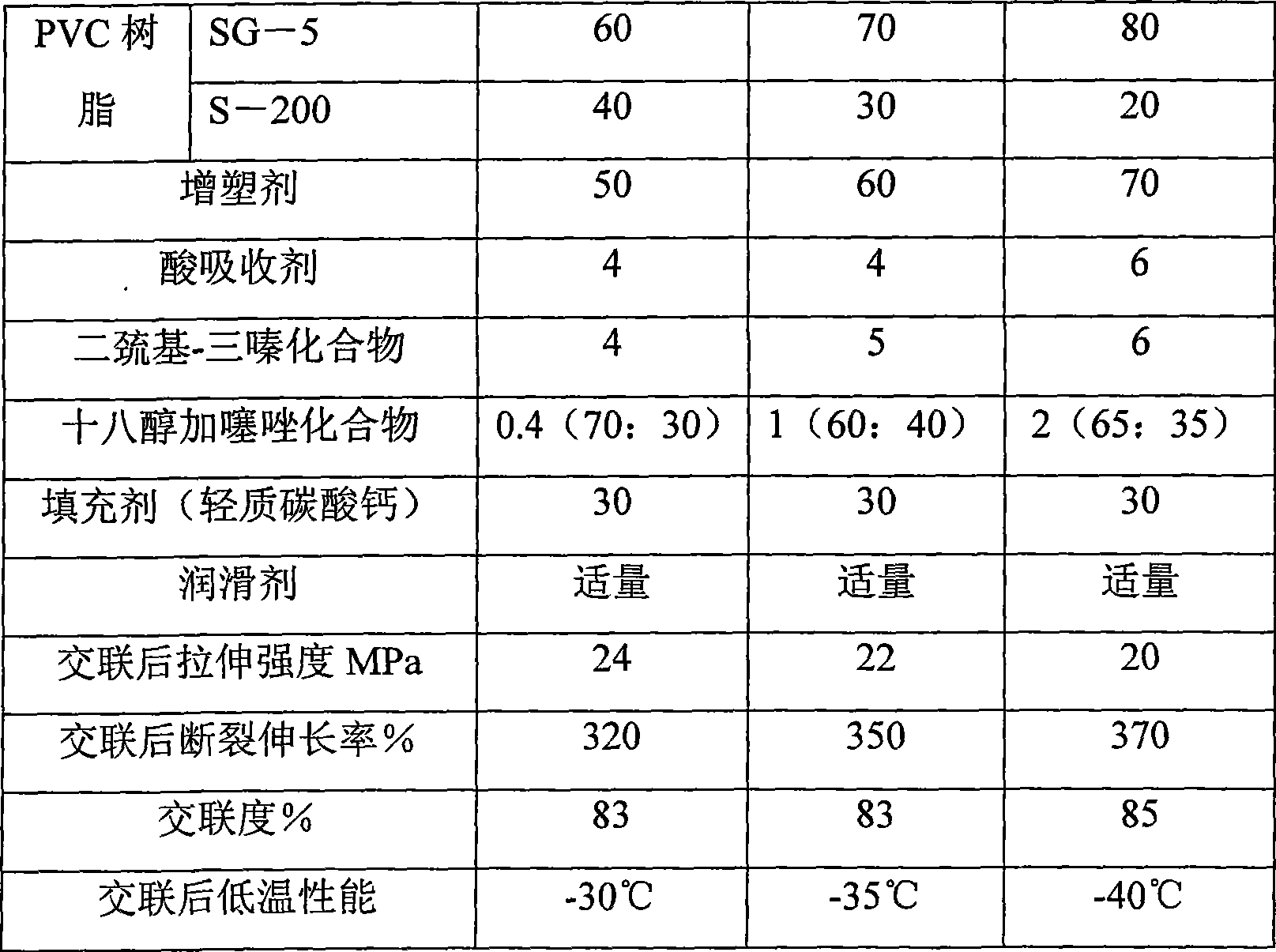

Polyvinyl chloride cross linking through sulfhydryl compound

InactiveCN101445634AIncrease the degree of cross-linkingFast vulcanizationPlastic/resin/waxes insulatorsCross-linkVulcanization

