Lithium ion battery separator for new energy automobile and preparation method thereof

A technology for lithium-ion batteries and new energy vehicles, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., and can solve problems such as large thermal shrinkage of the diaphragm, direct contact between positive and negative electrodes, and short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Mix 30-50 parts by mass of polyethylene and 30 parts by mass of polypropylene with 5 parts by mass of lithium phosphate and 3 parts by mass of lithium sulfonate, and add 1 part by mass of n-stearyl alcohol and 2 Parts by mass of triphenyl phosphite were uniformly mixed in a high-speed mixing mixer, the stirring speed of high-speed mixing was 250r / min, the temperature was 260°C, and the time was 80min to obtain a mixed solution;

[0054] (2) Add the mixed liquid prepared in step (1) into the internal mixer, heat it with heat transfer oil at a temperature of 350°C, pressurize it through the top bolt, and enter the open mixer driven by the hydraulic system after mastication. After being fully plasticized by the strong extrusion and shearing action of the milling roller; then it enters the inverted L-shaped four-roller calender, and the film wrapped on the lower roller of the calender is peeled off and pulled out. The roller speed of the calender is 150mm / s, being drag...

Embodiment 2

[0074] (1) Mix 40 parts by mass of polyethylene and 40 parts by mass of polypropylene with 6 parts by mass of lithium phosphate and 4 parts by mass of lithium sulfonate, and add 1 part by mass of n-stearyl alcohol and 3 parts by mass of The triphenyl phosphite was uniformly mixed in a high-speed mixing mixer, the stirring speed of the high-speed mixing was 260r / min, the temperature was 265°C, and the time was 90min to obtain a mixed solution;

[0075] (2) Put the mixed solution prepared in step (1) into the internal mixer, heat it with heat-conducting oil at a temperature of 380°C, pressurize it through the top bolt, and enter the open mixer driven by the hydraulic system after mastication. After being fully plasticized by the strong extrusion and shearing action of the milling roller; then it enters the inverted L-shaped four-roller calender, and the film wrapped on the lower roller of the calender is peeled off and pulled out. The roller speed of the calender is 180mm / s, be...

Embodiment 3

[0096] (1) Mix 50 parts by mass of polyethylene and 50 parts by mass of polypropylene with 8 parts by mass of lithium phosphate and 5 parts by mass of lithium sulfonate, and add 2 parts by mass of n-stearyl alcohol and 4 parts by mass of The triphenyl phosphite was uniformly mixed in a high-speed mixing mixer, the stirring speed of the high-speed mixing was 280r / min, the temperature was 270°C, and the time was 100min to obtain a mixed solution;

[0097] (2) Add the mixed liquid prepared in step (1) into the internal mixer, heat it with heat transfer oil at a temperature of 400°C, and pressurize it through the top bolt, and enter the open mixer driven by the hydraulic system after mastication. After being fully plasticized by the strong extrusion and shearing action of the milling roller; then it enters the inverted L-shaped four-roller calender, and the film wrapped on the lower roller of the calender is peeled off and pulled out. The roller speed of the calender is 200mm / s, ...

PUM

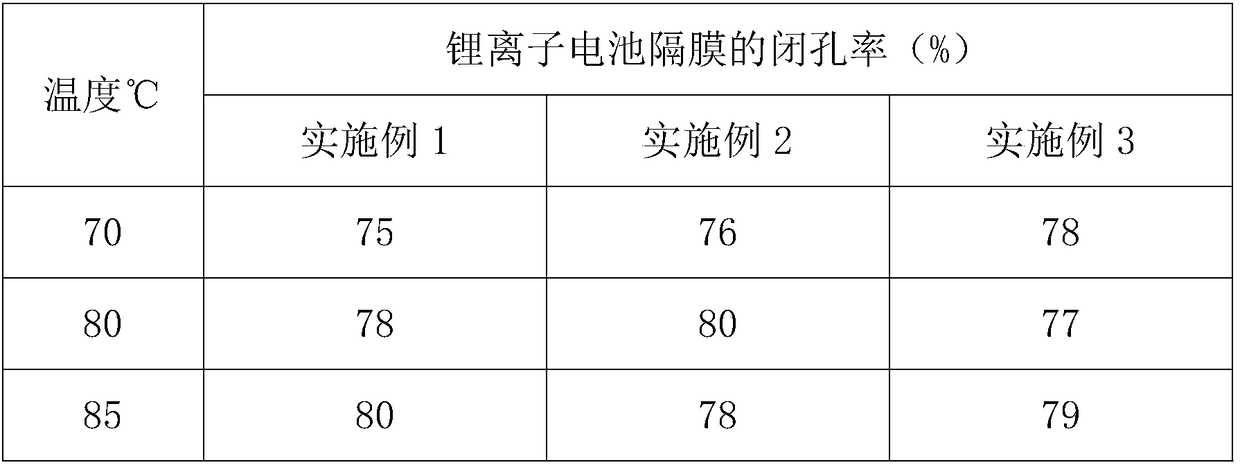

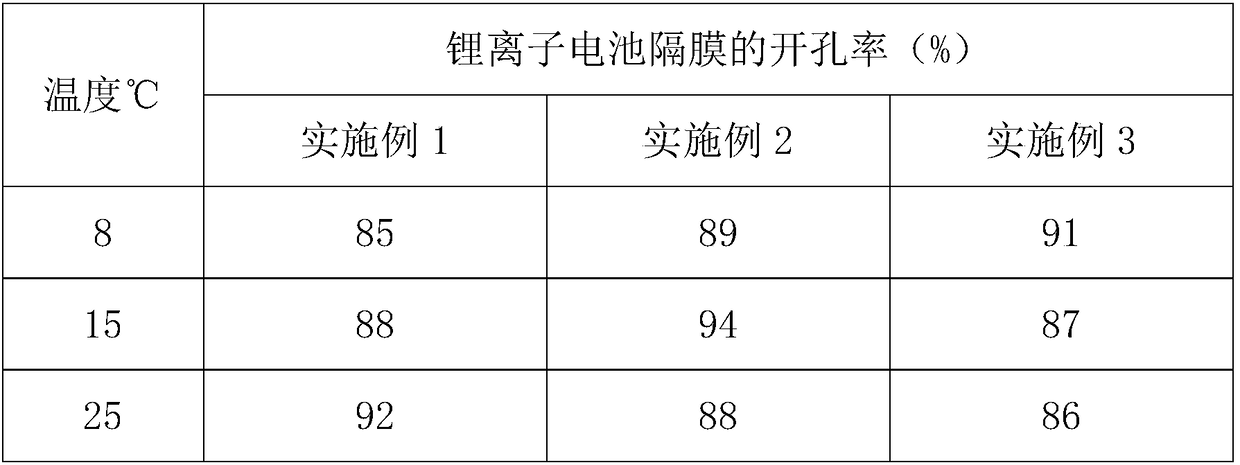

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com