Patents

Literature

67 results about "Glucurolactone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid effervescent mixture for oral absorption

InactiveCN101919801AEasy to carryEasy to takeNervous disorderHydroxy compound active ingredientsCoffea eugenioidesAlkaline earth metal

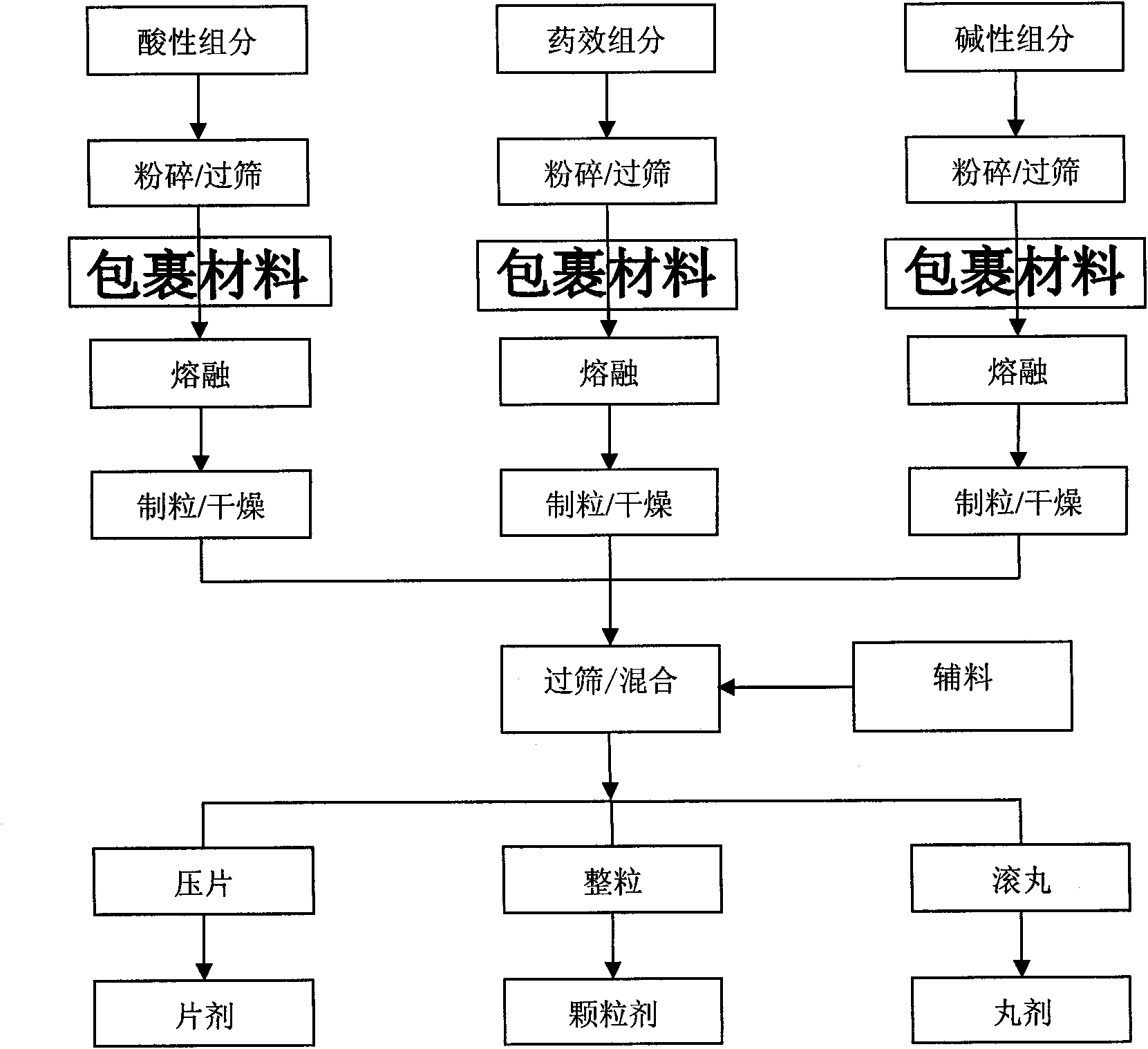

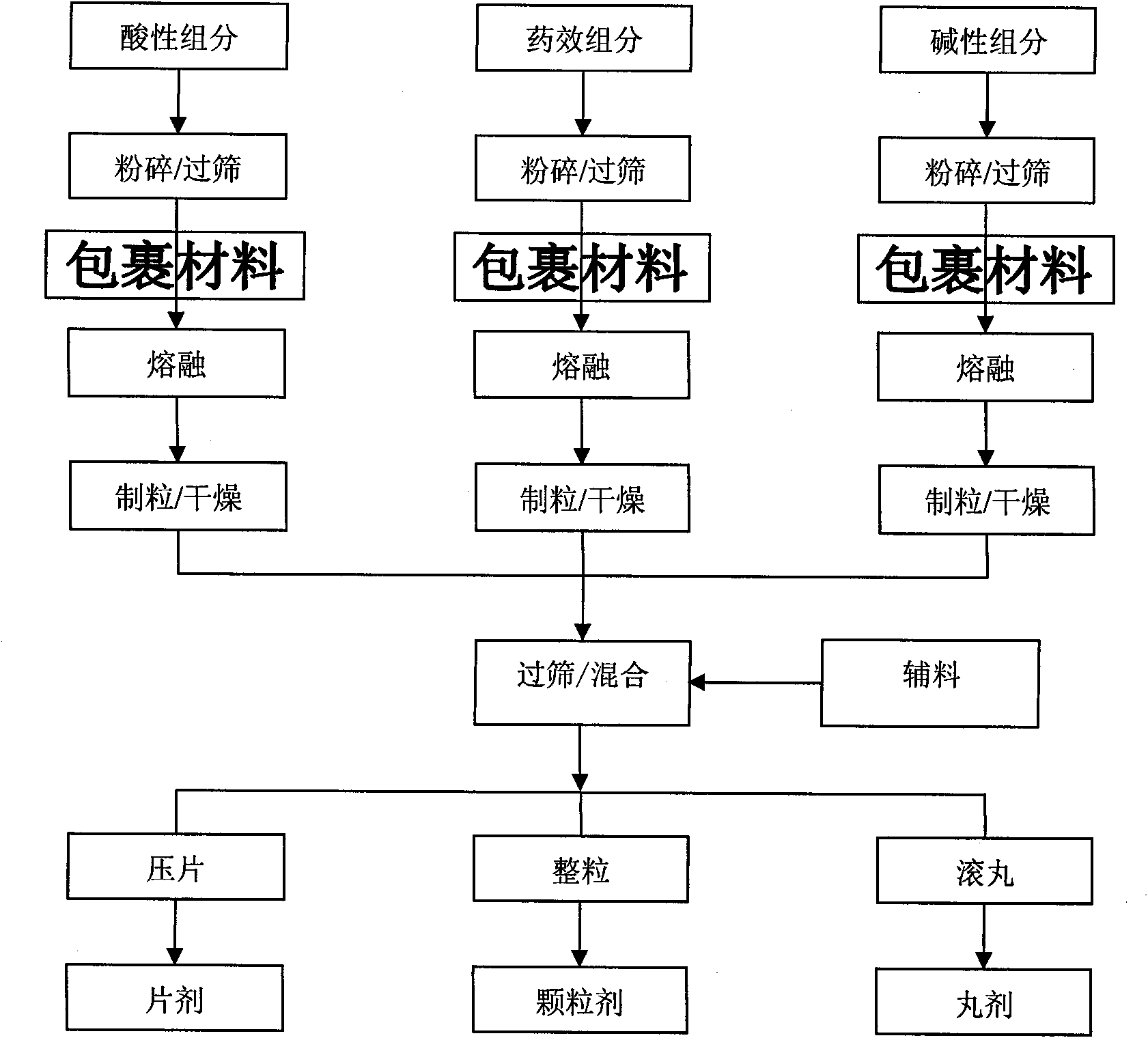

The invention relates to an effervescent mixture, specifically relates to a solid effervescent mixture for the oral absorption and a preparation method thereof. The invention comprises the alkalic component of a mixture consisting one or more than one of alkali metal carbonate, alkali metal bicarbonate, alkaline earth metal carbonate or pearl powder; the acid component of a mixture consisting one or more than one of tartaric acid, citric acid, adipic acid, fumaric acid, maleic acid, malic acid, folic acid andacid phosphate; the medical component of a mixture consisting one or more than one of ginseng extract, octacosanol, glucurolactone, taurine, natural caffeine, D-ribose; the wrapper and auxiliary material of a mixture consisting one or more than one of polyethylene glycol (PEG), panthenol and glycerin monostearate. The invention comprises, by weight, 5-50% of alkalic component; 5-50% of acid component; 1-40% of medical component; 0.5-35% of wrapper; 1-10% of auxiliary material. The invention has advantages of being fast in effect, and convenient in medicine taking and carrying.