The polyvinyl chloride cross linking method through sulfhydryl compound is an improved polyvinyl chloride cross linking method through sulfhydryl compound. The polyvinyl chloride cross linking method is characterized in that the sulfhydryl compound cross linked polyvinyl chloride comprises 100 parts of PVC resin, 40 to 90 parts of plasticizer, 2 to 6 parts of acid absorbent, 3 to 7 parts of dimercapto-triazine compound cross linking agents, 0.2 to 2 parts of composite catalyst, and the components are blended and vulcanized; the PVC resin comprises the following components: 60 wt% to 80wt% of PVC resin with polymerization degree of 950 to 1,050 and 20wt% to 40wt% of PVC resin with polymerization degree of 2,450 to 2,550; the composite catalyst is formed by blending 60wt% to 80wt% of octadecyl alcohol and 20wt% to 40wt% of thiazolium compound. Compared with the prior art, the polyvinyl chloride cross linking method has the advantages that the vulcanization rate is high, the vulcanization time is reduced to 8 minutes from 15 minutes originally, the cross linking degree is high and improved to 85% from 65% originally, the physical and mechanical performances are good, the tensile strength is improved to 20 MPa from 16 MPa originally, and the rebound elasticity and the low temperature flexibility are also improved.

Owner:JIANGSU HENGFENG CABLE

Plastic for flame-retardant, wear-resistant and aging-resistant mobile telephone shell

The invention discloses a plastic for a flame-retardant, wear-resistant and aging-resistant mobile telephone shell. The plastic comprises the following raw materials in parts by weight: 10-18 parts of polycarbonate, 5-18 parts of polypropylene, 20-40 parts of an ethylene-octene copolymer, 15-25 parts of polyvinyl chloride, 8-16 parts of a maleic anhydride grafted ethylene-ninyl acetate copolymer, 2-8 parts of silicon carbide, 1-2.5 parts of a silane coupling agent SI-69, 1-4 parts of aluminum oxide, 2-10 parts of iron-based montmorillonite, 1-3 parts of boron nitride, 8-12 parts of nanosilicon dioxide, 5-16 parts of modified opal powder, 8-14 parts of calcined kaolin, 1-3 parts of phenylene maleic imide, 1-3 parts of natural rubber grafted polymethyl methacrylate, 1-3 parts of caprolactam, 1-2 parts of benzoyl peroxide, 0.2-0.6 part of triethylenetetramine, 0.2-0.6 part of cyclohexanone peroxide, 1-2 parts of t-butyl perbenzoate, 1-3 parts of octadecyl alcohol, 1-3 parts of p-phenylenediamine and 1-3 parts of trioctyl. The plastic disclosed by the invention is wear-resistant, aging-resistant, and excellent in flame retardance.

Owner:安徽酷米智能科技股份有限公司

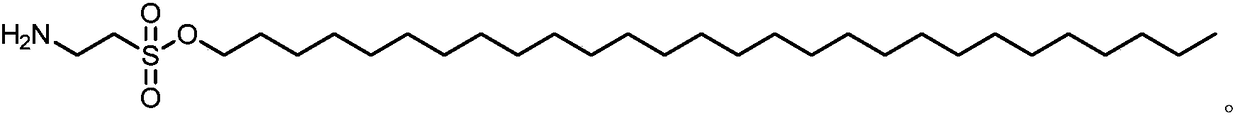

Preparation method and application of octacosanol-containing lipidosome

ActiveCN109077943AGood water solubilityImprove uniformityCosmetic preparationsToilet preparationsTaurine synthesisSolubility

The invention discloses a preparation method of octacosanol-containing lipidosome, including the steps of adding octacosanol and taurine into water-dichloromethane emulsion and performing catalytic synthesis to obtain taurine-octacosanol ester solution; adding cholesterol solution into the taurine-octacosanol ester solution obtained in the first step, performing ultrasonic emulsification, performing rotary evaporation at room temperature to remove dichloromethane to obtain lipidosome solution; hydrating the lipidosome solution, extruding to obtain octacosanol-containing lipidosome with uniformgrain size through a lipidosome extruder, and finally freezing and drying into powder to obtain the finished octacosanol-containing lipidosome product. Since the octacosanol-containing lipidosome isprepared by synthesis of octacosanol and taurine, the problem of poor water solubility of higher aliphatic alcohol is solved, the effect of colourless and odourless is achieved when added to foods, cosmetics and beverages, and the lipidosome has good homogeneity. Besides, octacosanol and taurine have complementary and synergistic effect to the organism and are good for absorption and in-vivo circulation.

