Method for treating glucurolactone mother liquor

A technology of glucurolactone and a treatment method is applied in the treatment field of glucurolactone mother liquor, can solve the problems of occupying large and neutralizing equipment, consumption of alkali raw materials, and high cost, and achieves low emission, sufficient combustion and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

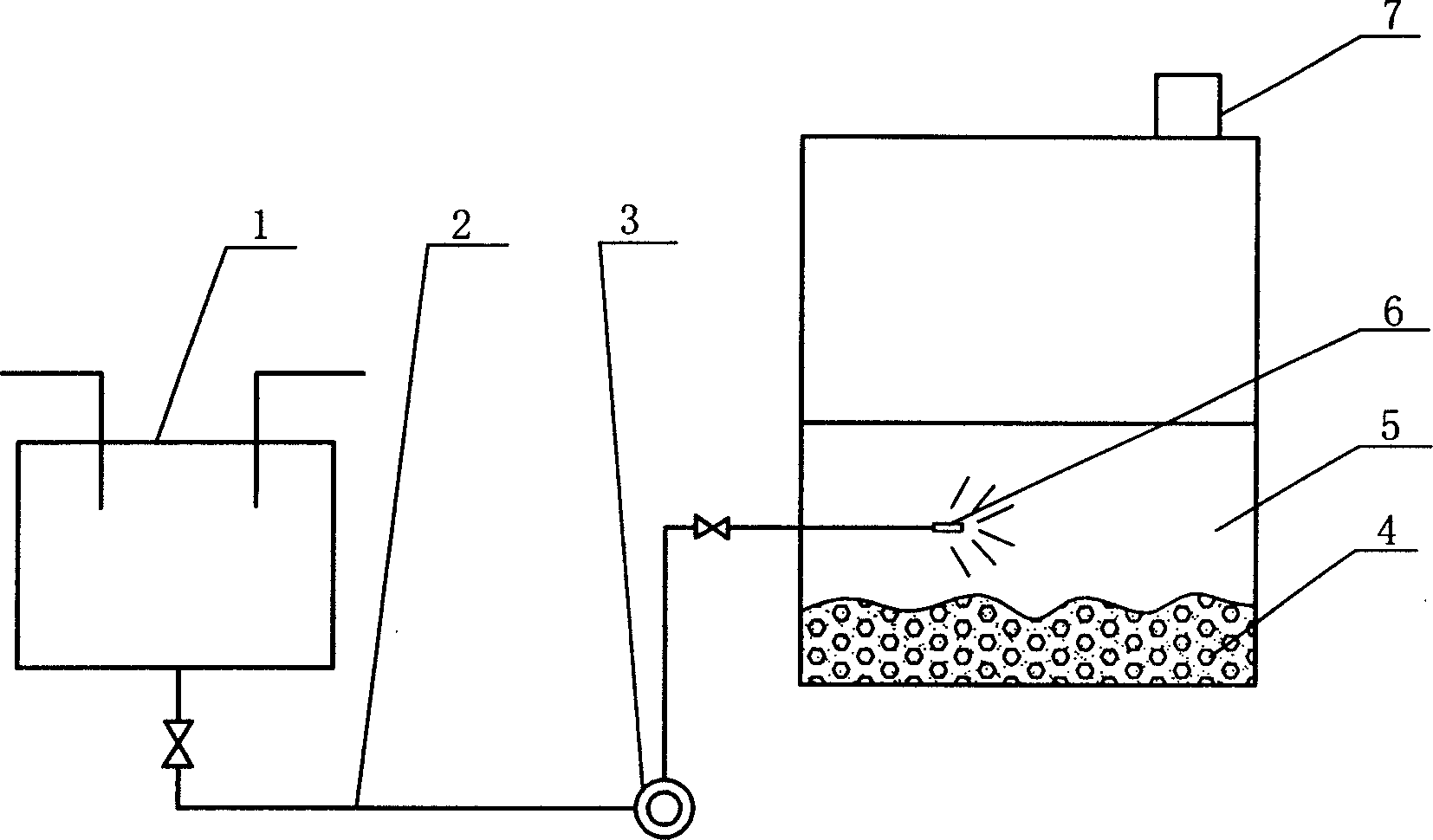

[0012] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

[0013] As shown in the figure, in the treatment method of the glucuron lactone mother liquor according to the present invention, the glucuron lactone mother liquor is prepared in the preparation tank 1 so that the concentration is 20, 22, 25, 28, 30, 33, 36, 40 Concentrated mother liquor with a concentration of Baume degree is pumped into the combustion chamber 5 of the boiler with a high-pressure pump 3 for atomization and combustion.

[0014] Exhaust combustion tail gas inspection: collect the exhaust gas after combustion, the combustion is complete, neutral, non-corrosive, without any corrosion damage to pipes and boiler facilities and accessories, and there is less smoke and dust in the tail gas.

[0015] In the direct atomization combustion test in a boiler without coal combustion, the effect is also good.

[0016] The same test is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com