Owner:无锡健而乐医药科技有限公司

Process for producing glucurolactone

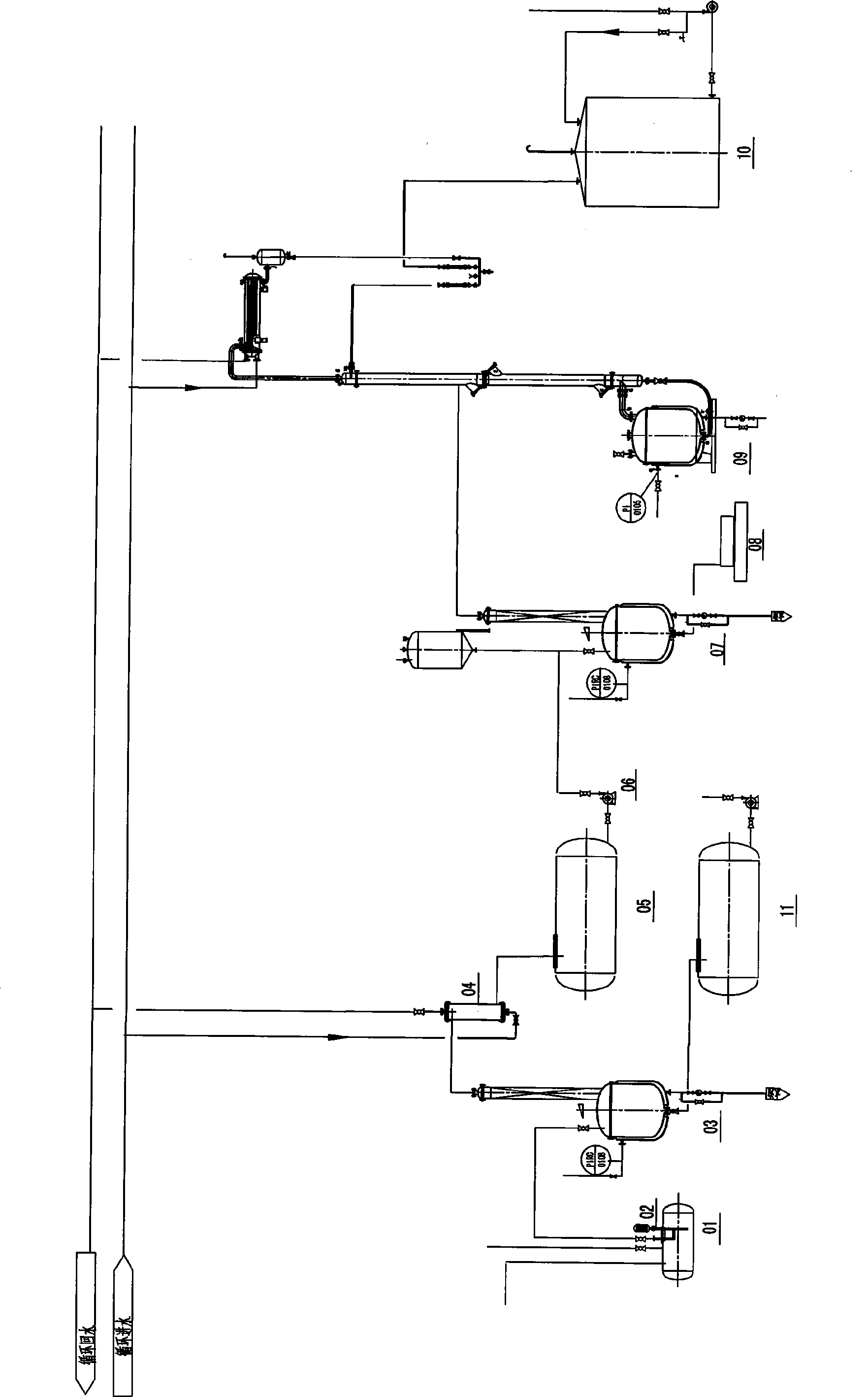

The invention relates to a production process for glucurono lactone, and comprises the working procedures of oxidization, hydrolization, concentration, esterification, crystallization, centrifugation, refinement, and product finishing. The invention is mainly and technically characterized in that the oxidation working procedure comprises the steps of completely adding amylum into nitric acid, insulating for above 5 hours at the temperature ranging from 37 to 43 DEG C, adding water, rising the temperature to 50-90 DEG C, and charging compressed air to react for 2 to 4 hours, so as to ensure the amylum to be fully oxidated; the concentration end point of hydrolysate is the baume degree being larger than or equal to 44 to 50, so that free water in solution is descended to the lower content to be favorable for lactonization in the next step; single esterification in the esterification working procedure is changed into multiple esterification, and the water generated in the esterification is carried over with water-carrying agent after the esterification, so that the repeated esterification is performed more thoroughly; the crystallization working procedure comprises the steps that alcohol is not required to be added for dilution, thereby ensuring a crystallization mother liquor system to be improved, and being favorable for the extraction of glucurono lactone crystallization, and also being favorable for distilling acetic acid out of parting mother liquor. The product total yield rate of the invention is enhanced to 14 to 15 percent (W / W), the consumption is reduced, the pollution is reduced, and the production cost is reduced.

Owner:王志浩

Solid effervescent mixture for the oral absorption

InactiveCN101919802AEasy to carryEasy to takeNervous disorderAntipyreticAlkaline earth metalCoffea eugenioides

The invention relates to an effervescent mixture, specifically relates to a solid effervescent mixture for the oral absorption and preparation method thereof. The invention comprises the alkalic component of a mixture consisting one or more than one of alkali metal carbonate, alkali metal bicarbonate, alkaline earth metal carbonate or pearl powder; the acid component of a mixture consisting one or more than one of tartaric acid, citric acid, adipic acid, fumaric acid, maleic acid, malic acid, folic acid andacid phosphate; The medical component of a mixture consisting of one or more than one of vitamin C, glucurolactone, natural caffeine, haw extract, green tea extract, hovenia acerba extract, semen myristicae extract, Poria cocos extract, Amomum tsao-ko extract, root of kudzu vine extract, spina date seed extract, cassia twig extract, Lesser Galangal Rhizome extract, and chrysanthemum extract; the wrapper and auxiliary material of a mixture consisting one or more than one of polyethylene glycol (PEG), panthenol and glycerin monostearate. The invention comprises, by weight, 5-50% of alkalic component; 5-50% of acid component; 1-40% of medical component; 0.5-35% of wrapper; 1-10% of auxiliary material. The invention has advantages of being fast in effect, and convenient in medicine taking and carrying.

Owner:无锡健而乐医药科技有限公司

D-glucuronolactone esterification process

InactiveCN101434623ALow priceHigh yieldSugar derivativesDigestive systemOperating instructionFood additive

The invention relates to the further improvement of an esterification technique of glucurolactone, which is characterized by changing acetic acid esterification adopted by the existing esterification technique of glucurolactone into the esterification technique of complex acids (phosphoric acid and sulphuric acid) and comprises the steps that: 4000ml of hydrolyzation solution for mass production is concentrated to 46 Baume degree to 47 Baume degree; the complex acids (phosphoric acid and sulphuric acid) are added into a concentrator while stirring according to a certain proportion so that the esterification temperature after the adding of the reagent of the complex acids is kept below 35 DEG C; after being evenly stirred, the mixture is placed still for esterification under the temperature of 10 DEG C to 35 DEG C; after the esterification is finished, 130ml of alcohol is added to directly enter crystallization operating instructions. The crystallization liquid is pumped and filtered to obtain crude products which are refined to obtain the finished products of glucurolactone; the quality of the finished products far exceeds the standard of current Chinese pharmacopoeia and reaches or even exceeds the standard for medicaments and food additives in developed European countries.

Owner:安徽富博医药化工股份有限公司

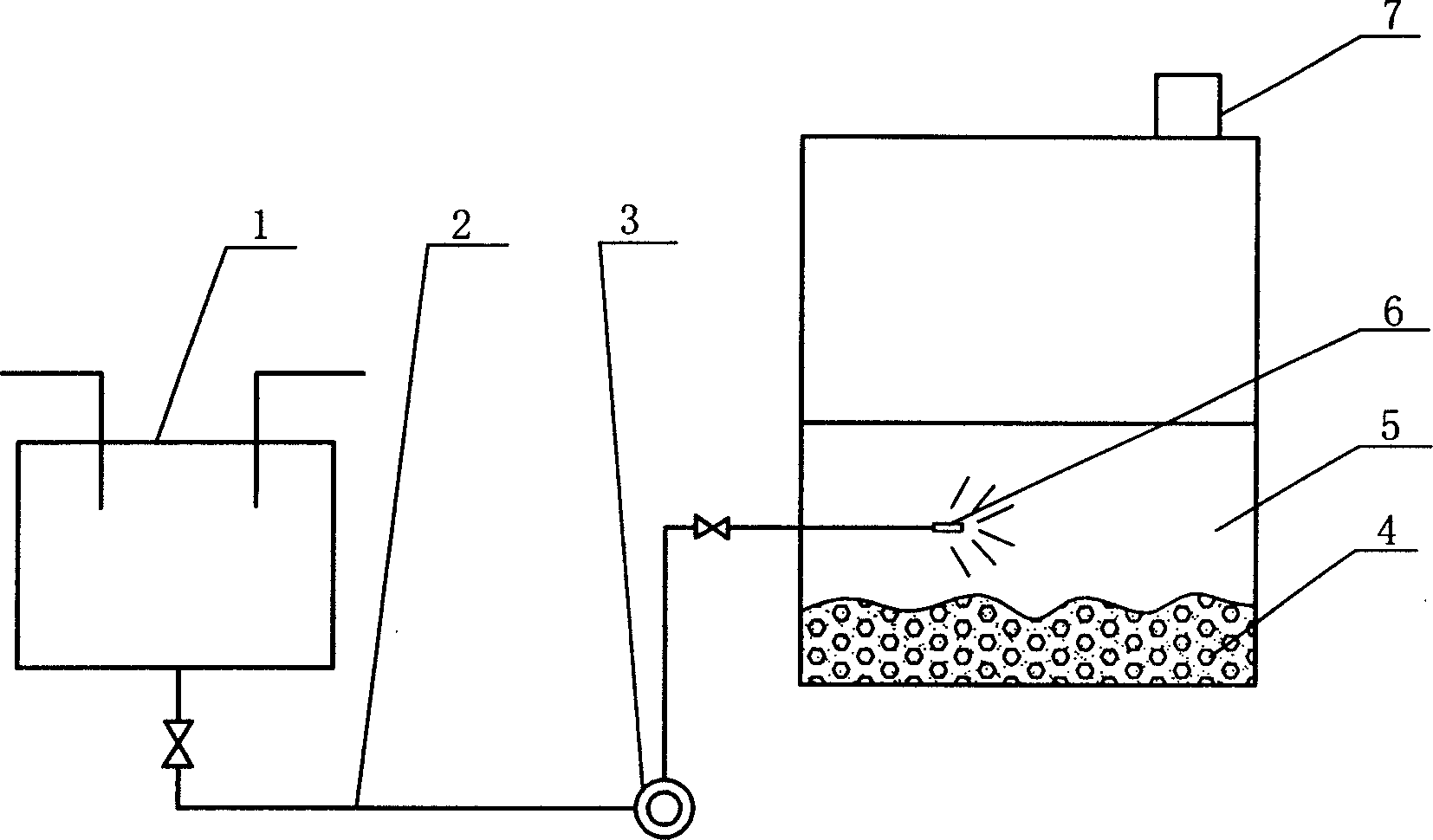

Comprehensive processing method and apparatus for mother solution in production of glucurolactone

ActiveCN101429111AReduce processing loadSugar derivativesSaccharide compounds with non-saccharide radicalsSodium acetateDistillation

The invention discloses a method for comprehensively treating and utilizing a mother solution in the production of glucurolactone and a device using the method. The mother solution is sent to a distillation kettle, is heated and is evaporated with a mixed solution of ester, ethanol and acetic acid till the Baume degree of the mother solution is between 40 and 50; the mixed solution is condensed through a condenser and enters a storage tank for standby; the mixed solution is sent to a neutralization and condensation kettle, is added with pure alkali or liquid alkali, is neutralized till the PH value is between 5 and 7 around, is heated and is evaporated with thin ethanol till the Baume degree is between 20 and 40; the mixed solution is cooled, crystallized and dehydrated to obtain sodium acetate; the thin ethanol enters a concentration tower, is concentrated and is supplied to the production of glucurolactone; and the residual mother solution in the distillation kettle is put to a thick mother solution tank and is directly used for producing oxalic acid. The treatment method simplifies a process, saves labor, has low cost, small energy consumption and convenient operation, can fully recycle organisms in the mother solution and can change waste to valuable.

