Polyvinyl chloride cross linking through sulfhydryl compound

A technology of mercapto compound and cross-linking polymerization, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of slow cross-linking speed, low cross-linking degree, performance improvement that cannot meet high requirements, etc., and achieve fast vulcanization speed , high degree of cross-linking, improved resilience and low-temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

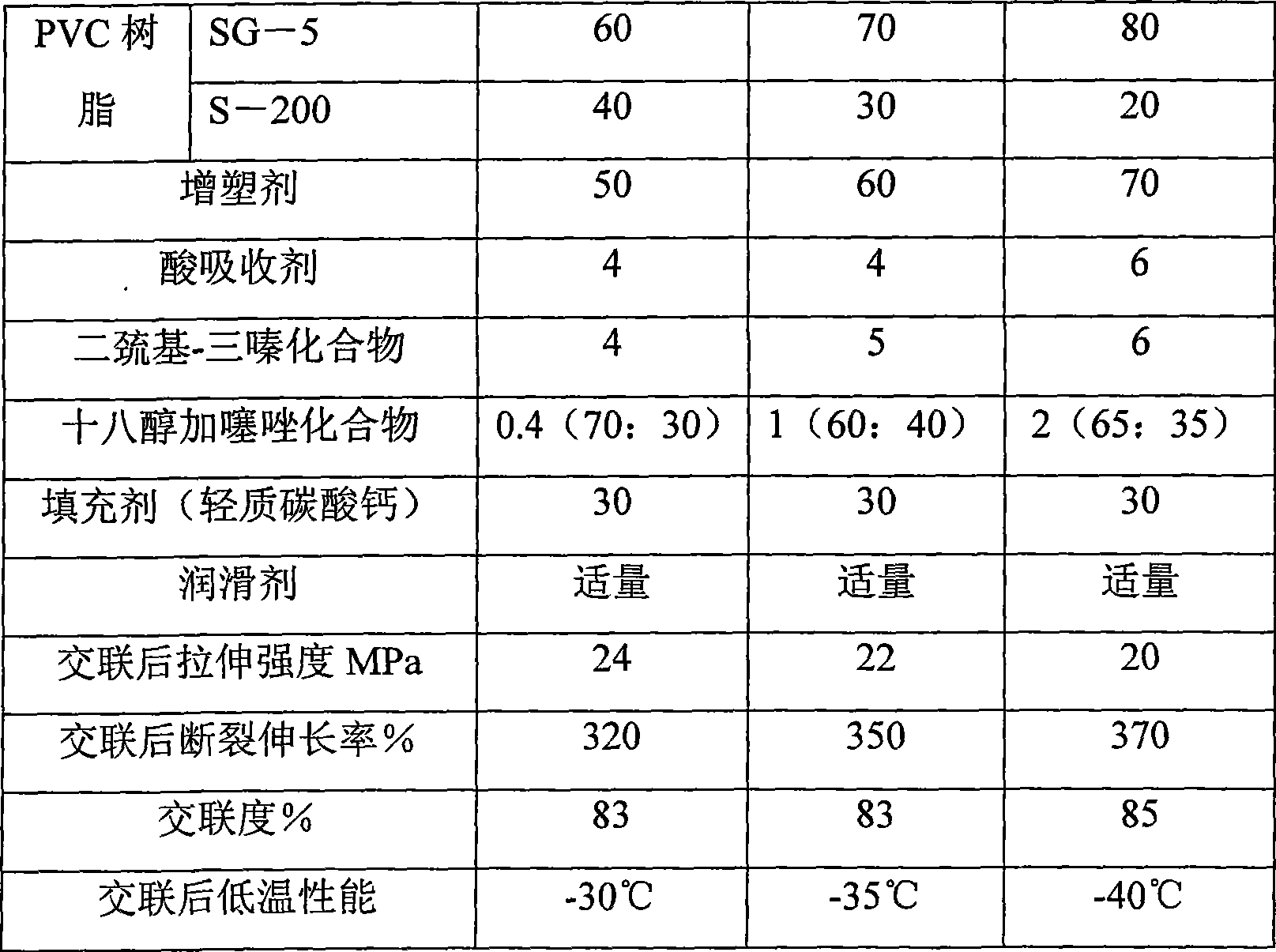

[0019] Embodiment: see attached table, first two kinds of PVC resins with different degrees of polymerization are mixed, add acid absorbent MgO or PbO, dimercapto-triazine compound linking agent DB or TCY, two kinds of catalysts (stearyl alcohol and DM or M or MZ), colorant, lubricant polyethylene wax, stir and disperse in a high-speed mixer, for example, 10 seconds; then add plasticizer DOP or TOTM, stir to make the plasticization fully absorbed by the resin, for example, heat up to 50-55 ℃, and finally add the filler calcium carbonate and stir until it is completely dispersed, for example, the temperature is raised to 95 ℃; finally put it into the extruder for granulation. After the cable is extruded, it can be vulcanized continuously for 10 minutes through a steam pipeline at 150-160°C, or in a steam tank at 150-160°C for 10 minutes. The specific process is basically the same as the original vulcanization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com