Owner:深圳市承泽信息科技有限公司

Preparation method and application of surfactant containing octacosanol

InactiveCN108852881AImprove staminaHigh energyCosmetic preparationsToilet preparationsActive agentBiochemical engineering

The invention discloses a preparation method and application of a surfactant containing octacosanol. According to the preparation method, octacosanol is added into a polyglutamic acid aqueous solution, catalytic synthesis is carried out through lipase so as to obtain a polyglutamic acid octacosanol ester emulsion, and spray drying is carried out so as to obtain polyglutamic acid octacosanol esterpowder. The preparation method has the advantages that the polymer surfactant of polyglutamic acid octacosanol ester is synthesized and prepared by utilizing octacosanol and polyglutamic acid, so thatthe problems that higher aliphatic alcohol is poor in water solubility, and no flavor and sense are generated when the surfactant is added in food, cosmetics and beverages can be solved, and the uniformity is good; and meanwhile, polyglutamic acid and octacosanol have complementary and synergistic effects on body regulation, so that the exercise ability of old people can be greatly improved.

Owner:NANTONG UNIVERSITY

Preparation method for octacosanol

InactiveCN101121636ARaw materials are easy to getRich sourcesOrganic compound preparationHydroxy compound preparationAlcoholOrganic synthesis

Owner:XIAMEN UNIV

Scouring agent for silk fabric and application method of scouring agent

InactiveCN107287889AProtective silk fibroinGood refining effectAnimal fibresDiphenyl etherReaction temperature

The invention discloses a scouring agent for a silk fabric and an application method of the scouring agent. The scouring agent is prepared from the following components in parts by weight: a liquid A, including 100 parts of potassium octyl diphenyl ether disulfonate, 20-40 parts of octadecyl alcohol polyoxyethylene ether, 8-12 parts of sodium diethylhexyl sulfosuccinate, 2-5 parts of a chelating dispersant and 4-6 parts of propargyl alcohol, and a liquid B, including 10 parts of papain and 80-110 parts of a buffering agent. The invention further provides an application method of the scouring agent for the silk fabric. The scouring agent is relatively low in reaction temperature, mild in pH and good in scouring effect. The scouring agent is capable of preventing the fabric from being damaged, and the fabric is capable of maintaining relatively good hand feeling and improving the commercial value of the silk fabric.

Owner:SUZHOU WILDER IND & TRADE

Environment-friendly medical-grade PVC (polyvinyl chloride) specialized powder calcium zinc stabilizer and preparation method thereof

The invention discloses an environment-friendly medical-grade PVC (polyvinyl chloride) specialized powder calcium zinc stabilizer. The environment-friendly medical-grade PVC (polyvinyl chloride) specialized powder calcium zinc stabilizer is prepared from, by weight, 100 parts of calcium stearate, 10-40 parts of zinc stearate, 5-10 parts of nanometer titania, 5-10 parts of nanosilicon dioxide, 5-10parts of glycerin monostearate, 5-10 parts of a carbon nanotube modified polyphosphazene-polyether sulfone block copolymer, 1-5 parts of beta-(3,5-ditert-butyl-4-hydroxyphenyl) propionate octadecyl alcohol and 1-5 parts of an ultraviolet light absorber UV-531. The environment-friendly medical-grade PVC (polyvinyl chloride) specialized powder calcium zinc stabilizer has the advantages of good weather fastness and less proneness to discoloration, service life of the PVC medical material can be prolonged, mechanical strength of the PVC medical material can be greatly improved, and good heat resistance and environment friendliness are achieved.

Owner:常熟市法艾新材料科技有限公司

Preparation method of hair conditioner

InactiveCN107951803AHas antistatic effectWon't tangle forksCosmetic preparationsHair cosmeticsCoconut oilPalmitates

The invention discloses a preparation method of hair conditioner, which comprises preparing sorbitol, polyglycerin, coconut oil, collagen, vitamin A palmitate, aloe gel, panthenol, lecithin, cetyl alcohol, stearyl alcohol, emulsifier and deionized water; sorbitol, polyglycerin, coconut oil, collagen, vitamin A palmitate, aloe vera gel and emulsifier were uniformly mixed and stirred to make an emulsified mixture; the emulsified mixture was mixed with panthenol , lecithin, and cetyl alcohol are mixed evenly; the mixture and stearyl alcohol are added to deionized water for heat preservation; after the heat preservation is completed, the hair conditioner is obtained by natural cooling. The beneficial effects of the present invention are: the present invention has excellent moisture retention and combability, can improve hair quality, especially has obvious improvement effect on damaged hair quality, prevents hair from tangling and splitting, and has antistatic effect Also does not irritate the scalp.