Owner:安徽富博医药化工股份有限公司

Chinese and western compound medicine for preventing WSSV disease of penaeid shrimps

InactiveCN101757209ASignificant effectNo side effectsOrganic active ingredientsAntiviralsAnti virusDisease

The invention discloses Chinese and western compound medicine for preventing WSSV disease of penaeid shrimps, which relates to compound medicine which is applicable to curing diseases of aquatic animals and penaeid shrimps. The Chinese and western compound medicine of the invention is prepared with the following components by weight parts: 20 to 40 parts of rhizoma coptidis, 50 to 70 parts of scutellaria, 50 to 70 parts of phellodendron, 35 to 55 parts of gardenia, 2 to 8 parts of astragalus polyose, 10 to 30 parts of glucurolactone and 5 to 15 parts of vitamin C. The product of the invention plays the dual roles of anti-bacteria, anti-virus and organism conditioning, effectively solves the WSSV of the penaeid shrimps caused by a plurality of reasons, and is characterized by significant curative effect in preventing the WSSV disease of penaeid shrimps and no any toxic and side effect.

Owner:TIANJIN SHENGJI GRP CO LTD

Saline-alkali land improving agent and method by using same to improve land for rice planting

ActiveCN107840761AImprove soda-type saline-alkali landSuitable pH valueSewage/sludge fertilisersAgriculture gas emission reductionAlkali soilSugar refinery

The invention discloses a soda type saline-alkali land improving agent for rice planting, and a method by using the same to improve land and plant rice after land improving. The saline-alkali soil improving agent is prepared from the following raw materials in parts by weight: filtered mud of a sugar refinery, sulfamic acid, ferrous sulfate, aluminum sulfate, zinc sulfate and glucurolactone. The saline-alkali soil improving agent has the advantages that the soda type saline-alkali land for the rice planting is improved by the multiple components at multiple aspects, the proper pH (potential ofhydrogen) value and degree of alkalization are provided for the rice growth, the rice can be planted after the saline-alkali land is improved, and the output of the rice per mu can reach the medium and high output after the improving agent is used for two to three years; by containing the filtered mud of the sugar refinery, the sodium ions in soil sol are replaced by calcium ions in the filteredmud of the sugar refinery, so that the purpose of decreasing the degree of alkalization is realized, and the filtered mud of the sugar refinery contains about 45 to 55% of calcium carbonate and 20% oforganic matter.

Owner:内蒙古漫瀚农业科技有限公司

Preparation method of medicine for preventing and controlling liver and gall syndromes of aquatic animals

InactiveCN101961373AImprove broken rateHigh dissolution rateOrganic active ingredientsDigestive systemAquatic animalGLYCYRRHIZA EXTRACT

The invention relates to a preparation method of a medicine for preventing and controlling liver and gall syndromes of aquatic animals. The preparation method comprises the following steps of: 1. weighing the following raw material medicines in parts by weight: 200-400 parts of astragalus, 300-400 parts of liquorice and 100-200 parts of silybum marianum; 2. placing all the raw material medicines weighed in the step 1 in a fully-closed powder device, and mechanically extruding and knocking to crush all the weighed raw material medicines into micropowder at 50 DEG C below zero to 30 DEG C by adopting a cell wall breaking micropowder production process; and 3. weighing 10-30 parts of glucurolactone and 100-200 parts of starch in parts by weight; and mixing the weighed glucurolactone and starch with the astragalus, liquorice and silybum marianum micropowder crushed in the step 2, and finally stirring evenly to obtain the finished product. The invention has the advantages of reasonable formula, simple preparation and remarkable effect; by adopting the cell wall breaking micropowder production process, the dissolution rate of the raw material medicines is increased, and the biological availability of effective components is improved; moreover, traditional Chinese medicines and western medicines work together to achieve good prevention and control effects on liver and gall syndromes of aquatic animals without medicine residue.

Owner:TIANJIN SHENGJI GRP CO LTD

Chinese and western compound medicament composition for preventing and controlling aquatic livestock hepatobiliary syndrome

InactiveCN101297873AImprove broken rateHigh dissolution rateOrganic active ingredientsDigestive systemAquaculture industryAquatic animal

The invention relates to the field of aquaculture industry, in particular to a compound Chinese-western pharmaceutical composition for prevention and treatment for liver and gall bladder syndrome of aquatic animals. The compound Chinese-western pharmaceutical composition is characterized in that: the composition according to parts by weight is as follows: 200 to 400 parts of Chinese thorowax root, 300 to 400 parts of indigowoad leaf, 100 to 200 parts of rhubarb, 20 to 70 parts of motherwort herb, 10 to 30 parts of glucurolactone and 100 to 200 parts of starch. The compound Chinese-western pharmaceutical composition has great effects on prevention and treatment for the liver and gall bladder syndrome of the aquatic animals and no medicine residue.

Owner:TIANJIN SHENGJI GRP CO LTD

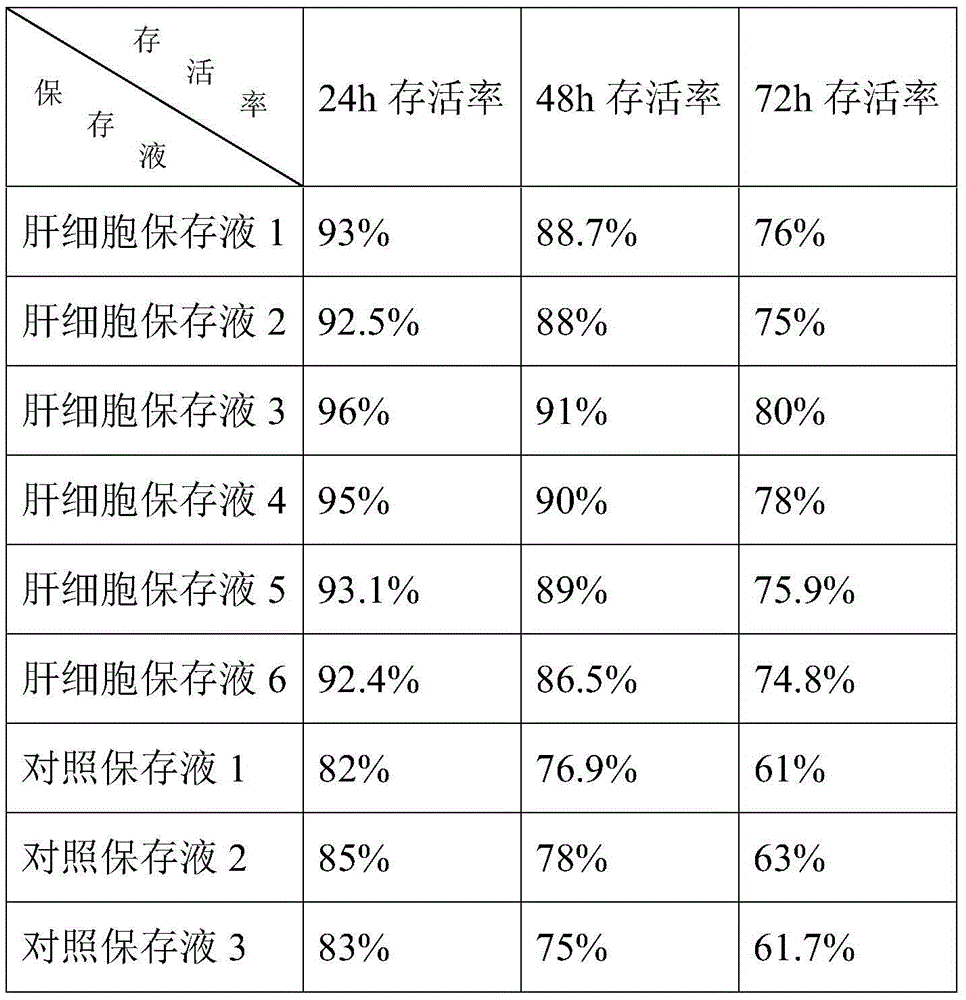

Liver cell preserving fluid and preparation method and application

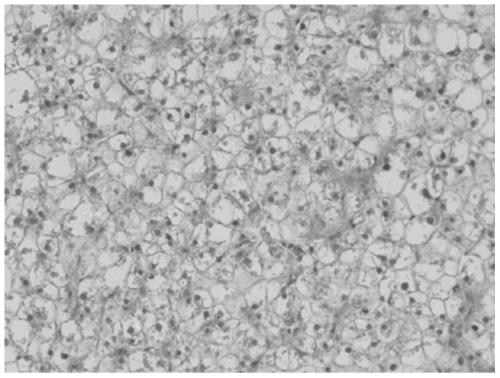

ActiveCN105532646AComposition is stableIncrease osmotic pressureDead animal preservationHydroxyethyl starchVitamin C

The invention discloses a liver cell preserving fluid and a preparation method and application thereof. The liver cell preserving fluid which is stable in ingredient, diverse in nutrient substance and strong in solution permeating system buffering power is formed by mixing hydroxyethyl starch 130 / 0.4 sodium chloride injection, glucose, sodium glutamate, vitamin C, phenol red, glucurolactone, polyene phosphatidyl choline, a cell buffering solution and an amino acid mixed solution. The liver cell preserving fluid can not only provide nutrition for liver cells, can also well maintain cell activity and accordingly plays a better effect in subsequent clinical use.

