Comprehensive processing method and apparatus for mother solution in production of glucurolactone

A glucuronide, comprehensive treatment technology, applied in chemical instruments and methods, non-glycosyl sugar compounds, sugar derivatives, etc., can solve the problems of large investment in treatment facilities, low calorie utilization value, waste, etc. The effect of reducing the load of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

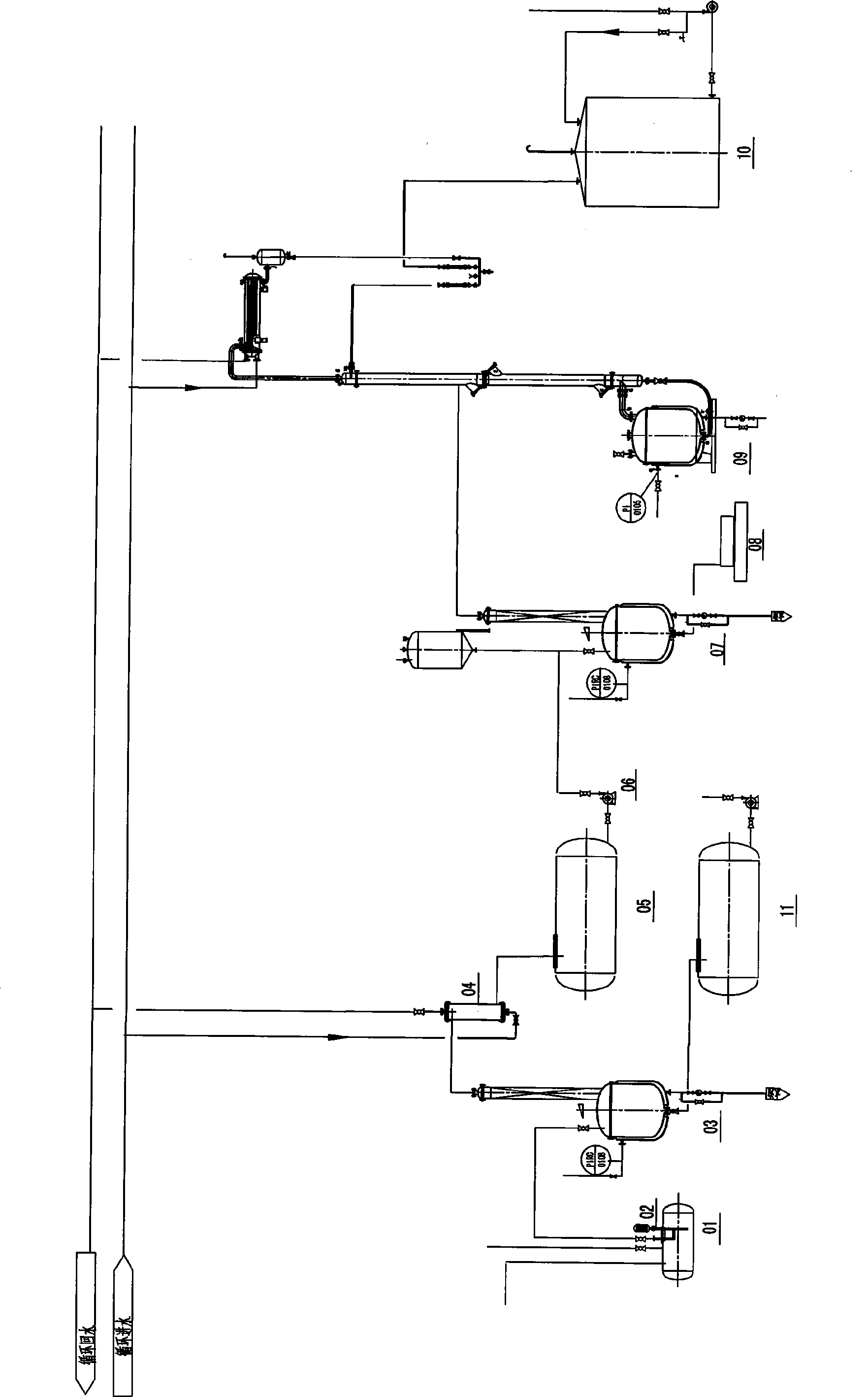

Method used

Image

Examples

Embodiment 1

[0024] a. Pump 3000L mother liquor into a 5000L distillation kettle to heat (including vacuum distillation) to distill the mixture of ester, ethanol and acetic acid to the mother liquor Baume degree of 35. The 1300L mixture is condensed by the condenser and then enters the storage tank.

[0025] b. Pump the mixed liquid into the neutralization concentration kettle, add 260KG of soda ash to neutralize to PH5, heat and steam dilute ethanol to Baume 35 to obtain 530KG of 25% dilute ethanol, and cool the mother liquor to 10℃ for crystallization and centrifuge dehydration Obtain 730KG of sodium acetate.

[0026] c. After the dilute ethanol enters the dilute ethanol concentration tower for concentration, 110KG of 95% ethanol is obtained for the production of glucurolactone.

[0027] d. The remaining mother liquor in the distillation kettle is put into the concentrated mother liquor tank for the production of oxalic acid.

[0028] The following table is the three examples provided, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com