Owner:CHENGDU YISHENGKE BIOTECH

Waterproof paint not liable to peel off

InactiveCN103614056AReduce pollutionWon't peel offAnti-corrosive paintsPolyether coatingsKaolin clayEthyl group

The invention discloses waterproof paint not liable to peel off. The paint is prepared from following raw materials by weight: 2.5-3.8 parts of dibromomethane, 3.5-3.7 parts of tetrahydrofuran, 3.5-4.7 parts of nonylphenol polyoxyethylene ether, 3-7 parts of kaolin, 1.2-1.7 parts of phenylethyl naphthol polyoxyethylene ether, 2.5-5 parts of octadecanol polyoxyethylene ether, 1.2-2.2 parts of N-methyl-alkylamido taurine salt and 1.8-3.6 parts of a sorbitol-fatty acid ester. Compared with waterproof paint at present, the paint provided by the invention has high water resistance, high water proofness and high tensile strength and is healthy and environmental friendly; environment pollution is reduced and wall peeling off caused by rain wash after longtime use is avoided; the paint provided by the invention can prevent being washed by acid rain; and the paint film wound not peel off after rain wash, thus reducing the probability that rain permeates into the wall and corrodes the wall to cause losses.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Improved difficult-flaking waterproof coating material

InactiveCN103602178AReduce pollutionWon't peel offPolyether coatingsDioxyethylene EtherFatty alcohol

The invention discloses an improved difficult-flaking waterproof coating material. The improved difficult-flaking waterproof coating material is prepared from the following raw materials in parts by weight: 2.5-3.8 parts of hexabromocyclododecane, 3.5-7 parts of tetrahydrofuran, 3.5-4.7 parts of nonylphenol polyoxyethylene ether, 3-7 parts of polyvinyl acetate emulsion, 1.2-1.7 parts of phenethyl naphthol polyoxyethylene ether, 2.5-5 parts of octadecanol polyoxyethylene ether, 1.2-2.2 parts of N-methyl fatty amide taurine salt and 1.8-3.6 parts of fatty alcohol sorbate. Compared with the existing waterproof coating materials, the waterproof coating material has the advantages that the water resistance and waterproofing performance are higher, the tensile strength is high, the waterproof coating material is healthy and environmental-friendly, the environmental pollution is reduced, and wall body flaking caused by rainwater scouring can not occur during long-time use; the waterproof coating material can prevent acid rain scouring, and a coated film can not flake off after the coated film is subjected to rainwater scouring, so that the probability that loss is caused due to the fact that rainwater penetrates into wall faces and corrodes the wall faces is reduced.