Owner:WUHAN TOGO MEDITECH CO LTD

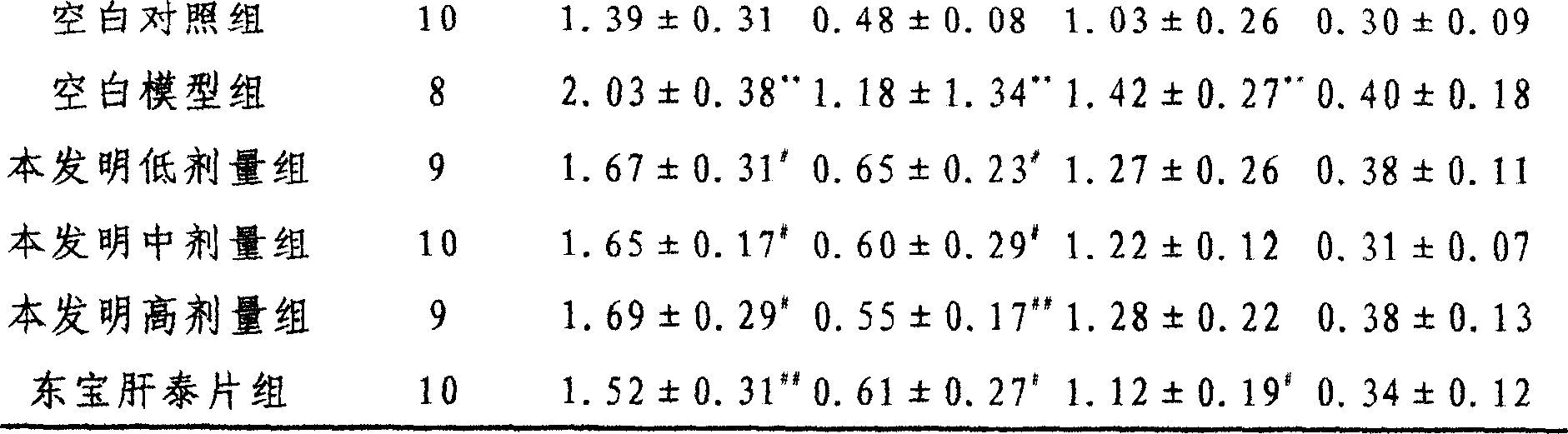

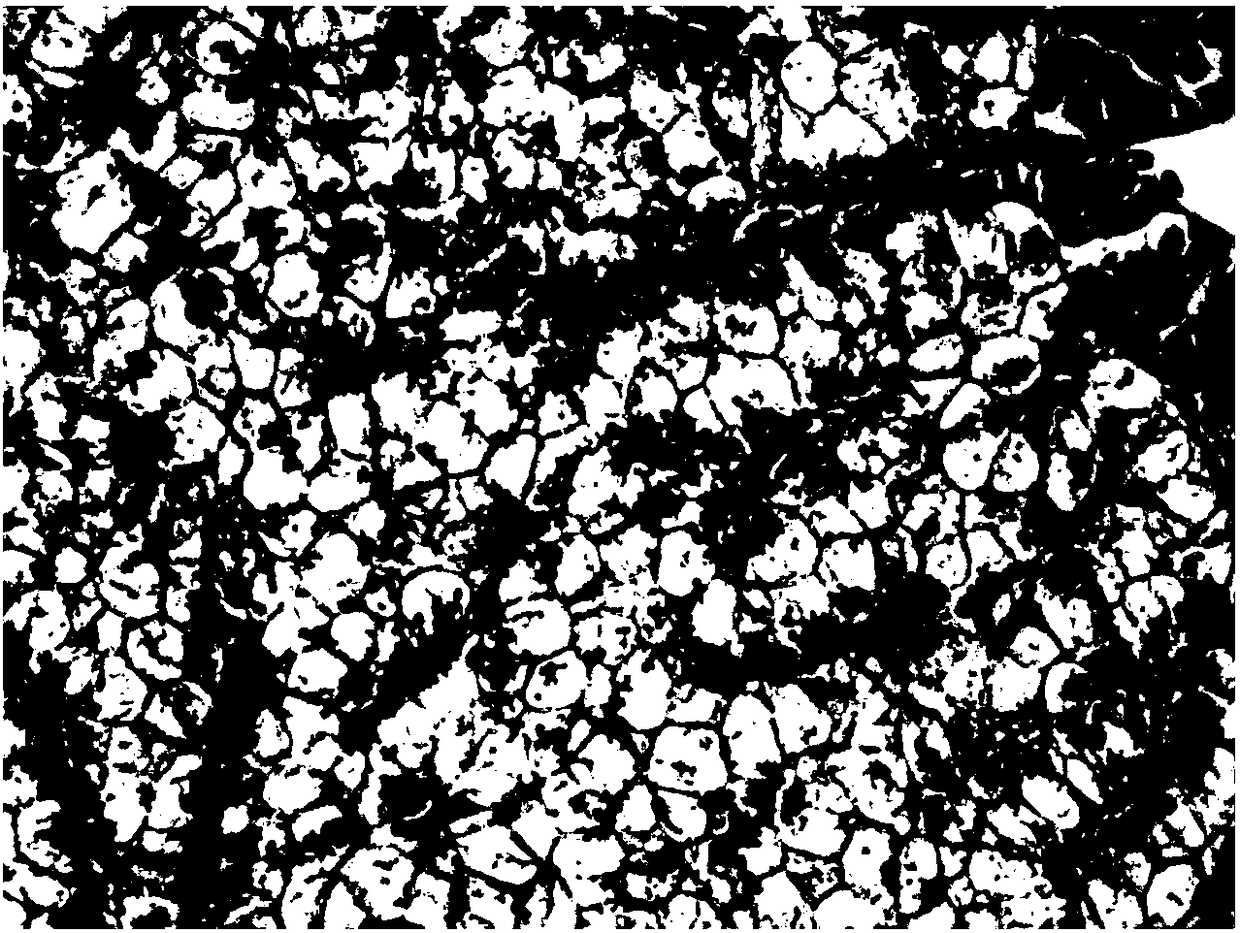

Application of anti-fatty liver Chinese traditional medicine and fistular onion stalk extractive on curing fatty liver

InactiveCN101204501AGood control effectMaterial excellenceDigestive systemSolution deliveryFatty liverSide effect

The invention discloses a traditional Chinese medicine used for prevention and treatment of fatty liver as well as an application of fistular onion stalk extractive for prevention and treatment of fatty liver. The invention is application and medicine preparation of fistular onion stalk extractive used for prevention and treatment of fatty liver.The fistular onion stalk extractive is a mixture of the fat-soluble effective extractive and the neutral effective extractive of the fistular onion stalk. The traditional Chinese medicine used for prevention and treatment of fatty liver is the fistular onion stalk extractive.The invention is superior to Dongbao glucurolactone, a traditional Chinese medicine preparation on the market. The invention has the advantages of clear mechanism of action, controllable quality, low cost, little toxic and side effects and good compliance.The invention has better prevention and treatment of fatty liver.

Owner:张介眉

Poultry feed additive and preparation method and application thereof

InactiveCN101703157AChange permeabilityLower resistanceAnimal feeding stuffAccessory food factorsVitamin CMycotoxin

The invention discloses a poultry feed additive and a preparation method and application thereof, and aims to provide the poultry feed additive used for detoxicating mycotoxin and preventing and controlling fungal infection, and the preparation method and application thereof. The feed additive comprises the following components in percentage by weight: 1 to 4 percent of clotrimazole or 1 to 3 percent of nystatin, 5 to 20 percent of malto-oligosaccharides, 5 to 12 percent of glucurolactone, 10 to 20 percent of glucomannan polymer, 20 to 40 percent of sepiolite, 0.2 to 1 percent of vitamin C and the balance of conventional feed additive auxiliary material. Different adsorbents are mixed in a proper ratio so as to contribute to improving detoxication effect. Various active components are reasonably compatible, so the feed additive has synergism, and has the effects in various aspects such as treating the fungal infection, avoiding mould damaging livestock organisms, detoxicating organisms and adsorbing the mycotoxin, and has quick response, good treatment effect and safe use when used for detoxicating the mycotoxin and preventing and controlling the fungal infection.

Owner:TIANJIN SHENGJI GRP CO LTD

Traditional Chinese pharmaceutical composition for preventing and treating prawn encephalitozoon intestinalis, powder and preparation method thereof

ActiveCN106994172AImprove autoimmunityPrevention and treatment of intestinal microsporidiosisOrganic active ingredientsPowder deliveryRadix Astragali seu HedysariAstaxanthin

The invention relates to a traditional Chinese pharmaceutical composition for preventing and treating prawn encephalitozoon intestinalis, powder and a preparation method thereof and belongs to the technical field of traditional Chinese medicine. The traditional Chinese pharmaceutical composition is prepared from the following raw materials in parts by weight: 3 to 5 parts of lightyellow sophora root, 2 to 5 parts of radix astragali seu hedysari, 5 to 8 parts of dark malt, 10 to 15 parts of stone-like omphalia, 5 to 8 parts of radix paeoniae alba, 10 to 14 parts of cyrtomium rhizome, 2 to 5 parts of drug sweet flag rhizome, 2 to 6 parts of radix stemonae, 4 to 7 parts of fructus ulmi, 3 to 7 parts of pericarpium citri reticulatae, 10 to 12 parts of radix puerariae, 3 to 6 parts of radix codonopsis and 6 to 8 parts of radix panacis quinquefolii. The powder disclosed by the invention is prepared from the following raw materials of 90% to 95% of the traditional Chinese pharmaceutical composition, 2% to 6% of glucurolactone and 1% to 4% of astaxanthin. The preparation method disclosed by the invention utilizes nanometer low-temperature wall breaking combined with lactobacillus lactis fermentation to improve the release rate of traditional Chinese medicine and keep medicine activity, and finally, the utilization rate is improved by 5 times; meanwhile, compound enzyme is added to perform enzymolysis, so that adhesion of the encephalitozoon intestinalis is effectively reduced, and preventing and treating effects are improved.

Owner:海一(厦门)水产科技有限公司

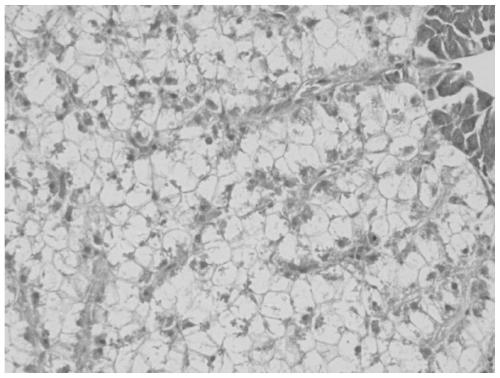

Application of coptisine or coptisine salts in preparation of medicines for preventing and treating fatty liver damage

ActiveCN103622959AAvoid accumulationLower triglyceride levelsOrganic active ingredientsMetabolism disorderTG - TriglycerideLipid lowering

The invention discloses an application of coptisine or coptisine salts in the preparation of medicines for preventing and treating fatty liver damage. The pharmacological research proves that the coptisine has the effects of lowering lipid, improving lipid metabolism and alleviating the hepatic lesion caused by hepatic tissue fat accumulation and is capable of inhibiting hepatocyte triglyceride accumulation; for experimental hyperlipemia symptoms, the coptisine has the effects of obviously reducing triglyceride, cholesterol and LDL-C (low-density lipoprotein cholesterol) in blood and reducing the content of triglyceride in hepatic tissues; for fatty liver caused by the overuse of cortisol, the coptisine is capable of reducing the accumulation of triglyceride in the liver, the rise of activity of glutamic-pyruvic transaminase (GPT) and glutamic oxalacetic transaminase (GOT) and alleviating the hepatic lesion and has an excellent fatty liver prevention effect; part indexes of the coptisine are obviously superior to those of lipid reducing medicines, namely simvastatin and fenofibrate and liver protecting medicines, namely tiopronin and glucurolactone; the coptisine can be applied to clinical fatty liver diseases.

Owner:QINGDAO BAILI CAIXIN MEDICAL TECH CO LTD

Compound florfenicol preparation for aquatic animals and preparation method of compound florfenicol preparation for aquatic animals

ActiveCN108261417AImprove permeabilitySmall toxicityAntibacterial agentsOrganic active ingredientsTreatment effectAquatic animal

The invention relates to the technical field of medicines and particularly discloses a compound florfenicol preparation for aquatic animals and a preparation method of the compound florfenicol preparation for the aquatic animals. The compound florfenicol preparation for the aquatic animals is prepared from, by mass, 10-20% of florfenicol, 5-15% of acetylisovaleryltylosin tartrate, 10-20% of glucurolactone, 12-20% of 2-deoxyglucose and the balance auxiliary materials. The preparation method includes manufacturing steps: drying the auxiliary materials until moisture content is 8% or below, respectively subjecting auxiliary and raw materials to grinding and screening through a 80-mesh screen, and well mixing the screened powdery auxiliary and raw materials in a mixer. The compound florfenicolpreparation for aquatic animals is easy to produce, effective in treatment of bacterial diseases of the aquatic animals, low in drug resistance and effective in protection and repair livers of the aquatic animals. By formula and process optimization, problems of poor treatment effects, high animal liver burden and the like of antibacterial medicines are solved. The compound florfenicol preparation is suitable for aquatic animals and used for treatment of various bacterial diseases.