Owner:贵州道尔科技有限公司

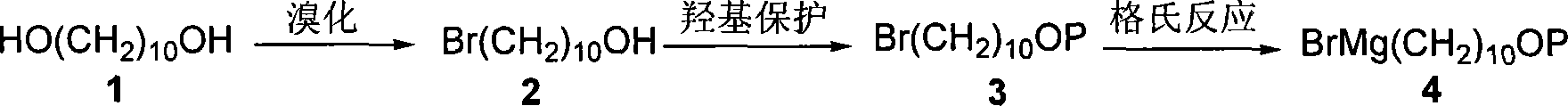

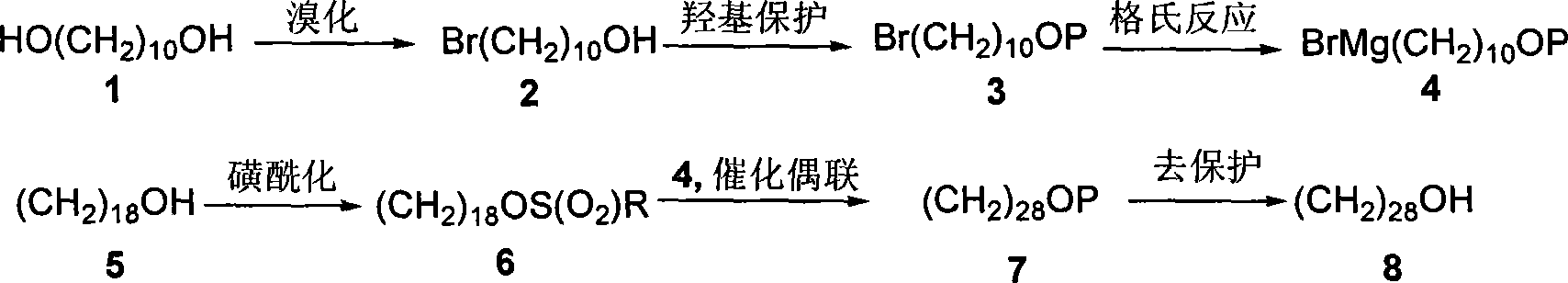

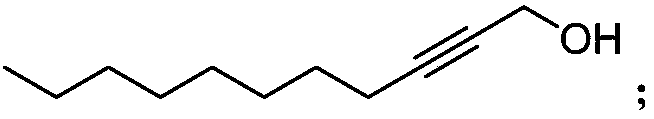

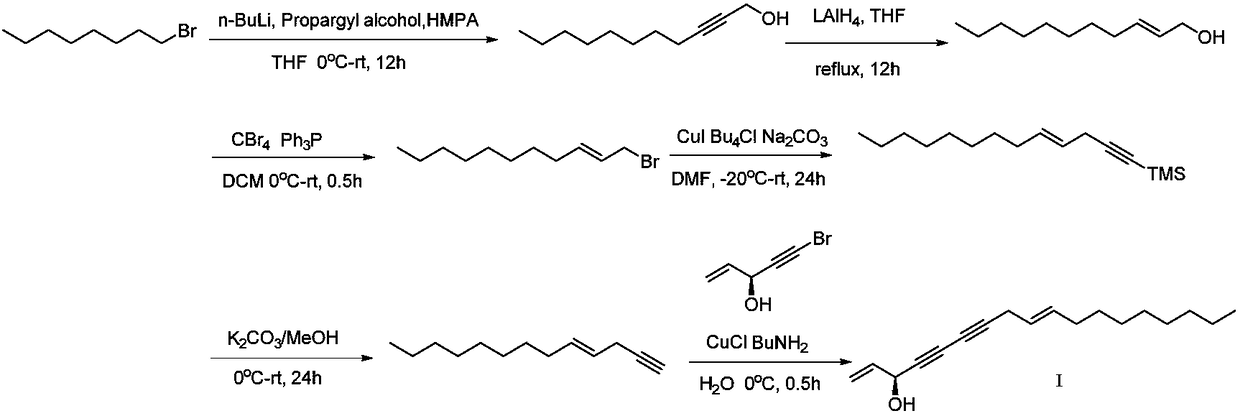

Synthetic method of highly-activity chiral acetylenic alcohol (S,E)-1,9-diene-4,6-diacetyl-3-octadecyl alcohol

InactiveCN108440242AFeeding ratio is reasonableHigh purityGroup 4/14 element organic compoundsOrganic compound preparationCouplingAcetylenic alcohol

The invention discloses a synthetic method of highly-activity chiral acetylenic alcohol (S,E)-1,9-diene-4,6-diacetyl-3-octadecyl alcohol. The synthetic method disclosed by the invention comprises thefollowing steps: bromooctane is taken as a starting raw material and is reacted in a reasonable proportion to synthesize required alkynol; and the efficient synthesis of active molecule (S,E)-1,9-diene-4,6-diyne-3-octadecanol is realized through reduction, bromination, coupling reactions, desilication and docking with a chiral molecule. According to the method, the yield in the reaction process ishigh, a synthetic route is simple, the raw material is simple and easy to obtain, the synthetic cost is low, reaction conditions are mild, the separation and purification operations are simple, and ahigh-purity target compound can be directly obtained; a chiral center is introduced in the last step, so that the possibility of racemization of the substance in the reaction is avoided; and in addition, the synthesized active molecule (S,E)-1,9-diene-4,6-diyne-3-octadecanol has a wide application prospect.

Owner:HENAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com