Owner:长沙施比龙动物药业有限公司

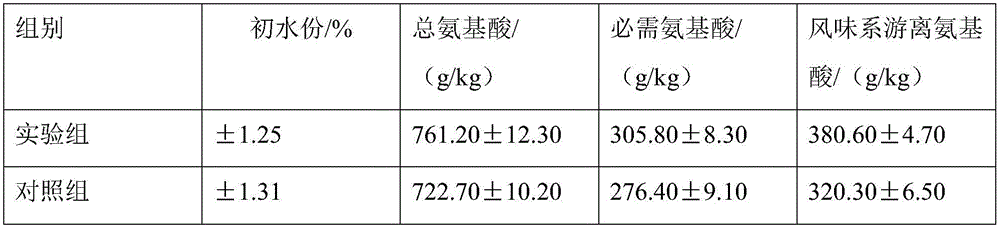

Additive and application thereof

ActiveCN113367249AImprove stabilityIncrease production capacityFood processingAccessory food factorsBiotechnologyAnimal science

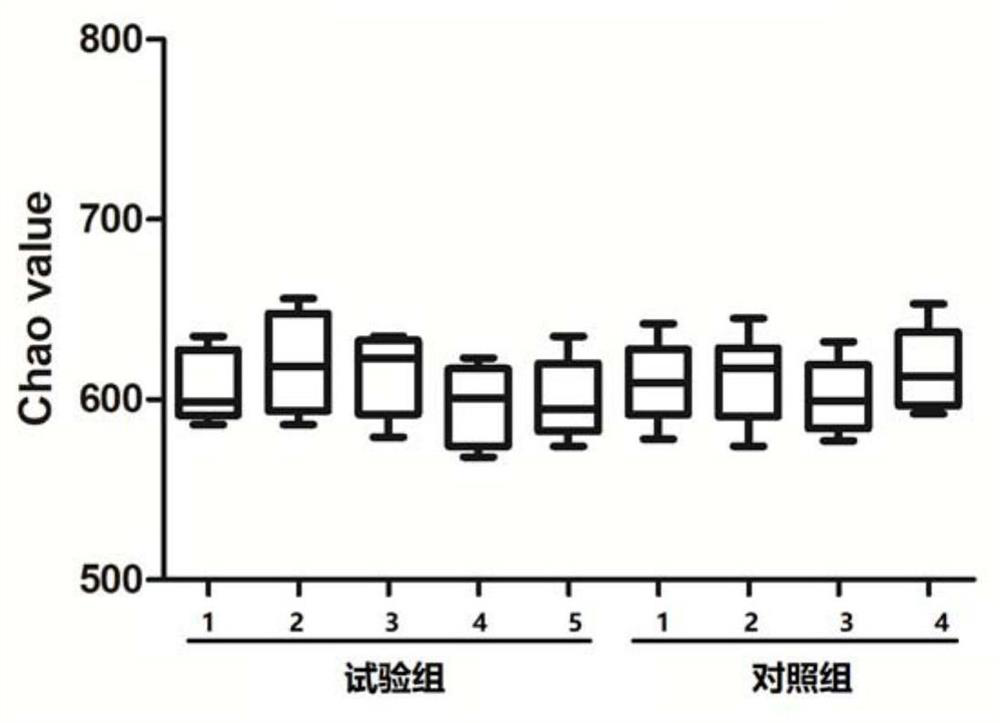

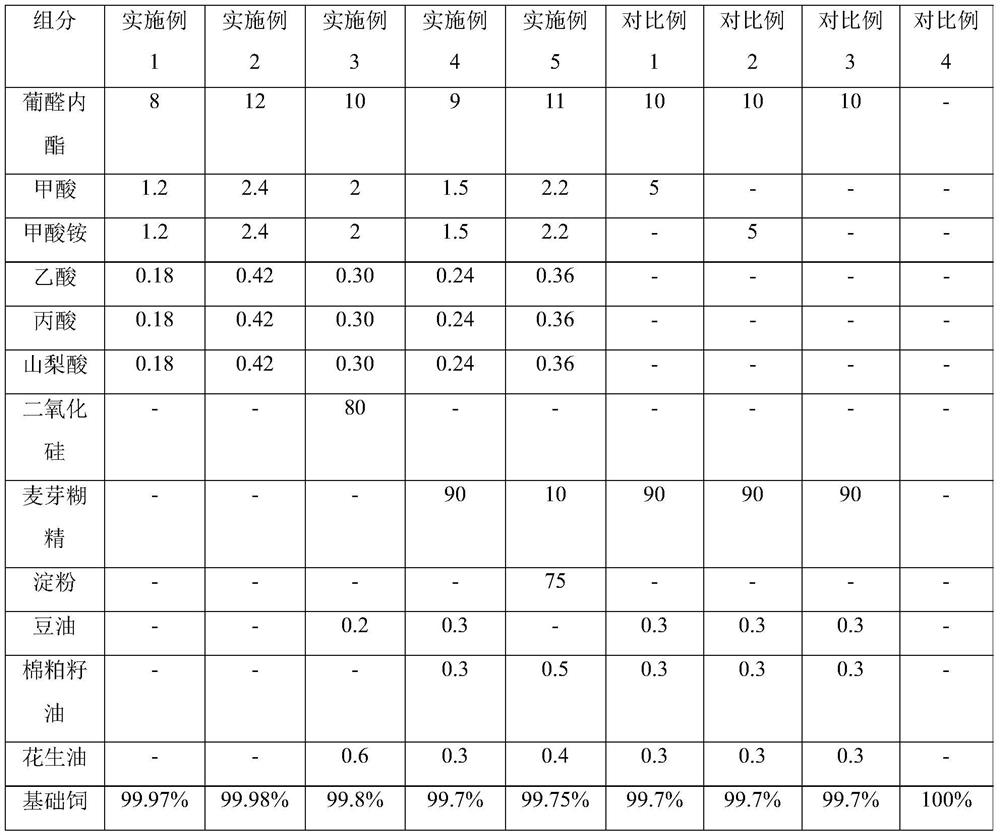

The invention discloses an additive and application thereof. The additive is prepared from the following components in parts by mass: 8 to 12 parts of glucurolactone and 3 to 6 parts of an acidifying agent, and the acidifying agent is prepared from the following components in parts by mass: 1.2 to 2.4 parts of formic acid, 1.2 to 2.4 parts of ammonium formate, 0.18 to 0.42 part of acetic acid, 0.18 to 0.42 part of propionic acid and 0.18 to 0.42 part of sorbic acid. The exogenous glucurolactone is used as an additive and is matched with the acidifying agent, the glucurolactone is mainly used for relieving the fatty liver, and the acidifying agent is used, so that the stability of the glucurolactone can be improved, and the content of active ingredients which play a role of the glucurolactone can be increased; and the acidifying agent can effectively reduce harmful bacteria in the feed, kill the harmful bacteria in intestinal tracts, reduce toxicity of the harmful bacteria and increase the content of beneficial bacteria in the intestinal tracts when being added to the feed for the laying hens, and by combined action of the glucurolactone and the acidifying agent, the fatty liver syndrome of the laying hens is effectively prevented and treated, and the production performance of the laying hens in the later egg laying period is improved, so that the breeding cycle of the laying hens is prolonged.

Owner:JIANGSU INST OF POULTRY SCI

Method for treating glucurolactone mother liquor

InactiveCN1752520ALow costReduce energy consumptionIncinerator apparatusLiquid wasteCombustion chamber

The present invention relates to a method for processing glucurolactone mother liquor. Said method includes the following steps: firstly, comcentrating the concentration of glucurolactone mother liquor to 20-40 Baume deg., then adopting high-pressure spray-combustion method to make the glucurolactone mother liquor undergo the presses of atomized combustion treatment. Said atomized combustion is implemented in the thermotechnical equipment.

Owner:BEIJING JINGFENG PHARM (SHANDONG) CO LTD

Compound preparation for treating cholestatic jaundice and preparing method thereof

InactiveCN105998052AAnti-inflammatoryCompatibility is reasonableDigestive systemEther/acetal active ingredientsTherapeutic effectBile fluid

The invention discloses a compound preparation for treating cholestatic jaundice and a preparing method thereof. The compound preparation is prepared from ademetionine 1,4-butanedisulfonate, diammonium glycyrrhizinate, dihydroxydibutylether, baicalin, methionine, anethol trithione, potassium magnesium aspartate, crocetin dimethyl ester, glucurolactone, cholestyramlne, hydroxymethylnicotinamide, trimethoprim lactate, bumetanide, piperazine citrate and azathioprine. The compound preparation has the effects of resisting bacteria and diminishing inflammations, clearing dampness and heat, soothing the liver and benefiting the gallbladder, removing the toxicity and eliminating jaundice and strengthening the spleen and the stomach, can reduce stasis of bile in liver cells, promote bile excretion, improve the liver functions and the tissue cell respiration function, reduce accumulation of fat in the liver and promote jaundice elimination and liver function recovery and is significant in treatment effect, safe and few in side effect when the compound preparation is used for treating the cholestatic jaundice and complications thereof.

Owner:徐海燕

A kind of compound florfenicol preparation for aquatic animals and preparation method thereof

ActiveCN108261417BRaw materials are easy to getEasy to makeAntibacterial agentsOrganic active ingredientsAnimal scienceAquatic animal

The invention relates to the technical field of medicines and particularly discloses a compound florfenicol preparation for aquatic animals and a preparation method of the compound florfenicol preparation for the aquatic animals. The compound florfenicol preparation for the aquatic animals is prepared from, by mass, 10-20% of florfenicol, 5-15% of acetylisovaleryltylosin tartrate, 10-20% of glucurolactone, 12-20% of 2-deoxyglucose and the balance auxiliary materials. The preparation method includes manufacturing steps: drying the auxiliary materials until moisture content is 8% or below, respectively subjecting auxiliary and raw materials to grinding and screening through a 80-mesh screen, and well mixing the screened powdery auxiliary and raw materials in a mixer. The compound florfenicolpreparation for aquatic animals is easy to produce, effective in treatment of bacterial diseases of the aquatic animals, low in drug resistance and effective in protection and repair livers of the aquatic animals. By formula and process optimization, problems of poor treatment effects, high animal liver burden and the like of antibacterial medicines are solved. The compound florfenicol preparation is suitable for aquatic animals and used for treatment of various bacterial diseases.

Owner:长沙施比龙动物药业有限公司

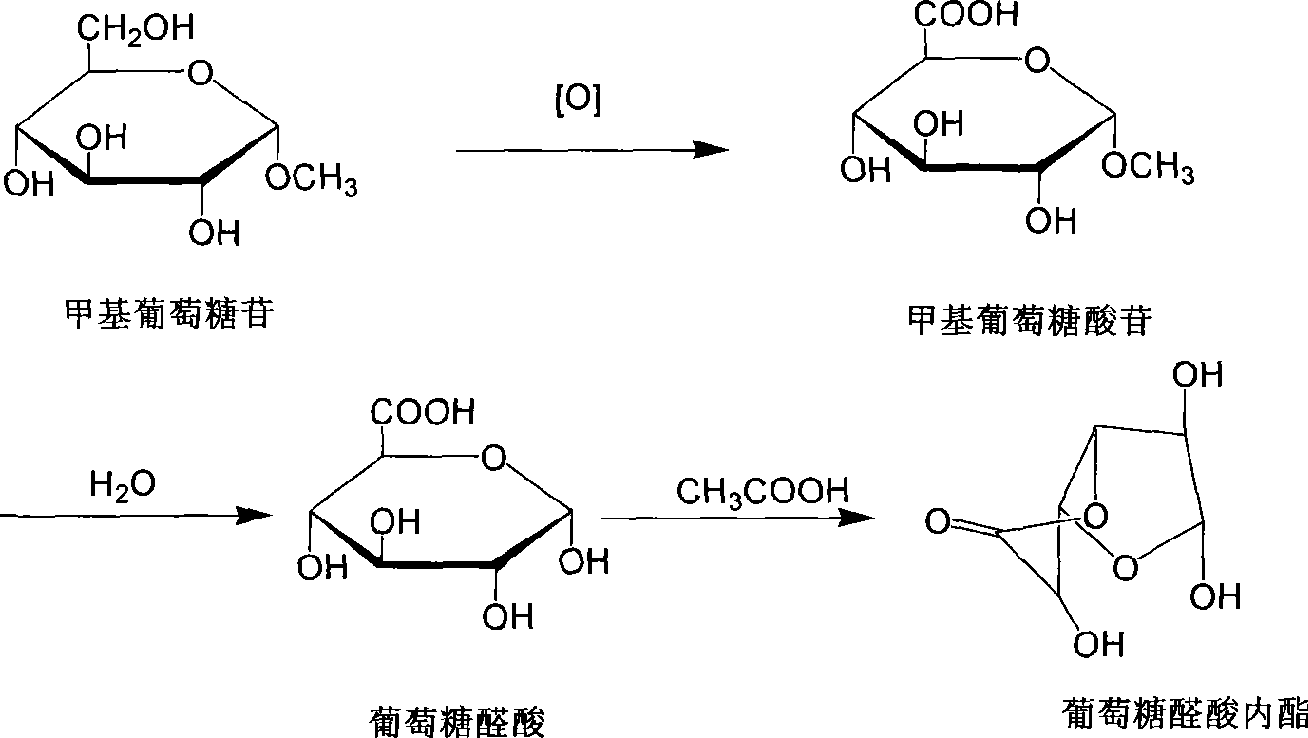

Method for synthesizing glucurolactone

ActiveCN101503434AEasy to separate and purifyAvoid nitric acidSugar derivativesDigestive systemAcetic acidAcetic anhydride

The invention discloses a synthetic method for glucurolactone, which comprises the following steps: (1) in the alkalescence condition, methyl glycoside, metal halide, and nitroxyl free radical compound are added, stirred and dissolved; oxidant solution is added and reacts for 0.5-8 hours to obtain an oxidizing solution; (2) the obtained oxidizing solution is hydrolyzed for 2-10 hours in the temperature of 50-100 DEG C in the alkalescence condition in the temperature of 50 to 100 DEG C; (3) glacial acetic acid or acetic anhydride are added into hydrolysate and react for 6-16 hours in the temperature of 40-60 DEG C; (4) the reaction solution obtained in the step (3) is concentrated into 35-45 Be, then is cooled to be minus 5 to 5 DEG C, filtered and dried. The synthetic method has good selectivity, few byproducts, easy monitoring reaction process, simplified operation, low cost, and high yield coefficient. The obtained product has good quality; and the production process has little pollution and is environmental friendly.

Owner:JIANGSU TASLY DIYI PHARMA CO LTD

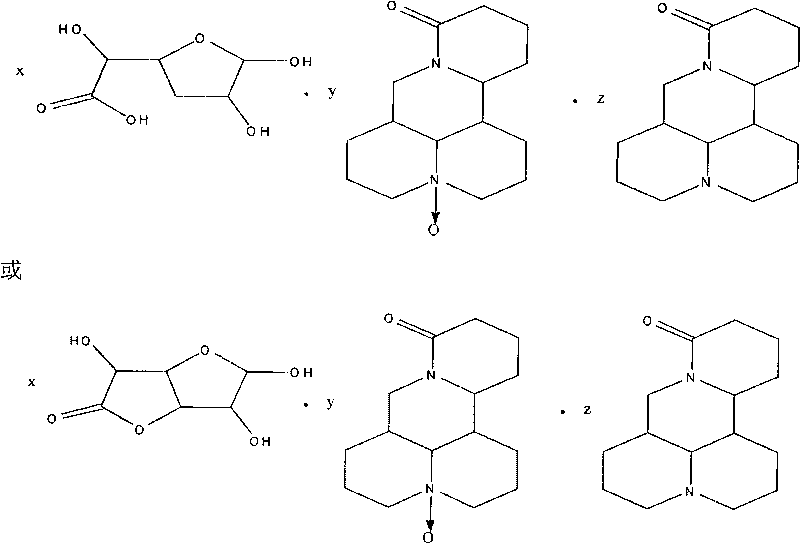

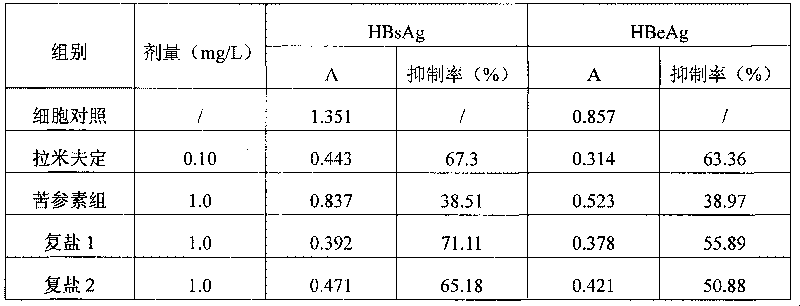

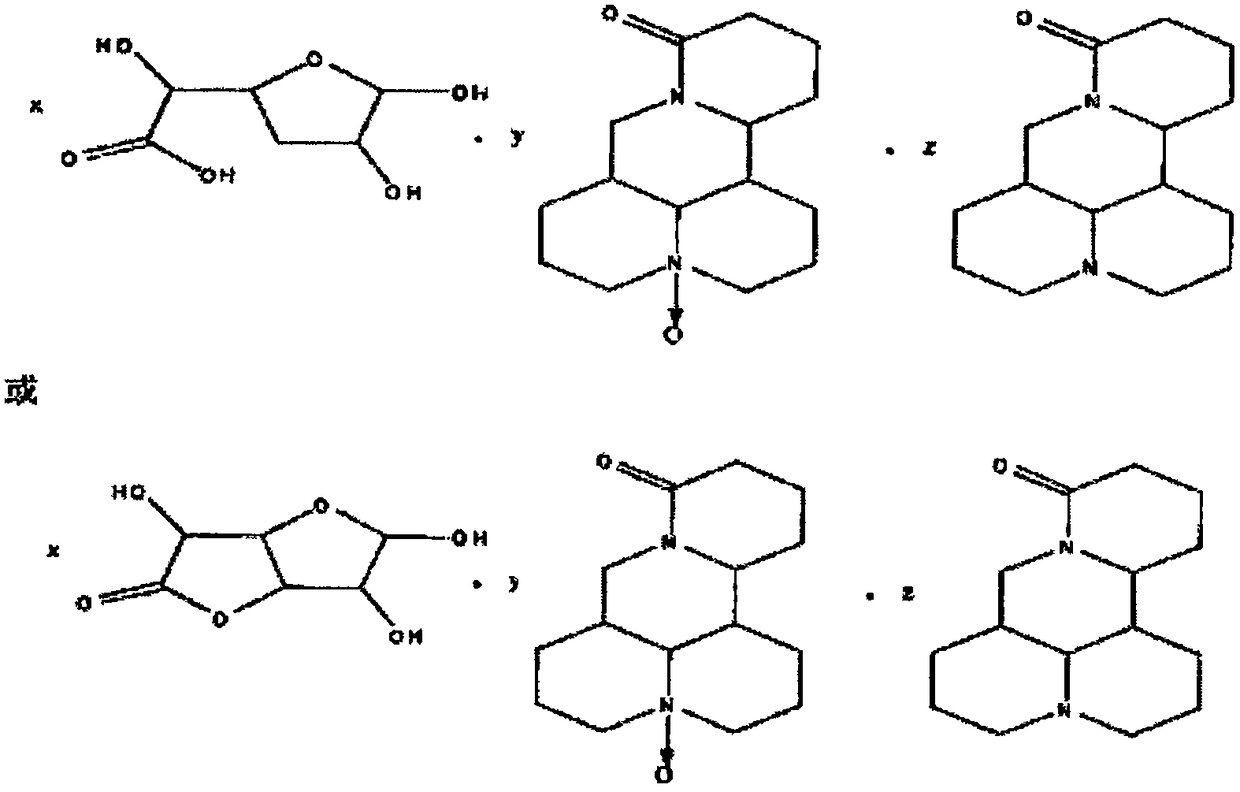

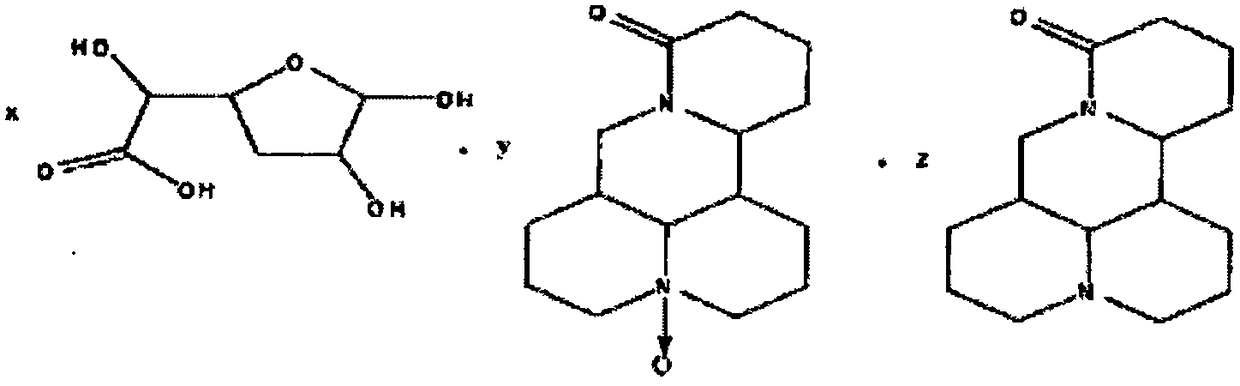

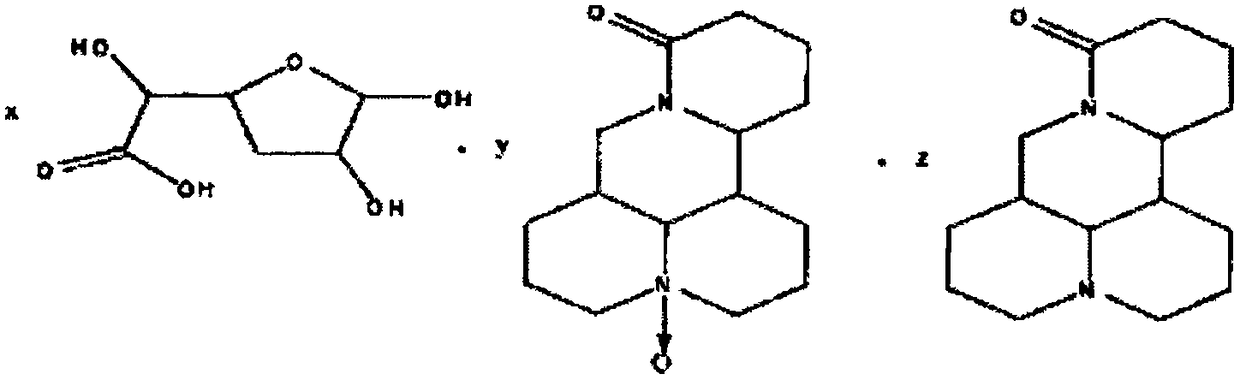

Complex salt consisting of glucuronic acid or glucurolactone and kushenin or matrine and application thereof

The invention relates to the medicament field, in particular to a complex salt consisting of glucuronic acid or glucurolactone and kushenin and / or matrine, a method for preparing the complex salt, application of the complex salt in treating liver diseases, in particular the diseases such as hepatitis, hepatic injury, liver cancer and the like, and a complex salt medicament capable of being used as an oral administration dosage form as well as a non-oral administration dosage form. Pharmacodynamic laboratory science for comparing the complex salt with the glucurolactone, sodium glucuronate, the kushenin and the matrine shows that the functions of the complex salt are better than that of using the glucurolactone, the sodium glucuronate, the kushenin and the matrine independently. The enhancement action is proved on a plurality of animal models.

Owner:刘兆平

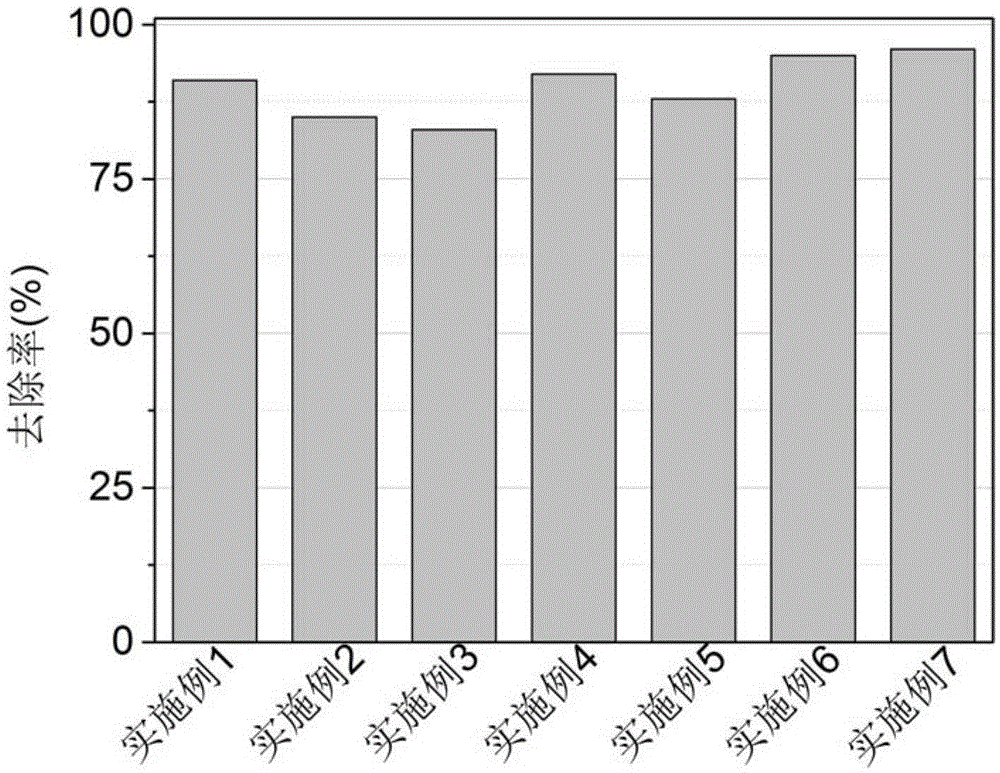

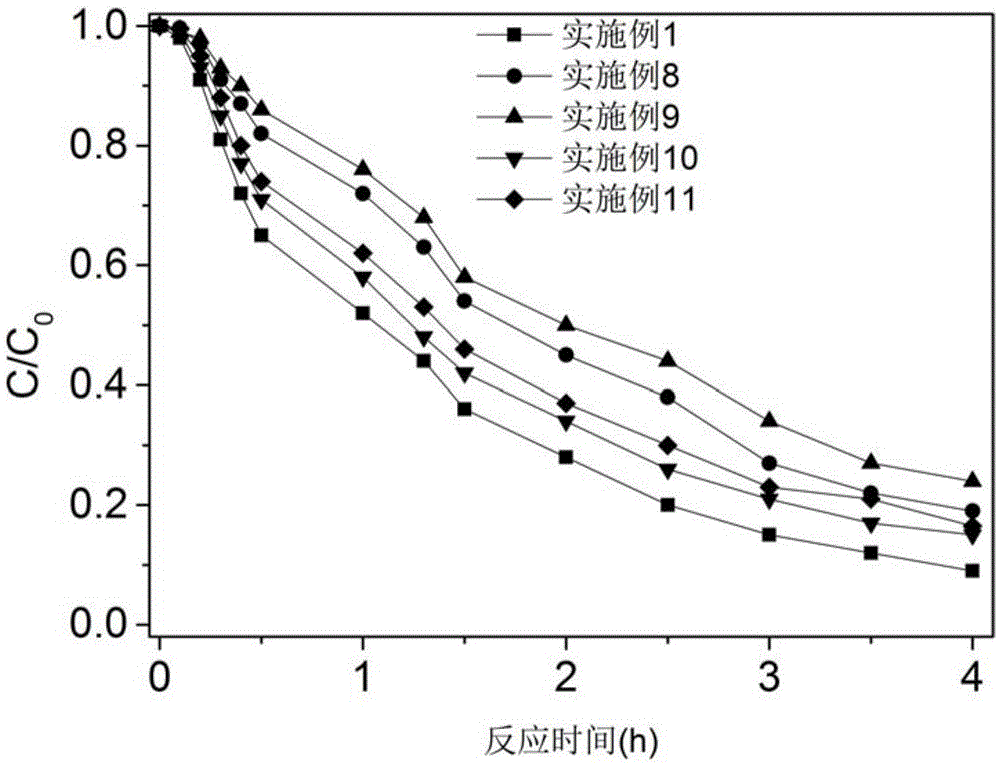

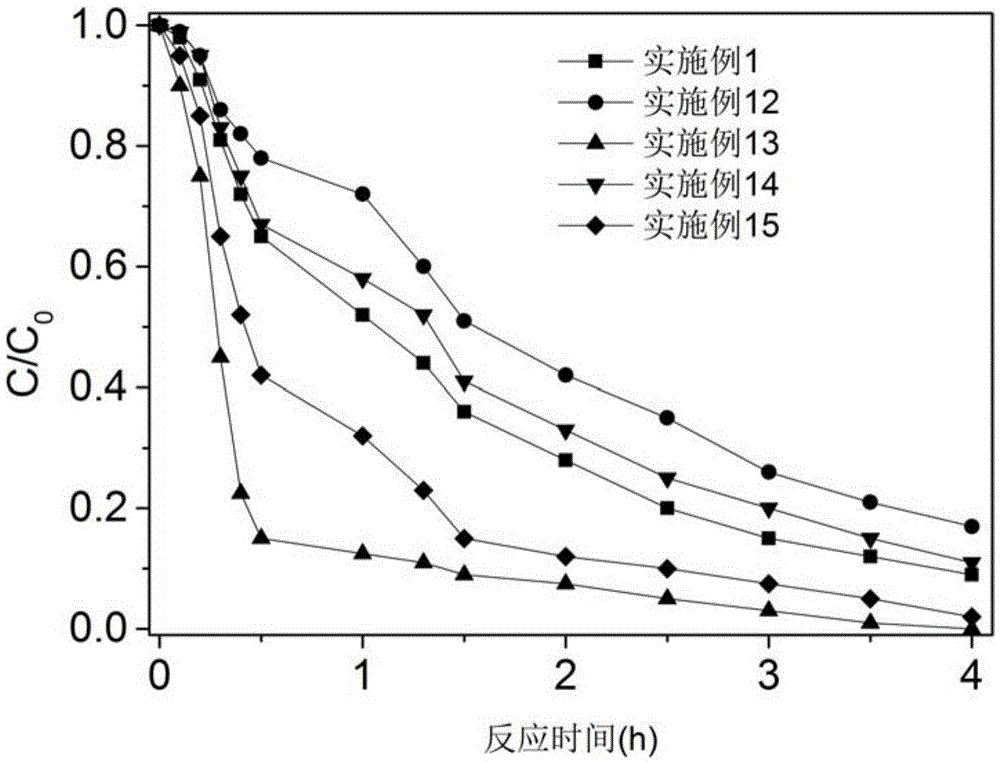

Method for degrading chloro-nitroaromatic by using sulfate radicals

InactiveCN105621587ASimple methodLow reaction temperature requirementWater contaminantsWater/sewage treatment by oxidationPerillaldehydeSulfate radicals

The invention relates to a method for degrading chloro-nitroaromatic by using sulfate radicals. Single persulfate and / or persulfate and an accelerator are added into water containing chloro-nitroaromatic for degrading; the accelerator is chosen from a group consisting of one or more of citronellal, citral, perillaldehyde, hemigossypol, acanthospermal, isodonal, gypsogenin, vanillin, cinnamyl aldehyde, magnal-dehyde, americanin A, paridifomoside, vincristine, glucurolactone, houttuynin, and helicid or phytone. The method is simple to perform, needs no additional treatment equipment, is widely applicable and has low requirement on reaction temperature; a green pollution-free natural plant extract is used as an accelerator, reducing environmental pollution.

Owner:ZHEJIANG UNIV

Process method for producing glucurolactone

InactiveCN102875609AGood lookingHigh yieldEsterified saccharide compoundsSugar derivativesImproved methodHydrolysis

The invention discloses a process method for producing glucurolactone, and relates to a method for producing the glucurolactone by an improved method of oxidizing starch through nitric acid. The method comprises 1) oxidation, 2) hydrolysis, 3) concentration, 4) esterification and 5) refining. The process method for producing the glucurolactone has the advantages of high yield, good appearance of finished product and low energy consumption.

Owner:TIANJIN PACIFIC PHARMA

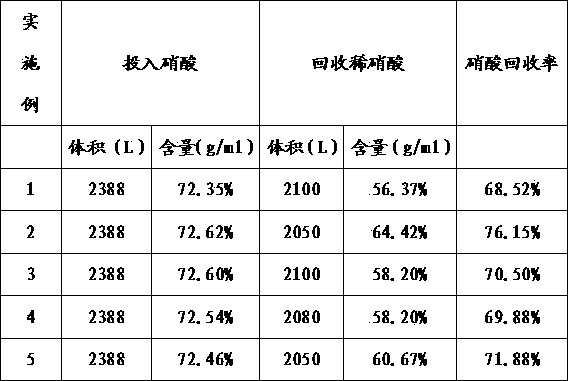

Method for improving recovery rate of nitric acid in glucurolactone production

InactiveCN103877838APromote absorption and transformationReduce manufacturing costDispersed particle separationNitric acidPhysical chemistryNitric oxide gas

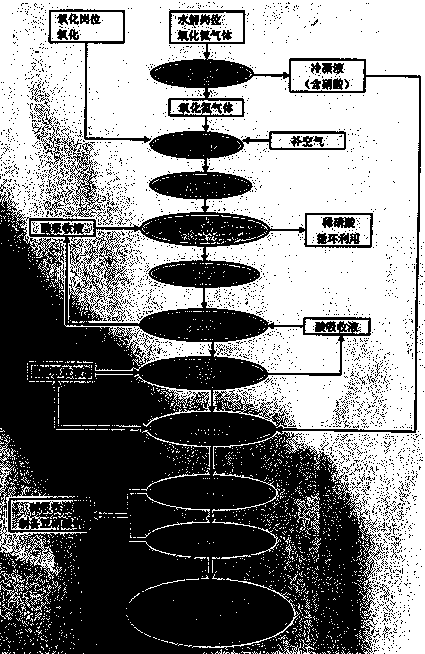

The invention relates to a method for improving the recovery rate of nitric acid in glucurolactone production. The method comprises the following steps: firstly, scrubbing nitric oxide gas generated by hydrolysis reaction during production of glucurolactone by a circulating scrubber tower, and condensing high-temperature water vapor in nitric oxide gas generated by hydrolysis reaction in circulating scrubbing water; secondly, mixing nitric oxide gas generated by hydrolysis reaction after circulating scrubbing with nitric oxide gas generated by oxidation reaction and then introducing air in the mixture; thirdly, inputting NO2 into 1-10-level cooling absorption towers, and controlling the spraying temperature of the circulating dilute nitric acid in the tower to be at 5-20 DEG C, wherein the NO2 and the dilute nitric acid are subjected to contact absorption to improve the concentration of the dilute nitric acid, when the concentration of the dilute nitric acid reaches 55-70%, mixing the dilute nitric acid with concentrated nitric acid to prepare the nitric acid with concentration of 72-73% for glucurolactone production; and fourthly, supplementing nitric-acid-containing steam condensate produced during circulating scrubbing of the nitric oxide gas generated by hydrolysis reaction into an acid absorption tower as a basic solution for dilute nitric acid absorption for cyclic utilization. The method can be used for reducing the total quantity of the nitric oxide gas entering the alkali absorption system, reducing the follow-up alkali absorption and consumption and reducing the cost for follow-up nitric oxide gas treatment.

Owner:HUBEI YITAI PHARMA

Medicinal composition for treating cholelithiasis and its preparing method

InactiveCN1286519CAccurate doseOrganic active ingredientsPeptide/protein ingredientsProglumideVerbena

The medicinal composition for treating cholelithiasis is prepared with giant knotwood, European verbena, compound bile powder, bupleurum root, gynostemma pentaphylla, curcuma root, glucurolactone, erythromycin and proglumide as material, and through stoving, crushing, solvent extraction, mixing in certain proportion, sterilizing and other steps. It is prepared into common preparation forms, and the present invention has unique recipe, unique preparation process and obvious curative effect.

Owner:梅喜

Poultry feed containing antimicrobial additives and preparation method thereof

InactiveCN109329580AAvoid harmImprove palatabilityAnimal feeding stuffAccessory food factorsAntibiotic YHuman health

The invention discloses poultry feed containing antimicrobial additives and a preparation method thereof, and relates to the field of preparation of feed additives. The poultry feed containing antimicrobial additives is composed of the following raw materials in parts by weight: 25-30 parts of clotrimazole, 30-34 parts of potassium iodide, 17-19 parts of sodium selenite, 22-27 parts of zinc sulfate, 2.5-4.5 parts of cupric sulfate maltooligosaccharide, 12.5-13.5 parts of glucurolactone, 5-7 parts of glucomannan polymers, 13-18 parts of sepiolite, 45-55 parts of bone powder, 14-19 parts of ferrous sulfate, 21-32 parts of calcium hydrogen phosphate, 3.5-5.5 parts of cobalt chloride, 1.15-2.25 parts of vitamins and 25-36 parts of antibiotics. The invention is capable of avoiding the harm of molds to poultry and promoting digestion and absorption of poultry and beneficial to human health through the synergistic action of active ingredients.

Owner:徐州众汇福英杰饲料有限公司

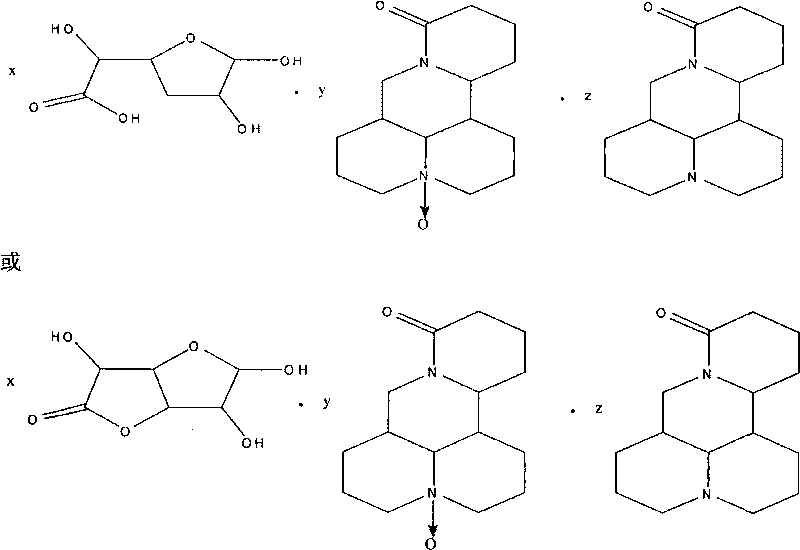

Preparation method and application of compound salt formed by glucuronic acid or glucurolactone and sophocarpidine and/or oxymatrine

InactiveCN108997449AEasy to prepareReduce stimulationEsterified saccharide compoundsOrganic active ingredientsSophocarpidineOxymatrine

The invention discloses a preparation method of compound salt formed by glucuronic acid or glucurolactone and sophocarpidine and / or oxymatrine. The preparation method comprises specific steps as follows: water and an organic solvent are added to a mixture of glucuronic acid or glucurolactone and sophocarpidine and / or oxymatrine, and a mixed solution is stirred and subjected to refluxing under thewater-bath condition at 20-60 DEG C until the mixed solution is clear; an obtained clear liquid is evaporated and concentrated at 40-80 DEG C; a concentrated product is cooled, refrigerated and then filtered, and washing and vacuum drying are performed. The invention further discloses pharmaceutical composition containing the compound salt and pharmaceutically acceptable auxiliary materials and used for treating hepatic diseases. Animal experiments prove that glucuronic acid or glucurolactone and sophocarpidine and / or oxymatrine have synergistic effects and do not have toxic or side effects onanimals.

Owner:刘兆平

Compounded medicine for treating esophagus cancer and stomach cancer and preparing method

InactiveCN101069724AEnhanced inhibitory effectPlay a protective effectHeavy metal active ingredientsOrganic active ingredientsDiseaseCancer cell

The present invention relates to a compound preparation for effectively curing the diseases of carcinoma of esophagus and gastric carcinoma. It includes a pure Chinese medicine preparation and a Chinese medicine and Western medicine combined preparation. Said pure Chinese medicine preparation is formed from 8 Chinese medicinal materials of aconite main tuber, wild aconite tuber, rhinoceros horn, radish seed, perilla stem, areca nut, lily bulb and licorice, and the Chinese medicine and Western medicine combined preparation includes effective component of Gaiweipine, effective component of compound sulfamethoxazole, effective component of rhubarb sodium hydrogen carbonate, effective component of compound acorus basic bismuth nitrate, effective component of glucurolactone, pearl powder and musk.

Owner:倪良臣

Nutritive lick blocks suitable for beef cattle and preparation method of nutritive lick blocks

InactiveCN106578436ARaise spiritsImprove meat qualityFood processingAnimal feeding stuffLycopeneAdditive ingredient

The invention discloses nutritive lick blocks suitable for beef cattle and a preparation method of the nutritive lick blocks. The nutritive lick blocks comprise the following raw materials of coarse salt, molasses fermentation liquor, ostrica cruda, zinc sulfate, iron chloride, potassium carbonate, calcium carbonate, manganese oxide, quercetin, lycopene, polyphenols, selenocysteine, genistein, glucurolactone and marjoram essential oil. The nutritive lick blocks disclosed by the invention are convenient to eat and comprehensive in nutrients, and can timely complement nutrient components desired for the growth of the beef cattle.

Owner:方良云

A traditional Chinese medicine composition, powder and preparation method for preventing and treating microsporidia in the intestinal tract of prawns

ActiveCN106994172BFast releaseKeep alivePowder deliveryOrganic active ingredientsBiotechnologyRadix Astragali seu Hedysari

The invention relates to a traditional Chinese pharmaceutical composition for preventing and treating prawn encephalitozoon intestinalis, powder and a preparation method thereof and belongs to the technical field of traditional Chinese medicine. The traditional Chinese pharmaceutical composition is prepared from the following raw materials in parts by weight: 3 to 5 parts of lightyellow sophora root, 2 to 5 parts of radix astragali seu hedysari, 5 to 8 parts of dark malt, 10 to 15 parts of stone-like omphalia, 5 to 8 parts of radix paeoniae alba, 10 to 14 parts of cyrtomium rhizome, 2 to 5 parts of drug sweet flag rhizome, 2 to 6 parts of radix stemonae, 4 to 7 parts of fructus ulmi, 3 to 7 parts of pericarpium citri reticulatae, 10 to 12 parts of radix puerariae, 3 to 6 parts of radix codonopsis and 6 to 8 parts of radix panacis quinquefolii. The powder disclosed by the invention is prepared from the following raw materials of 90% to 95% of the traditional Chinese pharmaceutical composition, 2% to 6% of glucurolactone and 1% to 4% of astaxanthin. The preparation method disclosed by the invention utilizes nanometer low-temperature wall breaking combined with lactobacillus lactis fermentation to improve the release rate of traditional Chinese medicine and keep medicine activity, and finally, the utilization rate is improved by 5 times; meanwhile, compound enzyme is added to perform enzymolysis, so that adhesion of the encephalitozoon intestinalis is effectively reduced, and preventing and treating effects are improved.

Owner:海一(厦门)水产科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com